Robertet

August 26, 2025

How Well-Managed Compressed Air Systems Avoid Downtime

September 3, 2025Centrifugal Air Compressor Sizing

Kaishan USA | August 27, 2025 | Uncategorized

The steel industry requires the high volumes and oil-free air that centrifugal compressors provide.

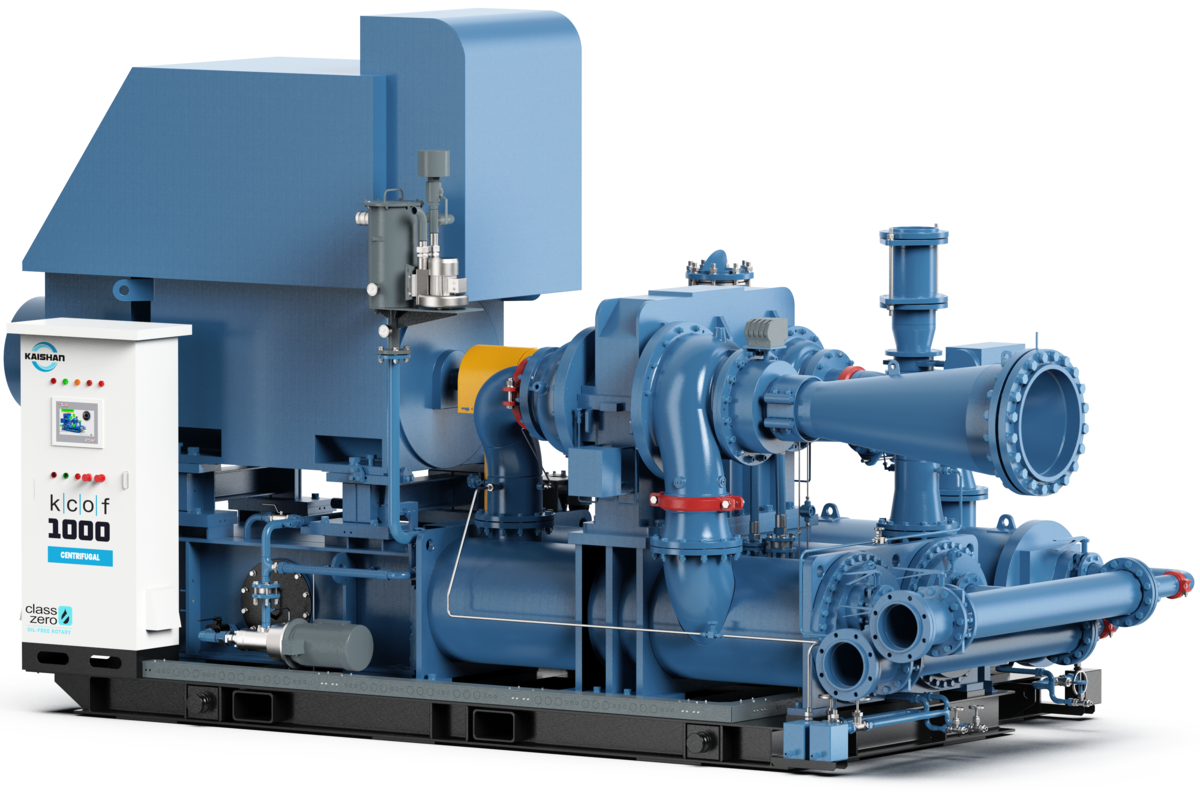

Centrifugal compressors like Kaishan’s KCOF are an essential power source in today’s industrial economy.

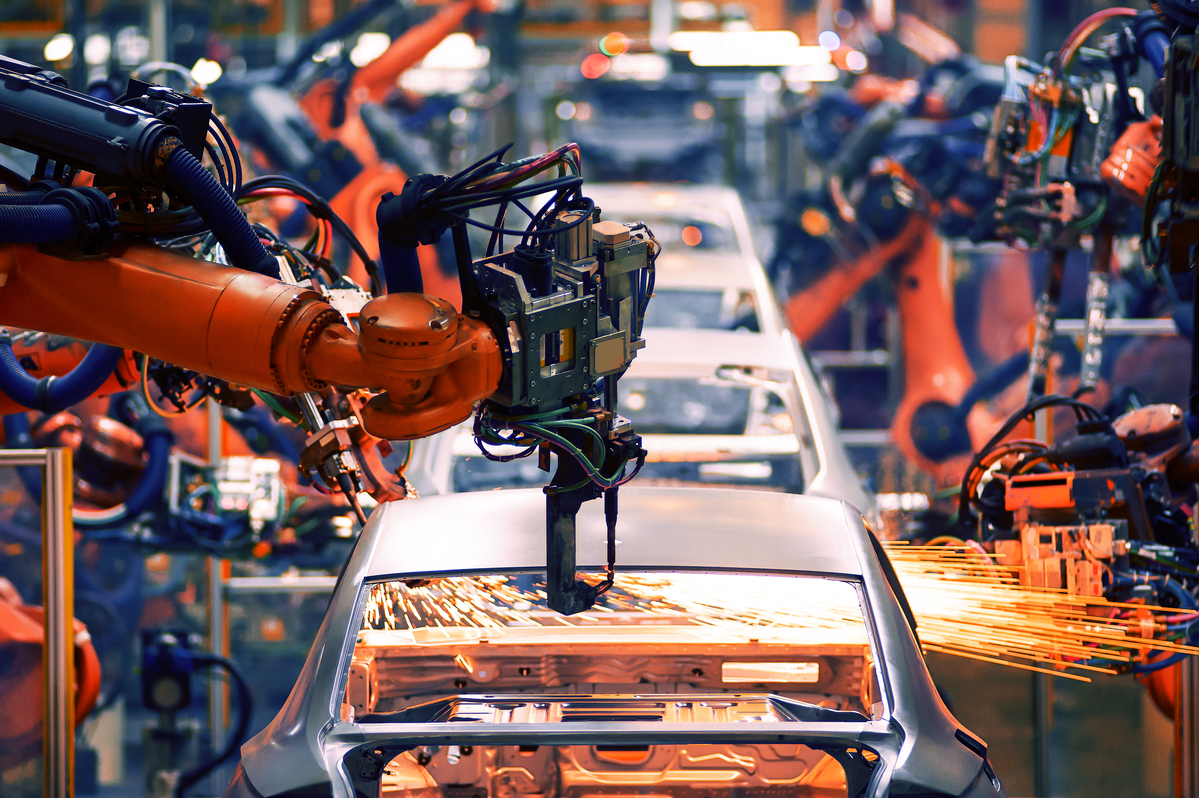

They can deliver impressive volumes of compressed air efficiently and are inherently oil-free. And while rotary screw air compressors are the compressor of choice in many small- to medium-sized operations, centrifugals are often the best fit for major automotive, steel and machine-building applications, where massive amounts of air are required.

And as with rotary screws, sizing centrifugal air compressors is crucial to its long-term health. If you size a compressor:

- Too high, your operating range and potentially your efficiency suffers. More on this below.

- Too low, you may not be able to meet the needs of your end-use applications. For more information, see our blog post, “What Happens When the Pressure Is Too Low for Your Air Tools?”

More importantly, oversizing is the leading cause of compressor short cycling. Although it occurs differently than with rotary screw compressors, short cycling caused by oversizing centrifugal compressors is still a problem, causing maintenance nightmares, equipment failures and downtime. For more on the general topic of rapid cycling, read our blog post, “My Compressor is Rapid Cycling. Now What?"

So, let’s talk about the sizing issues you’ll need to address with centrifugals.

The Special Needs of Centrifugals

Centrifugals are dynamic compressors, which means they respond to the changing nature of the ambient air they draw in. As a result, their capacity varies significantly with the ambient air conditions, including temperature, pressure and relative humidity.

Specifically, a centrifugal compressor will produce less pressure and less volume of air on days with the highest temperature, pressure and relative humidity.

Sizing a centrifugal thus requires that you consider three different types of conditions:

- Cold day. What are the lowest temperatures your compressor is likely to encounter?

- Average day. What are the ambient conditions your compressor is likely to face most of the time?

- Hot day. What are the highest temperatures, atmospheric pressures and humidity levels your compressor will need to operate in?

We need to know the coldest weather, of course, to design in freeze protection, heat tracing or heaters, if required.

However, most of our sizing efforts are focused on hot-day conditions. The goal is to size your compressor for the worst-case scenario, when it is operating in the most unfavorable situation.

Most of our sizing efforts are focused on hot day conditions. The goal is to size your compressor for the worst-case scenario, when it is operating in the most unfavorable situation.

But we don’t want to forget about the average day either. We’ll want to make sure your compressor is optimized to run as efficiently as possible for these conditions, since you’re operating in this zone most of the time.

That is all possible. Until we add in the proverbial “fudge factor.”

The Notorious Fudge Factor

Manufacturers and engineers have a natural tendency to oversize for contingencies, typically adding in a 10-15% “fudge factor” that complicates the task of compressed air system design.

Let’s take an example. Say a facility manager adds up all their uses and determines their system’s demands will be 4,275 CFM. If they size a centrifugal to meet this demand on a hot day, it will meet their needs in this most extreme condition. In addition, it will run relatively efficiently on average days as well. So far, so good.

But when you throw in the fudge factor, our typical facility manager suddenly needs a 4,750-CFM compressor. The downside of this larger-sized compressor is that we now have a range of 4,275 CFM to 4,750 CFM that is taking up a considerable amount of the ideal centrifugal compressor turndown range of the compressor that will likely never be used.

And remember, we’ve sized for the hot day condition, which is likely to happen less than 10% of the time throughout the year. The good news is that centrifugal compressor efficiency is still relatively high on average days, but the design operating point is now in the lower half of the turndown curve.

Most plants, however, don’t operate at maximum demand. Compressed Air Best Practices estimates normal factory demand at 65-100% of capacity. So, even with a 70% rate (30% turndown), our example plant would only be using 3,000-3,500 CFM, and your compressor would no longer be operating efficiently. It would need to blow off about 500 CFM at times, the equivalent of an additional 100 HP of power. And that’s at your typical rate of utilization.

So much for the “fudge factor.”

Automotive original equipment manufacturers rely on centrifugal compressors to provide high volumes of oil-free compressed air.

It’s worse if you’re operating at an even lower level of utilization, which is not unusual. Here’s why: Most experts agree that compressors get more efficient as they get larger—two compressors operating at 50% of capacity are less efficient than a single unit operating at full load. So, the natural tendency is to want a single compressor to handle all your needs. We get it; most of our customers want one machine to maintain and service, with perhaps an older model as a backup.

But when your facility goes below 50% of capacity for extended periods, Compressed Air Best Practices indicates that a multiple-compressor configuration may be more efficient, allowing you to shut down one of the smaller units for extended periods.

Multiple-compressor systems offer many other benefits.

Other Benefits of a Multi-Compressor Configuration

We often encourage customers to adopt a multi-compressor approach involving base, trim and backup units.

- A base load compressor to meet your system’s minimum compressed air load. Its output does not fluctuate as demand goes up and down. Instead, it runs full bore—at 100% of capacity—or it turns off. Depending on variations in your demand, you may have more than one unit as a base load.

- A trim compressor to handle fluctuations in demand above the base unit. Since the level of flow needed will rise and fall depending on the needs of your system, rotary screw compressors equipped with variable-speed drives are a natural for this application.

- A backup compressor is on standby in case a base or trim unit goes offline. To fill in appropriately, it should be the same size as the base load compressor.

Configuring a compressed air system design in this way is more reliable, providing a backup source of air if one compressor is down for maintenance. It thus virtually eliminates unplanned downtime, which, in the real world, is the biggest (and most avoidable) expense associated with your compressed air system.

We discuss multiple compressor configurations in greater detail in our blog post, “How Energy-Efficient Air Compressors Can Reduce Your Carbon Footprint.”

Kaishan KCOF: World-Class Efficiency, Reliability and Support

Kaishan’s centrifugal air compressor offers an exciting option for oil-free compressed air. It provides significant benefits in control capabilities, low maintenance and support:

- State-of-the-art controls. Our KCOF centrifugals are equipped with a field-proven control and energy management software solution that offers dynamic machine and system throttling and a full-flow range of operation. Kaishan offers a user-friendly open architecture that uses industry-standard Allen-Bradley PLC hardware.

- Easier maintenance. Like other centrifugal compressors, the KCOF requires less service inventory and minimal maintenance time. The KCOF has a self-cleaning inlet air filter as an option, reducing the need for filter change-outs in very dirty environments. As a result, filters do not clog as quickly. In addition, the KCOF has longer service intervals, requiring an oil change in many applications only after two years of continuous operation. Our coolers have tube bundles made from corrosion-resistant stainless steel with an epoxy coating on water passages and housings to ensure excellent reliability and long life.

- Unmatched parts availability. Because we are one of the world’s few fully integrated manufacturers of centrifugal compressors, no other manufacturer matches our parts availability. And no one delivers the parts you need as quickly. While other manufacturers make you wait weeks or months (!) for replacements, our parts often ship directly from our warehouse in days, if not hours.

Kaishan’s KCOF centrifugal compressors provide significant benefits in control capabilities, low maintenance and support. They range from 250 HP and 1,400 CFM to over 10,000 HP and 50,000 CFM. They are also available in a wide range of pressures, from 35 to 350 PSIG. Learn more by watching the KCOF video.

Other Considerations

You’ll also need to consider two other factors when you’re sizing and specifying a centrifugal compressor:

- Surge. Most manufacturers have some form of surge anticipation control that responds when the pressure head in the system approaches your compressor’s pressure output. The control opens the unloading valve when the compressor flow reaches that surge point.

- Controls. Although auto-dual control is available to save energy, most operators prefer to operate in constant pressure control to avoid compressor short cycling.

Centrifugal compressors provide machine builders with the high volumes and oil-free air they need.

Help in Sizing Centrifugals

Successful specification, installation and operation of a centrifugal compressor requires a high level of knowledge and experience. That’s why we recommend that most users work with their local compressed air professional to determine the right approach for their facility. They usually start with an audit of your system.

A trusted partner can help you evaluate your facility’s needs and determine the correct sizing for your compressor.

Almost any company can benefit from an air audit performed by an air compressor professional. To see how companies across many industries benefited from an audit, read our blog post, “How an Air Compressor Audit Can Reduce Operating Costs.”

To ensure you have access to that level of expertise, we partner with a nationwide network of independent distributors, who provide on-site help and consultation as needed, including air audits. These factory-trained air compression experts can also service your air compressor system without a problem.

We partner with independent, local distributors because it's the best way to make sure you have the expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right compressed air system design, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- Centrifugal compressors are an essential power supplier in today’s industrial economy.

- Centrifugals can deliver impressive volumes of compressed air efficiently and are inherently oil-free.

- Because centrifugals respond to the changing nature of the air they draw in, their capacity varies significantly with the ambient air conditions, including temperature, pressure and relative humidity.

- Most of our sizing efforts are focused on hot-day conditions.

- Manufacturers’ 10-15% “fudge factor” complicates the task of compressed air system design, often leading to oversizing and inefficiency.

- We often encourage customers to adopt a multi-compressor approach involving base, trim and backup units.

Let Us Help

Correctly sizing a centrifugal compressor is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help calculating the size compressor you need, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Sizing Matters with Centrifugal Compressors

Alright, welcome back to The Big Dog Podcast, folks. I’m Jason Reed, and as always, I’m here with Lisa Saunders. Today, we’re getting into the nitty-gritty of right-sizing centrifugal compressors. Now, if you’re in steel, automotive, or machine-building, you already know these beasts are the backbone for high-volume, oil-free air. But, Lisa, I feel like people still underestimate just how critical it is to get the sizing right on these things.Absolutely, Jason. I mean, we’ve talked about rotary screws a lot on this show, but centrifugals are a different animal. They’re inherently oil-free, which is huge for industries where air quality is non-negotiable. But what really sets them apart is how sensitive they are to ambient conditions—temperature, humidity, even barometric pressure. That’s something I think a lot of folks overlook when they’re designing out a system.

Yeah, and it’s not just a minor detail. Like, take a steel plant—on a hot, humid day, your compressor’s gonna put out less air at a lower pressure than it does on a cool, dry morning. If you don’t account for that, you’re either coming up short or, more likely, you’re way oversized. And that’s where the headaches start. I remember back on the shop floor, we had this one setup—management wanted to play it safe, so they went big. Too big. That compressor spent half its life short cycling, blowing off air, and the maintenance guys were pulling their hair out. I mean, it was just constant nuisance shutdowns and wasted power.

That’s such a classic story. And it’s not just steel—automotive OEMs, too, they need those high volumes, but if you don’t size for your actual demand and the real-world conditions, you’re just asking for trouble. I always tell people: you’ve got to look at your coldest days for freeze protection, but most of your sizing effort should be on those hot, sticky days when your compressor is working its hardest. But, you know, you can’t ignore the average day either, because that’s where you’re running most of the time. It’s a balancing act.

Exactly. And if you get it wrong, you’re not just risking downtime—you’re burning through energy and racking up maintenance bills. So, yeah, sizing matters. And it’s not as simple as just picking the biggest machine you can afford. There’s a lot more to it, and that’s what we’re gonna dig into today.

Avoiding the Fudge Factor and Oversizing Pitfalls

So, let’s talk about the infamous “fudge factor.” I love that term. It’s basically this habit engineers and manufacturers have—adding an extra 10 to 15 percent to the calculated demand, just in case. And, Jason, I get why they do it, but it really complicates things, doesn’t it?Oh, for sure. I mean, it’s human nature, right? Nobody wants to be the one who undersized the compressor and brought the line to a halt. But here’s the thing: you size for your worst-case, hot-day scenario, then you tack on that fudge factor, and suddenly you’re running a compressor that’s way too big for what you actually need 90% of the time. And that’s where you get into trouble with short cycling and efficiency loss. I mean, we talked about this in our episode on compressor cycling—oversizing is a silent killer. You end up blowing off air, wasting power, and your operating point drops into the lower half of the turndown curve, which is just not where you want to be.

Right, and the numbers back it up. Most plants are running at 65 to 100 percent of capacity, but even at 70 percent, you’re probably only using, what, 3,000 to 3,500 CFM out of a 4,750 CFM machine? That’s a lot of wasted horsepower. And if you’re running even lower, it gets worse. I always say, just because you can buy a bigger compressor doesn’t mean you should. It’s not like buying a pickup truck for the one time a year you haul a couch.

(laughs) Yeah, that’s a terrible analogy, but I get what you mean. And honestly, a lot of folks think, “Well, bigger is more efficient.” But that’s only true if you’re running it at full load. Two compressors at half capacity are less efficient than one at full load, but if your demand drops below 50% for long stretches, a multi-compressor setup is actually the smarter play. You can shut one down, run the other at full load, and avoid all that blow-off and wasted energy.

Exactly. I worked with a plant that switched to a base-trim-backup system—so, one big base load compressor, a trim unit with a variable-speed drive, and a backup. Their demand fluctuated a lot, and after the switch, they saw a big drop in energy use and way fewer maintenance calls. It’s just a more flexible, reliable setup. And you’re not stuck paying for capacity you only need a few days a year.

Yeah, and it’s not just about efficiency. It’s about reliability, too. If you’re constantly short cycling, you’re wearing out your equipment faster. So, ditch the fudge factor, size for your real needs, and think about how your demand actually looks over the year. That’s where the savings are.

Multi-Compressor Strategies and Expert Help

So, let’s dig a little deeper into these multi-compressor strategies. The base-trim-backup approach isn’t just about efficiency—it’s about keeping your plant running, no matter what. Your base load compressor handles the steady, minimum demand. The trim unit—usually a rotary screw with a VSD—takes care of the ups and downs. And the backup? That’s your insurance policy. If something goes down, you’re not dead in the water.And the control strategies are just as important. Most operators stick with constant pressure control because it helps avoid short cycling, which, as we’ve said, is a maintenance nightmare. Surge anticipation is another big one—when the system pressure gets close to the compressor’s output, the control system opens the unloading valve to keep you out of that surge zone. It’s all about protecting your equipment and keeping things stable.

Yeah, and honestly, this is where having a good local partner makes all the difference. I mean, you can read all the manuals you want, but nothing beats having someone on-site who knows your system and your facility. I’ve seen so many places benefit from a proper air audit—just having a pro come in, look at your demand profile, and help you right-size your setup. It’s not just about the compressor, it’s about the whole system working together.

Totally. I remember a facility that thought they needed a massive new centrifugal, but after an audit, they realized they could get by with a smaller unit and a smarter multi-compressor setup. Their operating costs dropped, downtime went down, and they had way more flexibility. Sometimes you just need that outside perspective to see what’s really going on.

And that’s why we always say—don’t go it alone. Work with your local compressed air professional, get that audit, and make sure you’re not leaving money on the table. Alright, that’s gonna do it for this episode of The Big Dog Podcast. Lisa, always a pleasure.

You too, Jason. And thanks to everyone for tuning in. If you’ve got questions about sizing, multi-compressor systems, or just want to avoid those classic mistakes, reach out to your local experts—or drop us a line. We’ll be back soon with more real talk on compressed air. See you next time!

Take care, everybody. Don’t let your compressors run you—run your compressors. Catch you on the next one.

Random stat or

customer quote

textXXtext

text