Swaggerty’s Farm

June 23, 2025

What’s the Difference Between Full Load and Duty Cycle? And Why Should You Care?

July 2, 2025What Are Compression Ratios and What Do They Tell Us About Compressor Performance?

Kaishan USA | June 25, 2025 | Uncategorized

Understanding the significance of compression ratios allowed our customer, Progressive Foundry of Perry, IA, to save $23,000 in electricity costs annually through the use of two KRSP2 premium rotary screw air compressors.

Not every compressed air user understands compression ratios. But that information can be crucial in selecting and operating a compressor.

The compression ratio compares the discharge pressure of your compressor to the pressure of the incoming (atmospheric) air. The higher the ratio, the more work is being done and, most likely, a higher pressure is generated.

For example, if a compressor is operating in Denver, CO, where the atmospheric pressure is lower, it'll require more horsepower to generate the desired discharge pressure compared to a compressor operating at sea level.

Most of the time, generating a lot of pressure is a good thing. But you can have too much of a good thing. Remember, for every 2 PSI increase in pressure, the compressor will consume 1% more power (HP).

A metal press may need compressed air at 100-PSIG levels, which will require the system’s air compressor to operate at a higher compression ratio than it normally would.

There are some other drawbacks at higher compression ratios. The most critical is that compressing air creates a lot of heat, so the higher the compression ratio, the more heat the compressor generates.

There are many applications in use today that require air pressures in the 90-PSIG (or higher) range, including:

- Pneumatics, like nail guns or tire inflators

- Tool and die machines

- Injection molding equipment

- Impact wrenches in auto body shops

- Heavy-duty machinery like presses and other large pieces of industrial equipment

- Robotic arms

- Cutting tools and routers

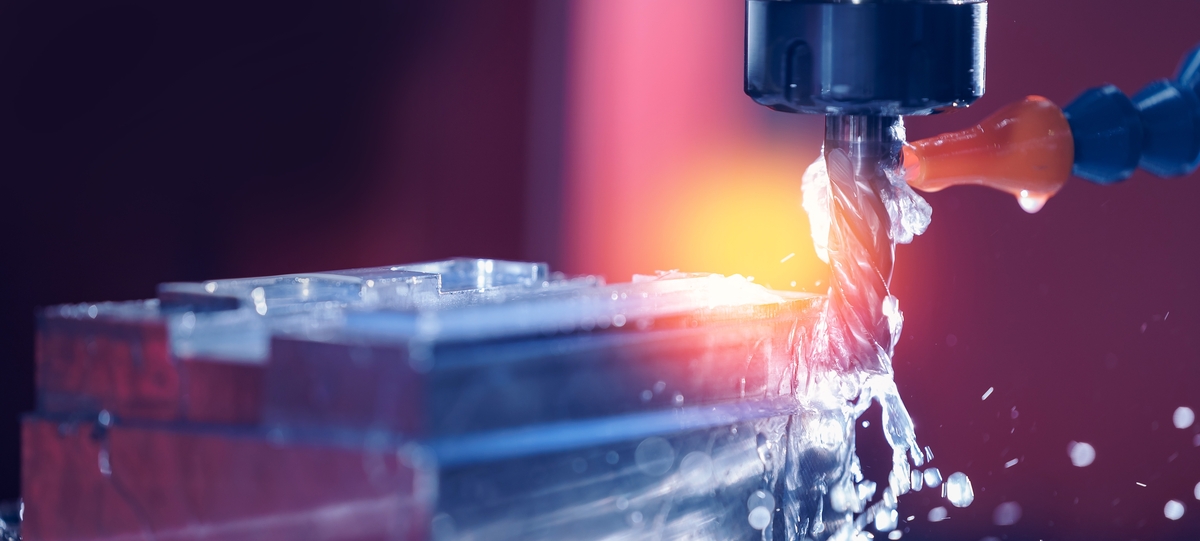

Metalworking equipment, such as CNC and tool-and-die machines, requires air pressure in the standard range.

One way to generate that pressure level while controlling the temperature increase is to break up the compression process into two or more stages.

Two-Stage Compressors

Two-stage rotary screw compressors create compressed air without overheating. They are used in all type of compressors and are especially common in rotary screw compressors.

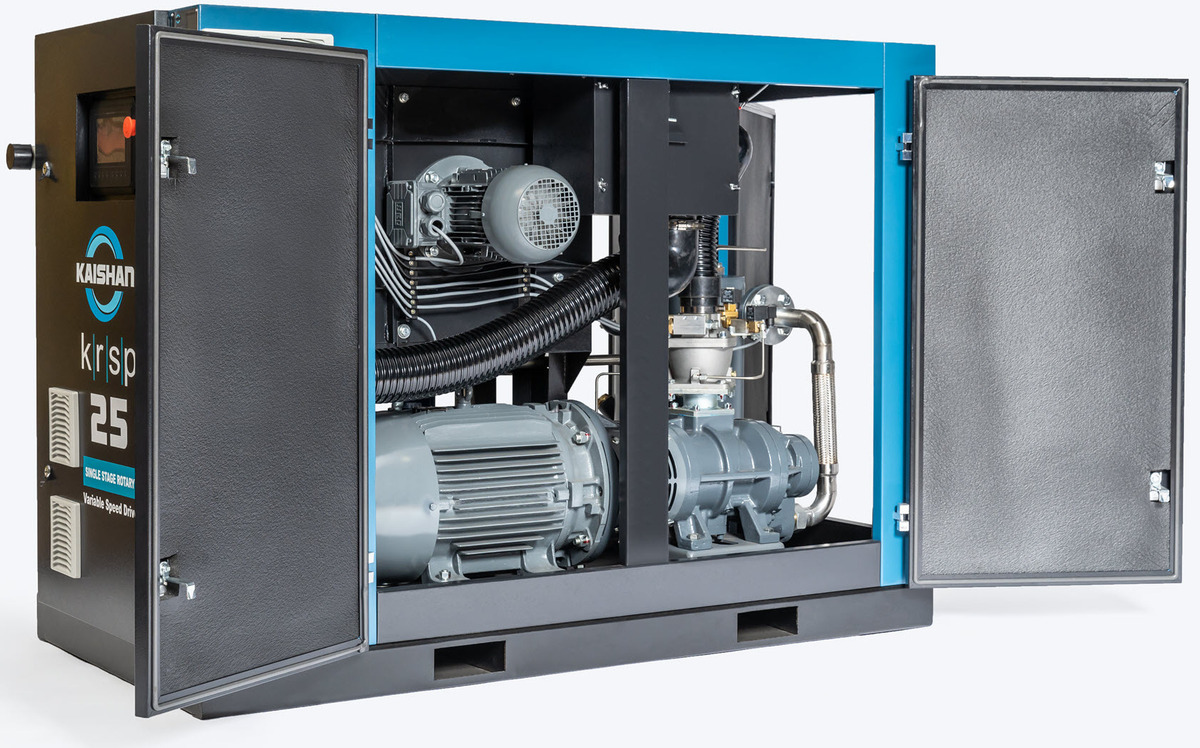

A single-stage compressor like Kaishan’s KRSP premium rotary screw air compressor generates a compression ratio of 7.8 to 1 to create 100 PSIG of pressure. It is one of the most cost-effective compressors on the market, and Kaishan backs it with an industry-leading lifetime airend warranty.

Kaishan’s KRSP single-stage rotary screw air compressors are among the most cost-effective options on the market.

But, as mentioned, a two-stage unit such as our KRSP2 premium rotary screw air compressor splits the workload into two separate stages:

- The first stage generates a compression ratio of 2.8 to 1.

- A second stage also compresses to that 2.8 to 1 ratio.

In addition, before the second stage, the air passes through an interstage cooling step, removing some of the heat of compression and improving efficiency.

By building on the pressure achieved in the first stage, the KRSP2 delivers more compressed air for less energy—up to 15 to 20% more flow than a single-stage compressor of the same size (HP). Paybacks on energy costs alone may be less than two to three years.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

Equipping your KRSP2 with a variable-speed drive can add even more efficiency at partial loads. For more on the advantages of variable speed drives, see our blog post, “How Variable Speed Drive Rotary Screw Air Compressors Save You Money.”

The VSD-equipped KRSP2 is so efficient, in fact, that one of our customers, Carlisle Construction Materials of Carlisle, PA, earned an $11,000 rebate from its utility company.

Our VSD version of the KRSP2 is one of the only two-stage units available in sizes as low as 30 HP.

In addition to energy efficiency, two-stage units offer several other benefits:

Reliability and Long Life

Because the KRSP2 spreads the work over two stages, there’s less mechanical stress and less heat, reducing wear and tear and extending the life of components.

A great example is the KRSP's bearings. Because there are four discharge bearings on the first stage and three on the second stage, they experience less stress than the two bearings that carry the entire thrust load in a typical single-stage unit.

So, with lower forces and more bearings, the KRSP2 is built to last, enabling us to offer an industry-leading lifetime airend warranty.

An industry-leading lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

A Smaller Size

Because a two-stage compressor generates more compressed air flow than a comparable single-stage unit, you may be able to use a smaller model. For example, you may be able to replace a 300-HP single-stage compressor with a 250-HP two-stage KRSP2. That could allow you to cut the initial cost gap to 15 to 20%. Carlisle Construction Materials, mentioned previously, found that our two-stage KRSP2 could produce significantly more CFM than a competitor’s single-stage machine of the same size. You can read their account on the Carlisle Construction Materials page on our website.

Lower Operating Cost

Because of the reduced electricity costs, lower lifetime maintenance requirements and fewer part replacements, operating costs for a two-stage compressor are lower than for a single-stage unit. Those benefits last for years or even decades, quickly paying back the higher initial cost.

Acquisition costs, after all, amount to only 12% of a compressor’s total cost of ownership, according to the U.S. Department of Energy. You pay the initial cost one time. You’ll be paying the power and maintenance costs for the life of the compressor.

When to Use a Two-Stage Rotary Screw Air Compressor

Because of the initial cost, we find that two-stage air compressors are most attractive in the following situations:

- As a base-load compressor in a two- or three-compressor configuration, running at 100% full-load capacity. For more on increasing reliability and energy efficiency with a three-compressor system, view our blog post, “Everything You Need to Know About Sizing Industrial Air Compressors for Manufacturing.”

- Mass production applications where reliability is critical, such as general manufacturing, automotive, aerospace, food and beverage and glass manufacturing.

Two-stage compressors, such as Kaishan’s KRSP2, are ideal for applications like glass manufacturing, where reliability and energy efficiency are crucial.

- Companies looking for an environmentally friendly unit with high energy efficiency and long lifespan.

In fact, by manufacturing two-stage air compressors as small as 30 HP, Kaishan is making these units cost-effective for a much larger universe of industrial users.

For more on the benefits of two-stage compressors, read our blog post, “Five Critical Differences Between a Single-Stage and a Two-Stage Air Compressor.”

Local Help in Outlining Your Compressed Air Choices

Deciding whether a two-stage compressor is a worthwhile investment for your company can be crucial. We strongly recommend you work with your local compressed air professional to weigh your options.

We partner with a nationwide network of independent distributors, who can help you understand the impact of compression ratios and two-stage compressors and generally provide on-site help and consultation as needed.

Working with these factory-trained air compression experts is the best way to serve you. They can offer expert guidance, faster response times and personalized support tailored to your needs. They are not just selling compressors but building relationships, ensuring you get the right system, reliable service and quick access to parts when you need them.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- The compression ratio compares the discharge pressure of your compressor to the pressure of the incoming (atmospheric) air.

- A two-stage air compressor generates up to 15 to 20% more flow than a single-stage compressor of the same size (HP).

- Two-stage compressors offer several benefits, including energy efficiency, reliability and lower operating costs.

- Because a two-stage air compressor generates more flow than a single-stage compressor of the same size (HP), you may be able to downsize to a smaller size.

- A two-stage compressor is an attractive alternative as a base-load compressor or in applications where reliability or energy efficiency are critical.

Let Us Help

Understanding compression ratios and the energy dynamics of your compressed air system allows you to make solid selections when choosing a new unit. And it even helps you understand the importance of removing the heat of compression and otherwise maintaining your compressed air system.

If you need help understanding the importance of pressure, heat and maintenance, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Understanding Compression Ratios

Alright, welcome back to The Big Dog Podcast. I’m Jason Reed, here with Lisa Saunders, and today we’re getting into the nitty gritty—compression ratios. I know, it sounds like one of those things you only care about if you’re an engineer, but trust me, it matters for everyone running compressed air on the floor.Yeah, and honestly, I used to think compression ratio was just a fancy way to say “how much pressure you’re getting out of your compressor.” But it’s actually about comparing the discharge pressure to the atmospheric pressure coming in, right?

Exactly. So, if you’re at sea level, you’ve got more atmospheric pressure to work with. But if you’re up in Denver, for example, you gotta work your compressor harder to get the same output. That’s your compression ratio in action. And the higher that ratio, the more work your compressor’s doing—and the more power you’re burning through.

And that’s where efficiency comes in. I read that for every 2 PSI you bump up your pressure, you’re using about 1% more power. That adds up fast, especially if you’re running multiple shifts or big equipment.

Oh, for sure. I mean, back at my old shop, we thought, “Hey, let’s just crank up the pressure, get a little more punch for the tools.” Didn’t realize we were basically lighting money on fire. Our power bill shot up, and it took us way too long to figure out it was just those extra few PSI. It’s one of those lessons you only learn the hard way, I guess.

Yeah, and it’s not just about the bill, right? If you’re running at higher pressures than you need, you’re also putting more stress on your system. So, it’s not just efficiency, it’s about keeping your equipment alive longer.

Managing Heat and Boosting Efficiency

So, let’s talk about heat. Because the higher your compression ratio, the more heat you’re generating. And that’s a big deal for how long your compressor’s gonna last.Yeah, heat’s the silent killer. You don’t always see it, but it’s there, wearing out your bearings, breaking down your oil, just making everything work harder. That’s why multi-stage compression is such a game changer. Instead of doing all the work in one go, you split it up—like with Kaishan’s KRSP2. You compress a bit, cool it down, then compress again. That interstage cooling step? It’s huge for cutting down on heat and wasted energy.

I actually talked to a plant manager last month who switched to a KRSP2. He said before, they were always fighting cooling issues—shutdowns, alarms, you name it. After the switch, way fewer headaches. Maintenance dropped off, and they weren’t scrambling to fix overheating problems every week. I mean, it’s not magic, but it’s a real difference.

Yeah, and it’s not just about less heat. Two-stage compressors like the KRSP2 can give you up to 15 to 20% more flow than a single-stage of the same horsepower. That’s a big deal if you’re trying to get more out of your system without upsizing everything.

And if you add a variable speed drive to that setup, you can squeeze out even more efficiency, especially if your demand goes up and down. I think Carlisle Construction Materials got an $11,000 rebate just for upgrading to a VSD-equipped KRSP2. That’s not pocket change.

Nope, not at all. And the reliability side—less heat, less stress, more bearings in the right places—it all adds up to longer life and less downtime. That’s what you want, right? Keep the air flowing, keep the shop running.

Choosing the Right Compressor for the Job

So, here’s the big question—when do you actually need a two-stage compressor? I mean, they’re not for every shop, but there are some places where they just make sense.Yeah, like if you’re running heavy-duty tools, robotics, or anything that needs steady, high pressure—think metal presses, injection molding, or even big CNC machines. That’s where two-stage units really shine. You get more flow, more reliability, and you might even be able to downsize. Like, swap a 300 HP single-stage for a 250 HP two-stage and still get more air. That’s wild.

And the upfront cost isn’t as bad as people think. If you can go smaller, you’re not just saving on the sticker price—you’re saving on power and maintenance for years. I always tell folks, the initial cost is just a piece of the puzzle. You’ll pay for power and repairs way longer than you’ll remember what you paid for the machine.

Totally. But I do think there’s a point where you gotta call in a local pro. Like, you can read all the specs you want, but matching the right system to your shop’s needs? That’s where a factory-trained distributor or tech can really help. They know the ins and outs, and they’re not just there to sell you something—they want you to get the right fit so you’re not calling them every month with problems.

Yeah, I mean, I’m all for DIY, but when you’re talking about a system that’s gonna run your whole operation, it’s worth getting some expert eyes on it. They’ll help you figure out what you actually need, not just what looks good on paper.

Alright, I think that’s a good place to wrap it up. Compression ratios, heat, efficiency, picking the right compressor—it all matters if you want to keep your shop running smooth and your costs down. If you’re not sure what’s right for you, don’t be afraid to reach out to a local expert.

Yeah, and we’ll be back next time with more straight talk on rotary screw tech and what’s really happening on the shop floor. Lisa, always a pleasure.

You too, Jason. Thanks for listening, everybody. Catch you on the next episode of The Big Dog Podcast.

Random stat or

customer quote

textXXtext

text