Five Questions You Need to Answer to Get Compressed Air Header Pressure Right

October 29, 2025

How Do You Define Compressed Air Success?

November 12, 2025How a Multi-Compressor System Can Help You Reduce Compressor Downtime

Kaishan USA | November 5, 2025 | Uncategorized

The cost of downtime has more than tripled over the past five years, according to a 2024 study by Siemens. The automotive industry leads the way with an hourly cost of $2.3 million. Yes, million.

Most facility managers know the cost of downtime in their plant. From lost production to damaged goods to employee safety to negative comments from management, downtime is costly, no matter how you slice it.

Losses in some industries cost $2.3 million per hour—$600 per second, according to the Siemens study.

As a result, keeping your compressors running has never been more crucial in today’s competitive environment. In the past, we’ve written about many ways to avoid downtime.

But one technique we often recommend—and one of the major elements in rotary screw compressor system design—is the use of a multi-compressor system to add additional reliability and stability to your compressed air system.

Multi-Compressor Systems

Here’s how a multi-compressor system works:

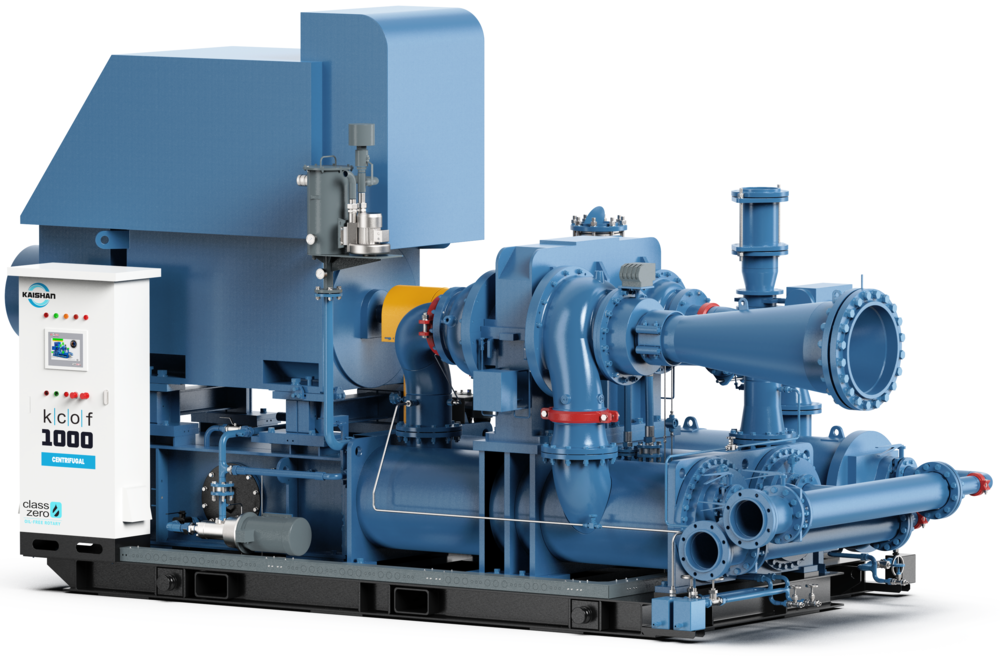

- A base-load compressor meets your system’s minimum compressed air load. Its output does not fluctuate as demand changes. Instead, it runs full bore—at 100% of capacity—or it turns off. Depending on variations in your demand, you may have more than one unit to fulfill that base-load function. You could even use a centrifugal air compressor as a base-load unit.

For facilities with high volumes, Kaishan’s KCOF centrifugal air compressors are extremely efficient base-load compressors.

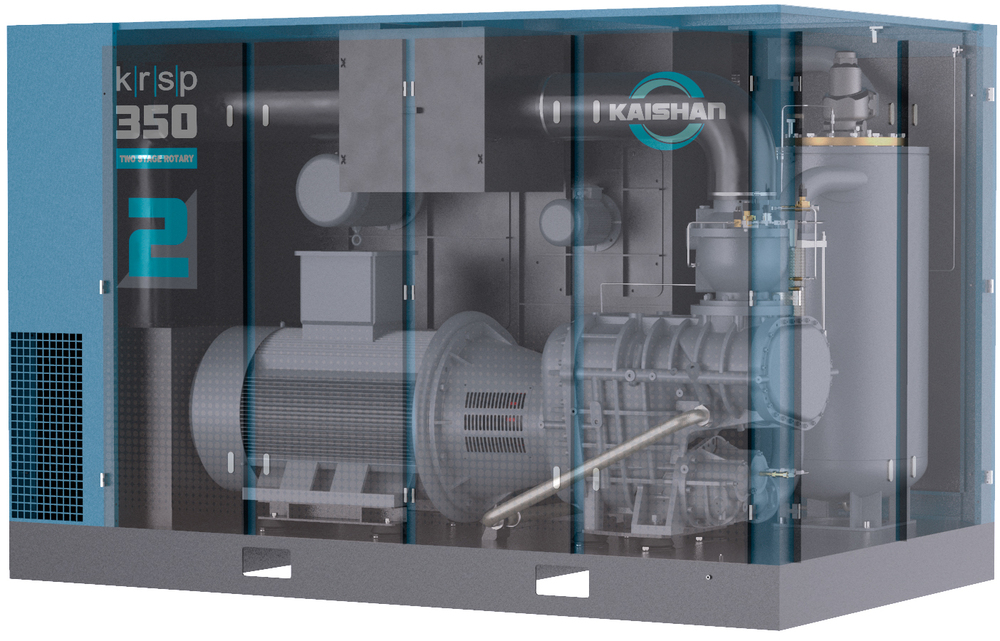

- A trim compressor handles fluctuations in demand above the base unit. Since the level of flow needed will rise and fall depending on the needs of your system, rotary screw compressors equipped with variable-speed drives are a natural for this application.

Kaishan’s KRSP2 premium, two-stage rotary screw air compressors equipped with variable-speed drives are an excellent choice for trim compressors. They are also a good selection for base-load units.

- A backup compressor is on standby if a base-load or trim unit goes offline. To fill in appropriately, it should be the same size as the base-load compressor.

Configuring your compressed air system in this way virtually eliminates unplanned downtime, which, in the real world, is the biggest (and most avoidable) expense associated with your compressed air system. A highly reliable backup, usually a rotary screw compressor, waits in the wings as a backup should a base-load or trim unit fail, keeping both pressure (PSIG) and flow (CFM) more consistent and reliable.

For most companies, avoiding a day of downtime more than justifies the additional expense of an air compressor backup system. And while you may be reluctant to invest in additional units, remember that equipment costs are only a 12% fraction of the total lifetime costs of owning an industrial air compressor, according to the U.S. Department of Energy.

Other Benefits of a Multi-Compressor System

In addition to reliability, there are several other significant advantages of a multi-compressor system:

- Reduce maintenance costs. You can rotate your base-load, trim and backup compressors in and out of service to even out the hours. That will extend your service hours since the compressors will require service less frequently. Instead of quarterly, for example, you may be able to perform routine service semiannually.

Configuring your units in a multi-compressor system may allow you to reduce maintenance costs.

- Save electricity. If your demand doesn’t vary that much (staying above 80% of capacity), using a single fixed-speed compressor will be most energy efficient. But most plants experience more variation than that. So, in those instances, two smaller compressors will be more energy-efficient. And since a large portion of the total cost of ownership of an industrial air compressor comes from electrical bills, even a slight improvement in energy use could save the price of a backup. Using a trim compressor will also allow you to maximize energy efficiency. You’re not wasting air and not cycling your fixed-speed compressor.

- Avoid emergency services. Plants without backup units often rent portable diesel units when a main compressor breaks down. Energy costs for a diesel backup run at least twice as much as an electric unit and a diesel typically doesn’t have an aftercooler, so it sends dirty or wet air into your system, usually more than your cleanup equipment can handle. There are also significant maintenance and operating costs: a portable diesel compressor will need oil and filters every 250 hours. If you’re operating 24/7, that could mean they require maintenance every ten days. And then there’s a problem of supplying the unit with diesel fuel every 12 hours!

- Extend equipment life. Distributing the hours more evenly will help extend the lifespan of your compressors.

Variable-speed drive compressors add even more flexibility to multi-compressor systems.

VSD vs. Trim Air Compressor

Some facility managers have capitalized on the unique flexibility of variable-speed drive compressors to offset the need for a trim compressor. It doesn’t hurt, of course, that they get rebates and incentives from utilities and government agencies designed to reduce the capital expenditure.

However, VSDs may not work for everyone.

You may be tempted to use variable-speed drive compressors to offset the need for a trim compressor. That may not work for everyone, however.

You have to look at your demand profile:

- If you have varying demand (50-80% of capacity), a primary VSD will work well. You may not, in fact, need a trim unit, since having a base-load compressor with a VSD may well perform both base-load and trim functions.

- But if your demand is more than 80% of capacity, you should go to a fixed-speed unit since VSDs really aren’t efficient at higher levels. As a result, you will still need a trim unit as described above, along with a backup unit.

As a result, if you’re considering a VSD, it’s smart to get an expert analysis of your demand.

When you have more than three compressors servicing your facility, consider cascading them.

Cascading Air Compressors

Facility managers with several compressors often set all of them at the same pressure to share the load. However, if they’re rotary screw compressors, that wastes a lot of energy.

Here’s why: rotary screw compressors do best at full load. If you’re running several compressors at 30% load, they’re probably consuming between 60% and 80% of the electricity they’d draw at full load. It’s much better to shut down one (or more) of those units than to run several at a very low level. The best idea is to implement air compressor load sharing.

As a general rule, the compressor that starts first is set at the target pressure band (say 120-125 PSIG), and each other compressor in a cascading control scenario comes on at a successive lower pressure to supplement that base-load compressor. The second compressor, in this example, would be set at 116-123 PSIG, coming on if the air pressure drops below 116 PSIG.

The best scenario is to have all your compressors running at full load, except for the trim compressor, which is best suited for partial load. Usually, that means the trim compressor is equipped with a variable-speed drive. A VSD can also help reduce the required pressure band by changing the motor RPMs to keep the pressure in a tight range, plus or minus two PSIG. That’s base compressor load sharing.

Learn more about air compressor load sharing and cascading multiple compressors in our blog post, “How Lowering the Pressure Band of Your Compressed Air System Can Save You Money.”

Getting Your Multi-Compressor System Up and Running

Most compressed air systems will benefit from the increased reliability, reduced maintenance, electricity savings and extended lifespan that a multi-compressor system offers. The best way to get started is to work with your compressed air professional to assess your demand profile and determine the best course of action.

We work with a nationwide network of independent distributors, who can help you analyze your system’s demands and determine the right mix of base-load, trim and backup units for your facility. They can also provide on-site help and consultation as needed and service your air compressor system without a problem.

Kaishan USA partners with these independent, local distributors because it's the best way to serve you. There's no red tape here: unlike large corporate suppliers, our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

Their factory-trained technicians possess a deep understanding of industrial applications and know how to maximize efficiency while minimizing downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and will work with you to help you succeed.

Key Takeaways

- The high cost of downtime makes it imperative that facility managers reduce compressor downtime.

- A multi-compressor system can add additional reliability and stability to your compressed air system.

- Key elements of a multi-compressor system include a base-load compressor meeting your system’s minimum demand, a trim compressor to handle variations and a backup unit on standby.

- A multi-compressor system can also help reduce maintenance costs, save electricity, avoid emergency service and extend equipment life.

- Some facility managers have used variable-speed drive technology to offset the need for a backup compressor.

- When you have more than three compressors servicing your facility, consider cascading them.

Let Us Help

Configuring your air compressors in a multi-compressor system is a significant step in improving the reliability and efficiency of your compressed air system and all the processes that rely on that system. If you need help determining the best way to implement a multi-compressor system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Real Cost of Downtime

Welcome back to the Big Dog Podcast! I’m Jason, coming at you with the hard realities today about compressor downtime, and I’ve got Lisa here with me too. Lisa, you ready to tackle this one?Absolutely, Jason. This is one of those topics that, honestly, just keeps getting more and more important. The numbers are wild—did you see that recent Siemens study? Global manufacturers lost, what, $1.4 trillion to unplanned downtime last year. It’s kind of staggering.

Yeah, and it gets crazier. Some industries, like automotive, are burning $2.3 million every hour the line’s down. $600 a second. I saw it up close my first gig in Detroit—place went dead because a single compressor failed. I’ll never forget the plant manager’s face, just pure panic. Whole crew standing around waiting on air. The production line’s dead, product’s backed up, and management? Let’s just say, they weren’t handing out any “thank you” cards that day.

No one wants to be in that meeting, for sure. You know, we’ve talked about this before—remember Episode 36, Defeating Downtime? We went over that daily maintenance checklist, but even with the best proactive plans, stuff happens. That’s why compressor reliability has gone from “nice to have” to, like, absolute mission critical. Downtime is just too expensive.

Exactly. So the obvious question—why put all your eggs in one basket? Why risk it all on a single compressor? And that’s where multi-compressor setups come in. I mean, if one unit trips out, the rest pick up the slack. You’re not dead in the water. It’s just added insurance, but smarter.

And it’s not just about avoiding the pain. It’s about keeping production on track, orders shipped, and honestly—keeping your job off the line. A multi-compressor system isn’t just a backup. It’s a smarter, more stable way to run compressed air, especially now when no one can afford surprise shutdowns.

The Anatomy of a Multi-Compressor System

Alright, let’s break down what a multi-compressor system actually looks like. You’ve got three main players—base-load, trim, and backup compressors. Each one’s got its own job, and if you get the setup right, you boost reliability across the board.Yeah, so, base-load is pretty straightforward. That’s your workhorse, running flat-out, meeting the plant’s minimum air demand. It doesn’t care if demand’s jumping around or holding steady—it’s always giving you that baseline flow. In bigger facilities, you’ll see centrifugal compressors like the Kaishan KCOF in that role. Those things are absolute tanks—seriously efficient for big volumes.

And then you layer in your trim compressor. This one’s like the system’s agile problem solver. It ramps up or down depending on what the plant needs in real time. Rotary screw compressors, especially the KRSP2s from Kaishan with variable-speed drives, are kind of built for this. They give you flexibility and keep the base-load unit from cycling too much.

And backup—don’t forget that. I always say, if you don’t have backup and something goes sideways, you’re one phone call away from a line-down event. And renting a diesel portable as a last-second fix? Twice as expensive on energy, filthy air, constant maintenance. You don’t want to go there unless you absolutely have to. Your backup should match your base-load in size, waiting to jump in when needed.

Totally. And here’s something a lot of people miss: rotating compressors between base-load, trim, and backup spots. You’re evening out wear and tear. That means you might stretch out maintenance intervals—from quarterly to maybe semiannual services—and each unit stays fresher, longer.

Plus, energy savings. If your demand swings a lot, two smaller units running smart will beat one big one cycling on and off all day. We touched on this back in our pressure drop episode too—smart system design means lower energy bills, less equipment stress, and you’re not burning through compressors just to cover peaks.

Not to mention—avoid that emergency rental diesel, save on surprise repairs, and actually extend the life of every compressor in your lineup. I mean, equipment is really just a fraction of lifetime system costs—what, around 12% according to the DOE? It’s the electricity and downtime that kill you. Building your system for reliability just makes all the numbers line up better at the end of the year.

And it’s real-world stuff. If a plant loses an entire day of production, the cost is brutal. Multi-compressor setups are like having insurance, only instead of paperwork you just get more uptime and fewer headaches.

Getting the Most from Advanced Controls

Alright, let’s dig into the brains of these systems—controls. Variable-speed drives, or VSDs, are everywhere now, but I think folks sometimes oversell them as a magic bullet. They’re awesome for varying demand—say your facility’s bouncing between 50 and 80% capacity? One good VSD can act as both base-load and trim, super flexible. But at high, steady demand? VSDs lose their efficiency edge fast. Fixed-speed still has its place.That’s the key—matching your setup to your actual demand profile. You don’t want to just swap in a VSD and call it a day. If you’re running close to maximum all the time, you need that fixed-speed reliability and then a trim or VSD unit for the swings. And if you’ve got more than three compressors, things get interesting—we’re talking cascading control and smart load-sharing, not just turning everything on at once and calling it “cover.”

Yeah, running all units at 30% load? Massive waste. It feels safer, but you’re burning cash on extra energy, and compressors don’t love running at low loads. With cascading, you set pressure bands so only the compressors you need are running. Like, base-load starts at 125 PSI, the next comes on if you drop to 123, and so on—stepwise engagement. It’s way more efficient. The trim VSD holds the line in the tight zone—plus or minus a couple PSI.

And I love this case from a mid-sized food plant—they’d been running all their compressors in parallel for years, and energy bills were eating them alive. Once they switched to true cascading control, with the right base-load/trim relationship and smart load sharing, they saw almost instant savings on power, and downtime just tanked. The system got way more reliable, with fewer starts and stops across all the units.

Yeah, sometimes it’s not about getting fancy—it’s just about getting smart. Advanced controls, right setup, rotating compressors, and load-sharing that makes sense for your actual daily swing. Put it all together, and you get reliability, savings, and a system that just runs. Simple, right?

That’s what we’re here for—cutting through the noise and showing people the real levers they can pull for their air systems. Alright, Jason, I think that wraps us for today. But there’s plenty more to talk about next time. Thanks for hanging out with us on The Big Dog Podcast—Jason, always a pleasure.

You too, Lisa. Thanks for joining us, everybody. We’ll catch you on the next episode. Keep your air clean, your systems running, and don’t let downtime be the boss. See ya, Lisa.

See you, Jason. And thanks, everyone, for listening. Take care!

Random stat or

customer quote

textXXtext

text