Industrial Vacuum Pumps Prove Their Value in Woodworking

June 5, 2024

Ways to Measure Air Compressor Performance and Know if You Need an Audit

June 19, 2024Why and How Winemakers Are Using Industrial Air Compressors

Kaishan USA | June 12, 2024 | Uncategorized

Part art and part science, winemaking is growing in the U.S, with 11,691 wineries, and counting.

Winemaking is big business in the U.S., with a market size estimated at $81.33 billion in 2023. And it’s growing. The U.S. Wine Market Insights study conducted by Skyquest projects a 6.80% combined annual growth rate through 2031 for a market size of $122.96 billion.

The U.S. now has 11,691 wineries, growing 4% yearly since 2010, according to Wine Business Monthly. The U.S. Bureau of Labor Statistics says nearly 64,000 people work in U.S. wineries, while the U.S. lobbying group Wine America estimates the total economic impact of U.S. winemaking at $276 billion with more than 1 million people employed.

A Major User of Compressed Air

Wineries are large-scale users of compressed air, applying it in a wide range of applications, from pressing and crushing grapes to palletizing and packaging:

-

- It controls the temperature range for fermentation.

- It powers the bladder presses used in pressing and crushing grapes.

- It drives transfer pumps, palletizing and hand tools.

- It allows the wine to breathe and creates the softness winemakers want, with low-pressure blowers adding oxygen during the aeration process.

Sparging, packaging and labeling are some of the most intensive uses of compressed air in wineries.

Most Intensive Use: Packaging

Winemaking’s most intensive use of air compressors, however, is in the packaging of the final product, including the following:

-

- Sparging. Because wines oxidize quickly during bottling, winemakers use compressed air to create tiny bubbles of nitrogen that remove any remaining oxygen from the wine. (See “Generating Your Own Nitrogen” below).

- Transporting. Moving the wine from holding tanks to barrels or bottles requires a lot of compressed air power.

- Bottling. Vintners apply another round of nitrogen to drive out any oxygen remaining in the bottles before the wine is added, thus improving the freshness of the final product. Compressed air drives the entire bottling process and also helps produce the nitrogen (See “Generating Your Own Nitrogen” below). In addition, compressed air also is used in making the bottles, blowing the glass into the distinctive wine-bottle shape.

- Labeling. Compressed air powers the equipment that attaches the labels on the bottles.

Vintners safeguard their products by introducing another round of nitrogen to drive out any oxygen remaining in the bottles before the wine is added.

In a related use, compressed air plays a critical role in making the final packaging—the bottles that eventually hold the wine as it’s delivered to wine fanciers around the world. Find out more about our role in making glass manufacturing more efficient and productive.

Generating Your Own Nitrogen

Some winemakers are choosing to develop their own nitrogen-generating capabilities to avoid the uncertainties of relying on outside vendors.

As mentioned, winemakers use nitrogen to remove oxygen during sparging and bottling.

While many companies have nitrogen brought in by a supplier, some have chosen to develop their own nitrogen-generating capacity, using compressed air to power that equipment.

In-house nitrogen-generating equipment helps winemakers in several ways:

-

- Supply-chain issues. Avoid the uncertainties of supply and delivery by developing your own nitrogen-making capabilities. The practice took a giant leap forward during the COVID-19 pandemic, as vintners found themselves without the needed materials because of supply chain issues.

- Cost. After an initial investment, the ROI is very attractive. You save as much as 80% of your nitrogen costs with a two-year payback.

- Space savings. If you’re making your own supply, you’ll need to store less nitrogen than you would if you were having it delivered.

Storing the nitrogen you’ll need takes a lot of space. That’s why so many winemakers have decided to make their own nitrogen.

-

- Quality. There’s no need to pay for purity you don’t need. By developing nitrogen-generating capacity, you can set the level of purity you need for your specific tasks.

- Safety. Avoid the risks associated with handling and storing high-pressure cylinders.

- Sustainability. Generating your own nitrogen has less environmental impact than traditional tank delivery and storage. It’s an energy-saving solution that reduces waste.

- Steady supply. Stop worrying about shipping delays, bad weather, delivery problems, storage or safety.

- Logistics. There’s no need to monitor inventory or schedule deliveries. Or find a second source if your primary supplier experiences problems.

Having your own generating capacity may mean you don’t have to worry about bad weather, delays or supply chain issues disrupting your nitrogen supply.

You’ll find more on generating your own nitrogen in our blog post on laser cutting, “How Industrial Air Compressors Improve Laser Cutting Performance.”

Both compressed air systems and nitrogen-generating capabilities work best with an industrial air compressor closely matched to a specific need. That’s why selecting the right compressor for your application is so important.

Choosing the Right Industrial Air Compressor

There are many different types of industrial air compressors, but most manufacturers find rotary screw air compressors are the best choice because of their reliability, efficiency and long life.

Rotary screw air compressors are known for producing steady streams of high-quality compressed air and handling large-capacity loads. And they are backed by the industry’s best warranties.

Oil-Lubricated Rotary Screw Air Compressors

In applications without any direct contact with the products, you can use oil-lubricating equipment under the following conditions:

-

- Filter aggressively. You can get oil down to negligible amounts with good filtration. Using a one-micron coalescing filter, an oil-lubricated rotary screw compressor can produce air with an oil content of less than one part per million. You can also add catalytic converters for even more advanced filtration.

- Use food-grade lubricants. It’s always a best practice to follow U.S. FDA regulations and use food-grade oils in your oil-lubricated air compressors in areas like packaging with incidental product contact. But remember, you will need to change the oil more often. Most manufacturers recommend changing food-grade lubricants at 4,000 hours (compared to 8,000-hour intervals for regular oils).

You’ll want to work closely with your independent Kaishan distributor to design a maintenance program. As always, poor maintenance will result in premature wear and will often void warranties.

Kaishan has several different oil-lubricated models that are used in food processing plants and wineries, including our KRSD single-stage direct drive rotary screw air compressor and our KRSP2 premium rotary screw air compressor.

Once again, that’s in non-contact areas. Where you have air that comes in direct contact with food and beverage products, oil-free air is the way to go. For applications such as wineries, our new KROF oil-free compressor provides the pure, high-quality air you need.

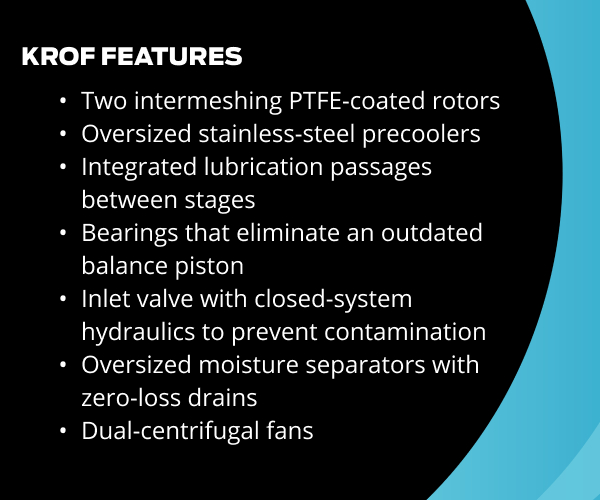

Kaishan KROF: Changing the Rules of the Oil-Free Game

Kaishan’s new oil-free compressor, the KROF, sets new standards for reliability, efficiency and warranty protection, producing ISO 8573-1, Class 0 oil-free compressed air that safeguards the integrity of the wine. It is available in 100-, 125- and 150-PSIG models with integrated air or water cooling.

The KROF has robust features that make it the best choice for demanding oil-free operation in a winery:

-

- Two intermeshing PTFE-coated rotors machined to micron precision.

- Oversized stainless-steel precoolers on each stage that lower temperatures for both intercoolers and aftercoolers.

- Integrated lubrication passages between stages to ensure proper lubrication and reduce leak points, service requirements and lifetime costs.

- Bearings that eliminate the need for an outdated balance piston and require no maintenance to achieve proper thrust loading.

- An inlet valve featuring closed-system hydraulics to guarantee sealing and prevent contamination.

- Oversized moisture separators equipped with reliable, zero-loss drains that prevent moisture from passing between stages and handle contamination better than traditional, orifice-style drains.

- A dual-centrifugal fan to reduce noise.

With precise engineering and high-quality output, the KROF rotary screw air compressor is a reliable workhorse you can count on to drive productivity for the long haul.

Best of all, it is the only oil-free compressor designed and engineered in the U.S. for a global market. And it is manufactured at our state-of-the-art, 65,000-square-foot plant in Loxley, AL (currently being expanded to 130,000 square feet).

Industry-Leading Warranty

Because of its built-in Kaishan reliability and longevity, Kaishan backs the KROF with an industry-leading five-year warranty on major components, including the airend.

Kaishan’s new KROF two-stage oil-free compressor is an excellent choice when you need uncontaminated, highly efficient, reliable air.

With the increasing emphasis on sustainability and carbon neutrality in many industries, you’ll want to consider the lifetime carbon footprint when purchasing an oil-free air compressor. If your organization is trying to go green, the KROF can help you achieve your goals.

Working with a compressed air professional is a great way to ensure you get the right air compressor for your winery.

Local Help

Getting the right air compressor can have a significant impact on the reliability of your compressed air system and the productivity of your winemaking operation.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed and help you determine the best way to meet your compressed air needs. These factory-trained air compression experts can also service your air compressor system and help you keep it running efficiently and reliably.

Key Takeaways

-

- Winemaking was an $81.33 billion market in 2023 and is expected to grow to $122.96 billion by 2031.

- Wineries are large-scale users of compressed air, applying it in a wide range of applications.

- The most intensive use of compressed air is in sparging, transporting, bottling and labeling.

- While many companies buy from suppliers, some develop their own nitrogen-generating capacity.

- There are many different types of industrial air compressors, but most vintners find rotary screw air compressors are the best choice because of their reliability, efficiency and long life.

- Kaishan’s new oil-free compressor, the KROF, sets new standards for reliability, efficiency and warranty protection.

Let Us Help

Selecting the right air compressor is critical to successfully operating your compressed air system and all the processes that rely on that system. If you need help finding the right compressor for your winery, get in touch with the experts at Kaishan. Contact us today.