The Importance of Industrial Air Compressors in the Mining Industry

January 24, 2024

How Many CFM Do I Need? Air Pressure by Different Applications

February 7, 2024How to Choose the Right Rotary Screw Air Compressor for Your Business

Kaishan USA | January 31, 2024 | Uncategorized

Applications where the air comes in direct contact with food need a rotary screw air compressor providing oil-free compressed air.

Articles and blog posts about choosing the right compressor often begin with a familiar litany of descriptions of the different types of equipment. Listing the relative benefits of reciprocating, centrifugal and rotary screw air compressors, including the strength and weaknesses of each.

We're not going to do that in this post.

In our experience, that’s often putting the cart before the horse. Starting with solutions before identifying the problems we’re trying to solve.

And guess what? That usually doesn’t work out well. It may well replace a poorly performing unit with a brand-new compressor. However, it often fails to address or even identify the underlying causes. Worse yet, it may even perpetuate them and cost a lot of money without producing the improvements you seek.

That’s why we recommend starting at square one. With a full and careful evaluation of your system.

Air Audits

We often recommend an air audit when a company is considering the purchase of a new rotary screw air compressor. And always when you’re having problems with your compressed air system. For more details on the value of audits, see our blog post, “How an Air Compressor Audit Can Reduce Operating Costs.”

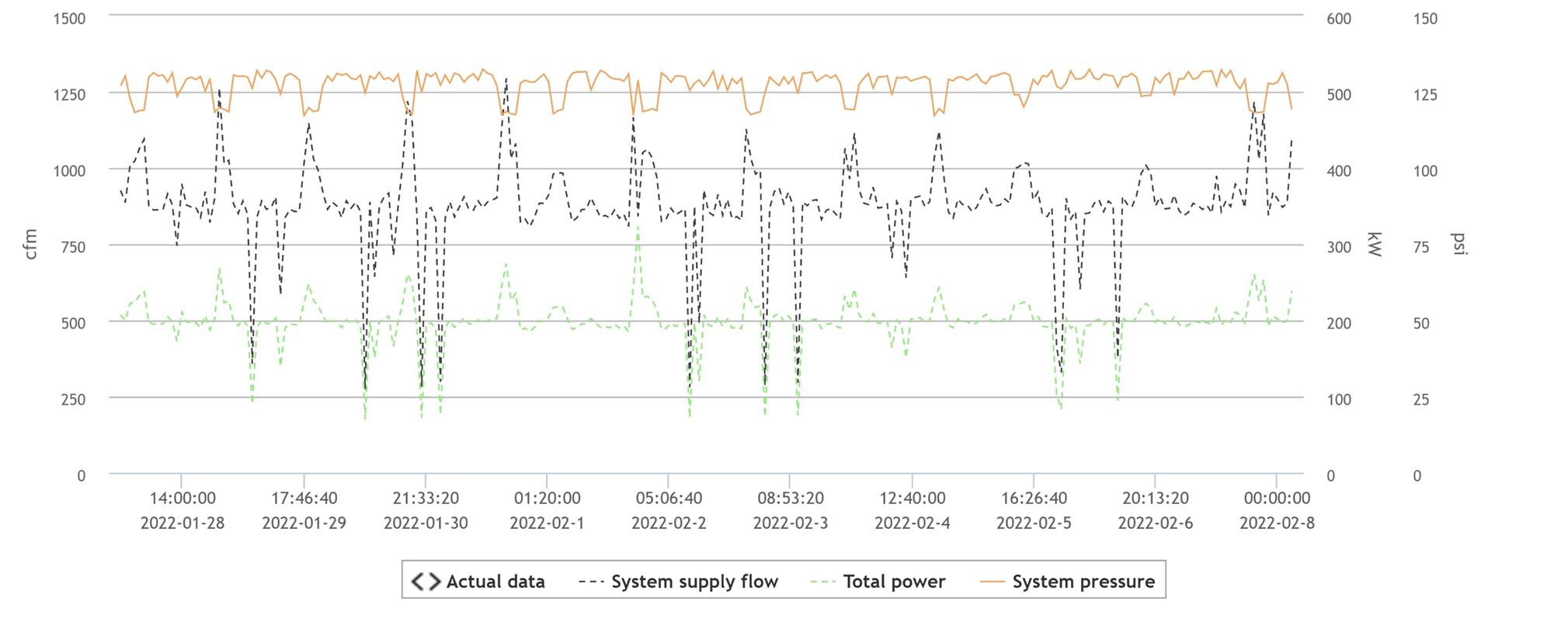

Air audits help determine what’s happening in your plant. This chart documents what happened to the air pressure when the company’s lead compressor failed over a weekend and the backup units came online. The number of times the system supply flow (dotted gray line) dropped clearly demonstrates that the system does not have enough backup capacity.

But while you’re waiting for your local professional to visit your plant and install data loggers, it’s a great idea to get the process rolling with a self-audit.

Know Your Plant

You’ll want to know your plant inside and out. Really listen to it.

-

- What is the equipment doing?

- What is the demand, real or artificial?

- What are your pain points?

And, of course, you’ll need to consider your industry and application. End uses where the air comes in direct contact with food need oil-free equipment like Kaishan’s new KROF two-stage oil-free compressor. Similarly, the electronics and advanced medical devices industries need high-quality compressed air.

Always Start with Why

Listen to your plant’s pain points.

-

- Why is your system starting to consume more electricity?

- Why are you having frequent shutdowns?

- Why do you experience pressure drops, especially in the more remote areas of your plant?

- Why are you finding oil in the air?

- Why is the air moisture-laden?

- Why are you having other quality issues?

Once again, in our experience, companies don’t simply call us with a burning desire to spend money on a new compressor. It’s usually not on the top of anyone’s wish list.

Maybe You Don’t Need to Buy a New Compressor. At Least Not Yet.

Usually, there are reasons why anyone starts the process of looking for a new rotary screw air compressor. And we make sure we know what they are before we start recommending solutions.

Here’s why: many of those problems do not require the purchase of a new compressor. Below are a few examples.

Pressure Drops

Yes, your aging compressor doesn’t have the oomph it once had. But there may be other reasons you’re not getting the pressure or flow you need throughout your system. One of the primary ones is artificial demand caused by leaks.

Leaks Are Always with Us

One of the consistent issues with compressed air systems is leaks. We’ve often visited plants experiencing leaks and heard visual evidence that the problem wasn’t so much with the compressor as with the leaky piping system.

If you’re like most compressed air users, you’re losing between 30% and 50% of your volume to air compressor leaks, with poorly maintained systems running as high as 80%. A 1/4-inch leak at 100 PSIG will cost your company $8,000, depending on energy costs. A 3/8-inch leak at 100 PSIG could cost as much as $36,000.

Most air leaks occur within the last 30 feet before the end-use application. Or even in the end-use tools.

The vast majority of leaks in the compressed air system—more than 80%—happen in “the dirty 30”—the last 30 feet of the distribution system before the end-use application. The dirty 30 includes hoses, reels, filters, regulators or lubricators on the piping that connect the air supply to your machinery. Even old or poorly maintained end-use tools can have internal leaks.

Buying a new compressor isn’t going to change that. And developing a solid leak-repair program could improve your current system’s performance and allow you to get a few more years of life out of your existing equipment. For more on leaks, see our blog post, “How to Find and Stop Air Leaks.”

Quality Issues

Rather than buying a new compressor, you may need to address other equipment in your system:

-

- Moisture. If you’re having moisture in the air your system is delivering, maybe you’re having problems with your drains or your air treatment system.

- Storage tanks. Another way to remove moisture is with a receiver tank. It’s a best practice for removing moisture and maintaining stable header pressure. Properly sized tanks also reduce compressor starts and stops, promoting energy conservation and extending the compressor's life. And get a heavy-duty, zero-loss drain for your wet tank.

- Oil. If you are having too much oil carryover into your system, there may be a problem with the compressor air-oil separation or the air treatment filtration. If this is detrimental to your production, you may need to consider oil-free compressors.

Kaishan’s new KROF two-stage oil-free compressor is an excellent choice when you need uncontaminated, highly efficient, reliable air.

Reliability Issues

If you’re experiencing unplanned shutdowns, rapid cycling or other problems, that may not be the fault of your equipment but rather its deployment in your system.

-

- Uneven demand. You could be experiencing wide variation in system demand. Listen to your system: What day of the week is the greatest demand? What time of day?

- Sizing. All too often, companies size a screw compressor with “room to grow.” Understandably, they are trying to anticipate end uses that they may want in the future. Many plant engineers apply a 20% “fudge factor” to make sure they get a compressor with enough horsepower. And while it may seem counterintuitive, “too much” is as bad as “not enough” with rotary screw air compressors, which are designed for a 100% duty cycle. Run them significantly less than that, and you’ll waste energy, reduce equipment lifetime and perform more maintenance. With that fudge factor? You’re oversized right out of the box. We sometimes visit plants with multiple-compressor set-ups and tell the system operator to turn off a compressor.

- Flow control. A compressed air system needs flow control to be truly functional. Flow control helps you maintain air pressure throughout your plant at the lowest optimum level, reducing artificial demand and increasing energy efficiency. Pressure-flow control thus buffers the compressors from the ups and downs of system demands.

- Rapid cycling. In rapid cycling, the transition between the load and no-load does not occur as rapidly as we might like. Your compressor then switches back into the loaded state before the transition to the no-load state is complete. If that happens too frequently, it can lead to rapid cycling, which is highly inefficient, causing increased wear, reduced compressor lifespan and potential safety hazards from overheating. Your compressor may get locked into rapid cycling because your compressor is oversized, your pressure band is too tight, your system needs more storage or some combination of the above.

Start with an Air Audit

Much as we’d love to sell you a new rotary screw air compressor, we try to do the right thing, helping you discover what’s in your best interests, whether you buy a new compressor or not. And the best place to start is with an air audit from a qualified local air compressor professional.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem.

Key Takeaways

-

- Know your plant.

- Always start with why.

- You may not need to buy a new compressor. At least not yet.

- Start with an air audit.

Let Us Help

Selecting the right rotary screw air compressor is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help, get in touch with the experts at Kaishan. We’ll help you find the right equipment for any application. Contact us today.

Random stat or

customer quote

textXXtext

text