Air Compressor Intake Air: The Original GIGO

December 17, 2025

Five Quick Wins That Add Value to Your Compressed Air System

December 31, 2025Compressed Air on a Budget: Four Golden Rules

Kaishan USA | December 24, 2025 | Uncategorized

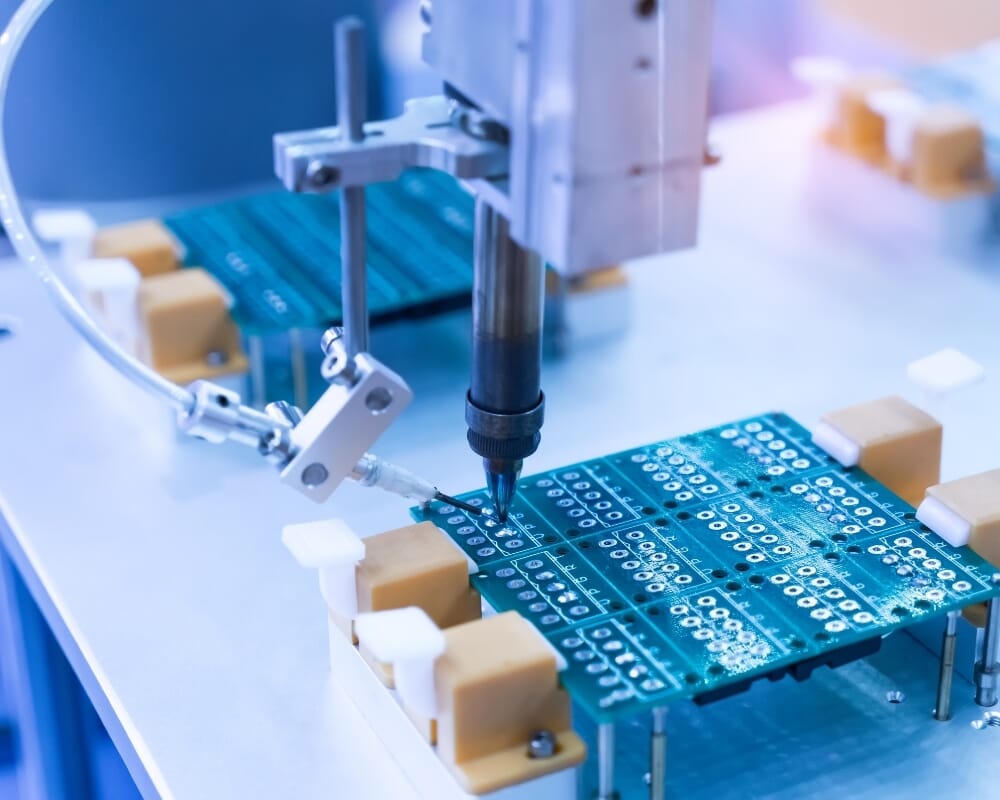

Maintaining a stable header pressure is critical in delivering the even flows of compressed air needed in the semiconductor, healthcare, pharmaceuticals and electronics industries for sensitive applications such as pneumatic controls and robotics.

Maintenance managers are constantly looking for ways to optimize compressed air system efficiency while keeping costs in check. Your compressed air system is often one of the largest energy consumers in your facility, making it crucial to manage it wisely.

The best way to keep your budget in check is to optimize your compressed air system. Making sure it operates efficiently and reducing costs without compromising on performance.

We’d like to offer four golden rules that will help you do that. We’ll start with attention to detail.

Golden Rule No. 1: Pay Attention to the Details

Small inefficiencies can lead to significant costs over time. By focusing on the small stuff, you can optimize your compressed air system and enhance its overall performance. First up, the smallest of issues, leaks.

Leak Detection in Compressed Air Systems

Leaks are a common issue in compressed air systems and can waste a surprising amount of energy. Regularly inspect your system for leaks and repair them promptly. Even a small leak can lead to increased energy consumption and higher operational costs.

In fact, poorly designed and maintained compressed air systems waste up to $3.2 billion in utility payments in the U.S. annually, according to the Compressed Air & Gas Institute (CAGI). CAGI further estimates that a quarter-inch leak in a 100-PSIG system will cost at least $17,000 annually, depending on utility rates.

Find out more about leak detection in compressed air systems in our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

Lower Header Pressure

Many operators set the system pressure to the level required by the tool or tools needing the most pressure. And we get it—you don’t want complaints.

However, in most cases, those high-pressure applications make up only a fraction of your system’s applications. And that means you are overpressurizing everything else. Significantly.

A crucial part of operating your compressed air system is setting the header pressure as low as possible:

- Set it too low, and your end-use applications will suffer.

- Set it too high, and you’ll sacrifice air compressor energy efficiency, also reducing reliability and damaging machinery.

For a complete discussion of the ins and outs of setting your system pressure, visit our blog post, “Five Questions You Need to Answer to Get Compressed Air Header Pressure Right.”

Maintain Your System, Especially Filters and Drains

Regular industrial air compressor maintenance is key to keeping your system running efficiently. Ensure that filters are clean and drains are functioning properly. Clogged filters can restrict air flow, leading to increased energy use and wear on your compressor.

Maintaining your equipment is one of the most cost-effective air compressor solutions.

Properly maintaining your rotary screw air compressor can yield many benefits, from reducing downtime and energy costs to improving safety. It will also enable you to deliver high-quality compressed air, boosting the performance and longevity of your downstream tools and applications.

For a comprehensive guide to industrial air compressor maintenance, download our white paper, “Air Compressor Maintenance: Ultimate Guide and Checklist.”

Make Sure You Have Enough Storage

Storage plays an integral role in any compressed air system. Air compressor tanks help balance the supply of air from the compressor with the demand from the system.

As a result, they can help your system accommodate surges in demand, acting as a reservoir during peak times. And they help minimize pulsations in the air flow and ensure smooth operation.

In addition, a well-sized storage tank can produce significant energy savings in compressed air systems. Properly sized tanks reduce the number of compressor starts and stops, promoting energy savings in compressed air systems and extending the compressor's life.

The Compressed Air & Gas Institute (CAGI) recommends up to 10 gallons per CFM and provides a formula to calculate the air receiver size based on the time allowed for the pressure drop. The main point is that the tank should be sized so the system does not cycle more than ten times per hour. And preferably less.

For more on storage, see our blog post, “A Quick Guide to Accurately Size Air Compressor Tanks.”

By addressing these minor issues, you can set the stage for greater savings and improved compressed air system efficiency. Now, let’s move on to thinking long-term.

Golden Rule No. 2: Think Long Term

When it comes to compressed air systems, it’s essential to look beyond the initial purchase price.

A Cheap Compressor Is No Bargain

Everyone loves a low price. Unfortunately, the products with the cheapest price may not deliver the lowest total cost of ownership for air compressors. Sometimes, a few hidden provisions can lurk in the contract details, making a seemingly irresistible deal more costly. And you can get stuck in a deal with a low initial price, but find yourself locked into a high-cost maintenance contract you can’t get out of.

Savvy buyers can save themselves a lot of trouble and headaches if they watch out for the “Six Gotchas That Turn Low Sticker Prices into High Lifetime Costs.”

And there are other traps you should be aware of. We’ve even written about “Five Ways Not to Save Money on Compressed Air.”

Other Investments

Compressed air systems offer other opportunities for long-term savings. Good examples of solid compressed air investments include:

- Variable-speed drives, especially if you qualify for rebates from utilities and federal programs. Find out “How Variable-Speed Drive Rotary Screw Air Compressors Save You Money.”

- Two-stage compressors, such as our KRSP2 rotary screw air compressor, can offer a payback on energy costs alone that may be less than two to three years. Learn about the “Five Critical Differences Between a Single-Stage and a Two-Stage Air Compressor” or watch a video showing how our two-stage KRSP works.

By thinking long-term, you can make a more informed decision about your compressed air investments. Next, let's discuss how to pick the right compressor type for your needs.

Golden Rule No. 3: Choose the Right Compressor Type

Choosing the right compressor type is critical in achieving both performance and cost-effectiveness. There are three main compressor types used in most commercial and industrial applications: centrifugal, reciprocating and rotary screw compressors. Each has its advantages.

Centrifugal Compressors: Efficient, But Probably Not in the “Budget” Price Range

Extremely efficient, especially at high volumes, centrifugal air compressors are durable and oil-free and can produce a lot of air from a small footprint. Unfortunately, because of their initial cost, they are only practical in larger applications (400 HP and above) with relatively stable pressure and flow demands. As a result, it usually comes down to rotary screw vs. reciprocating compressors.

The Drawbacks of Reciprocating Compressors

Reciprocating compressors may have a lower initial cost, but they can be noisy and less efficient. Lighter-duty reciprocating compressors are ideal for businesses with intermittent compressed-air needs, such as oil-change shops and tire-repair centers. In those cases, a smaller reciprocating compressor may fit the bill, providing compressed air efficiently at a lower price point. And maintenance is minimal because a recip has less oil than other types of compressors.

However, single-stage reciprocating compressors have a limited duty cycle, working best at 50% or less. That’s 30 minutes in an hour. Run it longer, and you risk damaging your compressor and shortening its life. As a result, to properly size a recip, you need to consider a compressor with a larger horsepower rating to give the pump time to cool down.

Benefits of Rotary Screw Air Compressors

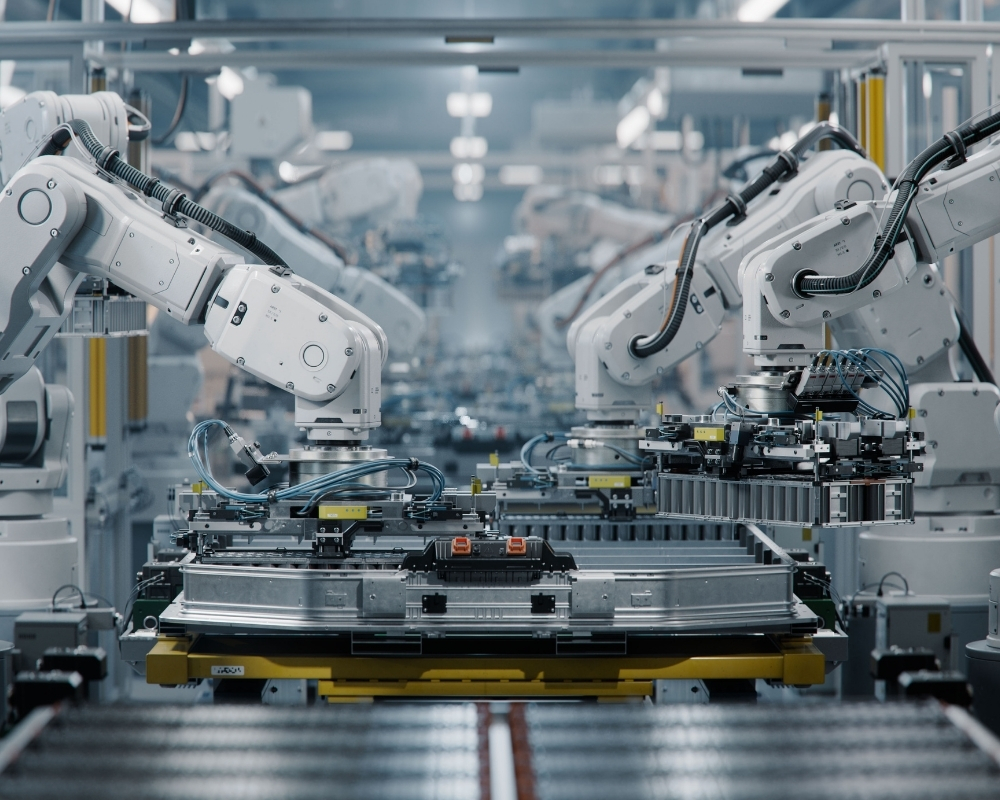

Because of their reliability, efficiency and long life, rotary screw air compressors are the industrial air compressors of choice for most applications. Even major manufacturers with thousands of employees often select rotary screw machines because their facilities are too large to make centralized units practical.

In addition, rotary screw air compressors are known for producing steady streams of high-quality compressed air and handling large-capacity loads. And they are backed by the industry’s best warranties—Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

KRSP2 premium two-stage rotary air compressors flourish in industries as varied as general manufacturing, construction, oil and gas, food and beverage, life sciences, semiconductor fabrication, textile, power generation and automotive manufacturing. They are backed by a lifetime warranty on the airend.

For a complete review of the advantages of rotary screw air compressors, visit our blog post, “The Top 20 Benefits of Rotary Screw Compressors for Industrial Use.”

Belt-drive units are a specific type of rotary screw air compressors.

Belt-Drive Rotary Screw Air Compressors for Budget-Conscious Applications

Belt-drive rotary screw air compressors are solid workhorses used everywhere from auto body shops PARA major manufacturing plants and are known for their versatility and low price tag.

Plus, they’re easy to install and maintenance is relatively straightforward. They’re also relatively cool and quiet. And they’re adaptable: you can adjust the output pressure easily, replacing a pulley, for instance, to go from 90 to 175 PSIG.

Belt-drive air compressors are a frequent choice for auto body shops.

Kaishan's KRSB Belt-Drive Rotary Screw Compressor

We designed the KRSB belt-drive rotary screw air compressor to deliver reliable performance at an affordable price. You’ll find it offers low operating costs, high productivity and reduced downtime and helps ensure the safety of your workers.

The KRSB’s control tubing is made from premium 316 stainless steel, providing longer life, lower service costs, increased reliability and less downtime. It features world-class SKF discharge bearings, sound-deadening enclosures and lower-RPM motors for quiet operation.

If you get the optional Kaishan KRSB belt-drive compressor package with a dryer and receiver tank, all the components are engineered to work together, saving you the time and expense of sourcing the parts separately. Plus, it is stackable, so it takes up minimal floor space.

By selecting the right compressor type, you can enhance your compressed air system efficiency and performance. Now, let's discuss the importance of proper sizing to avoid unnecessary costs.

Golden Rule No. 4: Right-Size Your Equipment

Sizing your compressor and piping properly can help prevent inefficiencies and higher costs.

Compressor Sizing: Why “Room to Grow” Is Not a Good Strategy

Many businesses make the mistake of purchasing a compressor that exceeds their actual requirements, thinking it will provide more power and flexibility. However, oversized compressors can lead to inefficiencies, higher energy costs and increased wear and tear on the equipment. It can even lead to short or rapid cycling.

To get a better understanding of the intricacies of sizing, read our post, “Everything You Need To Know About Sizing Industrial Air Compressors for Manufacturing.” Or download our white paper, “Demystifying Air Compressor Sizing.”

Importance of Proper Pipe Sizing

If your end-use applications are not getting enough pressure, it may not be that your compressor is not powerful enough. It’s possible that your piping is undersized.

Optimizing compressed air piping systems is a critical piece of any compressed air distribution system. If piping is too small, your system will be inefficient and consume more energy. Pressure drop in air piping will overwork your compressor, causing additional wear and maintenance.

Time and again, we’ve found companies reduce pipe sizes as they move away from their compressor. So instead of the typical 2-3 PSIG reduction in pressure over 100 feet of pipe, smaller pipe sizes can cause a pressure drop in the compressor system of 10-15 PSIG.

As a result, keep the pipe size the same from the compressor to the end use. For more details on pipe sizing and avoiding the associated pressure drops, see our blog post, “Six Sure-Fire Ways to Slash Air Compressor Pressure Drop.”

Following those golden rules will help you achieve compressed air success on a budget. But wait, there’s one more!

Bonus Golden Rule: Work with a Pro

Managing a compressed air system on a budget requires careful planning and attention to detail. Most companies are finding they need outside help: access to compressed air experts who can help them make the right choices for their budgets. And while you may think that working with a consultant will cost you money, the opposite is true. We have dozens of case histories that prove how much the right compressed air pro can save you.

That’s why we work with a nationwide network of independent distributors.

We partner with independent distributors because it's the best way to provide the on-site help and consultation you need. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Unlike large corporate suppliers, there's no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize compressed air system efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

The four golden rules for operating compressed air on a budget:

- Pay attention to the details—such as leaks and industrial air compressor maintenance—to achieve significant cost savings.

- Think long-term, considering the total cost of ownership for air compressors instead of just the initial price.

- Choose the right compressor type—most likely, rotary screw vs. reciprocating compressors.

- Right-size your equipment to enhance efficiency, reduce energy costs, minimize pressure drops and maximize system performance.

- And the bonus golden rule: work with a pro.

Let Us Help

Everyone faces financial pressure these days, and compressed air systems are not immune. But addressing them carefully can yield long-term benefits for the system as a whole and the end-use applications that rely on it. If you need help optimizing your compressed air system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Leaking Dollars: Plugging the Easy Efficiency Gaps

Welcome back to the Big Dog podcast! We're thrilled to join you for the next 8 minutes or so.Alright, Lisa, let’s get into the meat of this—optimizing your compressed air system when the budget’s tight. You know, I always say, leaks are like slow money drains. You can run a tidy shop, but if you’ve got air hissing out under the radar... well, you’re basically burning cash. And I’m not talking chump change here. CAGI says a quarter-inch leak in a 100-PSIG system can waste at least $17,000 a year. That’s a vacation fund—or honestly, a brand new compressor in some cases.

It’s wild, right? And most folks don’t even think about it until they hear that number. The worst part is, a lot of these leaks are just lurking in spots people never check—like that crusty drain or some neglected filter. Regular basics like maintenance on your filters and drains really pay off, especially for places like semiconductor or healthcare facilities where stable air supply is, like, non-negotiable. You don’t want pressure swings messing with your robotics line or pneumatic controls, you know?

Absolutely. I mean, I remember—this has gotta be, what, maybe six or seven years back—I was walking the floor and kept hearing this subtle “pfffft” near one of our old drain valves. Turns out, the valve wasn’t closing all the way. Fixed it in, like, ten minutes. But when we ran the numbers, that one little fix ended up saving us a couple grand that quarter. The little stuff really does add up, especially in tight operations.

That’s so classic. And don’t forget about system pressure. I see operators crank it up for the one tool that needs it, but then the whole system runs high—lots of wasted energy, unnecessary wear. Best thing is to set your header pressure just high enough for the most demanding application, and not a PSI more. Go too high, and you're pounding your equipment for no reason.

Yeah, too low and you start getting those callbacks—“my tool’s not working!”—but too high, and it’s just bleeding your utility bill dry. Plus, you’re putting extra stress on the whole system. I know it’s tempting to play it safe, but optimal pressure is about balance, not overkill.

And regular maintenance is just non-negotiable for filters and drains. A clogged filter or stuck drain doesn’t just cost you efficiency, but can snowball into unexpected downtime or even a breakdown. Keeping up those routines goes a long way if you want reliability without shelling out extra every month.

If you take only one thing away from this, it’s don’t ignore the small stuff—because that’s usually where the dollars are leaking out, literally and figuratively. And catching it early on—that’s money in your pocket.

Beyond the Sticker Price: Thinking Long Term with Your Investment

So, sticking with the theme of money, let’s dig into the big one: investing smart long-term. The cheapest compressor on the lot? Honestly, it’s rarely the best deal. I get it—everyone loves a good bargain. But those jaw-dropping low prices usually come with “gotcha” clauses—maintenance contracts, hidden surcharges, and don’t even get me started on the warranty fine print.Yeah, I mean, I’ve lost count how many times I’ve seen someone jump on a deal because the sticker price looks sweet, only to find out a year later they’re locked in with crazy service fees, or stuck hunting for parts that take weeks to arrive. It’s a real headache, and you end up paying way more when you zoom out to the total cost over five or ten years.

Yup, it’s always the “Six Gotchas That Turn Low Sticker Prices into High Lifetime Costs.” We talked about this way back when in, what was it, episode... 46? Whenever you’re signing up for a big spend, you need to look beyond that first number. Ask questions—what’s covered under warranty, are parts easy to get, and am I tied to a service contract that’s gonna haunt me later?

Exactly. And sometimes, it’s worth spending a little more upfront for features that make a real difference. Like, variable-speed drives. Look, if you qualify for utility rebates or incentives, that VSD can pay itself off in a couple years, easy. And with two-stage compressors—plenty of shops have seen quick paybacks purely from energy savings, sometimes in under three years. If your system runs steady for long periods, a two-stage screw is hard to beat for life cycle costs.

Totally! One plant manager told me once, “If it looks too good to be true, it probably is.” And, well, they were right. Bottom line—don’t get tunnel vision on the upfront cost. Consider things like energy efficiency, routine maintenance, access to expert help—all that stuff can make the difference between a system that’s a bargain and one that’s a bottomless pit.

Yeah—play the long game. Treat your compressor more like an ongoing investment than a one-off equipment buy, and you’ll feel a lot less pain down the road.

Right Type, Right Size: Picking and Sizing for True Savings

Alright, so we’ve talked about leaks and costs, but let’s get technical—choosing the right compressor type and, even more importantly, right-sizing everything. Too many times, folks either overbuy or, honestly, cheap out on the wrong style. So, quick rundown: centrifugal compressors are like the Ferraris—super efficient at large scale, but out of reach for most small-to-midsize budgets. Usually, we’re deciding between reciprocating and rotary screw.And recips have their place—great for shops with light, intermittent demand, like tire stores or oil-change bays. But if you run them too hard, they’ll overheat and burn out; single-stage ones really aren’t built for heavy cycling. Then you’ve got rotary screw units, which are basically the solid, reliable pickup truck of the compressed air world. They run quiet, handle big loads, and last forever if you keep them maintained. In fact, most large-scale manufacturers tend to default to rotary screw, just because the performance and warranties are so strong.

Fun fact: belt-drive rotary screws are a great option if you’re budget-focused but still want backbone and adaptability. Easy to install, quieter than most would guess, and with adjustable output—you just swap a pulley, and you’re set for 90 to 175 PSI. Plus, you can get them with an integrated receiver tank and dryer to save space and money. Real workhorses for body shops and mid-sized plants.

And that ties perfectly into right-sizing. One trap I see over and over—people buy a bigger compressor “for room to grow.” But honestly? That just introduces inefficiency and extra wear. Oversized compressors short cycle, burning through more power and parts, not to mention driving up your maintenance bills. I helped a customer last year swap out this massive, ancient compressor that rattled half the plant for a right-sized belt-drive rotary screw. They got a quieter workspace, lower energy bills, and suddenly had ten feet of floor space back.

Yeah, that “room to grow” logic is seductive, but usually ends up costing you. Same goes for piping—if it’s undersized, pressure drops sneak in and the compressor just works harder. Always keep your pipe diameter consistent from compressor to end use, or you’ll lose more pressure than you’d think—sometimes upwards of 10-15 PSI, just because of a bad design.

So, the bottom line—pick the type that best fits your actual needs, size everything for now, not some distant “maybe” expansion, and keep your system balanced. That’s compressed air on a budget, done right.

Alright, that’s a wrap for today. We covered leaks, smart investments, picking the right compressor and sizing it the sensible way. If you want more, we’ve got plenty of deep dives in earlier episodes—and as always, Kaishan’s got your back if you’re looking for expert help.

Couldn’t agree more, Jason. And hey, if you’ve got a thorny compressed air question or a wild budget story, send it our way. We’ll see you next time on The Big Dog Podcast.

Later, Lisa. Take care, everyone.

See ya, Jason. Thanks for listening, everyone.

Random stat or

customer quote

textXXtext

text