Water: The Compressor Killer

December 3, 2025

How Water Gets into Your Compressed Air System. And What It Does When It Gets There.

December 10, 2025CASE STUDY:

KAISHAN USA AND AIR & HYDRAULIC EQUIPMENT HELP PLASTICS MANUFACTURER PUT AN END TO $6,000-PER- HOUR “SCRAMBLIN”

Polymer Industries

Henagar, AL

The Situation

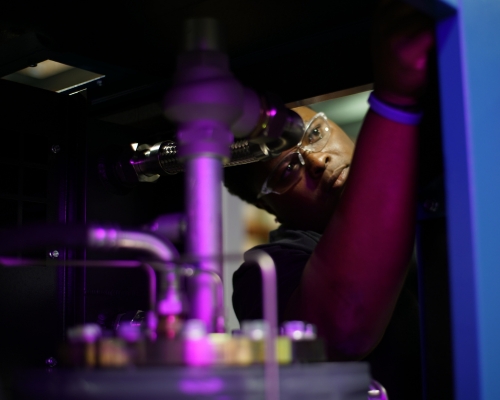

As a manufacturer of polyolefins, engineering plastics and high-performance plastics for dozens of industries, Polymer Industries is unmatched in the breadth of its product line. Its seven plants throughout the U.S. relyon compressed air for processing applications such as sheet extrusions and press molding. The compressed air systems in the main plant in Henagar drive the large chrome rolls on the extrusion lines, some of the press molds and all of the vacuum lifts. They all require a lot of pressure.

“If we go below 90 PSIG, we’re scramblin’,” said Tyler Knight, maintenance manager and project manager at the company’s two Alabama plants.

The Challenge

The company had an aging, unreliable 100-HP compressor and several 25-HP supplemental machines throughout the plant, often struggling to meet the system’s pressure demands. When the main machine was down, the smaller machines were all pressed into service but fell far short of keeping up with demand. When pressure dipped too low, they lost the six sheeting lines that process $6,000 worth of product per hour.

The Polymer Industries team had to add oil to the older compressor and struggled to get replacement parts. Plus, an expansion was being planned. “We were losing a fair amount of oil into the system,” Tyler said. “We were putting oil in that machine at least once every two weeks.”

The Solution

Polymer Industries relied on its decades-long partnership with Air & Hydraulic Equipment, an independent distributor of fluid power products in nearby Chattanooga. Polymer Industries purchased two 25-HP Kaishan KRSD direct-drive rotary screw air compressors (one of which was sent to its Tacoma, WA facility) and then acquired two 100-HP KRSDs, one of which was equipped with a variable-speed drive. A recent purchase, a 50-HP KRSD unit, completed the lineup.

The Results

- KEEPING THE PRESSURE ON!

The new compressors easily increased system pressure from 105 PSIG to 115 PSIG, meeting the needs of all applications. And maintaining that pressure consistently. As a result, air usage increased, as did the functionality of the equipment that relied on it. - THEN TAKING THE PRESSURE OFF!

Tyler appreciates how self-sufficient the Kaishan KRSDs are. “Day to day, I don’t have to mess with it,’ he said. “It just runs, and we don’t have to pay much attention to it. We do our thing, leave it alone. It keeps chugging along. - QUALITY YOU CAN BANK ON

The 100-HP KRSDs are both equipped with 900-CFM Mikropor dryers, and the company has none of the previous problems with oil use and water. The compressors are configured in a loop system, with the main 100-HP fixed-speed unit functioning as the lead compressor and the 100-HP VSD serving as a trim unit. The smaller units provide extra support as needed in the back of the shop.

The KRSDs are “as good a piece of equipment as I’ve used,” Tyler said. - A PARTNERSHIP YOU CAN’T BEAT

Polymer Industries has found a true partner in Air & Hydraulic Equipment. “I have to beat people off with a stick, trying to get our business,” Tyler said. “Nobody is gonna put them out of business for us.”

"It just runs, and we don’t have to pay much attention to it. We do our thing, leave it alone. It keeps chugging along."

— Tyler Knight, Maintenance Manager, Polymer Industries

More case studies:

Random stat or

customer quote

textXXtext

text