Ten Key Facts You Need to Know About Rotary Screw Air Compressor Motors

April 23, 2025

The Role Rotary Screw Air Compressors Play in a Disaster

May 7, 2025Your Rotary Screw Compressor Airend: Where the Magic Happens

Kaishan USA | April 30, 2025| Uncategorized

Manufacturing the airend of a rotary screw air compressor is a process we take very seriously at Kaishan USA.

The airend is the secret sauce of any rotary screw air compressor. Where the advanced science of thermodynamics meets the exotic art of product development.

It combines with a similarly proprietary air inlet valve to create the crown jewels of each manufacturer’s rotary screw air compressor design.

It is the guts of the machine. Where a rotary screw machine does the main work of pressurizing the air.

Air comes in at atmospheric pressure, and it leaves compressed, ready for final treatment before being distributed to your end-use applications.

The airend’s efficiency and integrity directly affect the performance of the compressor. The more efficient the airend, the more efficient the compressor, with the most efficient airend producing more air and using less energy. The design engineer’s goal: to get the most air flow with the least amount of energy.

The specific power measures efficiency, the amount of energy required to produce a cubic meter of air per minute. To learn how to identify the specific power for any new compressor, read our blog post, “A Beginner’s Guide to Reading Rotary Screw Compressor Performance Curves.”

So how does an airend do all that? Let’s take a look at how an airend functions in your compressor.

How It Works

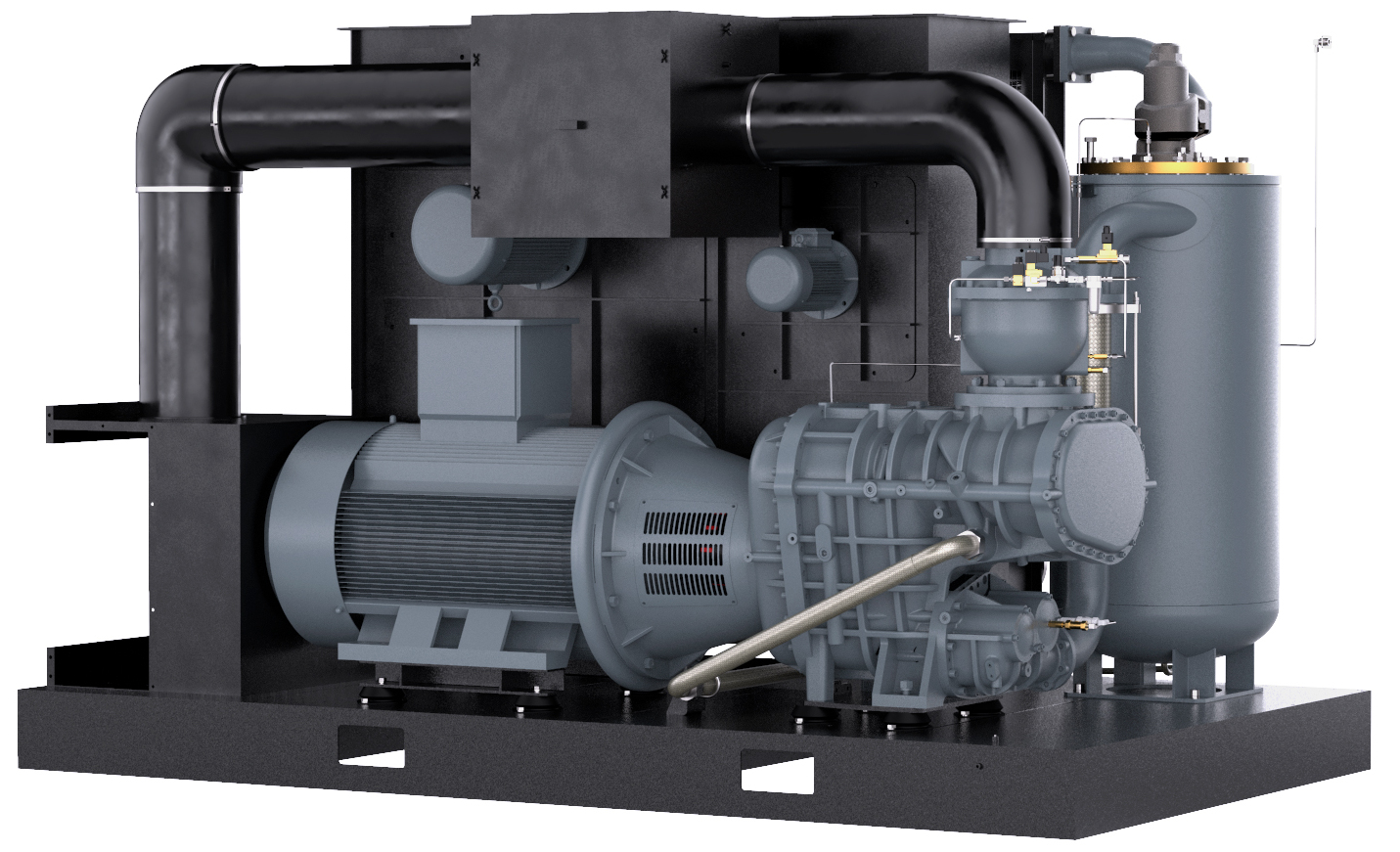

As the air enters a compression chamber, the two interlocking helical rotors or screws turn in opposite directions, trapping the air and reducing the space between the rotors and casing, compressing the air.

The rotors are powered by an electric motor directly or via a belt drive. To learn more about the motors used in rotary screw air compressors, see our blog post, “Ten Key Facts You Need to Know About Rotary Screw Air Compressor Motors.”

How It’s Made

Kaishan is one of the largest compressor manufacturers in the world. We have our own foundry, and we procure our own metal, thus avoiding the price shocks and supply chain issues other manufacturers must deal with.

Rotors

We cut our own rotors in our 65,000-square-foot (soon to be 130,000) state-of-the-art facility in Loxley, AL. Advanced CNC equipment machines them within extremely tight tolerances.

We do our own tooling and do extensive quality checks. We even test the completed airend after assembly to verify that it meets our exacting specifications.

The rotors never touch and don’t wear, so they last a long time, creating long-term reliability that has become one of the hallmarks of rotary screw compressors. The motor typically drives the male rotor, which drives the female rotor.

The male rotor has four lobes, and the female has six matching flutes or grooves, a 1:1.5 ratio that makes the magic of compression happen.

Stators

The rotors are encased in a stator (or housing), which is cast individually for each product category and size.

Bearings

We use premium SKF stack bearings to absorb axial and radial loads from the spinning rotors:

- Axial bearings. As they compress the air, the rotors encounter resistance that pushes them away from the discharge face, and they tend to “climb” each other because of their helix shape. That creates axial loads. Loading and unloading also create axial force.

- Radial bearings. As the rotors turn, they push away from each other as the air pressure builds, creating radial forces.

Poorly fitting bearings will deteriorate rapidly and ultimately leak, degrading the performance of the airend.

Two-Stage Compressors

A compressor can also have several stages. A single-stage compressor like Kaishan’s KRSP premium rotary screw air compressor is one of the most cost-effective compressors on the market.

Kaishan’s KRSP single-stage rotary screw air compressors are among the most cost-effective options on the market.

However, a two-stage compressor like Kaishan’s KRSP2 premium rotary screw air compressor splits the compressor’s workload into a second stage, building on the pressure generated in the first stage.

As a result, the KRSP2 generates up to 15 to 20% more flow than a single-stage compressor of the same size or horsepower. Payback on energy costs alone may be less than two to three years. Two-stage compressors, however, cannot be used in applications with a discharge pressure that is too low (under 50 PSIG for an oil-flooded compressor or under 80 PSIG for an oil-free unit). Oil carryover can result in oil-flooded compressors at lower discharge pressures.

Both Kaishan’s KRSP and KRSP2 premium rotary screw air compressors are backed by a lifetime warranty on the airend. We’ll discuss more about this topic in a moment.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

For more on the benefits of two-stage compressors, read our blog post, “Five Critical Differences Between a Single-Stage and a Two-Stage Air Compressor.”

The spinning of the rotors generates heat that must be removed. An oil-lubricated rotary screw air compressor uses oil to help cool the airend.

The Role of Oil

Oil-lubricated compressors inject oil into the compression chamber that adds a coating to the rotors and does the following critical tasks:

- Cooling. It removes the heat of compression and lowers the operating temperature. Thus, oil-lubricated compressors can handle hotter environments and operate more efficiently (and cooler).

- Removing impurities. Oil removes contaminants and protects your unit’s components from oxidation and corrosion.

- Sealing. It acts as a sealant between the male and female rotors, making the compressor more efficient.

- Prolonging compressor life. Oil reduces friction and wear and lubricates components, thus lengthening a compressor’s service life.

Oil is so critical we often say it is the lifeblood of an oil-lubricated compressor. For more on the part it plays, read our blog post, “Four Key Steps to Extend the Lifespan of Your Rotary Screw Compressor with Proper Lubrication.”

Oil-Free Airends

On the other hand, oil-free machines, like our KROF two-stage, oil-free, rotary screw air compressor, do not inject oil into the airend. This technology is used in sensitive applications where the purity of the air is especially paramount—such as food processing, semiconductors and electronics—to avoid introducing oil to the pressurized air flow.

The airends on our KROF two-stage, oil-free, rotary screw air compressor have special adaptations to accommodate oil-free operation:

- Micron precision. We carefully machine the rotors of our KROF to micron precision to keep the working gap—the space the oil seals between the rotors in an oil-flooded machine—as small as possible. Yet, the rotors still must spin without touching.

- Special seals. We have created seals inside the airend to keep oil out of the compression chamber.

- Coating. The rotors have a special coating to protect them and reduce the clearance between them, making the working gap as small as possible. The coating also seals the rotors, prevents friction and reduces corrosion and wear.

The rotors of Kaishan’s KROF two-stage, oil-free, rotary screw air compressor are machined to micron precision and are specially coated.

Oil-free machines need extra cooling because they do not use oil to cool the airend. As a result, our KROF oil-free machine has oversized stainless-steel precoolers on each stage that lower temperatures for both intercoolers and aftercoolers.

Maintenance Is Crucial

Regular maintenance plays a critical role in the longevity of oil-free and oil-flooded rotary screw air compressors. A clogged or dirty air filter, for example, will cause extra pressure drop, making the machine work harder and less efficiently. For a comprehensive air compressor maintenance checklist, download our white paper, “Air Compressor Maintenance: Ultimate Guide and Checklist.”

The airend is not only a critical part of your compressor but also one of the more expensive components of a rotary screw air compressor. That’s why warranties on the airend are so important.

Unmatched Lifetime Airend Warranty

Because of their reliability, efficiency and long life, rotary screw air compressors generally have better warranties than other types of compressors. We go even further, however.

Because we have such tight, vertically integrated control of the manufacturing process, we offer the best airend warranty in the industry:

Our standard warranties cover the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with a 24-month airend warranty.

Our extended warranties (provided at no additional cost) offer a lifetime warranty on the airend for our Kaishan’s KRSP and KRSP2 screw compressors.

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

It’s part of an overall strategy that allows Kaishan USA to offer industry-leading warranty protection.

For more information on warranty protection, read our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

The complexity and sophistication of today’s rotary screw air compressors make working with a compressed air professional a critical step. The right consultant can help you maintain your warranty and maximize your compressor's efficiency and service life. Fortunately, help is close at hand.

Local Compressed Air Professionals

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

We partner with independent, local distributors because we know no better way to serve you. There's none of the red tape you find with large corporate operations; our distributors are local partners who care about your business and seeing it succeed.

They can provide expert guidance, faster response times and personalized support tailored to your needs. They’re not just selling you a compressor. They’re building a relationship, ensuring you get the right system, reliable service and quick access to parts when you need them most.

Their factory-trained technicians have a deep understanding of industrial applications and can help you maximize efficiency and minimize downtime.

Key Takeaways

- The airend is where a rotary screw air compressor does the main work of pressurizing the air.

- Two interlocking helical rotors turn in opposite directions in a compression chamber, trapping and compressing the air.

- The rotors of a rotary screw compressor never touch and don’t wear, so they last a long time.

- A two-stage compressor generates up to 15 to 20% more flow than a single-stage compressor of the same size.

- Oil-lubricated compressors inject oil into the compression chamber to cool and seal the compressor, removing impurities and prolonging compressor life.

- Oil-free rotary screw compressors need more cooling than oil-lubricating compressors.

- Kaishan offers the best airend warranties in the industry.

Let Us Help

The airend is critical to the operation of rotary screw air compressors and all the processes that rely on that system. If you need help understanding how to select the right compressor for your application, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Understanding the Airend

Welcome back to the Big Dog podcast, gang! Appreciate the love, as always.Alright, so picture this, Lisa. I’m standing in Kaishan’s facility down in Loxley, Alabama. We’re talking 65,000 square feet of pure precision. Machines humming, these huge rotors being cut down to a level of accuracy that, honestly, I didn’t even think was possible till I saw it myself.

Wait, like, how accurate are we talking?

Microns. We’re talking microns. It’s so precise that even a hair-width difference could throw the entire thing off. That’s how much care goes into making these airends work perfectly.

And the airend is, what… the main part of the compressor that actually pressurizes the air, right?

Exactly. It’s where the magic happens. Air comes into the chamber, and the interlocking rotors—the male and female ones—start spinning in opposite directions. That traps the air, reduces its space, and pressurizes it.

Ah, so the rotors are what really drive everything.

Yeah, yeah, they do. And here’s the crazy thing—they never touch. They’re so precisely machined and aligned that they spin super close to each other without making contact.

That... sounds ridiculously complicated to manufacture. Like, how do they even keep everything in line? The rotors, the bearings, all of it.

It’s all about control, Lisa. That’s why Kaishan does everything in-house. From cutting their own rotors to casting the housing—what they call the stator—right down to using premium SKF bearings to handle all the loads those rotors create. It means there's no guessing; nothing’s left to chance.

So, by keeping it in-house, they get to avoid all the supply chain drama and ensure top-notch quality from start to finish.

Exactly. That’s why they’re known for reliability. I mean, think about it—most compressors fail because of some weak link, right? But Kaishan’s got it locked down. They even test the complete airend after assembly to make sure it’s up to spec.

Okay, so with the air pressurizing and all the components moving smoothly, that’s how you get the efficiency, right?

Right. The efficiency of the airend directly affects the entire compressor's performance. The better it’s built, the more air it pumps out using less energy. That’s the whole design engineer’s goal here—getting maximum airflow without wasting power.

Makes sense. And if it’s not built to those tolerances...

Then you’re looking at wear and tear, inefficiency, leaks—the whole machine starts going downhill. That’s why this part of the compressor—the airend—is not just critical, it’s everything.

Efficiency and Design Innovations

So, Jason, you were talking about efficiency being a key design goal. That’s got me wondering—how does that efficiency change when we’re talking about single-stage versus two-stage compressors? What’s the practical difference in performance?Oh, it’s huge. Single-stage compressors, like the Kaishan KRSP, they’re great for, you know, general-purpose applications. But when you step up to a two-stage model, like the KRSP2? That’s a whole different ballgame.

Okay, I’m guessing we’re talking better efficiency?

Not just better—like night and day better. Think about this: the two-stage compressor splits the workload. The first stage compresses the air partway, then hands it off to the second stage to finish the job. What that does is reduce the energy needed to get the same pressure. We’re talking 15 to 20% more airflow for the same size or horsepower.

Wow, so you’re getting more work done with less energy. That’s a no-brainer for anyone trying to cut costs.

Exactly. And over time, the savings on energy alone can pay off the upgrade in, what, two or three years? It’s a smart move, especially for places running their compressors 24/7.

Actually, that reminds me of a plant manager I spoke with a few months ago. They were running on older single-stage compressors—getting by, but not much more than that. So, they decided to upgrade to the KRSP2.

Yeah? How’d that work out?

Game-changer. They told me their energy costs dropped dramatically, like, within the first month. Plus, they saw a big jump in overall output. Apparently, they were able to meet demand spikes without having to run additional compressors. And here’s the kicker—it all started because they calculated the specific power, like you talked about earlier. It showed them the inefficiencies in their old setup.

Classic case of, “you don’t know what you don’t know.” Honestly, it pays to get those numbers. Specific power is the metric—it tells you how much energy you’re burning to make that airflow. Lower numbers mean you’re running more efficiently.

Right, and two-stage compressors, by design, are just better at keeping those numbers low. But are there limits to where they can be used?

Yeah, there are. Two-stage models need a certain discharge pressure to operate efficiently. Too low, and you’re not going to get the full benefit. That’s why it’s important to know your application inside out before upgrading. Get the wrong system, and even the best compressor can struggle.

Fair point—and it’s why these conversations matter, right? People need to know what options are available and what works best for their needs.

Absolutely. And honestly, the innovation in these designs doesn’t stop at energy efficiency. It’s also about long-term reliability. A two-stage compressor isn’t just about saving energy—it’s built to last. Less wear, better cooling—it’s the full package.

Maintenance and Support Systems

We’ve covered how design innovation boosts efficiency and reliability, but there’s another key piece to the puzzle—maintenance. Jason, what’s your take on how critical regular maintenance really is?Oh, it’s make-or-break. You can have the best compressor in the world, but if you’re not maintaining it, you’re just asking for trouble. I mean, even something as simple as a dirty air filter can mess up efficiency and put extra strain on the system.

Exactly. It’s like running a marathon in sneakers with holes in them—you’re just making everything harder than it needs to be. The thing is, maintenance doesn’t just improve performance; it extends the lifespan of these machines, saving you big bucks down the line.

Totally. And that’s where Kaishan shines. Their warranties back it up too. I mean, a lifetime warranty on the airend? That’s pretty much unheard of in this industry.

Yeah, that’s a huge deal. They put a lot of trust in their products. But I think what really sets them apart is how they work with their independent distributors. It's not just about selling compressors—it’s about giving operators and plant managers the local, specialized support they actually need.

Exactly. Those distributors are like an extension of the company. They’re factory-trained, they know the tech inside out, and they’re right there when you need them. None of that corporate red tape slowing things down—it’s all about keeping operations smooth and efficient.

And that kind of support is invaluable, especially since people rely on these systems to keep their processes running 24/7. But okay, let’s shift gears a bit. Oil-free versus oil-lubricated compressors—it’s a debate that always comes up. Where do you land on this?

It’s not a one-size-fits-all answer. Oil-lubricated compressors are workhorses. They handle hotter environments better, they’re super efficient, and with proper lubrication, they just last longer.

True, but oil-free compressors have their place too, especially in industries like food processing or semiconductors where air purity is non-negotiable. No one wants a trace of oil in those environments—it’s just not an option.

Totally. But here’s the thing—oil-free compressors need extra cooling systems, and they can be more expensive to maintain, you know? You’ve gotta weigh the upfront cost against the specific needs of your application.

Right, it really comes down to understanding what your operation requires. And that’s where those distributors we talked about come in clutch. They help figure out what works best for each situation, so you don’t end up overpaying—or under-prepared.

Couldn’t agree more. Whether it’s maintenance, choosing the right compressor, or working with the right distributor network, it’s all about taking the guesswork out of the equation.

And that’s why conversations like this are so important. There’s a lot to unpack when it comes to compressed air systems, but the goal is always the same—reliability, efficiency, and keeping things running smoothly.

Absolutely. And on that note, that’s gonna wrap it up for today. Thanks for listening, and we’ll see you next time.

Random stat or

customer quote

textXXtext

text