What Happens When the Pressure Is Too Low for Your Air Tools?

August 6, 2025

Six “Gotchas” That Turn Low Sticker Prices into High Lifetime Costs

August 20, 2025How Often Should an Air Compressor Cycle?

Kaishan USA | August 13, 2025 | Uncategorized

Like a car accelerating and slamming on its brakes, load and unload cycles can have a violent impact on your air compressor.

Rotary screw compressors move through cycles of loading and unloading to meet your system’s demand for compressed air:

- In the loaded state, the inlet air valve opens to allow air into the compressor to begin compressing it.

- In the unloaded state, the inlet air valve closes to keep air from entering the compression chamber.

One of the most critical and complex components of a rotary screw air compressor, the air inlet valve allows air into the compression chamber, opening fully during the load portion of the cycle and closing in the unload stage. For more information on this critical part, read our blog post, “What Is the Air Compressor Inlet Valve, and How Does It Work?”

You can tell when a compressor cycles. It sounds like a car shifting gears. Every time you switch from the loaded state to the unloaded state or back again, that’s another cycle. When the pressure goes down, it switches to the load state, and the cycle starts again. And beyond the auditory cues, you can also view this on your controller.

That’s relatively straightforward. Unfortunately, most compressed air users don’t understand the violence that occurs inside their machines when all that loading and unloading is happening.

Think about it. Air enters the compressor at hundreds or thousands of cubic feet per minute. Then we suddenly slam on the brakes and stop. And then we do it again.

That’s horrible. For everything. The more often you do that, the shorter the lifespan of your compressor.

The worst-case scenario is compressor short cycling, also called rapid cycling or fast cycling.

Compressor Short Cycling

Compressor short cycling happens when you’re constantly turning your compressor on and off, loading and unloading.

All of that turning on and off can be devastating to your compressor, causing:

- Extra wear and tear on the motor, valves, bearings and other internal parts

- Overheating

- Carry-over of moisture and oil

- Wasted energy

- Additional maintenance

- A shorter lifespan

Compressor short cycling may require additional maintenance.

Compressors have completely burned out after only six months of compressor short cycling. It’s basic physics.

The main causes of compressor short cycling include:

- You don’t have enough storage.

- You’ve set your pressure band too tight—the gap between the load and unload pressures.

- Your compressor is oversized.

- Some combination of the above.

An air compressor may be cycling too often because there is not enough storage capacity.

The short explanation: if your pressure band is too tight, your system reaches the pressure and flow setpoints too quickly, and you’ll be loading and unloading frequently. Similarly, if your compressor is oversized, your system reaches the high setpoint quickly, and the compressor cycles off. And if there’s not enough storage, your compressor will need to respond quickly when demand from your applications suddenly increases.

To find out more about compressor short cycling, read our blog post, “My Compressor is Rapid Cycling. Now What?"

So, what is a good target number of cycles to shoot for?

How Do I Know If My Compressor Is Cycling Too Much?

Even asking that question means it probably is.

It’s not unusual for us to go into a compressor room and hear a compressor cycling every 40 seconds. Even every 60 seconds. That’s way too many times.

A compressor cycling every 60 seconds is like a driver who has their pedal to the metal, constantly speeding up and slamming on the brakes.

Full speed on the gas. Hard brake. Full speed on the gas. Hard break. Until the machine inevitably breaks down.

That’s how most compressors are set up. And they’re going to fail a lot faster that way. So:

- If your compressor is running at 60 cycles per hour, shoot for 30.

- If it’s doing 20 cycles per hour, try to get it down to 15.

- If you hear it cycling 15 times per hour, you’ll want it even lower.

You get the idea. Because of that violent, stop-and-start action, you want to keep the load cycles to the absolute minimum. Our controllers are set at every 10 minutes to keep our compressor at under six starts an hour. But don’t stop trying to reduce the cycles until you hit zero.

That’s right, zero.

You may not get there. But that’s the goal. Because every time your machine cycles, you shorten its lifespan. Admittedly, by small amounts. But the loss is real. And you prolong the life of the service items by reducing the number of cycles. The National Electrical Manufacturers Association, for example, publishes limits on the number of starts and stops you can expect from motors of various sizes.

Technology to the Rescue

Solutions that lessen the impact of cycling on compressors include additional storage, variable-speed drives and modulation.

- Additional storage helps balance the supply of air from the compressor with the demand from the system.

- VSDs have a track record of improving energy efficiency and also reducing the incidence of compressor short cycling. Plus, rebates from your utility company may help defray the higher initial cost. But they are not for every application, especially where the ambient air is corrosive or dirty. VSDs control the speed of the motor.

In the right applications, variable-speed drives reduce energy consumption and compressor short cycling.

- Modulation, on the other hand, is more adaptable, adjusting the inlet valve, which controls the air entering your compression chamber. There’s no violence in the process. It simply reduces the flow into the machine, just enough to adapt to the new pressure.

Storage, of course, accommodates surges in demand, acting as a reservoir during peak times.

VSDs adjust the speed of the motor while modulation adjusts the inlet valve. The key is that both techniques make the cycling transitions happen more slowly, gradually. With much less of the “slam-the-brakes” impact of typical load-unload cycles.

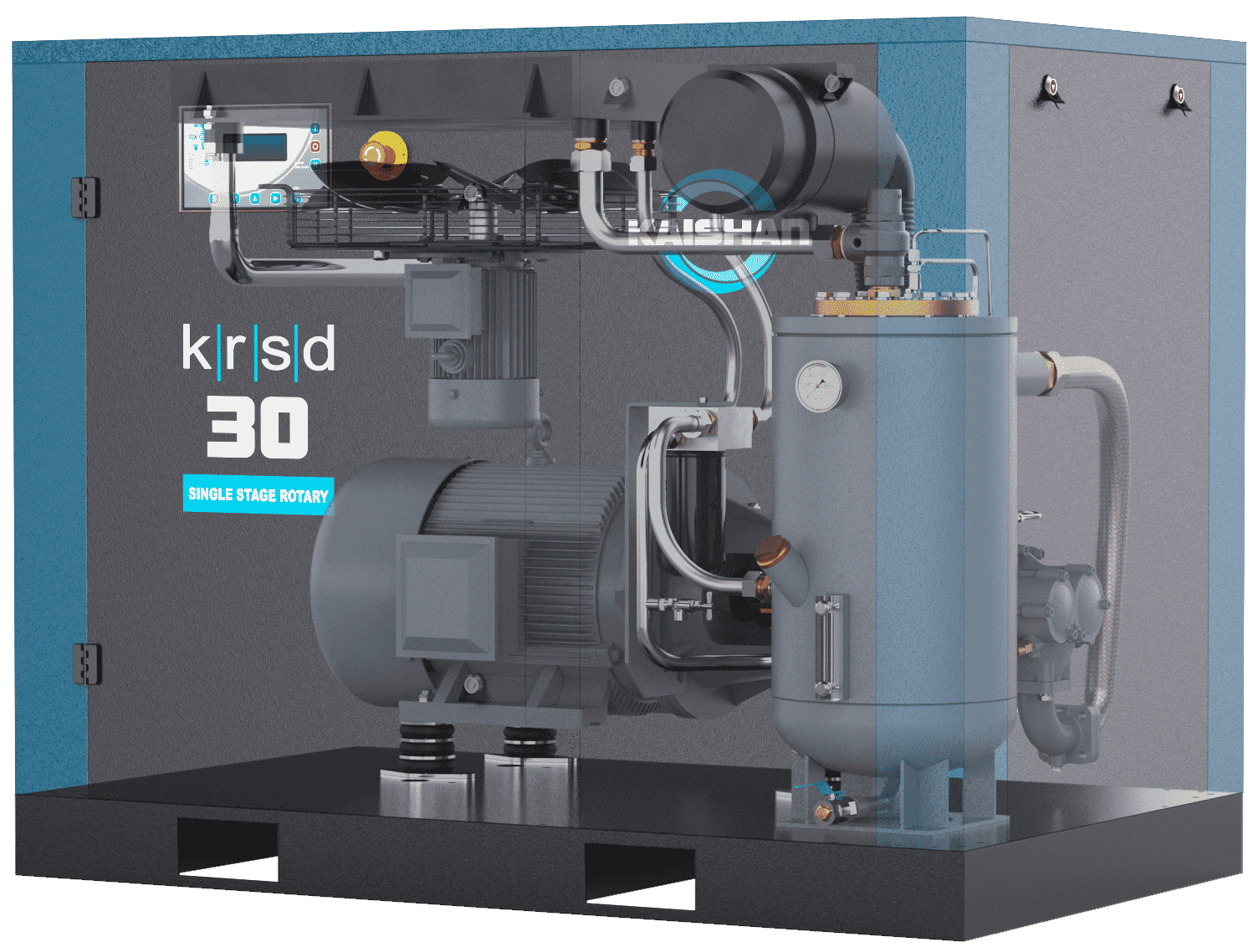

That’s why we include modulation as a standard on our KRSD direct-drive and all our premium products, such as our KRSP, and our KRSP2 two-stage rotary screw air compressors.

We incorporate modulation into some of our models, including our KRSD direct-drive our KRSP and our KRSP2 two-stage.

For years, critics have argued that modulation is inefficient. But the facts don’t support that idea. Most compressed air users find that modulation eliminates the violence of the load cycling, significantly reducing the impact on all the wear parts. Those savings far outweigh any energy loss.

It's much better to use modulation in situations that would be a challenge for a VSD, such as dirty or corrosive environments. There are very few downsides to modulation.

Whatever method you choose, try to minimize the number of cycles your compressor undergoes.

Your First Stop in Cycling Down

If your compressor is cycling 20 or more times per hour, you will benefit from a discussion with your compressed air professional. Your compressor will thank you.

A qualified consultant can help you determine the reasons why your compressor is cycling so much, such as a lack of storage, a tight pressure band or an oversized compressor. Then they can help you weigh alternatives, including VSD compressors or modulation.

Our nationwide network of independent distributors, is uniquely qualified to provide this kind of on-site help and consultation to address cycling issues.

We partner with these independent, local businesses because there’s no better way to make such a high level of compressed air expertise available to you in your facility. They can address not only these cycling issues but also any other concerns you might have about your compressed air system, from design to operation to maintenance. Plus, they can service your air compressor system and have staff members who are skilled in advanced technology.

They offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- Rotary screw compressors move through cycles of loading and unloading to meet your system’s demand for compressed air.

- A rotary screw compressor going through these load and unloaded cycles is like a car accelerating and braking.

- Most compressed air users don’t understand the violence that occurs inside their machines when all that loading and unloading is happening.

- The worst-case scenario is compressor short cycling, which happens when you’re constantly turning your compressor off and on, loading and unloading.

- Compressor short cycling can waste energy, reduce your compressor’s lifespan and cause extra wear, overheating and carry-over of moisture and oil.

- A compressor cycling 60 times per hour is like the driver who has their pedal to the metal, constantly speeding up and slamming on the brakes.

- Technological solutions that lessen the impact of cycling on compressors include variable-speed drives and modulation.

- Whatever method you choose, try to minimize the number of cycles your compressor undergoes.

Let Us Help

Answering the question, “how often should an air compressor cycle?” is critical to lengthening your compressor’s lifespan and ensuring smooth operation of your compressed air system and all the processes that rely on it. If you need help reducing compressor cycling, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Understanding the Cycle

Alright, welcome back to The Big Dog Podcast. I’m Jason Reed, and as always, I’ve got Lisa Saunders with me. Today, we’re talking about something that’s, honestly, killing more rotary screw compressors than most folks realize—short cycling. Lisa, you ever walk into a compressor room and just hear that constant gear-shifting sound? It’s like the machine’s stuck in traffic, right?Oh, absolutely. It’s that “vroom, pause, vroom, pause” rhythm—like a car that can’t decide if it wants to go or stop. And you know, it’s funny, because a lot of people just tune it out. They think, “Well, that’s just how it runs.” But it’s not supposed to sound like a drag race in there.

Exactly. And for anyone new to this, let’s break it down real quick. Rotary screw compressors cycle between loaded and unloaded states. When it’s loaded, the inlet valve opens, air comes in, gets compressed. Unloaded, that valve shuts, and the machine’s basically idling. Every time it switches, that’s a cycle. You can hear it, and you can see it on the controller if you’re paying attention.

But here’s the thing—most users don’t really think about how often that’s happening. I mean, why do you think that is, Jason? Is it just “business as usual” syndrome?

Yeah, I think so. People get used to the noise, or they assume it’s normal. But what they don’t see is the violence going on inside that machine every time it loads and unloads. It’s like slamming on the brakes and then flooring it, over and over. And, honestly, the danger is that you’re just burning through the lifespan of your compressor without even realizing it.

Right, and it’s not just about the noise or the annoyance. It’s about what’s happening to your equipment. If you’re ignoring cycling frequency, you’re basically setting yourself up for more maintenance, more downtime, and a much shorter compressor life. And, as we’ve talked about in past episodes, that’s the kind of “business as usual” that gets expensive fast.

Yeah, and if you’re hearing that gear-shifting sound every minute or so, that’s a red flag. We’ll get into what that actually costs you in a second, but first, just know—if you’re not paying attention to cycling, you’re missing one of the biggest silent killers in your system.

The Cost of Short Cycling

So let’s talk about what’s really happening inside your compressor when it’s short cycling. Every time it loads and unloads rapidly, you’re putting extra wear on the motor, the valves, the bearings—basically all the moving parts. And it’s not just wear and tear. You get overheating, wasted energy, and even carry-over of moisture and oil. It’s a mess.Yeah, and I’ve seen compressors burn out in six months because of this. Six months! That’s wild. It’s basic physics—if you’re constantly starting and stopping, you’re just asking for trouble. And the main culprits? Not enough storage, pressure bands set too tight, or the compressor’s just oversized for the job. Sometimes it’s all three.

I had a client once—big facility, lots of demand swings. They put in this massive compressor, thinking bigger was better. But what happened? The thing was cycling on and off non-stop. Maintenance was out there every week, swapping out parts, dealing with overheating alarms. Their budget for repairs just kept climbing, and the downtime was killing their production schedule.

That’s the thing—how often is too often? If your compressor’s cycling every 40 or 60 seconds, that’s way too much. I mean, we’ve walked into rooms where it’s cycling 60 times an hour. That’s like driving with your foot on the gas and then slamming the brakes, over and over. It’s not sustainable.

And the real-world impact? It’s not just the cost of parts. It’s the lost production, the emergency service calls, the energy bills. If you’re running 20 cycles an hour, you should be trying to get it down to 15, or even lower. Honestly, the goal is as close to zero as you can get. Every cycle you cut out is money saved and life added to your compressor.

Yeah, and as we said in our episode on maintenance and cost-cutting, these little things add up. If you’re not tracking cycling, you’re probably spending more than you need to—on both repairs and energy. So, if you’re seeing 20 or more cycles per hour, it’s time to take a hard look at your setup.

Solutions That Stick

Alright, so what do you actually do about it? There are a few solid fixes. First, adding more storage—bigger air receivers—can help balance out those demand spikes. That way, your compressor isn’t reacting to every little blip in usage. Then you’ve got variable-speed drives, or VSDs. They let the motor ramp up and down smoothly, instead of just on-off, on-off. That alone can cut cycling way down.And don’t forget modulation. It’s a little different from VSDs—it adjusts the inlet valve to control how much air is coming in, so you don’t get that violent stop-start action. It’s a lot gentler on the machine, and it’s actually standard on some of the Kaishan models, like the KRSD and KRSP lines. I know some folks worry about efficiency with modulation, but the data just doesn’t back that up. In most cases, it’s a huge win for reliability.

Yeah, I saw this firsthand at a local manufacturer. They were dealing with constant cycling—like, every minute. We swapped in a VSD, and it cut their cycling in half, almost overnight. Maintenance calls dropped, energy use went down, and the machine just ran smoother. Sometimes it really is that simple.

But here’s the thing—if you’re not sure what’s causing your cycling, or you’re seeing 20-plus cycles an hour, that’s when you call in the pros. A good compressed air consultant can look at your storage, your pressure settings, your compressor size, and help you figure out what’s really going on. And, honestly, that first conversation can save you a ton of headaches down the road.

Yeah, don’t wait until you’re burning through motors or dealing with constant downtime. If you’re hearing that gear-shifting sound more than a handful of times an hour, it’s time to act. Start with storage, look at VSDs or modulation, and don’t be afraid to get expert help. That’s what keeps your system running—and your budget in check.

Alright, that’s gonna do it for this episode of The Big Dog Podcast. If you’re dealing with cycling headaches, or just want to make sure your system’s set up right, reach out to your local expert or check out the resources on the Kaishan website. Jason, always a pleasure.

Same here, Lisa. Thanks for tuning in, everybody. We’ll be back soon with more ways to keep your compressed air system running strong. Take care!

See you next time on The Big Dog Podcast!

Random stat or

customer quote

textXXtext

text