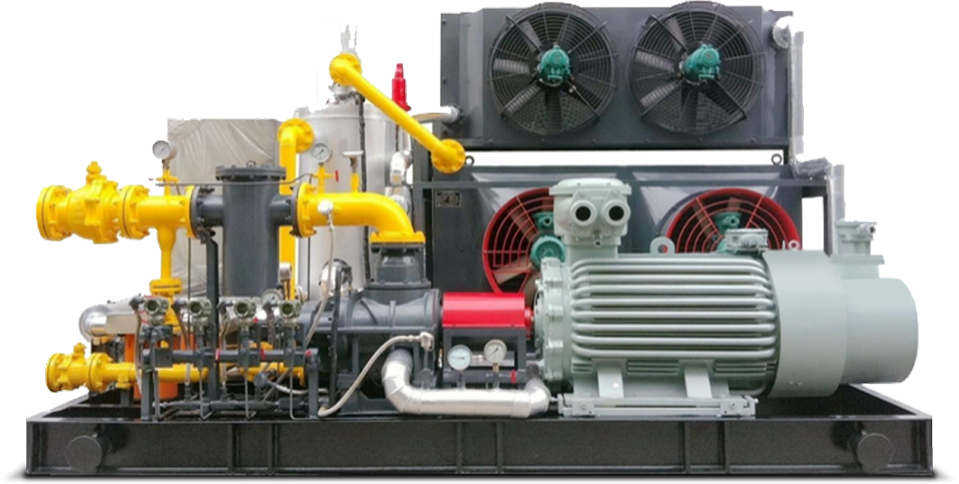

COMPRESORES DE GAS DE TORNILLO GIRATORIO

En algunas aplicaciones de alta exigencia puede ser necesario comprimir gases distintos al aire. Kaishan fabrica una línea completa de compresores de gas de tornillo rotativo para satisfacer diversas necesidades de material, aplicación y presupuesto en entornos industriales y de proceso de alta demanda. Cada equipo de nuestra línea de compresores de gas de tornillo rotativo cuenta con tecnología innovadora, confiabilidad líder en la industria y un precio adecuado para ti.

Los compresores de gas de tornillo rotativo funcionan al atraer el gas hacia la cámara de compresión, donde los tornillos comprimen el gas y lo expulsan a través de los puertos de descarga. Nuestros compresores están diseñados para aplicaciones que requieren altos volúmenes de gas comprimido de manera continua, operando al 100% de su capacidad para lograr la máxima eficiencia y confiabilidad.

Aplicaciones e Industrias de los Compresores de Gas de Tornillo Giratorio

Un compresor de gas de tornillo rotativo puede utilizarse en diversas aplicaciones industriales de alta exigencia donde se debe comprimir un gas distinto al aire. Algunos de nuestros compresores son adecuados para uso comercial, pero las industrias típicas en las que se emplean son:

- Aceite y gas

- Energía

- Procesamiento químico

- Carbón

- Biocombustible

Las aplicaciones de los compresores de gas industriales incluyen:

- Compresión de gas natural para extracción y distribución

- Aplicaciones petroquímicas y de refinería, como hidrógeno para gasolina y helio para criogenia.

- Productos químicos del carbón, como gas para hornos de coque.

- Usos ambientales, como biocombustibles y la eliminación de gas de biomasa, gas de rellenos sanitarios y otros usos enfocados en CO.2.

- Aplicaciones energéticas, como combustible para turbinas accionadas por gas.

Materiales Comprimidos por Compresores de Gas de Tornillo Giratorio.

- Etileno

- Estireno

- Gas de alto horno.

- Butadieno

- Hidrocarburo ácido.

- Steam reclamation

- Vapor

- Tail gas

- Destruction producer

- Nitrogen

- Acetylene

- CNG

- Lime-kiln gas

- Hydrogen

- CO2

- Flare gas

- Ethane

- Propylene

- Propane

- Ammonia

- Sour gas

- Chlorine

- Coke oven gas

- Coal gas

- CO

Rotary Gas Screw Compressor Benefits

We offer five different types of rotary screw gas compressors, each backed by innovative technology and our signature reliability for always-on operation. These gas compressors offer the following features and benefits:

- High Efficiency: Kaishan’s compressors are designed and engineered to provide superior efficiency and optimized, energy-efficient performance. Our rotary screw gas compressors are designed to reliably meet your needs in ways that other equipment can’t.

- Total Electronic Control: Users can manage all the essential parameters from one central interface. Built-in alarms notify you of any abnormal performance while password-protected control systems keep your operations safe.

- Remote Status Monitoring: Kaishan compressors were built to collect and monitor performance data from anywhere. This feature also enables you to track energy efficiency and ROI over time, thereby improving future usage as you collect more data.

- Self-Lubricating Oil System: Engineered for maximum safety and reliability, our lubricating oil system has been tailored over the years to ensure that maintenance requirements remain minimal and operations are as self-sustaining as possible.

- Safety: Keeping your team safe is a key concern for Kaishan. Our rotary screw gas compressors contain several features to support operator and facility safety. These features include machinery enclosures, shields, and guards, as well as easy-to-use, intuitive temperature, pressure, water, oil, and other monitors, gauges, and alarms that reduce the probability of accidents.

Reach out today to learn more about rotary gas screw compressors and see how the Kaishan team can help you better meet your goals. Contáctanos ahora.