Polymer Industries

December 4, 2025

Air Compressor Intake Air: The Original GIGO

December 17, 2025How Water Gets into Your Compressed Air System. And What It Does When It Gets There.

Kaishan USA | December 10, 2025 | Uncategorized

Water can wreak havoc with a compressed air system, so removing it is critical.

Whether you’re talking about a rotary screw air compressor or a centrifugal air compressor, the presence of water is a serious issue, causing rust, damage and compressed air contamination throughout your machine. We cover all the ways in our blog post, “Water: The Compressor Killer.”

Serious as those impacts are, water also wreaks havoc in your downstream compressed air system. From corrosion and rust to oil degradation, blockages, capacity reduction and component failure, water is bad news.

Water issues are a natural part of the compression process, of course, as water in the ambient air condenses out as the air pressure increases. That’s why most companies have air dryers for their compressor systems. Unfortunately, dryers can be overwhelmed with moisture far beyond what might be expected, or from sources that occur after the drying step. And drying incurs energy and cost.

As a result, preventing moisture in air compressors is a critical part of operating a compressed air system. We’ll start by listing the ways moisture gets into your system.

How Water Gets In

There are several ways to get water in a compressed air system, some more obvious than others:

- Through your compressor. Your compressor draws in humidity from the ambient air. In most cases, that’s enough to do damage. A lot.

- Unprotected outdoor installations. Unless your compressor is under a roof and shielded on at least three sides, water can get into your unit.

- Poor interstage moisture separation. If you don’t remove the water with a floating drain that discharges into an open reservoir, it can get sucked back into the into the downstream stages of a two- or three-stage compressor and then become entrained in the air. That’s especially a problem with the interstage cooling of a two-stage oil-free compressor or a multi-stage centrifugal compressor.

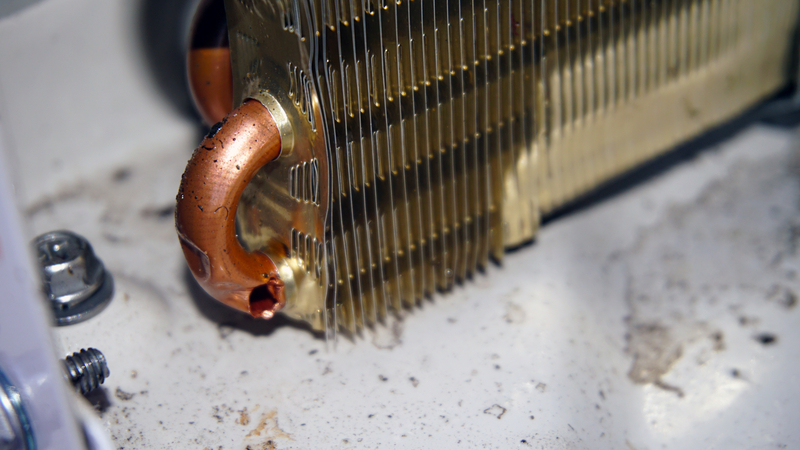

- Cracked heat exchangers. Water can enter the airstream or the oil stream if there’s a failure in your water or air cooler.

Damage to a heat exchanger can allow water to enter your compressed air system.

Once water’s in your system, all hell breaks loose.

What Water Does to Your Compressed Air System

There are several impacts from water in your compressed air system:

- Clogs. Rust and other debris flake off and obstruct air flow throughout the system, including aftercoolers, oil coolers, coolant passages and oil injection passages. It can also affect your scavenger lines and any of your small pilot lines.

- Loss of capacity. The clogs and blockages reduce airflow. In addition, wet air is heavier, increasing pressure drops through the system.

- Filter and dryer overloads. Filters, separators and dryers will have to work harder. Filters will become saturated more quickly and need more frequent replacement.

- Freezing. Water can freeze in your system, leading to frozen air compressor lines, blockages, broken pipes, ruptured seals and component failures.

Water can freeze, resulting in frozen air compressor lines and ruptures pipes.

- False readings. Water can damage valves, sensors and other measuring equipment, causing them to malfunction.

- Compressed air contamination. Water promotes the growth of bacteria and mold, which can compromise product integrity.

- Component damage. Water is highly corrosive, causing metal components and subcomponents, such as tanks, pipes and valves, to oxidize and rust.

And then there are the quality issues and damage to your products or workpieces.

Quality Issues and Production Losses

The potential damage to your products depends on your process and your products:

- For painting, water can cause blisters and adhesion problems.

Water in a compressed air flow can cause “blisters” or other imperfections in a paint job.

- For automobile body shops, water in the compressed air stream may cause discoloration, faults and fisheyes in the paint, marring the perfect finish the customer is paying for.

- For food production, water can cause compressed air contamination and spoilage.

- For pharmaceuticals, water may dilute or otherwise compromise sterility or product integrity.

- For electronics, water can ruin batches or cause defects.

Water in a compressed air system can cause compressed air contamination that might cost a bakery an entire batch of products.

Next, we’ll discuss how to remove water from your compressed air.

Removing Water from Your Compressed Air System

Compressed air drains are one of the obvious ways you can extract water from your system. Not surprisingly, clogged, backed-up, or malfunctioning compressed air drains are the leading failure point for air-stream moisture. Depending on their design, they can become clogged with debris, rust or sludge.

As a result, we strongly recommend that you test your compressed air drains daily in all your key system equipment, including dryers, filters and receiver tanks. Or have a drain alarm notifying you of a drain failure.

There are several different types of compressed air drains.

Time-Interval Drains

Most compressed air users have time interval drains, especially in budget-conscious companies. As it sounds, time-interval drains open at regular intervals for a present amount of time, whether there’s moisture present or not.

Unfortunately, if you don’t have moisture, you will release air, wasting money. And on days when the humidity is off the charts, the drain may not stay open long enough, allowing moisture to build up.

As a result, you may need to adjust the time intervals to make sure you’re getting all the water out of your system. You may even need to change the intervals several times a day. Most likely, you will have to set them to be open longer than necessary to ensure all the liquid is removed.

They can do the job, but they require close attention. That’s why many users look for a better solution.

Egg Drain or Float Drain

The next level up from time-interval drains is an egg or float-type drain. It functions like the float in the cabinet behind a toilet, opening as the water level rises and closing as the water level drops.

Zero-Loss Drain

There are several different types of zero-loss drains. They use inductive resistance measurements to sense the amount of water in the drain and the rate at which the water level is rising or falling. The zero-loss unit precisely controls the drain operation, preventing air loss.

A relatively costly version opens when the water level, tracked by a pneumatically controlled magnetic float, begins to rise, then closes when the moisture is removed. They maintain a liquid seal at the bottom of the reservoir to prevent air from being wasted.

Are zero-loss drains worth the additional expenditure? The answer may vary from one application to another.

But it’s a relatively straightforward calculation: how much would it cost to lose a batch or work item because of air compressor moisture problems?

Compared to a ruined paint job, a batch of semiconductor chips or a day’s worth of baked goods, the additional cost may be chump change.

Don’t Get Soaked. Work with Your Local Professional.

If you’re having air compressor moisture problems, the best place to start is with your local compressed air professional. They not only understand air compressor moisture problems, but they also deal with local conditions every day.

That’s why we partner with independent, local distributors, working with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Unlike large corporate suppliers, there's no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than just a product—you're getting a local partner who genuinely cares about your business and wants to see it succeed.

Key Takeaways

- Water enters your system through incoming air, unprotected outdoor installations, cracked heat exchangers and poor interstage moisture separation.

- Water causes a wide range of problems, including lubricant loss, oil degradation, bearing damage, clogs, reduced capacity, filter and dryer overloads, freezing, inaccurate readings, compressed air contamination and component damage.

- Water can also damage end products, for example, by causing blisters or adhesion problems in painting, compressed air contamination in food and pharmaceutical products and ruining batches or causing defects in electronics.

- There are several types of compressed air drains for removing water, including time-interval, egg or float and zero-loss drains.

Let Us Help

Dealing with air compressor moisture problems is a critical operation of your compressed air system and all the processes that rely on it. If you need help reducing the water in your system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

How Water Sneaks Into Your System

Alright folks, welcome back to The Big Dog Podcast! And before we get started today, Lisa, today's episode is a special one. Do you know why?!I'm all ears, Jason. What's up?

Today marks our 50th podcast together! 50 sessions of bringing compressed air insights to the world together, with the best co-host I know. If I haven't said it enough, Lisa, thanks again for doing this with me. I love this show!

WOW! 50 episodes?! Kudos to you, Jason. You've been awesome this whole ride.

Alright, on with the show! Lisa, you ready to talk about everyone’s least favorite uninvited guest: water in your air system?

Absolutely, Jason! This is one topic that just does not quit. Water has a special knack for slipping into places it doesn’t belong. So, let’s just get right into it—there are some big entry points we see again and again. First up, humidity in ambient air. That’s the one nobody can dodge, whether you’re running a rotary screw or a centrifugal unit, that moisture is guaranteed to come along for the ride every time you compress air.

Yeah, and it’s not just what’s in the air. A ton of systems get burned by outdoor installs—seriously, you leave a compressor out in the rain with barely a shed over it? I mean, I remember this plant—out in Ohio—where they thought a little leak was nothing, until a major downpour came through. Water got into an outdoor unit, and what could’ve been an afternoon fix wound up shutting ‘em down for a full week. I’m talking a week of lost production just because the outdoor weather wasn’t handled right. That’s avoidable pain.

You know what’s overlooked too? Poor moisture separation—especially between stages in multi-stage compressors. If you skip or half-bake that step, water makes it downstream and sits in places you really do not want it, like aftercoolers, filters… sometimes even receivers. And then there’s the hidden devil: cracked heat exchangers. If you’ve got failure in your water or air cooler, that can dump liquid water right into your airstream or, worse, the oil circuit. Not a fun fix.

Yeah, and a lotta maintenance crews still think, “Eh, as long as we dry the air, we’re good.” But dryers get overwhelmed, especially in high-moisture situations or if the problem pops up after drying. So, Lisa, out of all these points, which one do you think gets missed the most on a plant walkthrough?

Ooo, good one. I’d say the cracked heat exchanger is the sneakiest. Maintenance folks are usually looking at outside air or checking their filters, but that internal failure just doesn’t jump out until—you know—everything starts rusting or breaking down. What about you, what do you think's the most persistent threat?

I gotta go with ambient humidity. You can’t do anything about the weather, and if your intake is pulling humid air day after day, eventually, you’re fighting a losing battle unless you really dial in your separation and drainage. Alright, let’s roll right into what all this water actually does—because just getting in is only the beginning of the nightmare.

The Cost of Getting Wet: Equipment and Product Damage

Oh, totally, the damage water can cause—it’s not just equipment failure; we’re talking about rust, blockages, pressure loss, and even lines freezing up. I've seen rust flakes clog aftercoolers and tiny scavenger lines, and suddenly the whole system’s backed up. Not to mention when stuff actually freezes? Broken pipes, seals blown out, sensors going haywire—it’s just chaos. And, the filters and dryers get overloaded trying to keep up, so you’re replacing them way more often.Yup, and it goes deeper than blown hardware. Think about process quality. For example, I was in a shop where paint jobs turned out all bubbly and flaky—that was water blisters thanks to moisture in the air. Ruined an entire shipment. And sometimes, it’s not about what you see, it’s the invisible bacteria and mold that water can help spread through your lines. Messes with pharmaceuticals, electronics, you name it.

Speaking of ruined batches—let’s not forget food production. I remember a bakery had to toss out an entire day’s worth of bread. All the buns contaminated, because water made it through the compressed air, contaminated the product right on the production line. That is a punch to the gut, both for food safety and for the cost.

I think the worst hit I ever saw was at an electronics plant. Moisture got into the pneumatic system, shorted out sensors and the finished boards got rejected over minute contamination no one caught in time. That’s gotta be, I dunno, a hundred grand maybe? Easy. And a lotta times, the operators just don’t see the threat until half the system’s compromised. It flies under the radar ‘cause symptoms don't show up until it’s almost too late. What do you think’s the reason water causes such sneaky problems, Lisa?

Part of it is, most people expect to see water dripping out if there’s a problem, but it’s usually hidden—like in valves, or it just hangs out in low points until it wreaks havoc. And with today’s systems, compressed air goes everywhere, so contamination spreads before anyone spots a red flag. Plus, if your sensors get wet, suddenly you can’t even trust the instrument readings. Honestly, by the time you notice the problem, the damage is usually done. Prevention really is everything here.

And that’s a perfect lead into drains and how folks can get out in front of this stuff before it escalates.

Keeping It Dry: Drain Solutions and Preventative Steps

Alright, drains—these are the unsung heroes… or well, sometimes the villains if they’re not set up right. Most plants start out with time-interval drains. That’s the “set it and forget it” style: opens at preset times whether there’s any water or not. But here’s the kicker—no water, you’re just dumping air and money; too much water, and it can’t keep up, so water piles up anyway. So then everyone starts fiddling with the timers and before you know it, it’s a guessing game on intervals.Exactly! And then you end up with a float drain, or as some call it, the ‘egg’ drain. This is a tiny bit smarter—opens when water fills up to a certain level and closes after. Like the toilet tank float, right? Better than a time drain, especially if you don’t want to babysit the system all day, but it can still get gunked up if you’ve got rust or sludge in the lines.

But here’s where I always put my foot down: zero-loss drains. These are the gold standard. They use sensors—inductive, magnetic, whatever—to spot water buildup and drain it out without letting compressed air escape. That means you’re not just saving air, you’re saving cash every single cycle. Saw a plant lose tens of thousands of dollars on wasted air and ruined paint jobs before they switched over. After installing zero-loss drains? Problems practically disappeared. Look, yeah, it costs more upfront—but when you do the math against ruined products or wasted energy, the ROI is a no-brainer for most places.

The big question I always get: how do you even know if your drains are doing their job? Honestly, it’s daily checks or, even better, get a drain alarm. If you’re not testing them—or you’re assuming everything is fine—you’re setting yourself up for a nasty surprise down the line. It’s one of those tiny investments in time or tech that pays back in a big way. Whether it’s zero-loss or just keeping an eye on your float, any neglect becomes expensive real quick.

Yeah, and don’t underestimate working with a local pro. They know the local weather, your system quirks, and they can spot trouble way before it hits. So, invest in smarter drains and keep someone accountable for checking them—I mean, that’s just basic insurance for uptime. Anyway, Lisa, anything else people need to hear before we wrap?

I’d just say—don’t be the plant stuck fighting the same water nightmare year after year. Take those preventive steps now, invest in the right drain tech for your setup, and if in doubt, call your local expert. They really can save your system—and your budget—in the long run.

Alright, that’s it for this round of the Big Dog Podcast, thanks for hanging with us. Lisa, been a good one!

Definitely, Jason. We’ll be back next time to tackle more of the tough stuff that keeps your plant moving. Take care, everybody.

Catch you all on the next episode. Later!

Random stat or

customer quote

textXXtext

text