Five Ways Not to Save Money on Compressed Air

September 10, 2025

Leak Detection: Compressed Air Loss Prevention

September 24, 2025Eliminating Artificial Demand

Kaishan USA | September 17, 2025 | Uncategorized

Artificial demand can come from a variety of sources, including leaks in piping, fittings, tubing, couplings, hoses or seals.

A key part of compressed air demand reduction is the elimination of artificial demand. Simply stated, artificial demand in compressed air is anything that is not an authorized use. It can include air leaks, high header pressure problems and even workers blowing dust off their clothes at the end of a shift.

It all seems innocent enough. Accidental, off-the-books. Harmless. Especially if, as many believe, compressed air is free. The problem is, compressed air isn’t free.

As with any other resource, there are costs involved. So, by definition, artificial demand is waste.

But even that concern doesn’t capture the problem. Since it’s not a real use, no planning has gone into any artificial demand use. It’s not designed into the system. Alternative uses were neither considered nor tried. And it’s not encompassed in attempts to conserve energy, optimize operation or conserve resources.

And you know how this works: If you don’t know about it, you can’t manage it, can’t fix it, can’t optimize it. And it throws a monkey wrench into your efforts to optimize legitimate uses. Did your compressed air consumption actually increase last month? Or did your numbers rise because Brad in maintenance hooked up a nifty blower to clean his clothes before his girlfriend picks him up at the end of his shift?

That’s why the most sophisticated compressed air systems take a hard line on artificial demand, eliminating it as much as possible.

As a result, it’s helpful to recognize artificial demand in all its forms, from leaks to high header pressure problems to unnecessary uses. Even impromptu dry cleaning.

We’ll start with air leaks and artificial demand.

Air Leaks and Artificial Demand

The average compressed air system loses between 30% and 50% of its volume to air compressor leaks, according to Compressed Air Best Practices.

Losses in capacity could run as high as 80%, with a 1/4-inch leak at 100 PSIG costing anywhere from $8,000 to $17,000, depending on local energy costs. At higher pressures, it’s even more.

The Compressed Air & Gas Institute (CAGI) says poorly designed and maintained compressed air systems waste up to $3.2 billion in utility payments in the U.S. annually.

Causes of Leaks

Hoses leak. Pipes leak. Fittings leak. Even end-use equipment leaks. Leaks are a part of the reality of running a compressed air system. But that is no excuse to ignore them.

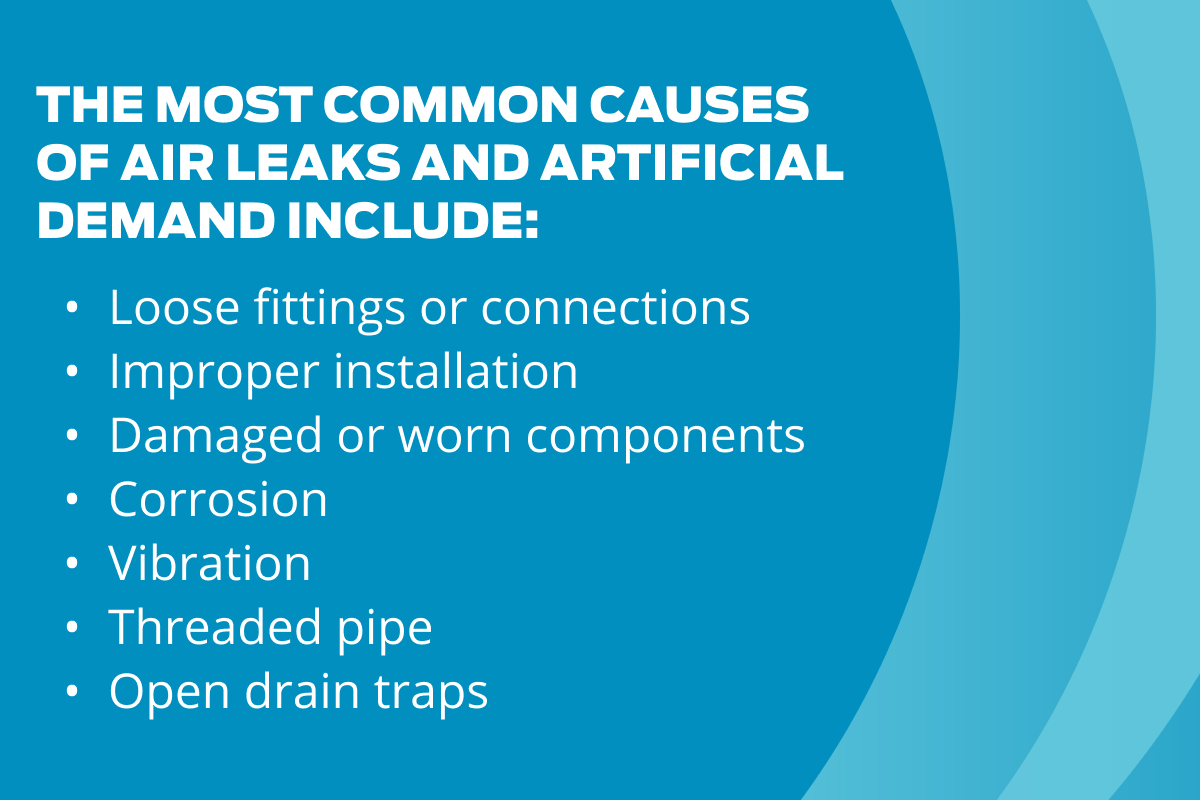

The most common causes of air leaks and artificial demand include:

- Loose fittings or connections. Fittings or connections can come loose in many different parts of your system, including piping, fittings, tubing, couplings, hoses or seals.

- Improper installation. Frequent leaking problems include low-cost filters, regulators and lubricators (FRLs), especially when they’re installed improperly. Pipe joints and flanges can also have missing welds.

- Damaged or worn components. Hoses, valves or regulators can be damaged or can wear out. And cylinders and valves can have worn packing materials.

- Corrosion. Anywhere water condenses, there’s potential for corrosion and leaks. Piping, fittings and other system components can corrode, allowing air to escape.

- Vibration. Vibrations and thermal cycling can cause fittings and connections to loosen. That’s especially a problem with reciprocating compressors, which generate a lot of vibration.

- Threaded pipe. Welded pipe usually doesn't leak as often as screw or threaded pipe does. Incorrect or improperly applied thread sealants can also cause leaks. And some use hose instead of hard piping.

- Open drain traps. Scale, rust, dirt and other solid materials can accumulate in drain traps, causing them to become stuck in the open position and allowing air to escape.

For more information on finding and fixing leaks, read our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

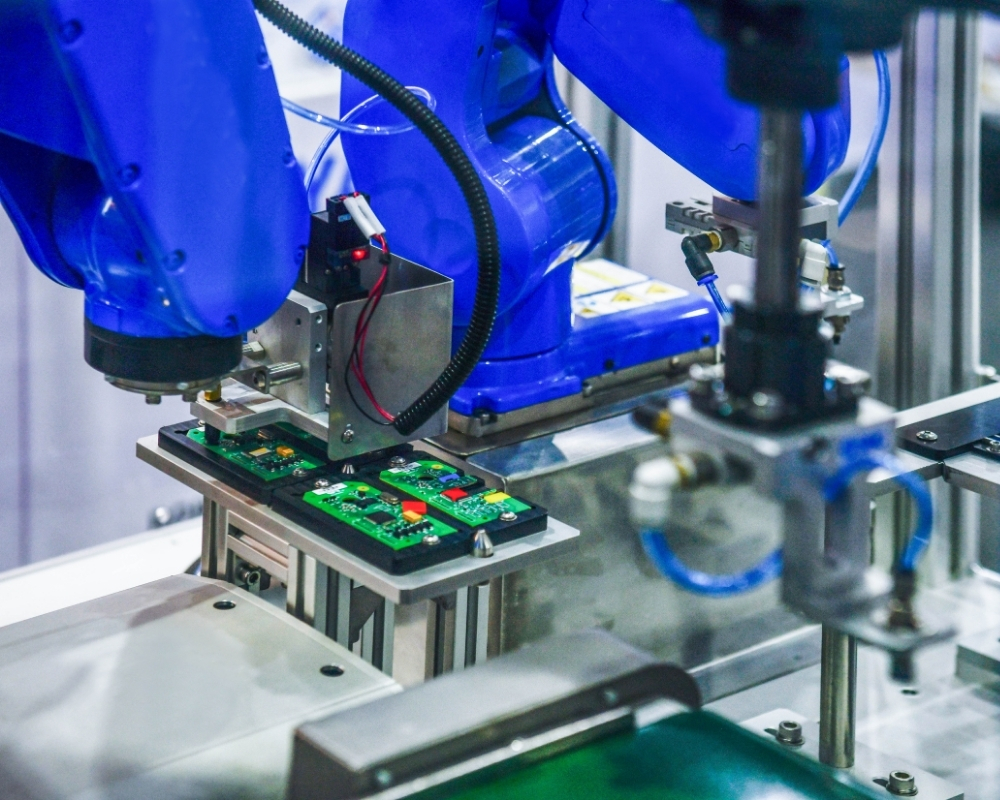

Worn hoses and quick-release valves can often be a source of compressed air leaks.

A related source of artificial demand is setting your header pressure too high.

High Header Pressure Problems

All too often, companies boost the pressure in their system when they notice a pressure drop at the more distant applications they’re servicing. That almost always causes more problems than it solves, for the following reasons:

It Wastes Energy

Typically, your header pressure should be set to accommodate the highest requirements in your shop. Around 90 PSIG will be enough for most tools other than sandblasters.

But all too often, we see plants set their header pressure at 100, 110 or even 120 PSIG, then use regulators to bring the pressures down for individual tools. Why does your compressor have to supply every application with 110 PSIG when you’re going to lower that pressure at almost every use? That’s incredibly wasteful. The goal is to maintain your compressed air system at the lowest pressure possible. You’ll conserve energy by setting the header pressure as low as possible. A lot of energy.

The key point is that higher-pressure uses are usually only a fraction of the total system demand. It’s much better to set header pressure to handle the majority of uses, then deploy a booster or even an additional compressor to handle the high-PSIG use. You’ll save money in the long run and build in redundancy if your system is configured correctly.

Manufacturers of end-use equipment can be part of the problem, adding buffers to their CFM and PSIG requirements to ensure their equipment gets the air it needs to work well. That may mean they say an air tool needs 70 CFM of flow at a pressure of 100 PSIG when it only needs 50 CFM at 80 or 90 PSIG.

It Increases the Likelihood of Short or Rapid Cycling

Setting the header pressure too high is one of the leading causes of short cycling, also called rapid cycling or fast cycling. Rapid cycling happens when you’re constantly turning your compressor on and off, loading and unloading, something every compressed air user should avoid.

And it can be devastating to your compressor, causing:

- Extra wear and tear on the motor, valves, bearings and other internal parts

- Overheating

- Carryover of moisture and oil

- Wasted energy

- Additional maintenance

- A shorter lifespan

It Makes Leaks Worse

In addition to increasing the likelihood of rapid cycling, setting the header pressure too high makes leaks worse. Setting pressure higher allows more air to escape from the small gaps in the piping or connections. Every time you increase the header pressure, you increase the amount of air escaping from the system. At every leak.

And the increased volume rushing through the gaps makes the leaks even larger over time.

It Makes Your Pressure Problem Worse

In addition to wasting energy and risking short cycling, setting the header pressure too high rarely works. Because of the inverse relationship between pressure and flow, increasing the pressure at the compressors actually reduces the flow, making the situation worse at the end-use applications.

The main point is that it’s the flow that is reduced as you deliver air to end-use tools, not the pressure. So, the problem almost always is not with the system pressure, but with the flow. In fact, a study by the Energy Efficiency Center at Oregon State University showed that a reduction in header pressure from 112 PSIG to 105 PSIG lowered energy consumption in a test system by 41,986 kWh per year, with an annual savings of $2,985. Additionally, an article in Compressed Air Best Practices estimated a multi-compressor system could achieve 20% savings from lowering plant air pressure and networking compressors with system master control.

Your mechanic may say they are not getting enough pressure to power their impact wrench. But boosting the pressure at the compressor probably won’t work. It will most likely result in even lower pressure to their tool.

Here’s another example. Let’s say your system is set at 85 PSIG, and you bump it up to 90, hoping to get that extra pressure you need. Then, because of that inverse relationship, you’ll have less compressed air flow, and it will be at a higher pressure.

And, all those regulators you set to decrease the 85 PSIG to 80 PSIG will now have to reduce the pressure by an additional 5 PSIG. Costing you even more flow. The result is less compressed air volume (and lower pressure) at the end of the line. And a lot of energy waste.

Your maintenance team will likely not believe it, but the best way to get more pressure at the end of the line is often to lower the pressure at the air compressor. That boosts CFM and delivers more air flow to the tool. And it’s at the correct pressure.

Regulators help control the air pressure going to an end-use application—and that’s good. However, they waste energy, and having too many regulators may indicate you could save significantly by reconfiguring your compressed air system.

In short, anytime your system operates at a higher pressure, you’re creating artificial demand and wasting air, according to CAGI.

Finally, there’s the issue of unnecessary uses.

Unnecessary Compressed Air Use

As mentioned, too many facilities act as if compressed air is free. But it isn’t. There’s a cost associated with every use, whether it’s planned or not.

We’ve seen too many occasions where a facility manager said a compressor “just wasn’t keeping up.” Then an air audit uncovers a variety of off-the-books uses—someone tapping into the air supply to cool a product emerging from a hot oven or to clean up their workspace.

Removing debris from a work product may be an authorized use, depending on the application. But using compressed air to blow it off your clothes? Not so much.

All too often, we’ve found that most unnecessary compressed air use occurs because companies are employing the wrong technology. Ingenious product designers have already designed products that will perform these functions much more efficiently.

Compressed air users will be much better served, for instance, by using a zero-loss drain, rather than opening a valve to blast off water. Just keep in mind that many of these renegade uses do not need compressed air. It’s a waste, for instance, to cool off a product with compressed air, when a low-pressure blower or fan would suffice.

Some even use compressed air for breathing systems. We once saw a painting application that someone had “automatically” supplied with a compressed air breathing capability, assuming workers would need it, without investigating the plans. On further investigation, we learned it was a robotic application; there were no “workers” to use the air.

We’ve even seen occasions where workers cooled themselves off with compressed air, some even aiming an air hose at their face. That’s crazy expensive. And, more importantly, it’s dangerous.

Beyond the energy waste and cost issues, layering in too many extraneous uses creates a false impression about your needs. If you have too many of these “fixes,” it’s tough to know how much air flow and even pressure you need.

But help is close at hand.

Your Local Artificial Demand Sleuth

Expert help is available to assist you in identifying and eliminating artificial demand in your compressed air system. We have chosen to work with a nationwide network of independent distributors, who can provide that level of on-site help. And the consultation you need.

These factory-trained air compression experts can service your air compressor system without a problem. They can help you find stubborn leaks, set your pressure at the right level and spot maverick uses anywhere in your plant. And they have staff members who are skilled in advanced technology, such as leak detection.

We partner with independent, local distributors because it's the best way to serve you. Unlike large corporate suppliers, there's no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants it to succeed.

Key Takeaways

Artificial demand, which includes anything not serving an authorized use, makes it harder to manage and optimize a compressed air system.

The leading causes include:

- Air leaks

- High header pressure problems

- Unnecessary compressed air use

Let Us Help

Eliminating artificial demand in your compressed air system will make it easier to operate your system reliably and improve its reliability and performance. If you need help identifying and eliminating artificial demand, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

What Is Artificial Demand?

Welcome back to The Big Dog Podcast! I’m Jason Reed, and I’m here with Lisa Saunders. Today, we’re getting into a topic that, honestly, trips up a lot of folks on the shop floor—artificial demand. Lisa, you wanna kick us off?Yeah, let’s do it. So, artificial demand—if you haven’t heard the term before, it’s basically anything that isn’t an authorized use of compressed air. We’re talking leaks, running your header pressure too high, or, you know, those little shortcuts people take—like blowing dust off their clothes at the end of a shift. It all adds up.

And I think a lot of people still buy into this myth that compressed air is free. I mean, I get it—air’s all around us, right? But once you start compressing it, running those machines, paying for the energy, it’s anything but free. Every unauthorized use is just money out the door. And it’s not just about the cost, either. It messes with your whole system planning. If you don’t know about it, you can’t manage it, and you definitely can’t fix it.

Exactly. And the thing is, artificial demand is sneaky. It’s not designed into your system, so nobody’s really tracking it. It’s just this hidden waste that throws off your numbers. Like, did your air consumption actually go up last month, or did someone just start using air for something off the books?

Oh, I’ve got a story for that. Years ago, I was working with a plant where the monthly air bill suddenly spiked. Everyone was scratching their heads, thinking maybe a machine was failing or something. Turns out, one of the maintenance guys had rigged up a little blower to clean his work clothes before heading home. He thought it was harmless, but that “innocent” habit was costing the plant hundreds every month. It’s those little things that add up fast.

That’s such a classic example. And it’s not just about the money, either. If you’re not tracking these uses, you can’t optimize your system. You’re basically flying blind. So, recognizing artificial demand in all its forms—leaks, high header pressure, unnecessary uses—is the first step to getting control of your compressed air costs.

Yeah, and as we’ve said in past episodes, if you don’t know what’s really going on with your air, you’re just guessing. And guessing is expensive. So, let’s dig into the biggest culprits—starting with leaks and header pressure.

Leaks and Header Pressure Pitfalls

Alright, so leaks. This is the big one. According to Compressed Air Best Practices, the average system loses between 30 and 50 percent of its air to leaks. I mean, that’s wild. And in some cases, it can be even higher—like, up to 80 percent if you’ve got a quarter-inch leak at 100 PSIG. That could cost you anywhere from $8,000 to $17,000 a year, depending on your energy rates. That’s not pocket change.No, it’s not. And leaks can come from just about anywhere—loose fittings, worn hoses, bad valves, you name it. Even end-use equipment can leak. And let’s be honest, hoses and pipes are gonna leak eventually. But that’s no excuse to ignore it. If you’re not checking for leaks, you’re just burning cash.

And it’s not just leaks. Running your header pressure too high is another big pitfall. A lot of plants crank up the pressure when they see a drop at the far end of the line, thinking it’ll solve the problem. But all that does is waste energy, make leaks worse, and cause your compressors to cycle on and off way more than they should. That’s a recipe for extra wear and tear, overheating, and a shorter compressor life.

Yeah, and I always say—your header pressure should be set just high enough for your highest-need tool. Most shops can get by with 90 PSIG, unless you’re running something like a sandblaster. But I see places running at 110, 120 PSIG, then using regulators to bring it back down for every tool. That’s just throwing energy away. And every time you bump up the pressure, you’re making every leak in the system worse. More air escapes, and the leaks get bigger over time.

And here’s the kicker—sometimes, raising the pressure actually makes your pressure problem worse. There’s this inverse relationship between pressure and flow, so when you increase the pressure at the compressor, you can actually end up with less flow at the end of the line. I saw a case where a client dropped their header pressure by just 7 PSIG, and they saved almost $3,000 a year in energy costs. That’s a super easy win that a lot of plants overlook.

Yeah, and if you’re seeing a pressure drop, it’s usually a flow issue, not a pressure issue. So, before you reach for that pressure adjustment, check for leaks, check your piping, and make sure you’re not just masking a bigger problem. And if you’re not sure, get a pro in to audit your system. It’s worth it.

Absolutely. And if you missed our episode on getting pressure “just right,” go back and give it a listen. We dig into this in a lot more detail. But for now, let’s talk about those unnecessary uses—the ones that really sneak up on you.

Unnecessary Uses and Real-World Fixes

Yeah, so, unnecessary uses. This is where things get a little wild. I’ve seen everything—people using compressed air to cool down products, clean up their workspace, or even just to cool themselves off on a hot day. I mean, I get it, but that’s not what compressed air is for. And every time you use air for something it wasn’t designed for, you’re warping your system planning and racking up costs you didn’t budget for.And a lot of the time, it’s just because people don’t know there’s a better way. Like, instead of opening a valve to blast out water, you could use a zero-loss drain. Or swap out compressed air for a fan if you’re just trying to cool something down. There are tech solutions for almost every rogue habit out there—you just have to look for them.

Yeah, and I’d say, before you start pointing fingers, ask yourself—what’s really an authorized use in your plant? What’s your team doing with air that’s off the books? Sometimes it’s just habit, or “that’s how we’ve always done it.” But those habits add up. And if you’re not sure what’s legit, lean on your local distributor or get Kaishan’s trained techs in there. They know how to spot the hidden waste and help you root it out.

That’s the key—don’t try to go it alone. Local distributors and factory-trained techs can help you find leaks, set your pressure right, and spot those maverick uses that are costing you money. And they’re not just there to sell you a compressor—they’re there to build a relationship and help your business succeed. So, if you’re serious about cutting artificial demand, get some expert eyes on your system.

Alright, I think that’s a good place to wrap it up for today. Artificial demand is one of those things that’s easy to ignore, but it’ll bite you if you let it. Take a hard look at your system, question those “innocent” uses, and don’t be afraid to ask for help. Lisa, anything else before we sign off?

No, I think that covers it. If you’ve got questions or want to dig deeper, reach out to your local Kaishan distributor or check out our previous episodes for more tips. Thanks for listening, Jason—always a pleasure.

Same here, Lisa. We’ll catch you all next time on The Big Dog Podcast. Take care, everybody.

Random stat or

customer quote

textXXtext

text