Eight Causes of Compressed Air Leaks and How to Find Them

June 21, 2023

Four Compelling Applications of Vacuum Technology

July 5, 2023Industrial Compressors for Automotive Shops

Kaishan USA | June 28, 2023 | Uncategorized

Is your automotive shop ready to trade up to an industrial air compressor?

Five Reasons to Consider an Industrial Air Compressor for Your Automotive Shop

Trading up to a larger industrial air compressor is a major step in the life of any automotive shop for good reason. It represents a major investment, a commitment of working capital, training time, and management effort to purchase and install a new piece of equipment. Not to mention the ramp-up time for your team to adjust to the new device.

But the benefits of purchasing greater compressor air capacity are significant. Done correctly, you’ll get more power from your fourth utility, the term recognizing compressed air joins water, electricity, and natural gas in importance to your operation. You’ll get greater reliability. Reduced electricity costs. Higher quality air. A safer, more comfortable environment. And greater peace of mind.

Conversely, failing to make that investment could very well slow you down. Hamper your growth. Give you declining performance from critical tools like your spray painter, sandblaster, or cutting tools. And perhaps even put your workers at risk.

Let’s review the sound business reasons why you should consider upgrading your existing equipment to an industrial air compressor.

Five Reasons to Pull the Trigger on a Trade Up

There are some specific trigger points that make a move to a larger compressor a no-brainer.

1. You’re Expanding

Expanding the size of your facility usually means your compressed air system needs to cover more ground. Supply compressed air to more tools. Support the work of more mechanics.

Expansion may also include marketing or promotional efforts to bring in more business. You don’t want unplanned compressor downtime to cause you to disappoint your new customers or frustrate your people by failing to deliver on time.

A new compressor, especially a rotary screw air compressor, will boost your capacity significantly. But, most importantly, it will give you the reliability you need to grow your business. The most important thing is getting the right amount of capacity for your needs. For some guidance in that area, read our blog post, “How to Determine What Size Air Compressor You Need for Industrial Use.”

2. You’re Adding Another Shift

Maybe your business isn’t growing so quickly that you need a new building or an addition to your existing facility. But it is expanding so much that you need to add a second (or third) shift, figuring the impact on existing equipment will be minimal.

That may work for most of your machinery. But you’ll want to be cautious about your compressed air capabilities. Not all air compressors can handle continuous duty.

You’re most likely good to go if you have a rotary screw air compressor because they do best with continuous operation. That’s not true of all compressors, however. If you’re unsure what kind you have, see our recent blog post, “Which Type of Air Compressor Is Best for Your Application?” Or check with your compressed air consultant.

3. You’re Moving

If your business has grown enough to need a new location, you will probably add staff, equipment and capabilities. And it’s often best to leave your old compressor behind when the moving van pulls out.

After all, wouldn’t it be crazy to be in tomorrow’s new building, with a bigger staff, more tools and more business, but frustrating everyone with the limitations of yesterday’s air compressor?

Plus, you may be adding a new capability, like painting. If so, you’ll need smooth air flow, avoiding the pulsations in air flow coming from a reciprocating or piston compressor.

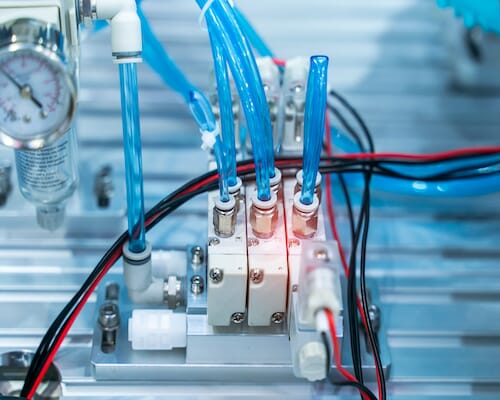

Automotive shops require a large quantity of high-quality compressed air for painting.

The same is true if you’re concerned about noise. We’ve had many small shops who only needed a recip but wanted to trade up to a screw compressor to reduce the sound level.

We should add, however, that there are some occasions where recips are the best choice, especially for applications where the load profile is too light or sporadic for a screw compressor to operate effectively.

4. You’re Starting Anew

New location or refurbish an old one. New staff or existing ones. You decide it’s time to start over, start afresh. And you know you’ll need significant compressed air capacity. The question is, how much?

There are three critical measurements you will want to pay attention to:

-

-

- CFM stands for cubic feet per minute, specifying the amount of compressed air that flows through your system. It’s a measure of the amount or volume of compressed air your compressor is producing. A higher CFM rate in an air compressor gives you more power and greater versatility in the number of applications you can service and the volume and pressure requirements those applications will require.

- PSIG. PSIG stands for pounds per square inch gauge, and measures the system pressure relative to the ambient atmosphere. It’s the force your end-use application needs to perform a task. Having more PSIG available enables you to do more work with less effort. Most air tools need between 80 and 90 PSIG of pressure.

- HP stands for horsepower, a measure of an air compressor’s motor performance. It's the ability to transfer energy. The HP rating indicates the size or power output of the motor that drives the air compressor. The more horsepower, the greater the capacity of the compressor to deliver compressed air at the required CFM and PSIG.

-

To summarize, you need enough PSIG, or pressure, to do the work. You need enough CFM, or flow, to transfer the total energy you need for the tool’s particular task at the pressure you need. And you need a compressor with enough HP, or performance, to generate that energy.

See more information on these key terms in our blog post, “Answers to Six Common Questions About Compressed Air.”

5. Adding More Powerful Tools

It’s not unusual for owners of all kinds of businesses to add more tools and equipment but forget to factor in the impact the addition will have on compressed air flow. And some tools won’t work with an underpowered compressor.

You may even find pressure requirements are higher if your addition is a high-pressure tool like a sandblaster.

One critical mistake people make is that they sometimes overestimate the amount of CFM they need. If, for example, they have ten tools that all require 5 CFM of flow, they jump to the conclusion that they then need 50 CFM of flow. As Compressor Services points out in its blog post, “How to Choose the Right Air Compressor for the Automotive Industry,” that may be appropriate for collision repair shops using high levels of compressed air for sandblasting, grinding and spray painting. But for an auto repair shop that doesn’t use those power-hungry tools, that’s probably much more than they need.

Collision repair shops use high levels of compressed air for sandblasting, grinding and spray painting.

The reason is what’s called “use factor,” which measures the amount of time a tool is in operation. Most likely, the mechanic’s ten tools are not all working simultaneously. Some, admittedly, are in continuous use. But others are “intermittent,” at best. So rather than needing the entire 50 CFM mentioned above, the repair shop needs only 10 CFM.

Rotary Screw Air Compressors—the Best Choice for Most Automotive Shops

When they trade up to an industrial air compressor, all but the largest companies—think original equipment manufacturer (OEM) assembly plants or larger fleet operations with thousands of employees—choose rotary screw air compressors.

In general, a centrifugal air compressor is most cost-effective for high-volume applications (above 2,500 CFM). A reciprocating compressor is the best choice for low-volume applications (less than 20 CFM). But screw compressors are the best for everything in between.

Because of their reliability, efficiency and long life, air compressors like Kaishan’s KRSB belt-drive rotary screw compressors are an excellent choice for automotive shops. It is available as a tank mount with dryer.

Rotary screw machines are remarkable for their ability to provide steady streams of high-quality compressed air and handle large-capacity loads. They have become the air compressors of choice for most industrial applications because of their reliability, efficiency and long life. And they have the industry’s best warranties—Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

Local Help

With your company’s future on the line, you want to make the right decision when it comes to trading up to an industrial air compressor. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed to help you make sure you are getting the best compressor for your operation.

These factory-trained air compressor experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in using leak-detection technology on a daily basis.

Key Takeaways

- Big investment. Trading up to a larger industrial air compressor is a major step in the life of any automotive shop.

- The benefits. More compressed air power. Greater reliability. Lower electricity costs. Higher air quality. A safer, more comfortable environment. And peace of mind.

- Five reasons. There are five main reasons to trade up to a larger compressor: you’re expanding, moving, adding another shift, starting afresh or adding more powerful tools.

- Compressors of choice. Rotary screw machines have become the air compressors of choice for most industrial applications because of their reliability, efficiency and long life.

- Selection help. With your company’s future on the line, you want to make the right decision. Kaishan USA works with a nationwide network of independent distributors, who help ensure you are getting the best compressor for your operation.

Let Us Help

Are you ready to trade up to an industrial air compressor for your automotive shop? If you need help determining whether your business is ready to take this important step, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Trading up to a larger industrial air compressor is a major step in the life of any automotive shop for good reason.