What To Do When Your Air Compressor Is Not Building Pressure

July 17, 2024

Berry Global

July 25, 2024How to Choose the Best Air Compressor for Wastewater Treatment

Kaishan USA | July 24, 2024 | Uncategorized

Compressed air is used in all the stages of the wastewater treatment process, from aeration and separation to oxidation and sludge drying.

Choosing the best air compressor for an application in the wastewater treatment industry may go beyond the standard cost, performance and maintenance considerations.

There is another important issue: the use of low-pressure rotary screw air compressors.

On the one hand, many wastewater treatment plants use blowers for various purposes, such as bubblers and aeration.

On the other hand, some plant operators tap into their traditional compressed air system and use a regulator to reduce air pressure to the low-pressure range.

While these workarounds may seem cost-effective, avoiding the capital expense of a low-pressure compressed air system, they are pennywise but pound foolish. Remember, for every 2-PSIG increase in pressure, energy consumption is increased by 1%.

In fact, Compressed Air Best Practices observes that wastewater treatment plants can significantly reduce energy costs and improve productivity by carefully considering the full range of options, including low-pressure compressors.

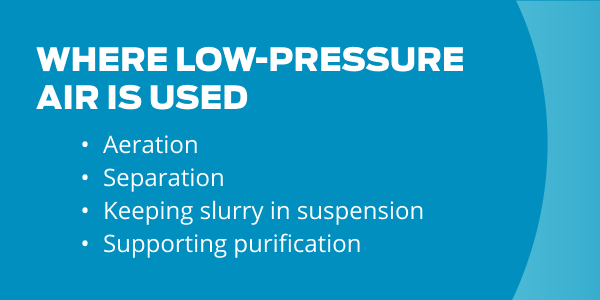

How Low-Pressure Compressed Air Is Used

Low-pressure compressed air helps break down organic materials and pollutants while wastewater is in treatment tanks or lagoons.

Low-pressure compressed air is often all that is needed for many of the following applications:

-

- Aeration. Diffusers or bubblers in treatment tanks and lagoons inject air into the wastewater to break down organic materials and pollutants.

- Aeration. Diffusers or bubblers in treatment tanks and lagoons inject air into the wastewater to break down organic materials and pollutants.

Low-pressure air supplies the bubbles that help break down organic materials and pollutants in wastewater.

-

- Separation. In the activated sludge process, a grid of diffusers disperses low-pressure air to help separate solids from the wastewater.

- Keeping slurry in suspension. Low-pressure air helps prevent solids from settling into the bottom of the treatment tank.

- Supporting purification. By providing oxygen levels five to seven times higher than occur naturally in room air, low-pressure aeration enables treatment plants to maintain higher levels of the microorganisms that remove waste from the water. In moving bed biofilm reactors, low-pressure compressed air helps grow biofilm on the media within the reactor.

Plant operators disperse low-pressure air through a grid of diffusers in an activated sludge tank.

Low-pressure air is also used to control foam. And, by helping remove volatile compounds, it reduces odors.

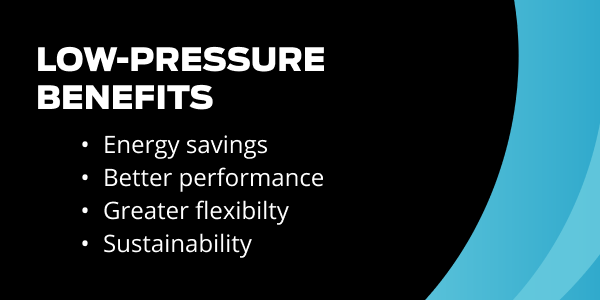

Benefits of Low-Pressure Air Compressors

Low-pressure air rotary screw air compressors provide significant benefits, including better performance, energy savings, flexibility and sustainability.

The Performance You Need

As plant operators turn to deeper and deeper tanks (to increase capacity without tackling costly plant expansions), they find that blowers can’t provide the pressures needed to function at the bottom of the tank.

Low-pressure air compressors give you the pressure you need. And the control required to optimize performance.

Energy Savings

Compressed air pumps and blowers consume as much as 80% of a plant’s energy usage, according to the U.S. Environmental Protection Agency and the U.S. Department of Energy.

Low-pressure compressed air is one of the most cost-effective and efficient ways to generate the fine bubbles you need in the aeration process, easily surpassing blowers and regulated high-pressure air.

Better Performance

Because aeration is such a crucial part of the process, low-pressure air plays a critical role by ensuring a steady and consistent supply of compressed air at the required pressure.

Greater Flexibility

A low-pressure rotary screw air compressor equipped with a variable-speed drive can automatically adjust to the treatment plant’s oxygen needs, which can fluctuate significantly. Failing to meet that oxygen need is inefficient and could cause the beneficial microorganisms to die. Many plants use dissolved oxygen meters to ensure readings stay within design parameters.

Sustainability

Low-pressure air reduces the environmental impact of wastewater treatment by allowing plant operators to reduce their energy consumption and supporting a more efficient method of processing wastewater and lessening pollution. Plants can thus reduce their carbon footprint and help their owners achieve their sustainability goals, while also meeting regulatory requirements.

Low-pressure air helps wastewater treatments reduce their carbon footprint and achieve sustainability goals.

Kaishan USA is one of the few rotary screw air compressor manufacturers that also offer a low-pressure model.

KRSL Low-Pressure Rotary Screw Air Compressor

Kaishan’s KRSL low-pressure rotary screw air compressor is almost ideally suited for wastewater treatment applications. It is the best air compressor for many crucial wastewater treatment applications. Especially those that only need low-pressure air.

Our KRSL low-pressure series was designed specifically for low-pressure applications such as the wastewater uses mentioned above.

Equipped with our breakthrough variable discharge port, the KRSL offers efficiency and versatility, delivering the right amount of air flow exactly when it's needed. Your compressor always operates at its most efficient point, minimizing energy consumption and costs.

The KRSL is available in models ranging from 25 PSIG to 45 PSIG, the “sweet spot” for wastewater treatment. It provides the industry with the consistent airflow, reduced noise levels, sustainability and smaller footprint that the industry needs.

The good news is that Kaishan offers a full range of rotary screw compressors to handle all your compressed air needs in wastewater treatment.

Air Compressors for Wastewater Treatment

Compressed air is used in all the stages of the wastewater treatment process, from aeration and separation to oxidation and sludge drying. It drives pumps and helps keep things clean. It’s used in treatment tanks, lagoons, membrane bioreactors and more.

Many treatment plants will find that rotary screw air compressors are the best air compressors for wastewater treatment because of a wide range of advantages, including their efficiency and versatility. They are known for producing steady streams of compressed air, resulting in smoother operation and significantly reduced energy waste.

Plus, they are not as noisy as reciprocating air compressors and low-pressure blowers and are designed for long-term reliability, giving them a relatively low total cost of ownership. They also have better warranties than other types of air compressors because of their reliability, efficiency and long life.

Kaishan USA provides wastewater treatment operations with a full range of rotary screw air compressors that thrive in heavy-duty environments. Our air compressors are built with very tight tolerances and exceptional features like stainless steel tubing and quadruple SKF bearings. They have a sound-deadening enclosure that keeps noise to a minimum and safety features to protect your team, such as guards to rotating components and UL and NEC-designed electrical components.

They offer superior reliability, ease of maintenance and optimized energy efficiency to reduce overall lifecycle costs. Kaishan compressors keep operational costs down while eliminating downtime.

Our KRSP premium rotary screw air compressors are used extensively in the wastewater treatment industry.

Kaishan’s KRSP and KRSP2 rotary screw compressors are backed by an unmatched lifetime warranty on the airend.

Kaishan’s KRSP and KRSP2 rotary screw compressors are backed by an unmatched lifetime airend warranty, thanks to their reliability, efficiency and long life.

The Full Range of Rotary Screw Compressors, Only from Kaishan

Kaishan USA is the only manufacturer offering the full range of rotary screw compressors for wastewater treatment, including:

-

- Our KRSP single-stage and KRSP2 two-stage premium rotary screw compressors offer the ultimate in efficiency. For more on single and two-stage compressors, read our blog post, “Five Critical Differences Between a Single-Stage and a Two-Stage Air Compressor.”

- For operators worried about oil carryover into effluent streams, our KROF oil-free rotary screw air compressor offers industry-leading warranty protection in an oil-free machine.

- Our KRSL low-pressure air compressor is built from the ground up for low-pressure applications, such as wastewater treatment uses.

Local Help in Choosing the Best Air Compressor for Your Application

Your local compressed air professional can help you select the best air compressor for your wastewater treatment application. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can help you optimize your compressed air system.

Key Takeaways

-

- In most plants, choosing the best air compressor may go beyond the standard cost, performance and maintenance issues.

- To save money, some facilities try to provide low-pressure air with blowers or by tapping into their high-pressure compressed air system and using a regulator to bring the pressure down to appropriate levels. This approach is not cost-effective: for every 2-PSIG increase in pressure, energy consumption is increased by 1%.

- Low-pressure rotary screw air compressors provide crucial benefits, including better performance, energy savings, flexibility and sustainability.

- For all compressed air applications, rotary screw air compressors are the best air compressors for wastewater treatment because of their reliability, efficiency, low maintenance and quiet operation.

- Kaishan USA is the only manufacturer offering the full range of rotary screw compressors for wastewater treatment, including premium single- and two-stage compressors, oil-free and low-pressure units.

Let Us Help

Selecting the best air compressor is critical to the operation of a wastewater treatment plant, especially in meeting your needs for low-pressure air. If you need help choosing the best air compressor for your plant, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text