Eliminating Artificial Demand

September 17, 2025

Six Sure-Fire Ways to Slash Air Compressor Pressure Drop

October 1, 2025Leak Detection: Compressed Air Loss Prevention

Kaishan USA | September 24, 2025 | Uncategorized

While loss prevention is a term rarely associated with compressed air, the industry might benefit from a similar approach, especially regarding compressed air leak detection.

In retail, a significant portion of the industry is dedicated to loss prevention, primarily focused on preventing theft or damage. Typically, that’s not something we talk about in the compressed air industry.

But consider these examples:

- In one instance, we found a plant had so many leaks it was wasting the equivalent of 500 HP of compressor capacity. Simply by fixing the leaks, an expenditure we estimated at $20,000 to $30,000, that company could save the initial cost of a 500-HP compressor, as well as the operational costs.

- In another facility, a 5-HP compressor was not doing the job. The facility manager said the compressor, which provided air to blow up bags the company used to secure freight, wasn’t keeping up. We walked through the loading dock and located 20 separate leaks, by sound alone, virtually the entire 22-CFM capacity of the compressor. Was it really the compressor that wasn’t keeping up?

- A refinery repaired about 70% of the leaks identified in a survey, shutting down three 3,000-CFM air compressors and saving millions in annual electricity costs, according to an account in Compressed Air Best Practices.

Those are just a few examples of losses from leaks in compressed air systems. So, while techniques employed by loss prevention professionals aren’t commonly applied to compressed air systems, perhaps the broad concept should be.

After all, industrial compressed air system leaks cost companies a lot of money—$3.2 billion in utility payments in the U.S. annually, according to the Compressed Air & Gas Institute (CAGI). That’s not just dipping into the petty cash fund.

Want to see how much you can save simply by fixing leaks? Go to our leak estimator page and plug the figures directly into the formula.

Causes of Air Compressor Leaks

There are several ways leaks can occur. Perhaps the system was installed improperly. There can be poor sealing or materials. Accidents, misuse or even corrosion may have damaged pipes, valves, fittings or connectors. And workers may have bypassed a drain or increased pressure when installing or even maintaining your compressed air system.

Installation alone is a frequent cause of leaks. In one example, there was significant vibration in one area of a plant, so all the equipment was on isolators. Unfortunately, the installers supplied compressed air to a key machine using a rigid pipe. There was no way a leak wouldn’t form, and ultimately, the pipe would blow up. We recommended installing flexible tubing to avoid damage or injury.

It's a good example of the temporary fixes or workarounds workers often employ. Those solutions usually don’t work long-term, and many make the problems worse.

So, where do you begin in finding leaks?

Finding Leaks

Looking at the system as a whole, you can start with the compressor, making sure the settings are correct, and the system is sized appropriately.

Most likely, however, you won’t find any. Compressors don’t leak, except under the most extreme circumstances. Especially rotary screw compressors and centrifugal air compressors.

So where do most leaks occur? In what compressed air pros call the “dirty 30.”

The Dirty 30

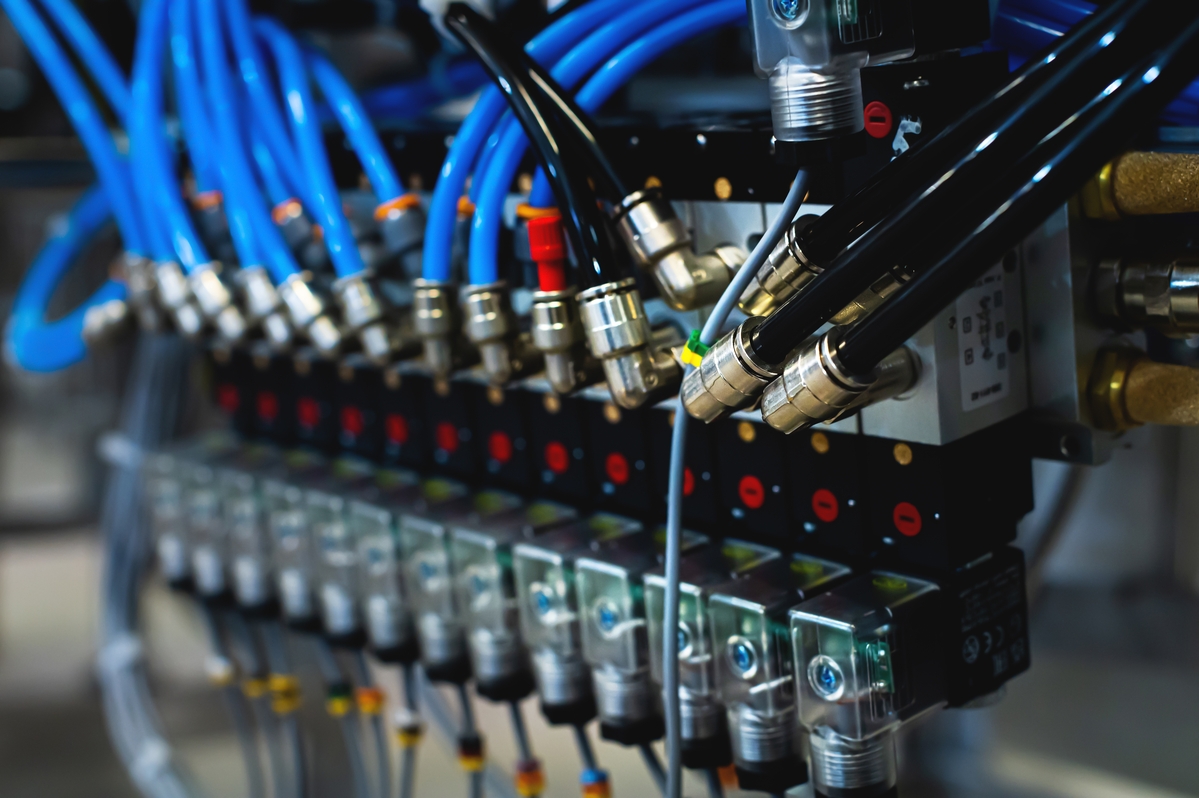

Compressed Air Best Practices notes that 30%-40% of leaks happen in the dirty 30—the last 30 feet before the end-use application.

Compressed Air Best Practices says 30%-40% of leaks happen in the dirty 30—the last 30 feet before the end-use application. That shouldn’t be surprising, however, considering the sheer volume of individual connections that happen in many applications.

You’ll find those leaks in the hoses, reels, filters, regulators or lubricators that connect the air supply to your machinery. And don’t forget the end-use tools, which can have internal leaks, especially if they’re old or poorly maintained.

That’s where you’ll need to focus during a walk-through of your system.

Doing the Walk-Through

As you trace compressed air piping through your system, listen for the telltale sounds of escaping air. Those are the leaks you should address first.

But don’t stop there. Nearly 80% of leaks are inaudible, and the ambient noise in most industrial facilities compounds the problem. So you won’t find everything on your walk-through. To get a larger percentage of the leaks, you need more advanced solutions.

Many companies use handheld leak guns, but they have limitations. They pick up signals from end-use tools or other sources like cathode ray tubes, fan blades, pumps and vacuum pick-ups. The ultimate choice is ultrasonic leak detection devices.

The Ultimate Detection Device: Ultrasonic Leak Detection

When pressurized air escapes through a leak, it emits a sound that may or may not be audible. Ultrasonic leak detection systems use multiple directional microphones to triangulate the position of a leak source, overlaying the leak’s ultrasonic “signal” on a video image of your plant. Thus, they make it easier to identify and locate leaks.

Ultrasonic leak detection equipment like this Fluke ii905 Acoustic Imager not only pinpoints the sources of leaks but also estimates the potential savings you’ll realize by fixing them. That’s especially important if you need to rent a lift to reach a 20-foot-high leak site.

They are very sensitive and use multiple directional microphones to detect small leaks. Because they are good at filtering out background noise and focusing on leaks, they are a significant improvement over handhelds. They make it less likely a technician would be deceived by signals reflecting off a wall or other flat surface, as they might with a handheld.

They can also estimate the leak volume and calculate the potential savings you can achieve by fixing it. They can even generate a printout that you can give to your maintenance team, helping them find and fix the leak.

They can detect leaks in any gas system, including industrial gas lines, vacuum or steam pipes. That may not be your primary concern, of course, but it can lead to additional savings. One disadvantage is that they are less effective with low-pressure systems because of the lower noise level leaks generate in these applications.

Infrared leak detectors are available, but they are generally less effective for detecting compressed air leaks. They are best at covering large areas and detecting large leaks with significant temperature differences.

For more information on finding and fixing leaks, read our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

Another way that compressed air users would benefit from a loss-prevention approach is by paying close attention to header pressure.

Setting Header Pressure

Companies often increase pressure in their system when they notice a pressure drop at the more distant applications they’re servicing. Unfortunately, setting header pressure too high causes several problems that drive up costs:

- First, it wastes energy, leading to increased electricity consumption and costs.

- Second, it increases the likelihood of short or rapid cycling, which can result in breakdowns and resultant downtime, extra wear and tear, increased maintenance and shorter equipment lifespan.

- Third, it increases both the quantity and size of leaks. The higher pressure forces more air through the leaks in their system.

- And fourth, it makes pressure problems worse. Because of the increased leaks and the inverse relationship between pressure and flow, setting the compressor’s output pressure higher actually lowers the PSIG available at the end use.

Rather than go for a quick fix, companies will find it’s much more efficient to find and fix leaks. Anytime your system operates at a higher pressure, you’re creating artificial demand and wasting air, according to CAGI.

The goal is to maintain your compressed air system at the lowest pressure possible.

It’s much better to find and repair system leaks than to increase header pressure in a (usually vain) attempt to get more PSIG to a remote location.

For a complete discussion about setting your system pressure, visit our blog post, “How Lowering the Pressure Band of Your Compressed Air System Can Save You Money.”

If you’re serious about wanting to prevent loss (and save money), consider a leak audit by a compressed air professional.

A Leak Audit from Your Local Professional

An audit, or compressed air system inspection by your local compressed air expert, employs advanced technology like ultrasonic leak detection devices to help you find compressed air leaks and prevent air compressor efficiency loss.

A leak audit by your local compressed air consultant is a great place to start your loss prevention approach to leak prevention.

Kaishan USA works with a nationwide network of independent distributors, to provide on-site help and consultation in facilities like yours. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in using advanced technology, such as ultrasonic leak detection.

Let them show you how they can do the same for you.

We partner with independent, local distributors because it's the best way to serve you. Unlike large corporate suppliers, there's no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- While techniques employed by loss prevention professionals aren’t commonly applied to compressed air systems, the broad concept probably should be.

- Industrial compressed air system leaks cost companies a lot of money—$3.2 billion in utility payments in the U.S. annually, according to the Compressed Air & Gas Institute (CAGI).

- Compressed Air Best Practices notes that 30%-40% of leaks happen in the dirty 30—the last 30 feet before the end-use application.

- Nearly 80% of leaks are inaudible, and the ambient noise in most industrial facilities compounds the problem.

- The ultimate choice is ultrasonic leak detection systems, which use multiple directional microphones to triangulate the position of a leak source.

- Rather than increasing header pressure in their system when they notice a pressure drop at the more distant applications, it’s much more efficient for companies to find and fix leaks.

- An audit, or compressed air system inspection by your local compressed air expert, employs advanced technology like ultrasonic leak detection devices to help you find compressed air leaks and prevent air compressor efficiency loss.

Let Us Help

Preventing losses, especially leaks in your compressed air system, is critical to your operation. If you need help stopping leaks, setting header pressure correctly and generally preventing loss, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

How Leaks Drain Your Bottom Line

Alright everyone, welcome back to The Big Dog Podcast! I’m Jason Reed—your guide for everything air that keeps the real world running. And as always, I’ve got Lisa Saunders here with me. Lisa, you ready to rattle some cages today?You know it, Jason! And today we’re talking leaks—not the little drip-drip kind but the kind that gnaw a hole straight through your energy budget if you’re not paying attention. This is probably one of the most overlooked money pits in any plant. I mean, you’d never just throw cash out the window, but that’s basically what leaks are doing in compressed air systems.

Yeah, if you care about the bottom line—and let’s be honest, who doesn’t—it’s wild how much gets lost to leaks. I’m talking real numbers here. According to industry reports, $3.2 billion, that’s billion with a B, gets wasted every year in the U.S. on compressed air leaks. And I think a lot of people still don’t realize how big that number is or where it’s coming from. It’s not just poor luck or bad maintenance—you get leaks from lousy installation, bad sealing materials, corrosion, workarounds that are meant to be temporary but stick around forever. Even stuff like bumping up the pressure to “solve” a problem, which—spoiler—that never actually solves anything.

Exactly. There are real-world examples all over. We had that one facility, right, where a 5-HP compressor just couldn’t keep up. The manager was sure they needed a bigger machine. But turns out, when we walked through and just listened—literally with our ears—there were 20 leaks, just hissing away. The whole compressor’s output, poof, gone. Another one I liked was the company wasting the entire output of a 500 HP compressor. That’s not dime-sized loss, that’s a disaster. Fixing the leaks was a fraction of what a new compressor would cost. I think they spent like, what, twenty to thirty grand to patch things up and saved themselves from buying and running another monster compressor.

Yeah, and I’ve gotta share this—I remember walking into a plant and before I even got to the production floor, you could hear that classic sssss in the air. I don’t wanna brag, but, you know, trusty ears and all—I tracked down six leaks in maybe fifteen minutes. The maintenance guys were standing around debating why their compressors were always “maxed out,” and here were all these little air geysers just hiding right under their noses. It wasn’t the compressor’s fault, not even close. Sometimes we get so fixated on “do I need a bigger compressor?” when the real answer is stop leaking all that air first. And it’s not always obvious, either, because the leaks can sound tiny, but you add them up? That’s a lot of horsepower just… gone.

And it can all come back to temporary solutions, too, right? Like, someone doesn’t have the right parts, so they rig something up—maybe with rigid piping where you should have flexible tubing. Those short-term fixes turn into long-term headaches. Corrosion, vibration, wear—it all adds up, and sooner or later, that patch just becomes another leak.

Where Leaks Hide and How to Find Them

So, let’s talk about where these leaks are actually hiding. Because if you think it’s some mystery deep inside the compressor, well, think again. Most of them show up in what the pros call the “dirty 30”—the last 30 feet of piping before you actually use the air. That’s hoses, reels, filters, regulators, worn-out tools. Just the crazy number of connectors you get at the end of the line. It’s not surprising—there are so many failure points in that last stretch, and a lot of them are totally out of sight and out of mind.Yeah, absolutely. You see this all the time—people do the walk-through and listen for leaks, which is a fine place to start. I mean, your ears can get you only so far, though, especially in a noisy plant. The truth is, about 80% of leaks are inaudible, so good luck picking them out over all that background noise. It’s kinda shocking.

And that’s where old-school handheld leak guns come in—but they’re honestly pretty limited, especially with all those other noises flying around. They pick up stray signals from tools or even weird things like cathode ray tubes—wait, does anyone even still have those? Anyway, you know what I mean. They’re not going to catch it all. The real upgrade happens when you bring in ultrasonic detection. That’s a game changer—especially with something like the Fluke ii905 Acoustic Imager. It doesn’t just listen for leaks, it actually shows you a visual leak map on a screen, pinpointing exactly where the air’s escaping, even through the loudest environments.

Yeah, and plus, those ultrasonic imagers estimate how much you’re losing, so you’re not just finding the leak; you’re seeing the dollars fly out the door. And if you’re running a plant with leaks up on high racks or behind machines, knowing where they are—before you rent a lift or pull a crew off the line—saves a ton of time and money. With the ultrasonic stuff, you’re making actual data-driven decisions. I mean, look, fixing leaks is already the smart move, but if you can put a number on it—“Hey, this leak is costing us $2,000 a year”—people finally start paying attention.

Exactly. And these systems are way less likely to get fooled by sound reflecting off a wall or picking up something from a motor across the room. They’re just so much more precise because of how the microphones work, triangulating the leak’s position and filtering out everything else. Sometimes you find leaks in lines you didn’t even realize had a problem—like ducts for vacuum, steam, or even other gases. I mean, for most people, compressed air is the big focus, but there can be bonus savings if you catch those other leaks too.

Which is all to say, if you’re still only relying on the old “listen and feel” routine, you’re gonna miss out on the majority of what’s actually costing you. Imagine the maintenance hours saved, too—no more chasing ghosts all shift or getting distracted by a noise that turns out to be nothing.

Smart Prevention Beats Quick Fixes

Alright, so this is the part I probably harp on too much but—raising header pressure? That’s not a fix, don’t let anybody tell you it is. Every time you turn the header pressure up just to make up for leaks or pressure drops, you’re actually making things worse. You use more energy, you wear out the compressor faster, leaks get bigger, then you’re right back where you started but with higher costs and more downtime. It’s that classic false solution, and it’s one of the fastest ways to burn cash without solving anything.Absolutely. The real solution isn’t hiding in the control panel or maxing out the compressor—it’s a proper leak audit. We’re talking factory-trained professionals walking your plant with advanced tech—ultrasonic detectors, imagers, the whole deal. Not only do they find leaks you’d never see otherwise, but they also hand you a clear, actionable report with real savings attached. You get data, priorities, locations, and a plan that actually works. And with the right audit, you can maximize efficiency and minimize downtime—both of which equal dollars in your pocket.

And there are the success stories to prove it. I know one refinery that took this approach, repaired about 70% of their leaks, and were able to shut down three massive, 3,000-CFM compressors. Three. Imagine the electricity and maintenance they saved. That’s millions back, not just a nice round number for the accountants. That’s game-changing stuff—and you’ll never see results like that by just cranking up pressure or patching a hose with duct tape.

And I want to say—you get those results with local, independent experts. People who know your industry, who want to build a partnership, not just sell you something and disappear. It’s not just about finding the leaks, it’s having someone you trust help set system pressure, pick the right parts, and support you when stuff happens. We’ve seen it—plants cut downtime, boost reliability, shave massive chunks off energy bills just by partnering with the right folks. To me, that’s what makes audit programs really stick.

Bottom line—don’t fall for quick fixes. Take the time to do a real audit, invest in smart tech, and work with people who actually care about your facility. You’ll save money, your systems will run cleaner, and you’ll buy yourself a little peace of mind along the way. Lisa, I think we’re about out of time—but this is the kind of thing that’s never “one and done,” right?

Not even close. There’s always something new out there—tech, case studies, things we learn the hard way. So, if you care about turning air into profit, or just not lighting money on fire, stay tuned. We’ll keep digging into what matters most.

Alright, thanks for joining us on The Big Dog Podcast. Lisa, always fun—

Always. Take care, everyone—we’ll see you next episode.

Random stat or

customer quote

textXXtext

text