Centrifugal Air Compressor Sizing

August 27, 2025How Well-Managed Compressed Air Systems Avoid Downtime

Kaishan USA | September 3, 2025 | Uncategorized

Just one hour of downtime costs automotive companies $2.3 million—a staggering $638 per second.

For automotive companies, just one hour of downtime costs $2.3 million—a staggering $600 per second, according to the Siemens study, published in 2024.

So, while compressed air advocates take pride in being industry’s proverbial fourth utility, there’s a catch: we join electricity, natural gas and water in being able to hobble or even shut down entire factories. As a result, compressor downtime is a crucial issue.

And being simply operational isn’t good enough. As with the other utilities, impurities and flow problems not only reflect poorly on us but can also disable or damage crucial pieces of downstream equipment. Causing even more downtime.

That puts a lot of pressure on plant personnel to keep their compressors operating smoothly and efficiently. And to ensure they are not passing along oil, water or particulates in the air flow.

How to Prevent Air Compressor Downtime

A host of problems can create air compressor downtime, and we’ve covered them before in this series of blogs and whitepapers:

The most frequent and persistent cause of compressor downtime is poor air compressor maintenance.

However, the leading cause of compressor downtime, and especially screw compressor downtime, is poor air compressor maintenance.

All too often, facility maintenance crews take the reliability of air compressors for granted, especially rotary screw compressors. As if air compressors can run forever without minimal care. And, of course, many companies are downsizing their maintenance staff or failing to replace experienced hands when they retire.

Air Compressor Maintenance Is a Bargain

But those maintenance tasks each year will cost the average facility a few thousand dollars in materials and labor costs. A well-maintained compressor will have a long working life and can impact the longevity of the equipment it serves, also avoiding catastrophic failures that could result in significant repair and replacement costs. A timely oil change, on the other hand, costs about the same as a few minutes of downtime.

In addition to routine air compressor maintenance items, such as oil and filter changes, there are daily tasks that every compressed air user should undertake to ensure proper system operation.

Your Daily Air Compressor Downtime-Cancelling Checklist

We’d like to review four critical tasks you should keep in mind to ensure your compressed air power source continues to provide the essential fourth utility.

1. Check Oil Levels

Check the oil level using the sight glass before starting your compressor, and change oil filters every 2,000 hours of operation.

You should shorten the intervals for changing and sampling oil when you have demanding conditions such as high temperatures or dust and dirt in your intake air. And, when you’re using food-grade oil, you’ll want to sample your oil every 1,000 hours and take action on the recommendations outlined in the analyst’s report.

Even though they do not inject oil in the compression process, oil-free compressors (like the oil-free Kaishan KROF two-stage, oil-free, rotary screw air compressor require the same intervals for oil changes. Our user’s manual calls for oil filters to be swapped at 2,000 hours or semiannually, with oil changes every 8,000 hours or annually.

Our KCOF centrifugal air compressors require oil changes every 8,000 hours and oil filters every 2,000 hours.

2. Clean Condensate Traps and Drains Daily

Inspect and test the moisture trap drain on your compressor and the drains in and all your tanks, filters and dryers. You’ll want to remove any scale, rust, dirt or other solids from condensate traps and drain points daily. Dirt and debris can accumulate in drains, causing them to become stuck.

Stuck in an open position, the drain will leak air. A closed drain will allow moisture and other impurities to pass through, contaminating your compressed air and potentially damaging production equipment.

Drain any accumulated water from the oil sump daily.

3. Check for Alarms

Most late-night calls that compressor professionals receive are about a simple service alarm. It’s the number one air compressor problem we get.

It may happen because the machine has reached an hours-of-operation threshold. Or any number of other status conditions. So, there may not be an immediate issue, but you still need to take action.

The best way to respond is to schedule a service call. It may be something simple—your machine needs a new oil filter, for instance. However, consulting a compressed air professional may save you time, money and downtime.

Here’s why. The first question your service provider will ask is, “What other alarms are present?” They can help you ensure that there aren’t any other service intervals coming up soon and that you’re dealing with all of them, not just the one that came up.

So, you’re not just replacing that oil filter and then getting an alert a few days later that it’s time to replace your air filter. Incurring more downtime while you shut down your system and wait for a replacement part. Your local service provider can help you prevent that.

4. Check for New Noises and Vibrations

Noise and vibration are often the first indication that something is wrong with your compressed air system. Along with alarms, noise and vibration may indicate that something is seriously wrong with your compressor. You should not ignore these warning signals.

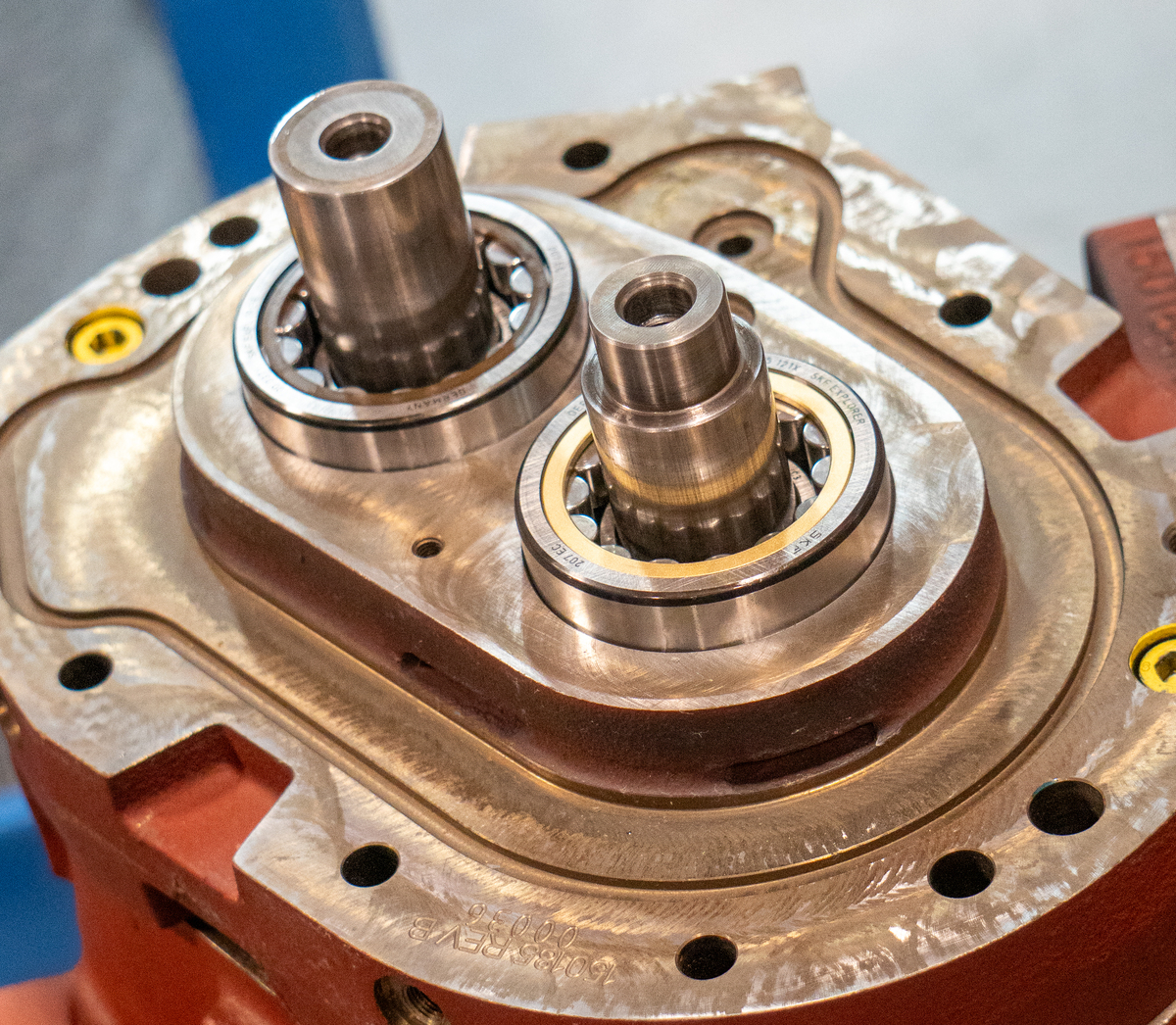

Many operators immediately jump to the conclusion that their bearings are failing, and they may be right. Grinding noises, of course, would be further confirmation of that assumption. It may indicate that bearings are showing signs of wear or that the rotors in a rotary screw air compressor are misaligned.

Excessive noise and vibration may be an indication that your compressor’s bearings are showing wear.

Belts could also be slipping or aging in a belt-driven machine (we have equipped our KRSB belt-drive rotary screw air compressors with automatic belt tensioning to provide longer belt life and ideal tension with no belt slippage).

Kaishan’s KRSB belt-drive rotary screw air compressors are equipped with automatic belt tensioning to provide longer belt life and ideal tension with no belt slippage.

But vibration itself is not the sole indicator. It’s like a runny nose—it could be a symptom of many things, some serious, some not. You could easily misdiagnose a problem if you focus solely on vibration. So you’ll first want to take some additional steps to address minor issues, such as tightening bolts and mounting brackets and making sure your compressor is on a flat, solid surface.

If those steps don’t stop the vibration, you should probably call in your compressed air professional. They can help you determine whether you have a serious problem.

You can help the process along by taking a reading using a shock pulse monitoring (SPM) meter. You should also draw an oil sample and send it for testing. Metal shavings in the oil sample might indicate bearing wear.

For more warning signs of compressor failure, see our blog post, “What Is the Most Common Cause of Air Compressor Failure?” In addition, we offer a more comprehensive list of air compressor maintenance tips in our white paper, “Air Compressor Maintenance: Ultimate Guide and Checklist.”

Your compressed air consultant is also your go-to resource for all your downtime prevention efforts.

Your Kaishan Distributor: Your Local Downtime-Prevention Expert

As with so many other compressed air issues, preventing downtime is not something someone can handle over the phone. It usually requires first-hand observation and on-site help and consultation that only a professional can provide.

That’s why we work with a nationwide network of independent distributors, who can offer expert guidance, faster response times and personalized support tailored to your needs. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

We love it when our customers proactively schedule quarterly inspections and maintenance with their local compressed air pro. That’s downtime-prevention in a nutshell.

We partner with independent, local distributors because it's the best way to serve you. Unlike large corporate suppliers, there's no red tape here. Our distributors don't just sell compressors, they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and will help you succeed.

Key Takeaways

- Unplanned downtime now costs the world’s largest manufacturers $1.4 trillion annually, 11% of their revenue.

- There are many different problems that can cause air compressor downtime, but the most persistent cause is poor air compressor maintenance.

- You should shorten the intervals for changing and sampling oil when you have demanding conditions such as high temperatures or dust and dirt in your intake air.

- When you receive a service alarm, there may not be an immediate issue, but you still need to take action.

- Noise and vibration are often the first indication that something is wrong with your compressed air system.

Let Us Help

Preventing downtime is crucial to the operation of your compressed air system and all the processes that rely on it. If you need help preventing compressor downtime and screw compressor downtime in your facility, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Downtime Hurts

Alright, welcome back to The Big Dog Podcast—where we get real about compressed air. I’m Jason Reed, here with Lisa Saunders. Today, we’re talking about something that keeps plant managers up at night: downtime. And not just any downtime—compressed air system downtime. This stuff is expensive, folks.Yeah, Jason, it’s wild. I mean, the numbers are just staggering. According to Siemens, unplanned downtime costs the world’s largest manufacturers $1.4 trillion a year. That’s, what, up to 11% of their revenue? And if you’re in automotive, it’s even scarier—a single hour of downtime can cost $2.3 million. That’s over $600 a second. I can’t even wrap my head around that.

It’s brutal. And here’s the thing—compressed air is the fourth utility. We’ve said it before, but it’s worth repeating. If your compressors go down, your whole factory can grind to a halt. Doesn’t matter if you’ve got the best machines in the world—no air, no production. And it’s not just about the air stopping, right? Even minor impurities—oil, water, particulates—can mess up downstream equipment. Suddenly, you’re not just fixing a compressor, you’re dealing with a whole chain reaction of problems.

Exactly. I actually saw this firsthand not too long ago. I was visiting a plant—won’t name names, but they had this tiny air leak that nobody noticed. It started as just a little hiss, but by the time someone caught it, the whole production line was down. And it wasn’t just the compressor—they had to stop everything to check for contamination in the tools and equipment. It’s like, one small issue with your air system can ripple out and cost you way more than just a repair bill.

Yeah, and that’s why we keep hammering on this. Downtime isn’t just a nuisance—it’s a profit killer. And honestly, a lot of it is preventable if you know what to look for and stay on top of the basics.

The Real Causes of Compressor Downtime

So, let’s dig into what actually causes all this downtime. There’s a laundry list—bad installation, sizing mistakes, overheating, rapid cycling, pressure band issues. We’ve covered a lot of these in past episodes, but the one that keeps coming up, over and over, is poor maintenance. Especially with rotary screw compressors. People just assume these things will run forever if you leave them alone. Spoiler alert: they won’t.Yeah, and it’s not just about the equipment, right? A lot of companies are downsizing their maintenance teams, or not replacing folks when they retire. So you end up with fewer people trying to keep more machines running, and stuff slips through the cracks. It’s like, you’re gambling with your uptime every day.

Totally. I’ve seen it happen. There was this local plant—again, not naming names—but they decided to push off an oil filter change. “We’ll get to it next week,” they said. Well, next week turned into a week of unplanned repairs because the filter clogged up, oil flow dropped, and the compressor went down hard. All because of a $20 filter and a half-hour job. That’s the kind of thing that drives me nuts. Routine maintenance is cheap compared to the cost of downtime.

And it’s not just oil changes. It’s the little things—checking drains, responding to alarms, listening for weird noises. If you ignore those, you’re just asking for trouble. I mean, we talked about this in our episode on short cycling, too. Small issues add up fast if you’re not paying attention.

Exactly. And look, I get it—everyone’s busy, budgets are tight, but you can’t afford to treat your compressor like it’s invincible. It’s not. And the cost of ignoring it is way higher than just doing the basics.

Your Daily Downtime-Prevention Checklist

So, let’s get practical. What can you actually do every day to keep your system running? There are four things—super simple, but they make all the difference. First, check your oil levels. Use the sight glass before you start up, and don’t skip those oil and filter changes. If you’re running in tough conditions—high temps, lots of dust—shorten your intervals. And don’t forget, even oil-free compressors need regular oil changes for the bearings and gears.Second, clean your drains and condensate traps. I know, it’s not glamorous, but if those get clogged, you’re either leaking air or letting water and gunk into your system. Either way, you’re risking damage to your compressor and your production equipment. Drain the water from your oil sump, too. It’s a five-minute job that can save you hours of headaches.

Third, check for alarms. Most late-night calls to compressor techs are about alarms that got ignored. Sometimes it’s just a service interval, but if you don’t deal with it, you could end up shutting down for something that was totally preventable. And if you’re not sure what the alarm means, call your local service provider—they’ll help you figure out if there’s something else coming up, so you’re not hit with back-to-back shutdowns.

And last, listen for new noises or vibrations. This is your early warning system. Grinding, rattling, weird hums—those are signs something’s off. Could be bearings, could be belts, could be misalignment. Don’t just crank up the radio and hope it goes away. Use tools like SPM meters or send out an oil sample for analysis. If you catch it early, you can fix it before it turns into a major failure.

And honestly, this is where having a good relationship with your local, factory-trained distributor pays off. They know your system, they can spot issues before they get big, and they’ll help you schedule quarterly inspections. It’s way better to be proactive than to scramble when something breaks. We see it all the time—plants that invest in those relationships have way less downtime than the ones who just call in a panic. Yeah, and that’s the bottom line. Downtime prevention isn’t rocket science, but it does take discipline and the right partners. So, check your oil, clean your drains, pay attention to alarms and noises, and don’t be afraid to call in the pros. That’s how you keep your shop running and your costs down.

Alright, that’s a wrap for today. If you want more tips, check out our previous episodes—we’ve covered everything from short cycling to pressure optimization. And if you’ve got questions, reach out to your local Kaishan distributor. Jason, always good talking shop with you.

Same here, Lisa. Thanks for tuning in, everybody. We’ll catch you next time on The Big Dog Podcast. Stay sharp, keep those compressors running, and we’ll see you soon.

Random stat or

customer quote

textXXtext

text