State-of-the-Art Manufacturing of Oil-Free Rotary Screw Air Compressors

January 14, 2026

Measuring For Air Compressor Energy Efficiency: What to Track, Why It Matters, What to Do Next

January 28, 2026When To Use a VSD on a Rotary Screw Air Compressor

Kaishan USA | January 21, 2026 | Uncategorized

Installing a rotary screw compressor with a variable-speed drive can help facility managers navigate seasonal demand peaks in industries such as food and beverage.

Almost everyone in today’s industrial environment has heard about variable-speed drives. And for good reason. VSDs have improved the energy efficiency of many different types of industrial machines.

Rotary screw compressors are one of the most obvious beneficiaries of VSD technology. Pairing them with a VSD can deliver significant energy savings, smoother performance and fewer electrical headaches at startup.

For maintenance managers and plant leaders who live and breathe uptime and operating cost, a VSD air compressor can be a game changer.

A variable-speed drive is an electronic component that adjusts the speed of your air compressor’s motor. Based on input from sensors throughout your system, the VSD speeds up or slows down the motor to match the compressed air demand, delivering several significant benefits.

The main benefit, of course, is energy savings. The Compressed Air and Gas Institute (CAGI) reports that VSDs can reduce energy use by about 33% in the right application. That’s because a variable-speed drive matches motor speed to real-time air demand rather than running full tilt and unloading. In a world where electricity is one of the largest lifecycle costs on a compressed air system, that’s real money.

Kaishan offers a complete family of variable-speed drives for our rotary screw air compressors.

Those energy savings, in turn, lead to immediate cost savings. Over the life of a rotary screw air compressor, energy is the big line item, dwarfing purchase price and maintenance.

When a VSD reduces your kWh consumption, the payback often arrives sooner than you’d expect. In many regions, you can also earn rebates or incentives from utilities or government programs to offset the higher initial investment in a variable-speed drive. That can turn a solid business case into a no-brainer.

You’ll also notice better performance day to day. A VSD helps maintain a tighter pressure band, often within a few PSIG, compared to the wider pressure range required by fixed-speed compressors.

That tighter band reduces waste from over-pressurization and protects processes that are sensitive to pressure variation, such as packaging and food and beverage applications. It’s a practical way to stabilize production while keeping your baseload compressor efficient.

With a VSD you can optimize the efficiency and energy consumption by narrowing the pressure band to a specific pressure. You have the ability to set the target pressure your application needs, saving energy by eliminating the large pressure band.

Another underappreciated advantage is avoiding high inrush current at startup. Fixed-speed motors draw a surge of current when they start, which can stress the electrical infrastructure and result in peak demand charges from your utility company.

With a VSD, the motor ramps up smoothly, significantly reducing inrush current and related penalties. That can prolong the life of electrical components and help you stay within your facility’s power quality envelope.

One quick note: VSDs pair exceptionally well with rotary screw air compressors, where continuous-duty operation and part-load efficiency matter. However, they’re not used on centrifugal air compressors, which employ inlet guide vanes to provide turndown.

For a more detailed discussion of the advantages of VSDs, see our blog post, “How Variable-Speed Drive Rotary Screw Air Compressors Save You Money.”

Now let’s discuss when a variable-speed drive is the right tool, when it isn’t and how to deploy it for maximum ROI.

Best Applications for VSDs in Rotary Screw Systems

There are several situations in which a VSD delivers significant value.

Use a VSD as Your Trim Compressor

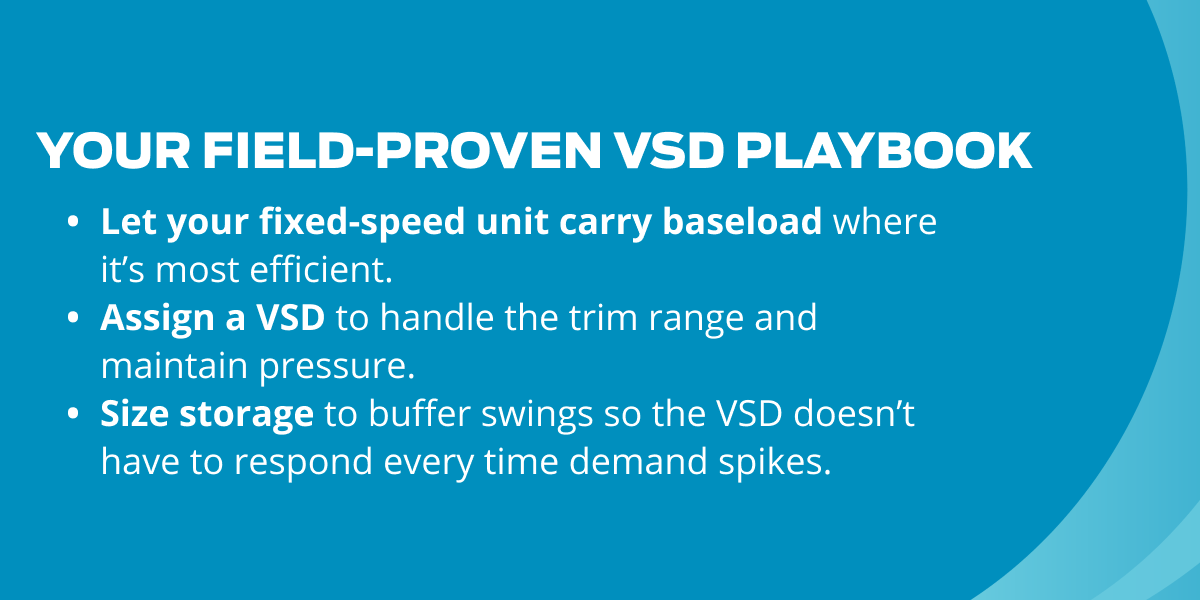

In multi-compressor systems, the classic strategy is to assign one fixed-speed unit as the baseload compressor and deploy a VSD air compressor as the trim compressor.

The baseload runs in its sweet spot—fully loaded and efficient—while the VSD trims to match changing demand. This approach leverages the best of both worlds: high full-load efficiency from the fixed-speed machine and excellent part-load efficiency and pressure control from the variable-speed drive.

Deploy Where Demand Varies Between 20% and 80%

The biggest wins show up when your demand profile swings between roughly 20% and 80% of capacity. Think of facilities with different shifts, seasonal production or intermittent processes. During the second shift, on weekends or during slower product runs, a VSD can ramp down to meet lower demand without wasting energy. During peaks, it scales up smoothly and maintains steady pressure.

A few examples maintenance managers will recognize:

- Between shifts, when only maintenance and minimal production run

- Seasonal peaks in packaging or food and beverage

- Intermittent uses like sandblasters, paint booths or CNC clusters that aren’t on 24/7

Facility managers may benefit from using a VSD air compressor for intermittent applications, such as spray booths and sandblasters.

When You Need a Tight Pressure Band

Certain processes don’t tolerate pressure swings. Paint lines, instrument air and precision assembly all require stable pressure. A VSD allows you to narrow the pressure band, reducing artificial demand and lowering the average setpoint you need to maintain. Dropping the setpoint even a few PSIG can deliver meaningful compressed air energy savings across your system.

VSDs help you control pressure variation, which can be critical in precision assembly applications.

Good Fit with Power-Sensitive Facilities

If you’re watching utility demand charges or have sensitive electrical equipment, avoiding inrush current matters. A VSD’s soft-start behavior prevents those big spikes that can trip breakers or impact your utility bill. Over time, that helps protect upstream equipment and supports system reliability.

Of course, VSDs aren’t a silver bullet. There are scenarios where they won’t deliver the promised benefits—and a few that can shorten equipment life if ignored.

Things To Avoid with VSDs

Not Enough Variation: Above 80% of Capacity

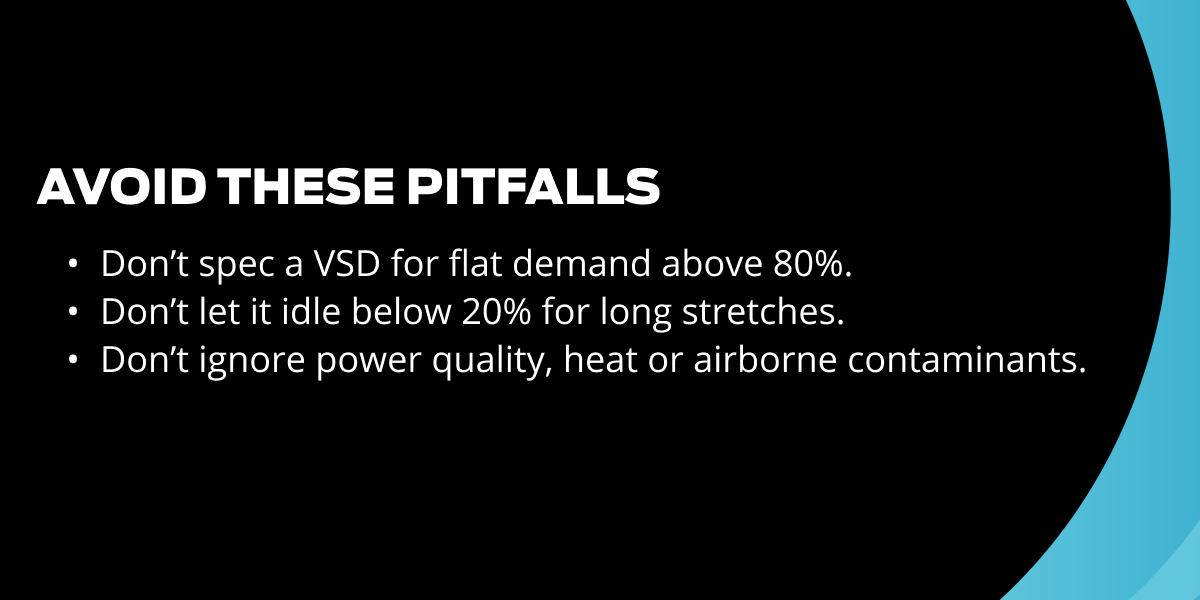

If your plant runs a steady load above 80% of capacity, a VSD may not be your most efficient choice.

That’s because the drive introduces conversion losses that erode the efficiency advantage you’d otherwise gain. In that case, a well-sized, fixed-speed baseload compressor usually wins on kWh per CFM.

You can still consider a small VSD trim compressor if you see occasional dips, but don’t expect significant returns if your demand is flat.

Consistently Below 20% of Capacity

On the other end of the spectrum, running a variable-speed drive consistently below 20% capacity can cause problems. The compressor won’t get hot enough—ideally above 150°F—to evaporate moisture.

That leads to internal condensation, water accumulation and the real risk of rust or corrosion. In short, run too cold for too long and your rotary screw air compressor can suffer expensive damage.

Inconsistent Power Supply

VSDs depend on stable input power. Voltage sags, harmonic distortion or frequent outages can cause nuisance trips or drive faults.

If your facility has power quality issues, address those first with proper filtering, line reactors or coordination with your utility. Otherwise, you’ll spend more time resetting faults than enjoying energy savings.

Temperature Extremes and Dirty, Dusty or Wet Environments

Drives are electronics, so heat, dust and moisture are not their friends. Dirt and dust clog a VSD’s air-cooling passages, leading to overheating and shutdowns.

In addition, high ambient temperatures stress components and shorten life. Likewise, wet environments invite corrosion.

Possible remedies:

- Liquid cooling. Consider liquid-cooled VSDs for harsh ambient conditions.

- Remote location. Relocate the VSD to a cleaner, controlled room. If you do, account for cable length, grounding and the potential for vibrations or harmonic resonance when the drive is too far from the compressor.

Knowing where to use a VSD is half the equation. The other half is making sure your overall system supports it and getting expert help to finalize the details.

Get Expert Help to Choose the Right Oil-Free Solution

A VSD can deliver excellent results in the right application. To get the most out of it, make sure the rest of your compressed air system is up to the task.

Sizing storage, piping and filtration matters. If those aren’t adequate, you’ll see too much starting and stopping, even short or rapid cycling, which is not good for a VSD or your uptime.

Right-sized storage and piping help avoid short cycling and stabilize system pressure.

The best move is to schedule an air audit with a compressed air expert who can assess your facility’s demand profile and determine whether a VSD air compressor will provide the benefits you want in your application.

Kaishan USA works with a nationwide network of independent distributors who can provide on-site help and consultation as needed. These factory-trained air compression experts can service your air compressor system without a problem, and they have staff members who are skilled in advanced technology.

We partner with independent, local distributors because it’s the best way to serve you. Unlike large corporate suppliers, there’s no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don’t just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. When you buy from Kaishan, you get more than a product—you get a local partner who cares about your business and wants to see it succeed.

If you’d like help or determining whether a VSD air compressor makes sense for your facility, reach out to your local compressed air professional to get started.

Key Takeaways

- A variable-speed drive on a rotary screw air compressor can reduce energy use by about 33% in the right application, leading to meaningful cost savings.

- Use a VSD as a trim compressor with a fixed-speed baseload compressor to balance efficiency and pressure stability.

- Aim for demand between 20% and 80% of capacity to capture the biggest benefits and maintain a tight pressure band.

- Avoid running a VSD consistently below 20% to prevent condensation, corrosion and premature failure.

- Skip VSDs where demand is flat and above 80% most of the time, since drive losses can outweigh benefits.

- Protect the drive from inconsistent power, heat, dust and moisture—consider liquid cooling or a cleaner remote location if needed.

- Validate your demand profile with an air audit and work with Kaishan USA’s distributor network to optimize selection and controls.

Let Us Help

Deciding whether you would benefit from including a VSD in your rotary screw air compressor purchase is critical to the operation of your compressed air system and to all the processes that rely on it. If you need help deciding whether a VSD air compressor is right for your application, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

VSD Basics and Real-World Benefits

Alright, welcome back to The Big Dog Podcast—where we cut through the hot air and just talk rotary screw compressors, no nonsense. I’m Jason Reed, and with me, as always, is Lisa Saunders.Hey everyone! Today, we’re getting into something we hear about all the time: variable-speed drives, or VSDs. Whether you call them VFDs or VSDs, they’re everywhere, and honestly, there’s a ton of buzz for a reason. But, like, are they really all that? When do they actually make sense?

Yeah, let’s start with the basics so nobody gets lost. A variable-speed drive—it's basically smart tech for your air compressor motor. Instead of running wide open all the time, a VSD dial ups or slows down your compressor to match what the plant is asking for, second by second. It’s all based on sensors and real-time data. So you avoid blasting out compressed air when you don’t actually need it.

Exactly. It’s like having, um, cruise control for your compressed air—terrible analogy, but you get the point. The big headline is energy savings—according to the Compressed Air and Gas Institute, VSDs in the right applications can chop energy use by up to 33%. That’s huge in terms of plant utility bills, right?

No doubt. And it’s not just about energy. With a VSD, instead of those big pressure swings you get with most fixed-speed units, you keep things in a tight little band. Less wasted air, less over-pressurizing, better for quality control too—especially where the process is sensitive, like, say, packaging lines or food and beverage.

Oh yeah, let me jump in here, because I’ve actually seen this play out. I was out at a food processing plant last year—these folks were getting hammered every summer with crazy spikes in demand. Their old compressor would just slam on, then lag behind, then over-pressurize, so half the time they were worried about breaking seals or throwing out product. Swapping in a VSD rotary screw? It let them handle those peaks so much smoother, and they saw actual, like, 20% drop in utility bills that first year. The facility manager was pretty happy—well, as happy as those food guys ever get.

Yeah, food plants are a tough crowd, but that’s real. And don’t forget, a VSD helps with stuff like inrush current, too. That means you don’t get smacked with those big utility charges when everything kicks on all at once. The payback on these things can hit faster than you’d think—sometimes with a bit of rebate help too.

And the other thing is, the ongoing headaches? Like tripped breakers or electrical wear? A soft-start from the VSD spares your electrical infrastructure a lot of grief—we covered some of those electric issues when we talked about portable systems versus diesel a few episodes back. Same principles apply here.

For sure. So, in short, VSDs give you energy savings, better pressure control, and help your motors live longer. But not just anywhere—you wanna match the tech to the problem. Let’s get into where VSDs really earn their keep.

Best Applications and Smart Strategies

Alright, so you’re convinced VSDs can save serious cash—where do you actually put ‘em to work? The classic play is making the VSD your trim compressor. That means you run a fixed-speed unit, totally loaded up, humming along as your baseload, and the VSD fills in the gaps with whatever the plant’s calling for as things ramp up or down. We see that all the time in bigger plants running more than one compressor.Yeah, I can’t tell you how many times I see folks try to use a VSD as the main, only machine, but really, it’s the magic of two working together that get you max efficiency. The fixed-speed handles steady loads nice and tidy where it’s most efficient; the VSD chases the ups and downs. The sweet spot is where your demand swings between—what, 20% and 80% of compressor capacity? I always mix that up, but I’m pretty sure that’s the range.

No, that’s exactly right—20% to 80%. And that covers, like, packaging lines that go on and off, those spray booths, or even plants with seasonal peaks—if you’ve got those second and third shifts on the weekends, the VSD just adapts. If everything runs steady, though, hold that thought—because that could spell trouble, which we’ll hit in a minute.

Another big tip? VSDs are a game changer for pressure-sensitive processes. Like, you need that pressure band tight—paint lines, precision assembly, instrument air. VSD really shines there, way better than any fixed-speed unit can.

Plus, that soft start’s a lifesaver for electrical bills. If you’ve ever gotten those peak-demand charges from the utility, you know what I mean. Utilities will hit you hard if your compressor goes full blast right out of the gate, especially in power-sensitive facilities with touchy equipment.

Right, and, you know, this reminds me of an air audit I was called into at this packaging plant—the maintenance manager was pulling his hair out with all the cycling and wasted energy. We dug in with some temporary meters and logged the demand profile, and what we found was classic: the fixed-speed compressor couldn’t keep up during peaks, and then idled at night burning energy. Switching to a hybrid setup with a VSD trim? Smoothed the pressure, slashed their run hours, and the lifetime costs just nosedived.

Yeah, and that’s the playbook for anyone listening: let fixed-speed carry baseload. Let VSD chase the fluctuations. Buffer with enough storage so your VSD isn’t cycling like mad. And make sure piping and controls are up to snuff—otherwise, you’re missing out on those promised savings.

Or worse, you’re creating new headaches down the line. But before we get ahead of ourselves, let’s talk about when NOT to use a VSD. Because they’re not a silver bullet for every system.

Common Pitfalls and Pro-Level Tips

Alright, here’s where people get tripped up: not every plant is gonna see magic numbers from a VSD. If your load is flat—like, the compressor’s running at over 80% all day long? Just stick with a good fixed-speed machine. All you’re really doing adding a VSD in that scenario is making things more complicated and possibly less efficient because you’re adding conversion losses. Can’t cheat physics, even with smart tech.And don’t forget the other extreme—if you’re running the compressor lower than 20% of its rated capacity, like, all the time, that’s a recipe for trouble. Compressors don’t get hot enough at those low loads. You’ll get condensation, maybe some rust, then you’re looking at corrosion and even early failure. That’s a maintenance nightmare waiting to happen.

Yeah, you gotta watch for other VSD gotchas, too. Power quality’s a biggie: those drives are fussy if you got dirty power—voltage sags, harmonics, brownouts. If your plant’s had the lights flicker more than once, sort your power issues before you put a VSD on the line. Otherwise, you’ll spend more time resetting trips than saving energy.

And the environment—the physical, not the, like, climate-change one. I mean, heat, dust, and moisture? Drives hate those. I’ve seen VSD cabinets just gunked to death in a dusty shop or cooked in a hot, unventilated room. If you know you’re pushing those extremes, think about liquid cooling the drive, or just, you know, moving it to a clean, climate-controlled spot. But uh, account for cable lengths and grounding if you do that… That’s important.

Totally. And the thing a lot of folks miss—your system has to be matched as a whole. If you’ve ignored your storage tank or your piping is too small, even the sharpest VSD’s not gonna save you from short cycling, pressure drops, or downtime.

Honestly, this is where an air audit changes everything. I’ve seen places try to drop a VSD in and keep all their old piping and tiny receiver, and within six months they’re complaining about noisy cycling and random shutdowns. One case, the maintenance team just didn’t account for start-stop frequency, so they were burning through components. They finally got a local expert involved, redesigned the storage and piping, and suddenly their VSD started paying off—plus way less downtime.

That’s why we always say: don’t go it alone. If you’re not dead sure that a VSD fits your demand profile, lean on the pros—get an air audit, talk to your distributor, whatever. And hey, if you need a partner that doesn’t just sell and ghost you, Kaishan’s got a whole distributor network trained up for this stuff—no red tape, real expertise.

Alright, I think that’s where we wrap: VSDs can be a game changer, if you use ‘em right, and if you avoid the classic mistakes. If you’re on the fence or dealing with weird cycling or power spikes, get a pro to check out your system—it’s worth the investment. Jason, always good talking this stuff over with you.

Yeah, you too, Lisa. That’s it for this one—thanks for listening to The Big Dog Podcast. We’ll be back next time diving into even more compressed air mysteries. Take care, Lisa.

You too, Jason! Bye everyone, talk soon.

Random stat or

customer quote

textXXtext

text