The Impact of Temperature on Air Compressor Efficiency

November 6, 2024

CFM vs. PSI: What You Need to Know to Size an Air Compressor

November 13, 2024CFM vs. PSI: Complete Guide to Sizing Air Compressors (2025)

Kaishan USA | November 26, 2025 | Uncategorized

Bulk conveying of powders, pellets or resins, requires a lot of flow (CFM), but not that much pressure (or PSIG).

Selecting the right air compressor for your needs requires understanding two critical specifications: CFM and PSI. These measurements often confuse buyers, leading to improperly sized equipment that underperforms or wastes energy. This comprehensive guide will demystify CFM vs PSI, explain their relationship, and provide practical tools to help you size the perfect air compressor for your application.

Understanding the Basics: What is CFM and PSI?

Before diving into compressor sizing, let's clearly define these fundamental measurements. CFM stands for Cubic Feet per Minute, which measures the volume of air flow. In simple terms, it tells you how much air the compressor can deliver in one minute. Think of CFM like the flow rate of water from a hose - a higher CFM means more air volume is available.

PSI, or Pounds per Square Inch, measures air pressure - the force at which air is delivered. If CFM is the volume, PSI is the pressure behind that volume. Using our water analogy, PSI would be like the water pressure in your plumbing system. Higher PSI means the air is delivered with more force.

So what does cfm stand for exactly? It's the standard measurement for air flow rate in compressed air systems, representing the volume of air (in cubic feet) that passes through a given point in one minute. This measurement is crucial because different tools and applications require different volumes of air to operate effectively.

And what does psi mean? PSI measures the force exerted by the air on a surface area of one square inch. In compressed air systems, it indicates the pressure level at which air is delivered. Tools are designed to operate within specific PSI ranges, and operating outside these ranges can cause poor performance or damage.

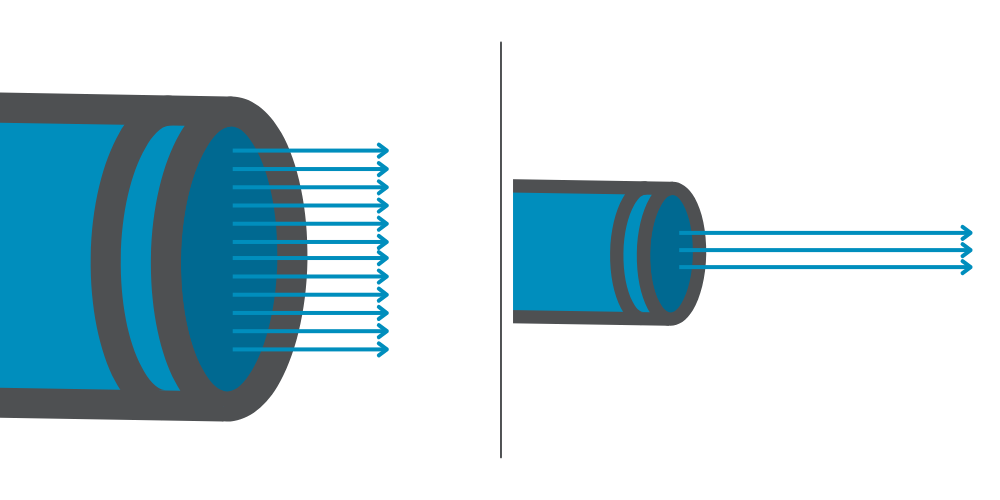

High CFM vs. high PSI airflow: a wide pipe moves a large volume of air slowly, while a narrow pipe forces a smaller volume of air out at higher speed.

To put it in perspective:

-

- A small handheld tire inflator might deliver 1 CFM at 100 PSI

- A large industrial compressor might deliver 100 CFM at 100 PSI

- Both have the same pressure, but the industrial compressor delivers 100 times more air volume

Understanding these basic concepts is essential because both measurements must match your application requirements for optimal performance.

The Relationship Between CFM and PSI

Before diving into compressor sizing, let's clearly define these fundamental measurements. CFM stands for Cubic Feet per Minute, which measures the volume of air flow. In simple terms, it tells you how much air the compressor can deliver in one minute. Think of CFM like the flow rate of water from a hose - a higher CFM means more air volume is available.

PSI, or Pounds per Square Inch, measures air pressure - the force at which air is delivered. If CFM is the volume, PSI is the pressure behind that volume. Using our water analogy, PSI would be like the water pressure in your plumbing system. Higher PSI means the air is delivered with more force.

So what does cfm stand for exactly? It's the standard measurement for air flow rate in compressed air systems, representing the volume of air (in cubic feet) that passes through a given point in one minute. This measurement is crucial because different tools and applications require different volumes of air to operate effectively.

And what does psi mean? PSI measures the force exerted by the air on a surface area of one square inch. In compressed air systems, it indicates the pressure level at which air is delivered. Tools are designed to operate within specific PSI ranges, and operating outside these ranges can cause poor performance or damage.

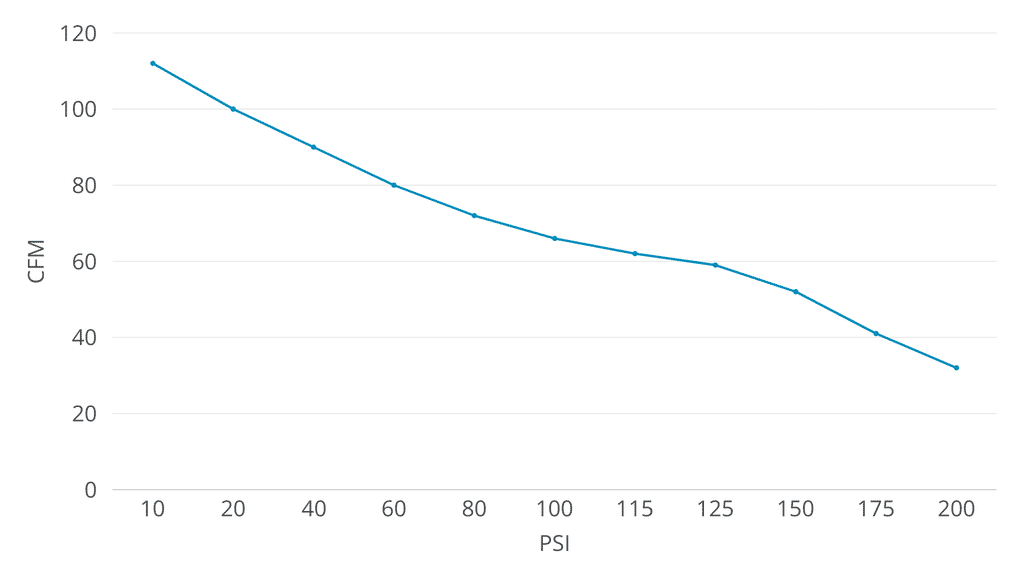

As PSI increases, CFM decreases. This chart illustrates the pressure–flow relationship seen in air compressors—higher pressure reduces available airflow.

This pressure versus flow relationship is crucial because tools require both adequate volume (CFM) and pressure (PSI) to function properly. A tool might specify "5 CFM at 90 PSI," meaning it needs 5 cubic feet of air per minute delivered at 90 pounds per square inch to operate correctly.

The flow versus pressure relationship also affects compressor performance. As you increase the demand for CFM at a given pressure, the compressor must work harder to maintain that pressure. If the demand exceeds the compressor's capacity, the pressure will drop, and the tool won't perform as expected.

Understanding this relationship helps you select a compressor that can deliver the required CFM at your needed PSI, ensuring consistent performance for your applications.

Why Both CFM and PSI Matter for Air Compressor Sizing

When sizing an air compressor, both CFM and PSI are critical factors that must work together. Air compressor cfm requirements determine if the compressor can deliver enough air volume for your tools, while air compressor psi requirements ensure that air is delivered with sufficient force.

Consider a scenario where you have a cfm air compressor that delivers plenty of volume but at low pressure. Your tools might receive enough air, but without adequate force, they won't operate effectively. Conversely, a psi air compressor that delivers high pressure but low volume might provide strong initial force but quickly run out of air, causing the tool to stall or perform poorly.

The consequences of mismatched CFM/PSI can be significant:

1. Undersized Compressor: If your compressor can't deliver the required CFM at the needed PSI, you'll experience:

-

-

- A small handheld tire inflator might deliver 1 CFM at 100 PSI

- A large industrial compressor might deliver 100 CFM at 100 PSI

- Both have the same pressure, but the industrial compressor delivers 100 times more air volume

-

2. Oversized Compressor: While less problematic, an oversized compressor leads to:

-

-

-

- Higher initial investment

- Increased energy consumption

- Unnecessary maintenance costs

- Wasted capacity

-

-

Understanding these basic concepts is essential because both measurements must match your application requirements for optimal performance.

Real-world examples illustrate this balance:

-

- Automotive Shop: A mechanic running an impact wrench (requiring 5 CFM at 90 PSI) and a paint sprayer (requiring 12 CFM at 40 PSI) simultaneously needs a compressor that can deliver at least 17 CFM at 90 PSI (since the higher pressure requirement dominates).

- Woodworking Shop: A woodworker using a random orbital sander (8 CFM at 90 PSI) and a brad nailer (0.5 CFM at 90 PSI) needs a compressor that can deliver at least 8.5 CFM at 90 PSI.

By understanding both your CFM and PSI requirements, you can select a compressor that meets your needs without wasting money on unnecessary capacity or suffering from inadequate performance.

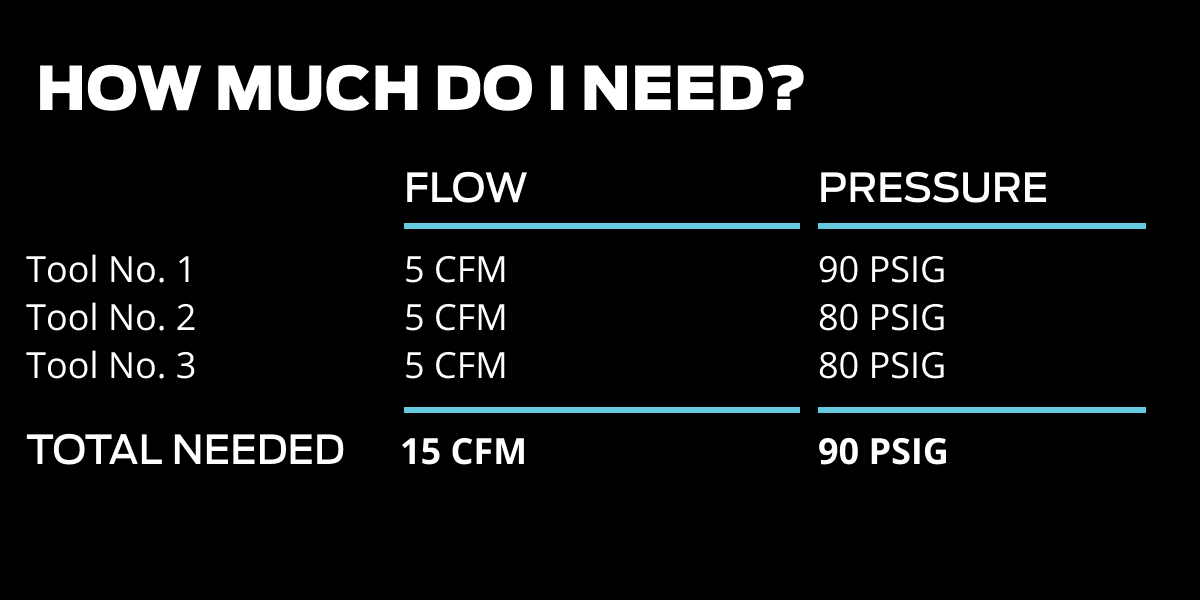

How to Calculate CFM Requirements

Calculating your CFM requirements is a crucial step in sizing the right air compressor. Here's a step-by-step guide to determine your air flow cfm needs:

Step 1: List All Air Tools

Make a comprehensive list of all pneumatic tools you'll use simultaneously. Include everything from impact wrenches to paint sprayers, nail guns to sanders.

Step 2: Find CFM Requirements

For each tool, find its CFM requirement at the working pressure (usually 90 PSI). This information is typically found in the tool's manual or on the manufacturer's website.

Step 3: Calculate Total CFM

Add the CFM requirements of all tools that will run simultaneously. This gives you your baseline CFM requirement.

Step 4: Add a Safety Margin

Multiply your total CFM by 1.25-1.5 to add a 25-50% safety margin. This accounts for:

-

- Future additions

- Air leaks in the system

- Variations in compressor performance

- Peak demand periods

CFM Calculation Formula

Required CFM = (Sum of all tools' CFM requirements) × 1.5 (safety factor)

Examples for Different Tools and Applications:

Automotive Shop:

-

- Impact wrench: 5 CFM @ 90 PSI

- Paint sprayer: 12 CFM @ 40 PSI

- Tire inflator: 2 CFM @ 90 PSI

- Total: 19 CFM

- With safety margin: 19 × 1.5 = 28.5 CFM

Woodworking Shop:

-

- Random orbital sander: 8 CFM @ 90 PSI

- Brad nailer: 0.5 CFM @ 90 PSI

- Framing nailer: 2.5 CFM @ 90 PSI

- Total: 11 CFM

- With safety margin: 11 × 1.5 = 16.5 CFM

Light DIY Use:

-

- Brad nailer: 0.5 CFM @ 90 PSI

- Tire inflator: 2 CFM @ 90 PSI

- Total: 2.5 CFM

- With safety margin: 2.5 × 1.5 = 3.75 CFM

For specialized applications, consider additional factors:

-

- Continuous vs. Intermittent Use: Tools that run continuously (like sanders) need a higher safety margin than intermittent tools (like nailers).

- Duty Cycle: If you'll use tools for extended periods, add an extra 25% to your calculation.

- Altitude: At higher altitudes, air density decreases, requiring larger compressors. Add 1% capacity per 1,000 feet above sea level.

Using this methodical approach ensures your air compressor cfm calculator will give you accurate results for your specific needs.

Understanding PSI Requirements

While CFM measures volume, PSI measures pressure - another critical factor in air compressor sizing. PSI (Pounds per Square Inch) indicates the force at which air is delivered to your tools. Understanding psi pressure requirements is essential because tools are designed to operate within specific pressure ranges.

To determine your PSI needs:

1. Check Tool Specifications: Most pneumatic tools have a recommended PSI range printed on them or in their manuals. This is typically 90 PSI for many tools, but it varies.

2. Consider the Highest Requirement: Identify the tool with the highest PSI requirement in your setup. Your compressor must be able to deliver at least this pressure.

3. Account for Pressure Drop: As air travels through hoses and fittings, pressure drops. Add 5-10 PSI to your highest tool requirement to compensate.

4. Include Safety Margin: Add another 10-15 PSI above your calculated requirement for consistent performance.

Typical PSI requirements for common tools:

| TOOL TYPE | TYPICAL PSI RANGE |

|---|---|

|

Brad Nailers |

70-100 PSI |

|

Framing Nailers |

80-120 PSI |

|

Impact Wrenches |

90-100 PSI |

|

Paint Sprayers |

40-60 PSI |

|

Sandblasters |

90-100 PSI |

|

Die Grinders |

90-100 PSI |

|

Tire Inflators |

90-120 PSI |

|

Air Drills |

80-100 PSI |

Air pressure in psi requirements vary by application:

-

- Light Duty (Home Use): 0-90 PSI

- Medium Duty (Professional/Workshop): 90-150 PSI

- Heavy Duty (Industrial): 150-250 PSI

When selecting a compressor, note its maximum PSI rating (typically 90-150 PSI for standard models, up to 250 PSI for industrial models). The compressor should have a maximum PSI at least 20-30 PSI above your highest requirement to ensure consistent performance.

Remember that psi air pressure is only half the equation. A compressor must deliver the required CFM at your needed PSI. Many compressors advertise high PSI but can't maintain it under load, so always check the CFM rating at your working pressure.

For specialized applications, additional considerations apply:

-

- Paint Spraying: Often requires lower PSI (40-60 PSI) but consistent pressure

- Sandblasting: Needs high volume (CFM) at moderate pressure (90-100 PSI)

- Automotive Tools: Typically require 90-100 PSI with adequate CFM

By understanding both your CFM and PSI requirements, you'll be well-equipped to select a compressor that meets your needs.

CFM to PSI Conversion: Is It Possible?

One of the most common misconceptions in compressed air systems is the idea that you can directly convert CFM to PSI or vice versa. Many people search for a cfm to psi calculator or cfm to psi conversion formula, but the reality is more complex.

CFM and PSI measure different properties - volume and pressure - and cannot be directly converted without additional information. The relationship between them depends on several factors:

1. Compressor Design: Different compressor designs deliver different CFM at the same PSI.

2. System Conditions: Temperature, humidity, and altitude affect the relationship.

3. System Restrictions: Hoses, fittings, and filters create pressure drops that affect the relationship.

4. Duty Cycle: How long and how hard the compressor runs affects its ability to maintain pressure.

To understand why you can't simply convert cfm to psi, consider this analogy: asking for a CFM to PSI conversion is like asking to convert gallons per minute to pounds per square inch in a water system. They measure different aspects of the system.

However, you can calculate the relationship for a specific compressor using its performance curve, which shows CFM output at various PSI levels. This curve is unique to each compressor model.

Mathematically, the relationship can be approximated using the ideal gas law, but this requires knowing additional variables like temperature, volume, and the amount of gas:

P₁V₁/T₁ = P₂V₂/T₂

Where:

-

- P = Pressure (PSI)

- V = Volume (CFM)

- T = Temperature (Rankine)

This formula shows that pressure and volume are inversely related when temperature is constant - as pressure increases, volume decreases, and vice versa.

For practical purposes, manufacturers provide performance curves that show CFM output at various PSI levels. These curves are more accurate than any conversion formula.

When you see a psi to cfm calculator online, it's typically based on generalized assumptions or specific compressor models. These tools can give rough estimates but shouldn't be relied upon for precise sizing.

The key takeaway is that CFM and PSI are related but distinct measurements. When sizing a compressor, you need to know both your required CFM and PSI, then select a compressor that can deliver the required CFM at your needed PSI.

Using a CFM to PSI Calculator

While direct CFM to PSI conversion isn't possible, various online tools can help you understand compressor performance and calculate your requirements. These calculators use manufacturer data or standardized formulas to provide useful estimates.

How to Use Online Calculators and Tools

Most cfm to psi calculator tools work in one of two ways:

1. Performance Curve Calculators: These use specific compressor performance data to show CFM output at various PSI levels.

2. Requirement Calculators: These help you determine your CFM and PSI needs based on your tools and applications.

Here's how to use them effectively:

Step 1: Gather Your Tool Information

List all tools you'll use, noting their CFM requirements at specific PSI levels.

Step 2: Input Your Data

Enter your tool information into the calculator. Some tools will ask for:

-

- Tool types and quantities

- Usage patterns (continuous vs. intermittent)

- System details (hose length, number of fittings)

Step 3: Interpret the Results

The calculator will typically provide:

-

- Recommended CFM at various PSI levels

- Minimum compressor specifications

- Safety margin recommendations

Step 4: Verify with Manufacturer Data

Cross-reference the calculator's recommendations with actual compressor performance curves to ensure accuracy.

Understanding the Results

When using a psi to cfm converter, you'll typically get results like:

-

- "Minimum 15 CFM at 90 PSI"

- "Recommended 20 CFM at 90 PSI with 30% safety margin"

These recommendations should be viewed as starting points. Always consider:

-

- Your specific usage patterns

- Future expansion plans

- Environmental factors (altitude, temperature)

Limitations of Online Calculators

While helpful, online calculators have limitations:

-

- They rely on generalized data that may not match your specific situation

- They can't account for all variables in your system

- They may not have data on newer or specialized compressor models

For critical applications, consult with a compressed air specialist who can perform a detailed analysis of your requirements.

Practical Application

Let's walk through an example using a cfm to psi calculator pdf or online tool:

1. Input:

-

-

- 2 impact wrenches (5 CFM @ 90 PSI each)

- 1 paint sprayer (12 CFM @ 40 PSI)

- 100 feet of 3/8" hose

- Intermittent use

-

2. Calculation:

-

-

- Total CFM requirement: 22 CFM

- Pressure drop calculation: 5 PSI for hose and fittings

- Safety margin: 30%

-

Result:

-

-

- Recommended: 28.6 CFM at 95 PSI

- Minimum compressor size: 30 CFM @ 100 PSI

-

This systematic approach helps ensure you select a compressor that meets your actual needs.

Practical Examples: Sizing Air Compressors for Common Applications

Let's apply our knowledge to real-world scenarios for different applications. These examples will help you understand how to size compressors for various needs.

Automotive Shop

An automotive shop typically uses multiple tools simultaneously, often with high CFM requirements.

Tools Used:

-

-

- Impact wrench: 5 CFM @ 90 PSI

- Paint sprayer: 12 CFM @ 40 PSI

- Tire inflator: 2 CFM @ 90 PSI

- Air ratchet: 4 CFM @ 90 PSI

- Die grinder: 8 CFM @ 90 PSI

-

Calculation:

-

-

- Total CFM requirement: 31 CFM

- Highest PSI requirement: 90 PSI

- Safety margin (30%): 9.3 CFM

- Total required: 40.3 CFM @ 90 PSI

-

Recommendation: A high cfm air compressor with at least 40 CFM @ 90 PSI, such as a two-stage 80-gallon model with 5 HP or greater.

Woodworking Shop

Woodworking shops typically use tools with moderate CFM requirements but need consistent pressure.

Tools Used:

-

-

- Random orbital sander: 8 CFM @ 90 PSI

- Brad nailer: 0.5 CFM @ 90 PSI

- Framing nailer: 2.5 CFM @ 90 PSI

- Air stapler: 1.5 CFM @ 90 PSI

-

Calculation:

-

-

- Total CFM requirement: 12.5 CFM

- Highest PSI requirement: 90 PSI

- Safety margin (25%): 3.1 CFM

- Total required: 15.6 CFM @ 90 PSI

-

Recommendation: A compressor with at least 16 CFM @ 90 PSI, such as a 60-gallon single-stage model with 3-5 HP.

Industrial Manufacturing

Industrial applications often require continuous operation with high demands.

Tools Used:

-

-

- Multiple sandblasters: 20 CFM @ 90 PSI each (3 units)

- Air-operated pumps: 15 CFM @ 100 PSI

- Control valves: 5 CFM @ 100 PSI

- Pneumatic conveyors: 25 CFM @ 80 PSI

-

Calculation:

-

-

- Total CFM requirement: 105 CFM

- Highest PSI requirement: 100 PSI

- Safety margin (40% for continuous operation): 42 CFM

- Total required: 147 CFM @ 100 PSI

-

Recommendation: A rotary screw compressor with 150+ CFM @ 100 PSI, possibly with a dryer and filtration system.

Light DIY/Home Use

For occasional home use, requirements are typically much lower.

Tools Used:

-

-

- Brad nailer: 0.5 CFM @ 90 PSI

- Tire inflator: 2 CFM @ 90 PSI

- Air blow gun: 3 CFM @ 90 PSI

-

Calculation:

-

-

- Total CFM requirement: 5.5 CFM

- Highest PSI requirement: 90 PSI

- Safety margin (20%): 1.1 CFM

- Total required: 6.6 CFM @ 90 PSI

-

Recommendation: A small portable compressor with 6-8 CFM @ 90 PSI, such as a 20-30 gallon pancake or wheeled model.

Comparison Table of Applications

| TOOL TYPE | TYPICAL CFM RANGE | TYPICAL PSI RANGE | RECOMMENDED TANK SIZE | RECOMMENDED HP |

|---|---|---|---|---|

|

Light DIY |

2-8 CFM |

90 PSI |

6-30 gallons |

1-2 HP |

|

Woodworking |

10-20 CFM |

90 PSI |

60-80 gallons |

3-5 HP |

|

Automotriz |

30-60 CFM |

90-150 PSI |

80-120 gallons |

5-10 HP |

|

Industrial |

50-200+ CFM |

100-250 PSI |

120+ gallons or tankless |

10-50+ HP |

These examples demonstrate how different applications have varying requirements. By carefully calculating your specific needs, you can select the right compressor without overspending or suffering from inadequate performance.

Common Mistakes When Sizing Air Compressors

Even with the right knowledge, it's easy to make mistakes when sizing air compressors. Here are the most common errors and how to avoid them.

1. Ignoring the Safety Margin

-

- Mistake: Calculating exact CFM requirements without adding a safety margin.

- Consequence: The compressor struggles to keep up, leading to poor performance and premature wear.

- Solution: Always add 25-50% to your calculated CFM requirements to account for leaks, future additions, and peak demand.

2. Confusing PSI and CFM

-

- Mistake: Focusing only on PSI and ignoring CFM requirements.

- Consequence: A compressor with high PSI but low CFM can't deliver enough air volume for tools to function properly.

- Solution: Always consider both CFM and PSI together. A tool needs sufficient air volume (CFM) at the correct pressure (PSI).

3. Not Accounting for Simultaneous Use

-

- Mistake: Sizing based on individual tools rather than simultaneous use.

- Consequence: When multiple tools run at once, the compressor can't keep up with demand.

- Solution: Calculate the total CFM requirements of all tools that will operate simultaneously, not just the highest single requirement.

4. Overlooking System Pressure Drops

-

- Mistake: Not accounting for pressure drops in hoses, fittings, and filters.

- Consequence: Tools don't receive adequate pressure even if the compressor output is correct.

- Solution: Add 5-10 PSI to your requirements to compensate for system pressure drops.

5. Ignoring Duty Cycle

-

- Mistake: Not considering how long and how hard the compressor will run.

- Consequence: Compressors not rated for continuous use overheat and fail prematurely.

- Solution: For continuous operation, select a compressor with a 100% duty cycle or add extra capacity.

6. Forgetting Future Expansion

-

- Mistake: Sizing for current needs only.

- Consequence: Outgrowing the compressor requires costly replacement or upgrades.

- Solution: Plan for future expansion by adding extra capacity to your calculations.

7. Misinterpreting Manufacturer Ratings

-

- Mistake: Taking CFM ratings at face value without noting the PSI level.

- Consequence: A compressor rated at 20 CFM might only deliver 12 CFM at your working pressure.

- Solution: Always check CFM ratings at the PSI you'll be using, not just the maximum CFM.

8. Neglecting Environmental Factors

-

- Mistake: Not accounting for altitude, temperature, and humidity.

- Consequence: Compressor performance decreases in hot or high-altitude environments.

- Solution: Add 1% capacity per 1,000 feet above sea level and consider ventilation for hot environments.

Checklist for Proper Sizing

Use this checklist to avoid common mistakes:

-

- List all tools and their CFM requirements at working PSI

- Calculate total CFM for simultaneous use

- Add 25-50% safety margin

- Verify PSI requirements and add 5-10 PSI for system drops

- Consider duty cycle (continuous vs. intermittent)

- Account for environmental factors

- Plan for future expansion

- Verify compressor performance at your working PSI

- Select appropriate tank size for your application

By avoiding these common mistakes, you'll ensure your compressor meets your needs both now and in the future.

Frequently Asked Questions

Conclusion

Understanding CFM vs PSI is fundamental to selecting the right air compressor for your needs. CFM measures air volume, while PSI measures air pressure - both are essential for proper tool performance. By calculating your specific requirements and adding appropriate safety margins, you can select a compressor that delivers reliable performance without wasting money on unnecessary capacity.

Remember that there's no direct conversion between CFM and PSI - they're related but distinct measurements. When sizing a compressor, consider both your CFM and PSI requirements, then select a model that can deliver the required CFM at your needed PSI.

Avoid common mistakes like ignoring safety margins, overlooking simultaneous tool use, and neglecting system pressure drops. Use the tools and resources available to make informed decisions, and don't hesitate to consult with professionals for complex or critical applications.

By following the guidelines in this comprehensive guide, you'll be well-equipped to select an air compressor that meets your needs both now and in the future, ensuring reliable performance and efficient operation for years to come.

Ready to find the perfect compressor for your needs? Download our free CFM vs PSI Calculator to determine your exact requirements, or contact our air compressor experts for personalized assistance with your selection.

Let Us Help

Understanding key terms like CFM and PSIG is critical to operating your compressed air system and all the processes that rely on that system. If you need more information on these essential measurement tools, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text