Leak Detection: Compressed Air Loss Prevention

September 24, 2025

How to Lockout/Tagout Air Compressors

October 8, 2025Six Sure-Fire Ways to Slash Air Compressor Pressure Drop

Kaishan USA | October 1, 2025 | Uncategorized

Maintaining consistent air pressure without pressure drop is critical in applications like automation electronics assembly.

It’s a story we’ve heard all too often. A maintenance manager says his compressor isn’t producing enough pressure. And when they boost the output of the compressor, the pressure at the end-use application goes even lower.

“What’s wrong with this thing?” our customer asks us.

The answer, usually, is nothing. Nothing is wrong with their compressor, whether it’s a reciprocating, rotary screw compressor or centrifugal air compressor.

Sometimes, compressed air pressure problems are caused by pressure loss from leaks or other types of artificial demand. And boosting the compressor’s discharge pressure only makes the end-use issue worse.

Another major problem, however, is pressure drop, a decrease in pressure over a length of pipe. Addressing air compressor pressure drop is a critical element of air compressor optimization.

We describe six causes of pressure drop in compressed air below, along with their solutions.

1. Clogged Filters

Clogged filters will impede and eventually block airflow, causing energy loss that is both unnecessary and avoidable.

The Solution

The critical consideration for filters is maintenance, so you’ll need to replace filter elements regularly.

How often? A lot depends on the quality of the supply air and how many hours you operate your system. One approach is to replace the filter elements every few months. A better choice is to install differential pressure sensors, which will detect any pressure change between a filter's supply and output pressures. For example, a pressure drop would indicate the filter is becoming clogged and needs to be replaced.

We recommend changing air filters every 4,000 hours or per the manufacturer’s recommendation or service indicators. And more often in challenging environments with a lot of airborne dirt and dust, such as cement plants.

2. Mechanical Issues

Often, pressure drop results from malfunctioning switches, valves or regulators.

Regulators are a special problem. All too often, we see plants set their header pressure at 100, 110 or even 120 PSIG, then use regulators to bring the pressures down for individual tools. Why does your compressor have to supply every application with 110 PSIG when you’re going to lower that pressure to 85 PSIG or 90 PSIG at almost every use? That’s incredibly wasteful. The rule-of-thumb is that for every 2 PSIG in increased pressure the electrical energy increases by 1%. So, the goal is to maintain your compressed air system at the lowest pressure possible.

Regulators help control the air pressure going to an end-use application—and that’s good. However, they waste energy, and having too many regulators may indicate you could save significantly by reconfiguring your compressed air system.

The Solution

Replace the malfunctioning equipment as soon as possible. And you’ll conserve energy by setting the header pressure as low as possible. A lot of energy.

Replace malfunctioning valves, switches or regulators as soon as possible.

3. Pipe Sizing

Properly sized piping is a critical piece of any compressed air distribution system. If piping is too small, your system will be inefficient and consume more energy. Pressure drop in air piping will overwork your compressor, causing additional wear and maintenance.

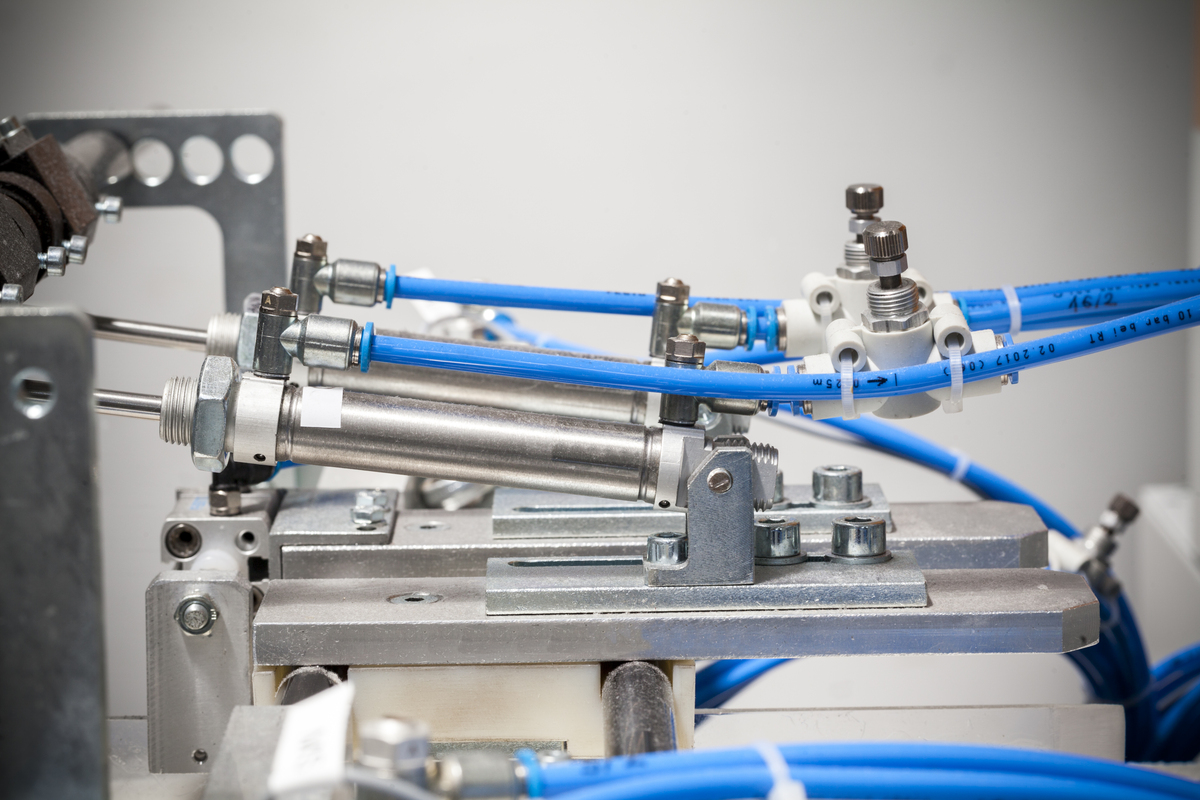

In addition, while Compressed Air Best Practices says 30%-40% of leaks happen in the “dirty 30”—the last 30 feet of pipe or tubing before an end-use application— poor installation practices are another reason why the “dirty 30” is so notorious in the compressed air world. That portion of the job is always the worst part of an installation, as workers often ignore sizing and flow requirements, instead using the piping and materials they have available.

A poor installation thus builds pressure drop into your system in the form of downsized piping, obstructions, poor piping material, sharp corners or unnecessary regulators. When you go from a two-inch pipe to a half-inch pipe, you really can’t blame the compressor for the resulting pressure drop.

Because of poor installation practices, the dirty 30—the last 30 feet of pipe or tubing before an end-use application—is a likely source of pressure drop in your system.

Time and again, we’ve found companies reduce pipe sizes as they move away from their compressor. So instead of the typical 2-3 PSIG reduction in pressure over 100 feet of pipe, smaller pipe sizes can cause a pressure drop in the compressor system of as much as 10-15 PSIG.

The Solution

Keep the pipe size the same as you move from the compressor to the end use. A second cause of pressure drop in air piping is your choice of pipe material.

4. Pipe Material

You may be surprised to learn that the material you choose for piping can have a significant impact on pressure drop.

Black iron is usually the starting point for most users because of price and durability. But you’ll have more friction and drag as the air moves through the pipes, creating a pressure drop. Black iron will also corrode when exposed to moisture, allowing pieces to flake off and block the air flow, also contaminating it.

The Solution

We recommend replacing black iron with aluminum piping because the interior surfaces are smoother and less likely to cause compressed air pressure problems. Pressure drop with aluminum pipe can be as low as 3 PSIG for 1,000 feet. It’s much more efficient.

5. System Layout

Your compressed air piping layout can significantly impact your system's operation. A faulty design will increase energy costs, equipment failure, production losses and maintenance. Meanwhile, investing in a well-crafted layout will have substantial payback over the life of the system.

It’s usually best to start with a loop system, in which the air flows in two directions. This design reduces pressure drop throughout the system and ensures the full airflow arrives at all your equipment downstream. A branch system, on the other hand, inherently produces less pressure and flow at the end of each run.

The Solution

Use a loop system whenever possible to prevent compressed air pressure problems.

6. Fittings

Using too many fittings or the wrong sizes can add obstructions to the system, as mentioned above.

The Solution

Plan your system so that the flow takes a direct route from your compressor to your end use. Avoid 90° corners or sharp turns, if possible.

Drop Kick Pressure Drop!

You’ll probably need a compressed air professional to help you identify and correct some of the air compressor pressure drop issues we’ve described.

The good news is that help is available in your area. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site assistance and consultation as needed. They are skilled at identifying issues such as problem fittings, switches, valves or regulators. And they can spot mistakes in piping selection or installation.

We partner with these independent, local distributors because it's the best way to ensure you have expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

Six Causes of Pressure Drop in Compressed Air:

1. Clogged Filters

2. Mechanical Issues

3. Pipe Sizing

4. Pipe Material

5. System Layout

6. Fittings

Let Us Help

Air compressor pressure drop is critical to air compressor optimization and the operation of your rotary screw air compressor or centrifugal air compressor. If you need help tackling pressure drop, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Pressure Drop Happens

Alright, welcome back to The Big Dog Podcast. Episode 40! Lisa, before we get started, I can't believe we've recorded this many episodes for our valued listeners. I'm incredibly, incredibly grateful.Agreed, Jason. I remember when you and I were first talking about a compressed air podcast, we figured a few shows and listeners here and there. But, like you, I never figured we'd be this far. Shout out to you, too, and all our listeners who continue to make this show the best one in the game.

Aw, thanks, Lisa. I feel the same.

Now, let's chew through another big pain point in the world of compressed air. Today, we're talkin’ pressure drop—what it is, why it wrecks your energy bill, and, you know, why the guys on the floor blame the compressor but usually it's not the compressor’s fault.

And honestly, Jason, this one pops up all the time. Whether you’re in a plant, a fab shop, or running a bottling line, everyone complains about low tool pressure. But the real villain? Pressure drop. So let’s lay it out—what exactly is pressure drop, and why should anyone care?

So, picture this: pressure drop is just the decrease in pressure as air travels through your pipes and systems. The longer the run, and the sketchier your piping or components, the more pressure you lose before it ever gets to your tools. That’s not just a headache for the operator. Every PSI you lose in transmission is energy and dollars down the drain.—I've seen too many folks try to crank up the compressor pressure to compensate, but like we’ve said before, that’s just asking for higher utility bills.

And it’s not just energy we’re talking about—it actually messes with system performance, right? Tools don’t work right, quality drops...oof, it affects everything.

Exactly, and when it comes to causes, there’s six major ones that come up over and over—clogged filters, busted mechanicals like valves or regulators, undersized piping, the wrong pipe material, bad system layout, and using too many fittings, especially sharp turns. It’s kind of amazing how predictable these problems are.

Okay, I have to hear your story. You mentioned one customer who was sure his compressor had finally let him down, right?

Oh yeah. This was classic. Guy complains, “my air tools are all down on power.” He’s sure something’s busted inside the rotary screw or, who knows, some part deep in there. We dig in, run the line...the compressor was fine—honestly clean as a whistle. Where do we find the problem? The last thirty feet—what everyone calls “the dirty 30.” Somebody had tossed in undersized half-inch line because, well, it was in the shop, and boom—pressure drop city. He could’ve replaced the compressor and been right back in the same mess.

Which is wild, but not surprising. It’s like, we talked leaks and artificial demand last episode—folks reach for the compressor first, but these simple causes get missed all the time. Alright, let's break down how to deal with these main troublemakers, because this “dirty thirty” and all the rest, I know we've both seen our share.

Tackling the Key Culprits

Let’s start with filters—that’s always first on the list. Like, a clogged filter can be such a sneaky drain on the whole system. What’s best practice here? Are we talking swap-out every few months, or is there a smarter way?Yeah, so, maintenance is everything here. But it depends. For some shops, maybe you can go a few months, but a better play is using differential pressure sensors. They’re awesome—one side measures before, one side after the filter. When you see a delta—pressure is lower coming out than going in—that’s your sign the filter’s clogging up and it’s time to swap it. But if you’re running in dusty places like cement plants, you might have to change filters even more often—every 4,000 hours is kind of the baseline, or just go with what your manufacturer says or whatever the service indicators are telling you.

So it’s not one-size-fits-all, but ignoring your filters pretty much guarantees you’re gonna lose pressure and waste energy. Alright, what about mechanical issues? I mean, valves, switches, regulators...these turn into silent killers, don’t they?

Totally. And regulators are a weird one. You see plants cranking up header pressure to like 110 or 120 PSI “just in case,” and then chopping it back down with individual regulators. If you’re running 120 at the compressor but dropping to 85 for every tool, you’re basically throwing money away. For every 2 PSI you over-pressurize, you bump electrical energy use by 1%. Multiply that over months—ouch.

So what’s better—just run everything at the lowest pressure that still gets the job done? Is there a telltale sign your regulator is actually costing you more than it’s saving?

Good question. Keep the header as low as possible. If you’ve got tons of regulators all over, that’s a red flag—maybe your system needs a different setup. And if a regulator’s sticking or leaking air, or you notice wild pressure swings at the point of use, that’s a pretty clear signal something’s wrong—just replace it quick.

Alright, last biggie in this batch: pipe sizing. And you mentioned the “dirty thirty” already, but let’s dig in—what happens when folks undersize their pipes?

Air gets starved, basically. Everyone thinks, “well, I’ve got enough pressure at the compressor, so I’m set.” But as you shrink pipe sizes moving away from the compressor, the drop just stacks up. Instead of a couple PSI over a hundred feet, you could lose 10 or even 15 PSI just in a short run. Not only are you killing performance, you’re making the compressor work harder and live a shorter life. That last run—again, the “dirty thirty”—is where so many problems hide, especially if someone cut corners with whatever scrap pipe was lying around at install.

And sometimes it’s not even obvious, right? You have to walk the system and look. Honestly, Jason, this is making me wish people would just call in pros from the start—skip the guesswork, avoid the headaches.

Exactly. But, you know, some lessons stick the hard way. Speaking of lessons, let’s talk about how the right pipe and layout can save even more pressure before it ever becomes a problem.

Smart Piping & Layout Choices

So, let’s talk pipe material. Most people default to black iron, right? It’s cheap, it’s everywhere, but it’s not exactly your best friend long-term. Aluminum piping—now that’s a game-changer. Less friction, smoother inside, and you’re looking at maybe 3 PSI drop over a thousand feet versus way more with black iron. Plus, black iron rusts out and gets all gnarly inside, throwing flakes into your system and blocking air. Not fun.Yeah, and if you’ve ever had to clean out a line full of rusty crap from black iron, you’ll never want to go back. But it’s not just the material, right? System layout makes a big difference, too. What are your thoughts—loop versus branch?

Honestly, if you can swing it, always go for a loop system. Air comes from both directions, so you get way less drop at the far ends. Branches, on the other hand, kind of starve the outlets at the far end of the run, especially if the demand picks up. I had a bottling plant once with big production headaches—couldn’t feed air to multiple lines at the same time. Swapped to a loop with bigger aluminum piping and suddenly, no more bottlenecks, no more downtime. Simple fix, massive payoff.

And fittings—we can’t let those go unmentioned. Every sharp turn, every extra elbow, that’s another pinch on pressure. Right? So keep the lines straight, minimize connections, and avoid those infamous 90-degree corners whenever possible. Honestly, planning upfront saves a whole lot of pain later.

Yep. The simple stuff makes the biggest difference, usually. Like we’ve said before, sometimes it’s about getting a good partner in to help—someone who spots those hidden issues before they cost you real money. That’s why having a local pro from the start just makes sense.

Couldn’t have said it better. So, that’s a wrap for today—six big causes of pressure drop, and even more ways to beat them. If you’re struggling with low pressure or high energy costs, you know where to start looking. Jason, thanks as always for keeping it real.

No problem, Lisa. If you need a hand, get in touch with your local pros or give us a shout at Kaishan. We’ll be back soon with new topics and more real-world answers. See you next time, Lisa.

See ya, Jason. And thanks to everyone out there for tuning in. Take care of your air, and we’ll catch you on the next Big Dog Podcast.

Random stat or

customer quote

textXXtext

text