Kaishan Compressor USA Celebrates $11 Million Expansion of Loxley Facility

September 9, 2025

Eliminating Artificial Demand

September 17, 2025Five Ways Not to Save Money on Compressed Air

Kaishan USA | September 10, 2025 | Uncategorized

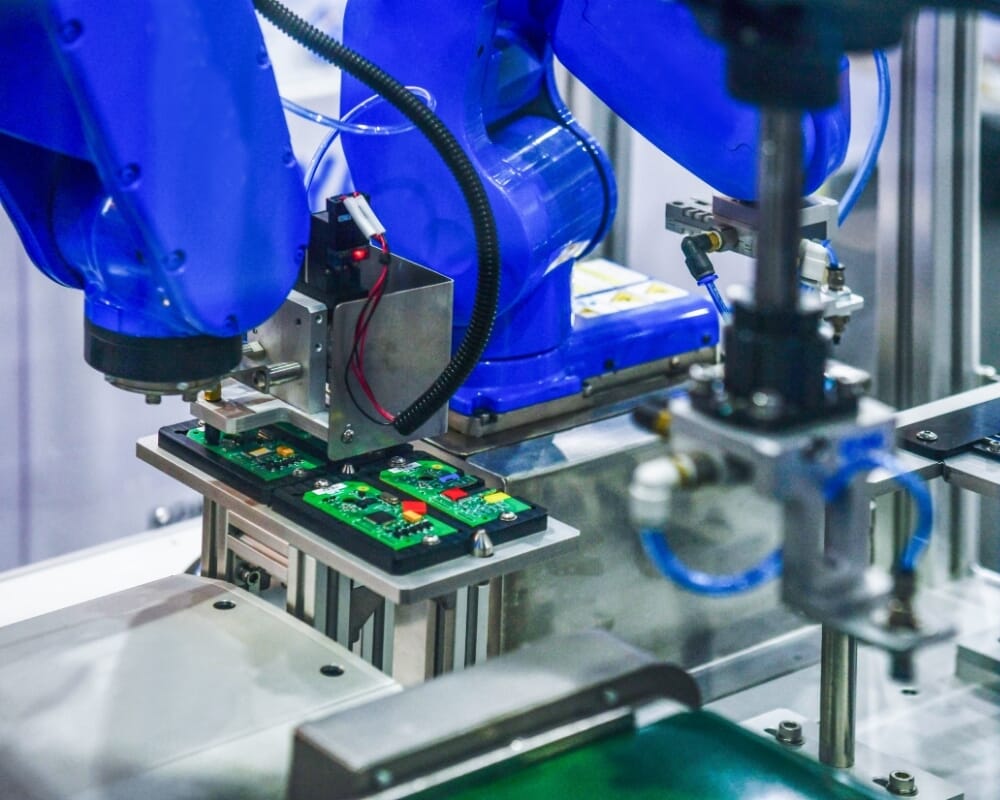

Using pirated parts in a sensitive application, such as electronics, is not a good way to save money.

We’ve written many blog posts about money-saving ways to optimize your compressed air system:

- In “Six Low-Cost Fixes for Compressed Air Optimization in Times of Economic Uncertainty,” we list several proven ways to economize, including fixing leaks, reducing header pressure, cutting artificial demand, making maintenance a priority, recovering heat and getting an expert audit.

- In “How You Can Turn Your Compressed Air System into a High-Efficiency Profit Center,” we provide several strategic steps you can take to invest in your system, including installing two-stage compressors, deploying a multi-compressor configuration and using our AirWatch system to monitor and control your system remotely.

In this post, we’d like to take a different approach, offering our thoughts on things you should not do in your quest to save money. We offer five “money-saving” tricks we’ve seen compressed air users try over and over again with poor or even disastrous results.

We’ll start with downsizing.

1. Downsizing Your Maintenance Staff

If there’s one lesson we’ve learned in today’s economy, it’s that having skilled people is more important than ever.

Whether you’re facing a round of layoffs or several of your core team members are nearing retirement, having expertise walk out the door, never to return, is a serious mistake.

Admittedly, some tasks can be automated or outsourced to a trusted compressed air consultant (like one of the independent distributors who are part of our nationwide network). But the key point is that wholesale cuts to skilled maintenance staff, without regard for how your compressed air system will be maintained in the future, are not cost-effective.

As you’ll see below, operating and maintaining a compressed air system is serious business, well worth the time and effort. Having knowledgeable people in your court, whether in-house or outsourced, is absolutely critical.

In today’s environment, people who maintain your equipment are some of your most valuable employees.

Another tempting way to save money is the use of knock-off or pirated parts.

2. Using Pirated Parts

When you’re not using parts from the original equipment manufacturer, you’re undermining the intent of the engineer who designed your compressor. Each of those air compressor parts was specified and manufactured to achieve specific design goals. Substituting an off-brand or pirated component to save money compromises your compressor’s design integrity.

Using our recommended industrial air compressor parts will enable you to extend the lifespan and reliability of your compressor. We engineer and manufacture genuine Kaishan parts to support and enhance your compressor’s performance. That longevity extends not only to the compressor, but also to its components and the end-use tools it serves.

They conform to stringent specifications and performance standards, undergoing the same quality-control testing as our compressors. That’s critical in delivering the high-quality air expected in industries such as food processing, semiconductor and electronics.

Finally, almost all compressor manufacturers, including Kaishan, require that you use their original OEM parts to maintain your warranty eligibility. Any perceived short-term savings you realize by purchasing aftermarket parts could ultimately raise your lifecycle costs, resulting in higher energy use, increased downtime and more frequent replacements, as well as potentially voiding your warranty. As Compressed Air Best Practices notes, “The money you save by purchasing generic parts is often the most expensive money you will ever save.”

For more information on the value of genuine OEM replacement parts, read our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

Our next faulty shortcut to savings is oversizing or buying in anticipation of future needs.

3. Buying for Future Needs

Whether you’re talking about a centrifugal air compressor or a rotary screw compressor, oversizing can lead to compressor short cycling, one of the most serious operational problems you can have in your compressed air system.

It may seem counterintuitive, but with air compressors, “too much” is almost as bad as “not enough.” So, it’s essential that you don’t oversize your system.

Overbuying is even a concern when you’re simply replacing one 150-HP compressor with another. The reason? New equipment is typically more energy-efficient than older equipment. So, you need to focus on CFM requirements and not replace HP for HP.

What about future plans? Our advice is to buy what you need when you need it. Plans change, after all. So, buying a compressor that’s sized appropriately for your current needs is always the best policy. Then, if you need more capacity later, you can purchase another unit. Done right, you’ll build flexibility and avoid the problems of rapid or short cycling.

For more on sizing your compressor correctly, download our white paper, “Demystifying Air Compressor Sizing.”

Once you have an appropriately sized compressor in your facility, you’ll need to maintain it.

4. Skimping on Maintenance

To keep your air compressor running reliably and efficiently, you need to take air compressor maintenance seriously. Industry research has proven that a proactive maintenance strategy can help you reduce maintenance costs by as much as 70%.

Properly maintaining your air compressor can yield many benefits, such as cutting downtime, reducing energy costs, extending equipment life and improving safety.

Some specifics include the following:

- Uptime. According to a recent survey by IndustryWeek in collaboration with Emerson, unplanned downtime costs industrial manufacturers $50 billion per year worldwide. Other estimates indicate unplanned downtime costs manufacturing enterprises as much as $9,000 per minute. By performing regular maintenance, you’ll keep unplanned downtime to a minimum.

- Energy efficiency. A properly maintained system will deliver significant energy savings. According to various estimates, the lifetime energy consumption of your compressor will be significantly higher than its initial cost. For more on energy efficiency, see our blog post, “Reduce Energy Costs: Four Tips for Plant Managers.”

- Equipment life. A well-maintained compressor will have a long working life and can impact the longevity of the equipment it serves. And avoid catastrophic failures that could result in significant repair and replacement costs. Not to mention downtime.

- Safety. Properly maintaining an air compressor will reduce the impact of heat, vibration, pollution and noise on your people. And your compressor is less likely to have serious failures that injure workers. For more on safety, see our blog post, “Eight Ways to Improve Air Compressor Safety.”

In addition, a well-maintained compressed air system will provide higher-quality air, improving the performance and longevity of your downstream tools and applications.

For specific maintenance procedures you need to implement, read “Ten Need-to-Know Rotary Screw Air Compressor Maintenance Tips.“

Finally, one crucial maintenance procedure you don’t want to neglect is oil sampling.

5. Skipping Oil Sampling

Some facility managers try to save money by ignoring oil sampling. But the pennies you save by not sending out a sample could easily cost you thousands of dollars.

Fluid sampling is critical to the life of an oil-flooded rotary screw air compressor. Sampling oil regularly will indicate whether it is being exposed to excessive heat or absorbing contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem and potentially avoid an unplanned shutdown.

Oil sampling is one of the most important procedures for your compressor.

We consider oil sampling the most critical maintenance procedure for our compressors. And we require that our customers collect an oil sample and have it analyzed every 2,000 hours (or semiannually) to maintain their warranty protection. (Every 1,000 hours for food-grade applications).

To find out how to take full advantage of all the information in an oil sampling report, read “Six Ways to Boost Compressor Performance with Oil Sampling” in Plant Engineering.

The key point: if you want to save money on your compressed air system, start by talking with your compressed air consultant.

Working closely with Kaishan’s independent distributor, Air & Hydraulic Equipment, global chemical manufacturer Henkel saved thousands in energy costs and millions of dollars per year in downtime.

We work with a nationwide network of independent distributors, because it’s the best way to provide the on-site help and consultation you need. Our distributors can analyze your system and provide the help and guidance you need to make substantive, beneficial changes in your compressed air system.

Talking to your local compressed air consultant should be the first step in your cost-cutting and optimization journey.

These factory-trained air compression experts offer expert guidance, faster response times and personalized support tailored to your needs. They are skilled in advanced technology and can service your air compressor system without a problem. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than just a product—you're getting a local partner who genuinely cares about your business and wants to see it succeed.

Five Things You Don’t Want To Do To Save Money

1. Downsize your maintenance staff

2. Use pirated parts

3. Buy for future needs

4. Skimp on maintenance

5. Skip oil sampling

Let Us Help

Saving money on your rotary screw air compressor is crucial to the operation of your compressed air system and all the processes that rely on it. But you have to be smart. If you need help in cutting costs and optimizing your compressed air system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The False Economy of Cutting Corners

Welcome back to The Big Dog Podcast, everyone! I’m Jason Reed, here with Lisa Saunders, and today we’re talking about something that, honestly, we see way too often—people trying to save money on compressed air systems in all the wrong ways. Lisa, you wanna kick us off?Yeah, let’s get right into it. I mean, the first thing that always comes up is downsizing maintenance staff. It sounds like an easy budget win, right? But, in reality, you’re just losing expertise that you can’t get back. I visited a plant not too long ago—great team, but they’d let a couple of their senior techs go to cut costs. Within six months, they had a breakdown that nobody on the new crew could diagnose. The downtime alone cost them way more than those salaries ever would’ve.

Yeah, and it’s not just about the headcount. It’s the knowledge that walks out the door. You can automate some stuff, sure, or bring in a consultant for the big jobs, but if you don’t have people who know your system inside and out, you’re just asking for trouble. And, honestly, you can’t outsource everything. There’s always that one weird noise or pressure drop that only your in-house guy knows how to handle.

Exactly. And then there’s the temptation to use off-brand or pirated parts. I get it—OEM parts can seem pricey. But, especially in sensitive applications like electronics or food processing, you’re risking way more than you’re saving. I saw a plant where they swapped in a pirated valve—just one part—and it led to a shutdown. Not only did they void their warranty, but the production and maintenance budgets took a hit. It’s like, the money you “save” on that part is the most expensive money you’ll ever spend.

Yeah, and that’s not just a scare tactic. Most manufacturers, Kaishan included, require OEM parts to keep your warranty valid. You start cutting corners there, and you’re on your own when something goes sideways. Plus, those parts are engineered for a reason—they’re not just random pieces of metal. You compromise the design, you compromise the whole system.

And it’s not just about the compressor, either. It’s the downstream tools, the quality of your air, the safety of your people. So, yeah, cutting corners might look good on a spreadsheet, but it’s a false economy. You end up paying for it one way or another.

Miscalculations in Equipment Sizing

Let’s talk about another classic mistake—oversizing equipment. I mean, we’ve seen this a lot, right? Folks buy a bigger compressor than they need because they’re planning for “future growth.” But what actually happens is you get short cycling, wasted energy, and a whole lot of money tied up in equipment that’s not doing you any favors.Yeah, and it’s so common. People think, “Well, I’ll just replace my old 150-horsepower unit with another 150-horsepower unit.” But modern compressors are way more efficient. If you don’t match your new system to your actual CFM requirements, you’re just burning cash on energy. It’s not a one-to-one swap anymore.

Right, and we talked about this in our episode on right-sizing centrifugal compressors. Oversizing leads to short cycling, which is brutal on your equipment. You get more wear, more maintenance, and less reliability. It’s like buying a semi-truck to drive to the grocery store—just doesn’t make sense.

And the thing is, plans change. You might think you’ll need more air in a year or two, but if that expansion doesn’t happen, you’re stuck with a system that’s too big for your needs. The smarter move is to buy what you need now, and add capacity later if you really need it. That’s what Henkel did—they worked with Kaishan’s distributor, right-sized their system, and ended up saving thousands in energy costs. Plus, they avoided millions in downtime. That’s real money, not just theoretical savings.

Yeah, and that’s the value of working with someone who actually understands your application. Don’t just buy for the “what if.” Get a system audit, look at your actual demand, and size accordingly. You’ll save way more in the long run.

Maintenance and Diagnostics: Where Not to Scrimp

Alright, so let’s get into maintenance and diagnostics—probably the area where people try to cut corners the most. Skimping on regular maintenance is just asking for trouble. You might save a little on labor or parts in the short term, but the risk of unplanned downtime, shortened equipment life, and even safety hazards is huge. I mean, unplanned downtime can cost thousands per minute in some industries.Yeah, and I’ve seen it firsthand. There was this maintenance team that thought they were being clever by skipping oil sampling—figured they’d save a few bucks and a little time. Well, guess what? They missed early signs of bearing wear, and the compressor failed right in the middle of peak production. The repair bill was massive, and the lost production? Don’t even get me started. That “savings” turned into a six-figure problem real quick.

Oil sampling is one of those things that seems optional until it isn’t. It’s critical for catching issues like overheating or contamination before they become catastrophic. And for food-grade applications, you’re supposed to do it even more often. It’s not just about the compressor, either—it’s about protecting your whole operation.

And, look, regular maintenance isn’t just about avoiding breakdowns. It’s about energy efficiency, equipment life, and safety. A well-maintained system runs better, lasts longer, and keeps your people safe. We’ve said it before, but it’s worth repeating—don’t try to save money by skipping the basics. It never works out in your favor.

Yeah, and if you’re not sure where to start, talk to your local compressed air consultant. They’ve seen it all, and they can help you avoid these costly mistakes. That’s what we’re here for, right?

Absolutely. Alright, that’s gonna do it for this episode of The Big Dog Podcast. If you’ve got questions or want to share your own “costly mistake” stories, hit us up. We’ll be back soon with more ways to keep your compressed air system running smarter, not harder. Lisa, always a pleasure.

Thanks, Jason. And thanks to everyone listening. Don’t cut corners—cut costs the right way. See you next time on The Big Dog Podcast.

Random stat or

customer quote

textXXtext

text