How a Multi-Compressor System Can Help You Reduce Compressor Downtime

November 5, 2025

Can Centrifugal and Rotary Screw Air Compressors Play Nice Together?

November 19, 2025How Do You Define Compressed Air Success?

Kaishan USA | November 12, 2025 | Uncategorized

With the average large plant losing 27 hours a month to unplanned downtime, the reliability of compressed air systems is a significant concern for facility managers.

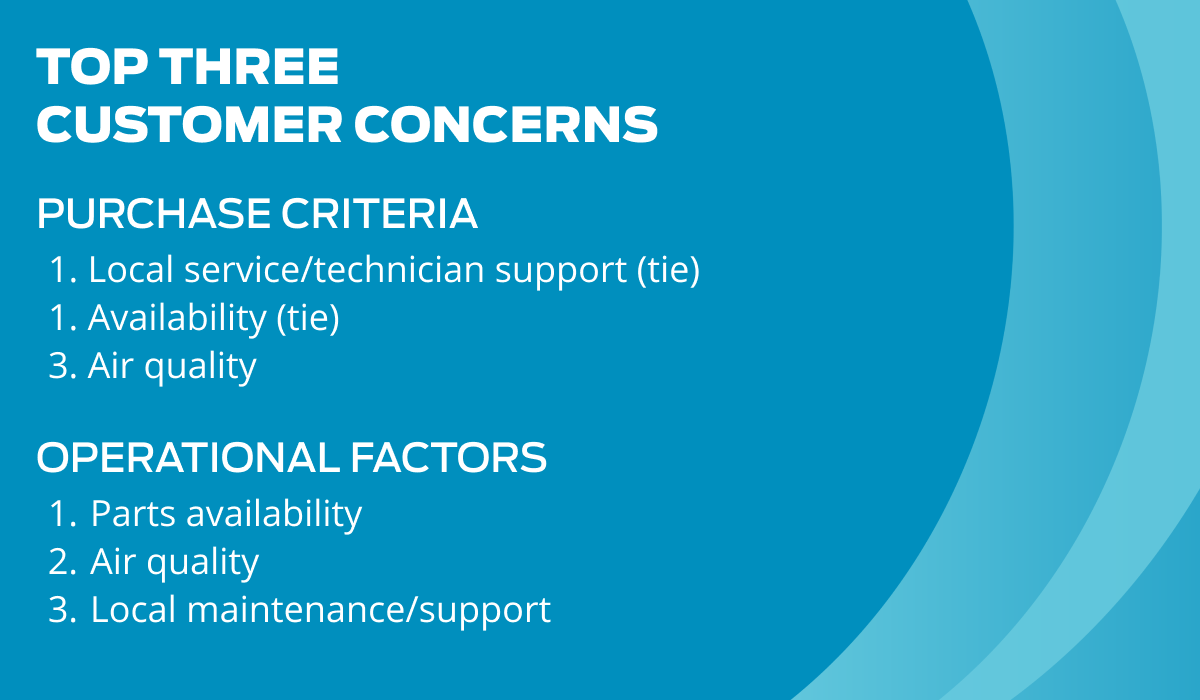

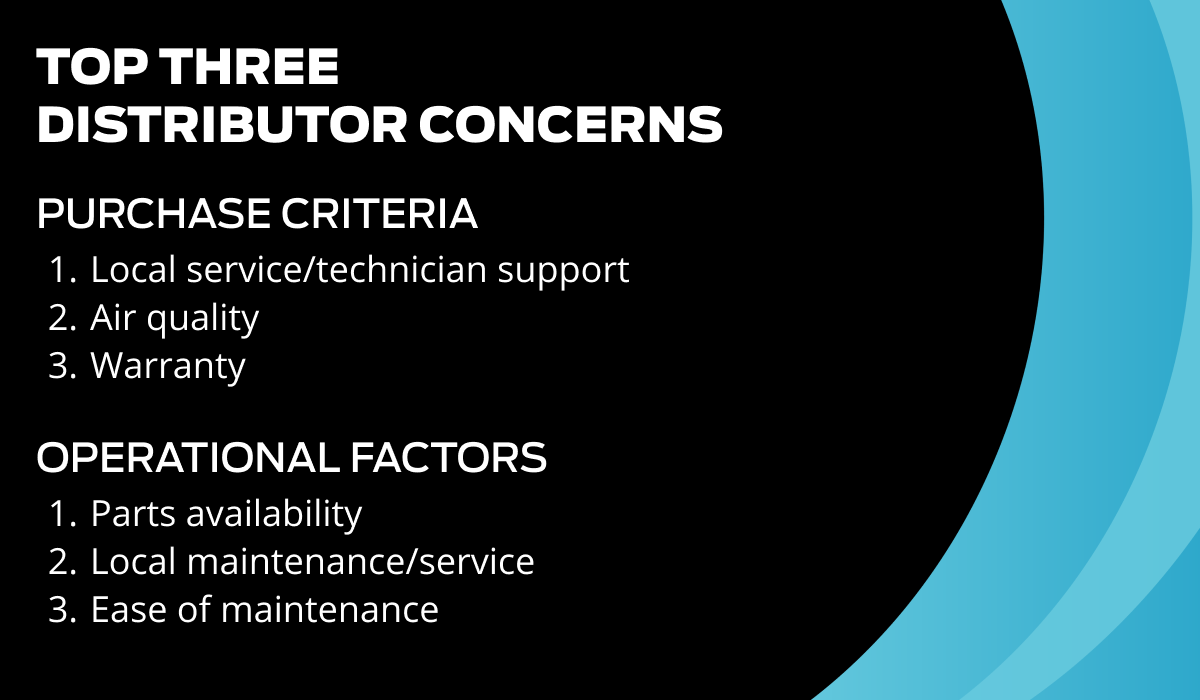

As a manufacturer, we hear from end users all the time. So, we wanted to take an opportunity to actually ask people what is on their minds by conducting an informal survey, gathering responses from both end users and from our independent distributors who represent Kaishan in your local area.

Considering the competitive environment, there weren’t a ton of surprises. Instead, the findings reinforced some core issues—things we don’t want to lose sight of—both in making purchase decisions and in operating compressed air systems.

Here’s a summary of what we learned. We’ll start with people’s expectations about the future.

1. Compressed Air Use Is Growing!

Most of our respondents indicated cautious optimism about the future. The prevailing sentiment was “steady as she goes,” with some even predicting growth. Some typical comments included:

- “We are growing exponentially within short periods, so we expect our compressed air demand to increase.”

- “We will need a larger compressor in the future as our business grows.”

Next was the initial cost.

2. Initial Cost

Not much of a surprise here, of course. Our customer group considered it moderately important, while distributors found it very important. In fact, one of them said of their end users, “They want to buy the most value for their dollar and expect it to operate flawlessly between maintenance cycles.”

Other thoughts from distributors included:

- “As price for everyone continues to go up, it can't help but be an issue.”

- “Depends on the customer, some like it cheap and bare bones, and others want it built for performing efficiency.”

- “Purchase price (doesn't have to be the lowest), but a good value.”

Another key issue was obtaining parts.

3. Parts Availability and Cost

Parts availability was the top-ranked factor among end users, with two-thirds of the respondents saying it was the most important. Distributors shared that sentiment, with three-quarters saying it was a significant issue for their end users.

Half of the end users in the survey called out parts in their added comments. For example, one customer said their key issue was, “Service parts, compressor lube and filters reasonably priced.”

Respondents also stressed the importance of air quality.

4. Air Quality

Air quality ranked highly as a factor for both the purchase and the operation of their compressors. Half of end users said it was the most critical operational factor, and a third listed it as an essential issue in their equipment purchase.

One customer called out the importance of “near water-free air.”

Another key concern was reliability and avoidance of downtime.

5. Reliability and Long Life

Several end users and a third of distributors emphasized the importance of reliability and longevity in their comments.

A typical response was, “Perceived reliability is always No. 1.”

Ease of maintenance was another key concern.

6. Ease of Maintenance

Ease of maintenance was important to the entire customer group, although fewer than a third ranked it as the most critical factor. Distributors rated it slightly higher.

One customer spelled it out: “Serviceability, meaning ease of maintenance, quick parts availability and knowledgeable technicians.”

A related issue, warranties, ranked No. 5 among end users and third among distributors, with more than a third of both groups classifying it as “most important.”

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

Product quality and performance, of course, was another key factor.

7. Product Quality, Performance and Energy Efficiency

A quarter of end users said energy efficiency was a significant decision point, while distributors consistently rated it as moderately important.

One customer noted, “Energy efficiency, since it drives the long-term operating cost of a unit that is inherently inefficient.”

Comments from distributors included:

- “I steer end users who want higher functionality to the premium equipment.”

- “There is a trend toward energy savings. Most people talk more than ever about ‘lifecycle’ costs since businesses today use these buzzwords and apply them to air compressors.”

- “The cost of energy is increasing, and this may make you decide to buy more efficient equipment, such as a two-stage rotary screw air compressor.”

Our KRSP2 premium rotary screw air compressor is one of the most efficient air compressors on the planet.

- “Quality of unit which includes minimal oil leaks, steady run temps and air quality after water and oil separation.”

Another critical factor was a compressor’s ability to handle tough conditions.

8. Ability to Handle Harsh Environments

While not a significant issue for everyone, the ability to handle a rugged setting was critical to a few respondents.

One customer summarized the key challenge as the “ability to meet my system requirements.”

For distributors, heat was the issue. A few representative comments included:

- “Heat is the worst enemy.”

- “Able to work in AZ ambient temps.”

- “Heat is our main issue/concern.”

Having the latest technology was another issue that came up.

9. Advanced Technology

End users were interested in technology, but did not call it out to the same extent as distributors.

One customer noted: “I need to make informed decisions when purchasing a new air compressor and weigh those against the operating cost of my existing equipment. Any new air compressor I buy will likely need to run well in conjunction with existing compressors to meet my process requirements (as this is a likely low-cost option).”

Typical distributor comments included:

- “Remaining current in operational features and benefits are expected, like PLC controls, HMI touch screen, etc.”

- “Energy efficiency and ways to improve, of course.”

- “I am hoping that remote monitoring can be integrated into these units in the near future. When done correctly, remote monitoring is a game-changer.”

Remote monitoring capabilities, such as those available with our AirWatch system, truly are a “game changer,” as one of our distributors noted.

Most importantly, all the respondents understood the value of having compressed air expertise available locally.

10. Local Support

Local support was a top-ranking factor for end users, with more than half saying it was most important. Typical customer comments included:

- “Same-day emergency repair on a down compressor.”

- “I am glad we have a good technician. They have helped us a lot with the breakdowns and getting us back working as fast as they could!”

- “If I decide to optimize efficiency and purchase a new compressor, relegating existing compressors to backup, I need to leverage utility incentives to meet my company's cost-effectiveness requirements.”

Not surprisingly, the majority of distributors called out local maintenance and service as a key decision point. Comments included:

- “More agreement/contract style maintenance where the customer wants us, the distributor, to take ownership of maintenance since they don't have the manpower or the ability to perform this work.”

- “Our end users are pretty loyal and believe in us; our recommendation goes a long way in their purchase.”

- “Trusting the distributor will service them after the sale.”

- “Ability of distributor to engineer the right system.”

- “Local, honest, timely, knowledgeable distributor who responds quickly and solves issues quickly.”

- “Someone local who knows how to keep everything running.”

- “Our end users seem to be most concerned with uptime, so local (good) service and parts availability are at the top. Most of the rest is on us, ease of maintenance and safety.”

End users want a “local, honest, timely, knowledgeable distributor who responds quickly and solves issues quickly,” according to one of our survey respondents.

Want Local Service? We’re All In!

We’ve never questioned the value of having a local expert available to help you navigate some of the tricky issues that can arise with compressed air systems. In fact, we are all in on local help.

That’s why we work with a nationwide network of independent distributors to provide the on-site assistance and consultation mentioned in our survey above. We agree that having local expertise available is the best way to serve you.

We partner with independent, local distributors because they offer expert guidance, faster response times and personalized support tailored to your needs. They can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Unlike large corporate suppliers, there's no red tape here. Our distributors don't just sell compressors, they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

They have factory-trained technicians who have a deep understanding of industrial applications and can help you maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and will work with you to make it succeed.

Not convinced? We lay out all the advantages of working with an independent, local distributor or consultant in our white paper, “The Top 25 Reasons an Independent Air Compressor Distributor Enhances Compressed Air Performance.”

Key Takeaways

Key comments from our informal survey about compressed air success:

- “As price for everyone continues to go up, it can't help but be an issue.”

- “Perceived reliability is always No. 1.”

- “There is a trend toward energy savings. Most people talk more than ever about ‘lifecycle’ costs since businesses today use these buzzwords and apply them to air compressors.”

- “Same-day emergency repair on a down compressor.”

- “Someone local who knows how to keep everything running.”

- “I am hoping that remote monitoring can be integrated into these units in the near future. When done correctly, remote monitoring is a game-changer.”

Let Us Help

Whether you have a rotary screw compressor or centrifugal air compressor, we can help you optimize your compressed air system to maximize reliability and efficiency. If you need help, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Defining Success in Compressed Air

What's up, everyone! Welcome back to The Big Dog Podcast, where industrial air meets, well, no-nonsense conversation. Today, we’re talking about what actually defines success in compressed air systems—straight from real survey data, too. Jason, it’s not just about having a compressor that turns on, right?No, not even close. I mean, the days where you just buy the cheapest thing on the spec sheet—those are over, especially if you care about long-term performance. According to the survey, most folks actually expect their compressed air use to grow as their operations expand. That’s a big deal. People are planning ahead, not just reacting to breakdowns.

Yeah. There was this strong sense of “steady as she goes,” but also a lot of folks said, “Hey, our demand’s going up. We’re growing.” And when they're buying, what pops up again and again is value, not just price. They want reliability. They want solid air quality. And I love how even distributors see it that way—it’s not just about who can sling the cheapest unit. People care about what works every single day.

Absolutely. Honestly, when I was working on the shop floor—back before all this podcast business—we had one week where we missed a subtle air quality issue. Thought the filters were good, but turns out, nope. Production came to a halt, and I remember how useless it felt just standing around, waiting for that air to get sorted. In the end, that one miss cost ten times what a proper, reliable compressor would’ve up front. I still get flashbacks when I hear “air quality.”

And that story’s in line with what came out of the survey. Both end users and distributors hammered reliability, air quality, and energy efficiency—these aren't just buzzwords. It’s what really keeps plants running. Even cost, people talked about it, but in terms of value and lifecycle—not just lowest sticker price, which is kinda refreshing, right?

Yeah, and energy efficiency is only getting more attention, especially as costs ride up. It’s not “how cheap can I buy,” it’s “what gets me the most for my money over years.” And honestly, that’s the smartest way to look at it—no shortcuts.

The Hidden Costs: Uptime, Maintenance, and Parts

So that brings us to the real, hidden costs in this whole game: downtime, maintenance, and especially, parts. This stat jumped out at me—on average, large plants are losing 27 hours a month to unplanned downtime. Twenty-seven! That is a nightmare.It’s brutal, right? If you look at it over a year, that’s hundreds of hours—and, honestly, most of it is avoidable if you get the system right up front. Reliability’s not just “nice to have.” Facility managers are obsessed with it. This came up in our “Defeating Downtime” episode too—planned maintenance versus putting out fires, it’s a huge difference.

Exactly. And here’s the piece people forget—parts. Two-thirds of end users in that survey said quick access to parts was mission critical. If you can’t get the right filter or a belt or even some lube, everything grinds to a halt. I had a customer last year, their compressor went down over a busted valve, and would you believe it, that part was out of stock for days. I mean, they lost thousands in productivity waiting for a delivery. It’s those ripple effects—nobody budgets for them, but they’re real.

It’s the difference between a hiccup and a full-blown production disaster. I’ll say—ease of maintenance matters, too. If you can’t get in there and do what you need, or the parts are some weird special order, it’s just… you may as well add up the overtime for the techs while you’re at it. And don't even get me started on when people try to run things on non-OEM parts just to save a buck—that almost always bites them in the long run.

And it all ties back to that trust—knowing someone local will have those parts on hand, they know what you need, and they get you back up fast. It’s honestly why people obsess over local service. It’s not glamourous but it’s what separates the good from the, uh, constantly scrambling.

Why Local Expertise Reigns

Yeah, speaking of local, the survey couldn’t have been clearer: Local support, techs who actually know your system, honest relationships with distributors—that’s top of the list. Some people said same-day repairs are literally the difference between a headache and, what did that one person say, “a total disaster”?Yep, and it’s not just about speed. Trust and expertise matter. A good local distributor isn’t just selling you a thing—they’re building a relationship, taking ownership when you need them. I loved that distributor comment about taking on maintenance contracts because the customer didn’t have the staff or experience. That’s evolving. It’s not just about selling boxes, it’s about partnering long-term.

And sure, things like remote monitoring are getting more popular—in a good way. I mean, having AirWatch or another system flag an issue before it becomes a problem is gold. But, at the end of the day, if you can’t get someone on site who understands your setup, all the fancy tech in the world isn’t gonna help much. At least, that’s what I keep seeing on plant floors.

Totally. Kaishan’s whole model with independent, local distributors is built around that—fast response, personalized support, and actual expertise on the ground. And, Jason, I think this is where the brand matters less than the people, right? Plants are shifting; they’re trusting relationships more than a logo on the box.

Exactly. If you know the distributor has your back, that’s what counts. Plus, no corporate red tape—just folks who know your application, bring you the right solution, and don’t leave you hanging while you wait for a part from halfway across the country.

Alright, so, key takeaway? Whether it’s uptime, efficiency, or just minimizing headaches, local expertise is the dealbreaker. That’s what’s coming straight from the people who live this stuff every day.

Couldn’t have said it better. And hey, if you want to dig deeper, we’re gonna keep breaking down these real-world survey insights and what it means for the future of compressed air. Lisa, always a pleasure—

Right back at you, Jason. Thanks for tuning in, everybody. We’ll be back soon—so stay sharp, and keep your air clean. Catch you next time!

Random stat or

customer quote

textXXtext

text