Five Quick Wins That Add Value to Your Compressed Air System

December 31, 2025

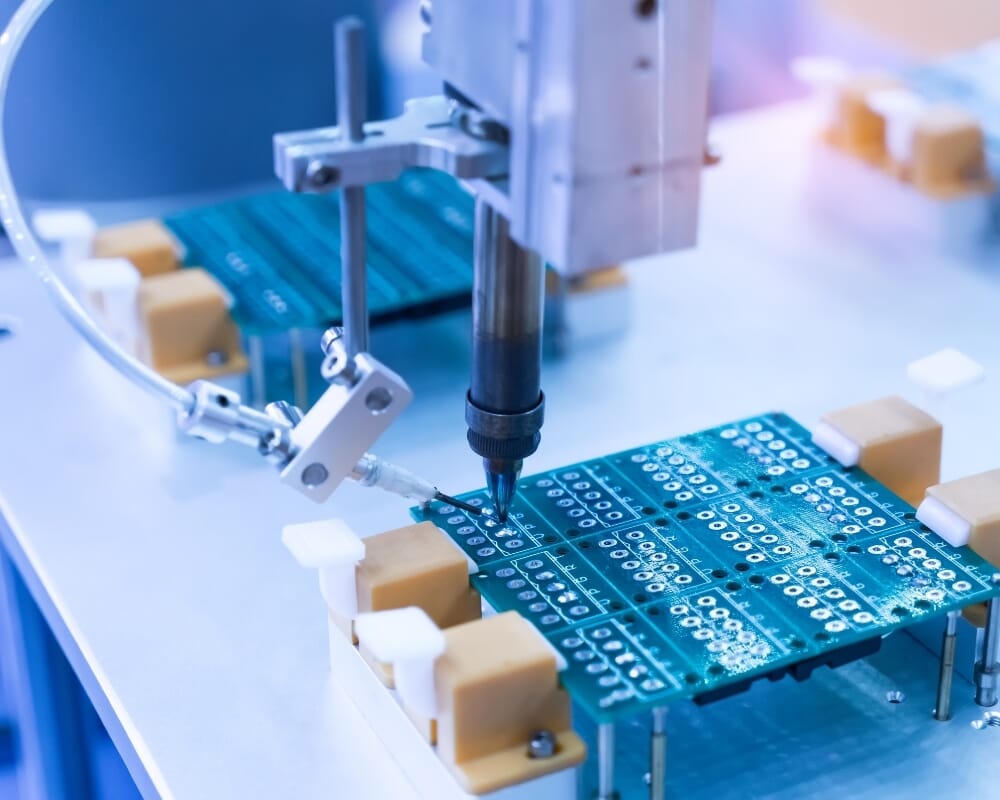

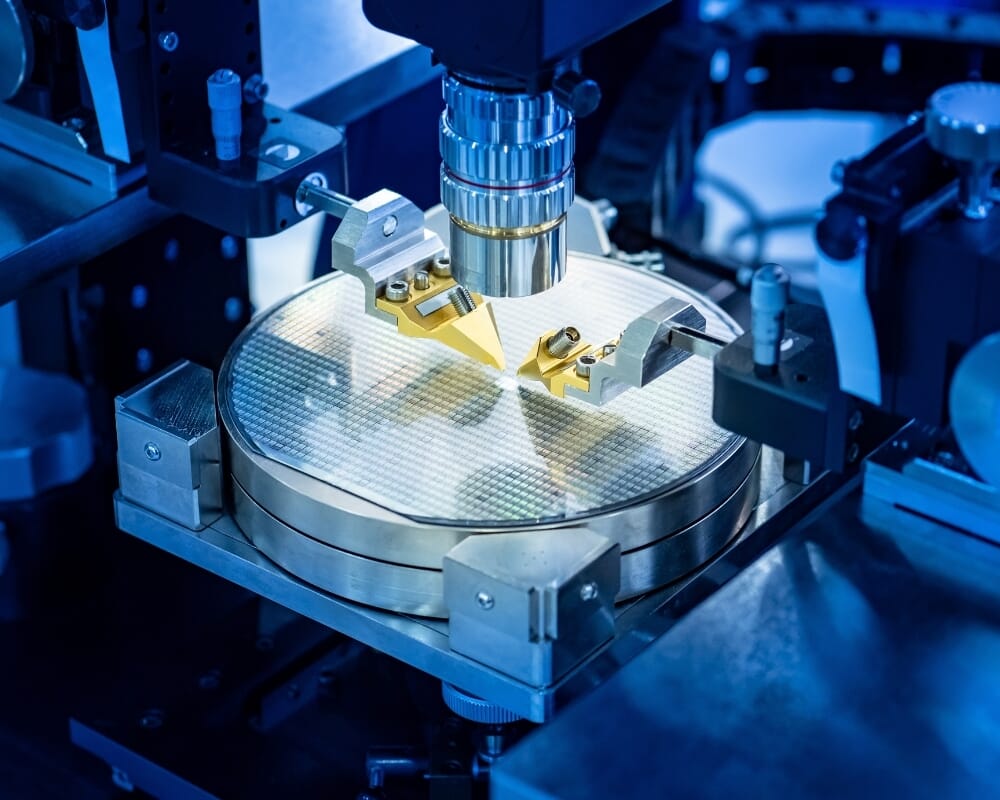

State-of-the-Art Manufacturing of Oil-Free Rotary Screw Air Compressors

January 14, 2026Electric Portable Air Compressors: A Smart Alternative to Diesel

Kaishan USA | January 7, 2026 | Uncategorized

If you rely on diesel compressors, you’ll spend a lot of time refueling. Figure on 8-12 hours of runtime per tank.

For years, when a plant needed temporary air—during a shutdown, a planned maintenance window or a sudden breakdown—the default has been to call the rental house and tow in a diesel portable compressor. It’s familiar. It runs anywhere. It gets the job done. But it also brings a lot of baggage: exhaust, fuel deliveries, noise, higher operating costs and added maintenance headaches.

There’s a better way. An electric portable air compressor gives you the air you need without the diesel drawbacks, especially if your facility already has 460-volt power.

Let’s review the areas where diesel portables fall short, why the market is ready for electric alternatives and how the new Kaishan portable electric (KPE) air compressor changes the game for maintenance managers and plant leaders.

We’ll start with the specific shortcomings that make diesel portables harder to live with than they need to be.

Shortcomings of Diesel Portable Compressors

If you’ve ever managed a diesel portable air compressor during a shutdown, you know the drill. The machine works hard, but it makes you work harder. Here’s why.

Environmental Impact

Diesel engines produce tailpipe emissions and noise that you have to manage. Even Tier 4 Final units still emit particulates and nitric oxide (NOx), which can complicate indoor use and permitting.

You may need to route exhaust, manage carbon monoxide risks and keep a tighter eye on ventilation and worker exposure. Not to mention sensitive applications in the electronics, food and beverage, healthcare/life science and semiconductor industries.

Diesel air compressors may not be appropriate for sensitive compressed air applications.

Cost of Diesel Fuel

The price of diesel fuel is volatile and typically higher per hour than electricity from the grid. Every hour a diesel unit runs, your operating cost creeps up. When diesel prices jump, your temporary air budget gets squeezed.

Maintenance Required

Diesel engines bring engine oil changes, fuel filters, DEF systems, aftertreatment components and routine service intervals that can’t be skipped. That means service windows, parts runs and downtime. Electric portable compressors have far fewer routine maintenance tasks.

Refueling Logistics

Diesel portables need scheduled fuel deliveries or on-site fueling, which introduces spill risk and storage and compliance requirements. It’s one more moving part during a maintenance event already packed with moving parts.

DEF Fluids for Tier 4 Final

Modern diesel portables typically require diesel exhaust fluid to comply with Tier 4 Final regulations. DEF adds consumable cost, storage considerations and one more thing that can run out at the worst moment. Plus, there’s additional paperwork—the MSDS sheets for the new fluids.

As with many diesel-powered vehicles, diesel air compressors may require DEF fluid to remove nitric oxide from the exhaust.

Extreme Conditions

If you’re renting a diesel, make sure it can handle conditions on your site. Not all diesels are equipped for extreme conditions, such as high elevations. Or cold weather.

Limited Portability

Most diesel compressors are equipped with tires. But that doesn’t mean you can take them on roadways. They are not legally towable, just towable on site.

The ROI Reality

When you include fuel, DEF, service and logistics, the total cost to provide temporary compressed air adds up. In many scenarios, an electric portable air compressor delivers a better ROI through lower energy cost per CFM-hour and far less maintenance. Plus, many companies do not allow diesel on site.

If diesel brings complexity and cost, the obvious question is whether the industry is ready for a more practical alternative. We think it is.

The Market Is Ready for an Electric Portable

Electric portable air compressors fit how plants already operate. Most industrial facilities that run a stationary air compressor already have the infrastructure in place—namely, 460-volt power—to run an electric portable when needed.

If you have electrically powered air compressors, your facility probably has the three-phase, 460-volt electrical service you need to power an electric portable. If you are concerned about the amperage required, we can limit the KPE to a lower maximum pressure, such as 150 HP rather than 190 HP.

Attractive to Industrial Rental Centers

Rental centers can expand their fleets with a portable electric compressor that reduces fuel logistics, cuts maintenance and broadens placement options, especially indoors or near sensitive areas where diesel exhaust is a nonstarter.

Infrastructure Is Already There

If your plant has a 460-volt, three-phase connection within reach, you can often power an electric portable compressor without special construction or temporary generators. That’s a big win for maintenance managers who want to simplify mobilization and reduce risk.

With demand building and infrastructure in place, the next step is choosing the right electric portable—let’s meet a new option engineered for real-world industrial air compressor rental and plant needs.

A New Opportunity for Kaishan Distributors

Compressed air distributors can now offer industrial customers the quieter, cleaner, lower-cost temporary air they have been asking for. Electric portables provide a cost-effective, energy-efficient, quiet and safer option for planned outages, new equipment startups, production spikes and emergency backups.

An electric portable air compressor delivers the air you need without the diesel headaches. No fuel runs. No exhaust. No DEF. No flat tires!

Meet Kaishan’s KPE Electric Portable Air Compressor

LA Kaishan KPE brings the performance you expect from a diesel portable. Without the diesel. It’s engineered for versatility, durability and ease of use in industrial environments.

With the reliability and performance the industry has come to expect from rotary screw compressors.

With its glycol-cooled VSD and wide application range, Kaishan’s KPE electric portable air compressor is a game-changer for facilities seeking alternatives to portable diesel compressors.

A Glycol-Cooled Compressor

Instead of relying on ambient air, the KPE uses a liquid-glycol circuit to cool both the drive and the motor via a single heat exchanger. That design isolates critical components from dusty, abrasive air streams and stabilizes temperatures under varying loads.

A single heat exchanger cools both the motor and the drive. And it stays efficient in the dirty, hot environments where air cooling struggles.

Variable-Speed Drive for a Broad Operating Range

A built-in variable-speed drive adjusts output to demand, which is ideal for industrial air compressor rental and backup scenarios where load profiles change by the hour. Rather than oversizing or cycling on and off, the KPE rides the curve to deliver the CFM you need with better energy efficiency and less mechanical stress.

Cooling and control are the foundation. Next, we’ll break down why a glycol-cooled variable-speed drive compressor gives you real advantages on the job site.

The KPE comes standard with heat tracing, keeping the unit properly protected from especially cold environments. We have heaters internally to avoid condensate lines from freezing and a sump heater.

Why Glycol-Cooled VSD Makes Sense in the Real World

If you’ve fought dust, heat and fluctuating demand, you already know why this combo matters.

Closed-Circuit Cooling Thrives in Dirty Environments

Concrete plants, quarries, mills and mining sites are notorious for dust that can choke air-cooled drives. With a glycol-cooled compressor, a closed liquid loop keeps contaminants away from sensitive electronics. The drive and motor stay protected and reliable.

One Unit, Wide Power Band

With a VSD, a single portable electric compressor can cover a wide range of applications. You can right-size on the fly rather than swapping machines, reducing transport and scheduling headaches for maintenance teams and industrial air compressor rental providers.

With a glycol-cooled VSD, one portable electric compressor can handle a wide range of jobs while remaining efficient and reliable.

Efficiency and Uptime

Running at the speed the application requires reduces energy waste and mechanical wear. That means fewer thermal trips, fewer nuisance alarms and a smoother day for your crew.

With the control strategy covered, let’s look at the nuts and bolts that make the KPE easy to own, rent and run.

Other Features Maintenance Managers Will Appreciate

Kaishan engineered the KPE with practical features that speed setup and reduce hassle.

Serious Performance

The KPE delivers pressures up to 190 PSIG and flows from 650 CFM-920 CFM.

It covers everything from plant air backup to abrasive blasting, pneumatic tools and purge operations.

Plug-and-Play Power

Cam-Lok™ connectors make setup faster and safer. Connect power with the Cam-Lok, attach your air hose and turn it on. No elaborate wiring or improvisation in the field.

Built for Harsh Conditions

The unit carries a NEMA 4 rating for protection against windblown dust and water spray, expanding your placement options and providing peace of mind in unpredictable weather. It is truly a NEMA 4 portable compressor.

Maintenance

You can also add the automatic motor greasers for the front and back main motor bearings.

Rugged, Move-Anywhere Package

However you want to move it, the KPE is ready. It has:

- Forklift skids underneath

- A lifting eye on top

- Lifting bolts on the side

Drag it, lift it or hoist it with a crane. KPE goes where you need it.

Now, how do you put it to work in your facility?

Putting Electric Portables to Work in Your Plant

Whether you’re planning a compressor rebuild, adding a new process line or responding to an emergency, the KPE makes temporary air simpler.

- For planned maintenance, stage the unit near your header, connect to 460-volt power and bring it online as you isolate your main compressor.

- For emergency backup, keep one on deck with your industrial air compressor rental partner so your team can mobilize fast without diesel deliveries or exhaust routing.

- For production swings, run it as a flexible assist to your baseload compressor, covering peak demand with better efficiency than a fixedspeed machine off its sweet spot.

Because it’s an electric portable air compressor, your operators avoid diesel refueling, DEF top-offs, indoor exhaust mitigation and the added maintenance that comes with an engine. Your safety team will appreciate the reduced risk profile. Your finance team will appreciate the lower operating cost and cleaner ROI.

If you want to explore an electric portable for your next shutdown or emergency plan, it helps to have a local partner who knows compressed air and your industry.

Conclusion: Talk To a Local Pro About the KPE

If you’re interested in renting a KPE electric portable air compressor or want to compare diesel vs. electric compressor options for your next outage, reach out to your local compressed air professional. A short conversation can confirm power availability, site placement and hose routing, then you can decide whether a portable electric compressor is the right fit.

Kaishan USA partners with a nationwide network of independent distributors who can come on-site, assess your needs and recommend the best approach. These factory-trained compressed air experts service systems every day and are comfortable with advanced technology.

We choose to work with independent, local distributors because they serve you better. There’s no red tape. Just expert guidance, faster response and support tailored to your application. They don’t just sell compressors—they build relationships. So, you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial environments, they help maximize efficiency and minimize downtime. When you work with Kaishan, you get more than a product—you get a local partner who cares about your operation and its success.

Key Takeaways

- Diesel portables carry hidden costs—fuel, DEF, maintenance and logistics—that inflate the actual cost of temporary air.

- Many facilities already have 460-volt power to support an electric portable air compressor during outages and emergencies.

- Kaishan’s KPE combines glycol cooling and VSD to thrive in dirty environments while matching output to demand with a performance range of 650 CFM-920 CFM at pressures up to 190 PSIG.

- Electric portables reduce safety and environmental concerns tied to diesel exhaust and refueling.

- Local Kaishan distributors can help plan, rent and deploy the right solution for your site.

Let Us Help

Electric portable air compressors offer a new level of reliability and support for compressed air users and the processes that rely on your system. If you need help determining whether an electric portable can meet your needs, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Diesel Dilemma

What's up everyone! Welcome back to the Big Dog podcast.Alright, Jason, let's just dive in—because if you’ve ever dealt with a diesel portable air compressor during a plant shutdown or an emergency, you know the pain points. Emissions, noise, refueling, DEF regulations... It sort of feels like diesels are more work than they're worth sometimes.

No kidding. You end up scheduling fuel deliveries, checking fluid levels—basic engine stuff, right? But with a diesel, you throw in aftertreatment components, constant oil and filter changes, DEF top-offs... Now you've got three more compliance headaches and a lot more downtime to juggle. Plus, that exhaust! Every time someone asks, “Can we run this inside the plant?”—you’ve gotta say nope, not unless you enjoy dealing with carbon monoxide and a bunch of permits.

Yeah, and it’s not just the air quality. Some industries—food and beverage, electronics, healthcare, semiconductors—you just can’t risk diesel fumes anywhere around the process. I’ll never forget my first plant tour where we lost, like, four hours hunting down DEF because the unit wouldn’t even start without it. And we couldn’t even bring it cleanly indoors, so the temporary fix became a full-day mess.

That DEF stuff is sneaky—it’s not just an extra jug you haul around, it’s paperwork, storage, one more thing to expire or spill. It’s almost funny. Even if your diesel compressor is Tier 4 Final, you’ve still got emissions to manage. And then there’s noise. I mean, try shouting over a running diesel in a small service bay. Not a fan.

It’s kinda wild how much you're forced to work around a diesel’s downsides, especially for sensitive applications. And don’t get me started on the fuel volatility—the price swings lately? Suddenly that “convenient” rental isn’t all that budget-friendly anymore.

And let’s not gloss over maintenance either. With a diesel, there are so many moving parts—engine oil, DEF systems, fuel filters. One missed service interval and your “plan B” is down for the count. When you’re already juggling a shutdown or a breakdown, you definitely don’t want another system to babysit.

Why Electric Portables Make Sense

So, here’s what I’m curious about, Jason—why are electric portable air compressors taking off now? It seems like the market’s finally ready to move away from diesel. What’s changed?The big thing is, most industrial plants already have 460-volt, three-phase power for their stationary compressors, right? So when a line goes down or you just need backup air, you don’t actually need diesel at all. You can roll in an electric portable, plug it in, and get going—no makeshift wiring, no temp generators. It’s simpler and it saves a ton on setup.

Totally. And for maintenance managers? If you don’t have to worry about fuel runs, spill prevention, or extra MSDS sheets for DEF, that’s already half the stress gone. Plus, if you’re renting, having broader options—especially quieter and safer for indoor use—just makes sense. The upfront electric rental is almost always less hassle than the hidden costs on a diesel.

I talked with a plant in the Midwest—a big quarry operation that switched out diesel portables for electrics during planned outages. It changed everything: no more tracking fuel deliveries, lower hourly energy costs, quieter shift changes, and way fewer “uh-oh” moments. They just hooked up to the plant power and let the KPE run. They told me straight-up, deployment was a breeze and long-term costs dropped way off.

And for rental centers, adding electric portables to the fleet opens up new business, right? They can serve indoor environments, sensitive processing areas, even food and life sciences—places where diesel isn’t even an option. It seems so obvious once you start thinking in terms of infrastructure and risk reduction instead of just, “Well, we’ve always done it this way.”

Yeah, it’s funny—we always harp on “total cost of ownership” in this space, and yet, with portable compressors, people used to just accept diesel as the default. Now, with grid electricity stable and clean, running electric portables is just smarter, especially when it comes to planned outages or emergency support. Honestly, it’s just more practical all around.

Inside the Kaishan KPE Advantage

Let’s get into what the Kaishan KPE brings to the table. Because, I mean, I saw the KPE demoed last month, and you’d hardly know it was running unless you walked right up to it—it was that quiet. For any plant manager tired of yelling over engine noise, that’s a huge win.For sure. The KPE is all about rugged, real-world reliability. Glycol cooling protects the drive and motor from the dust and heat that’d choke most air-cooled compressors—especially at quarries, mills, or concrete plants. It keeps things running stable under all sorts of loads. And with the variable-speed drive, you’re not locked into one CFM: you get 650 all the way up to 920 at pressures as high as 190 PSIG. It’s adaptable.

Yeah, and setup is about as plug-and-play as it gets. Cam-Lok connectors mean you’re not out there improvising with wiring—just connect, hook up your hose, flip the switch, and you’re off. Plus, the NEMA 4 rating keeps out dust and water spray, so weather’s pretty much a non-issue. You can forklift it, use the lift eye, even hoist it with a crane. Wherever you need air, it’s ready to go.

I love that it’s engineered for tough, unpredictable sites, but it’s still so low-maintenance. Fewer moving parts, easy motor greasing, heaters for winter—basically, it’s a portable workhorse for emergencies or planned work. For plant backup, abrasive blasting, or pneumatic tools, it just gets the job done without drama. You’re also sidestepping all those diesel headaches we were talking about earlier.

Seeing it run plant backup and abrasive blasting at the same demo, with zero fuss and barely a sound, kinda made me rethink the whole “diesel default.” If you already have the 460-volt infrastructure, why would you add complications? The uptime, the ROI, just makes sense.

Couldn’t have said it better. If you’re planning a shutdown, needing flexible backup, or tired of diesel’s hidden costs, talking to your local compressed air partner about a KPE is probably overdue.

That’s it for today, everyone. If you have questions on electric portables or want to hear more real-world cases, let us know—this conversation’s definitely not over. Jason, always good to dig in with you.

Same to you, Lisa. Thanks for joining us on The Big Dog Podcast. Catch you next time!

Random stat or

customer quote

textXXtext

text