Using Compressed Air Systems in Wastewater Treatment

October 25, 2023

Plant Manager Essentials: Seven Steps for a Greener Production

November 8, 2023How to Maintain Your Air Compressor with Genuine Spare Parts

Kaishan USA | November 01, 2023 | Uncategorized

An aftermarket air intake filter with a higher micron rating may not be able to deliver the air quality needed for sensitive semiconductor applications.

A thermal event.

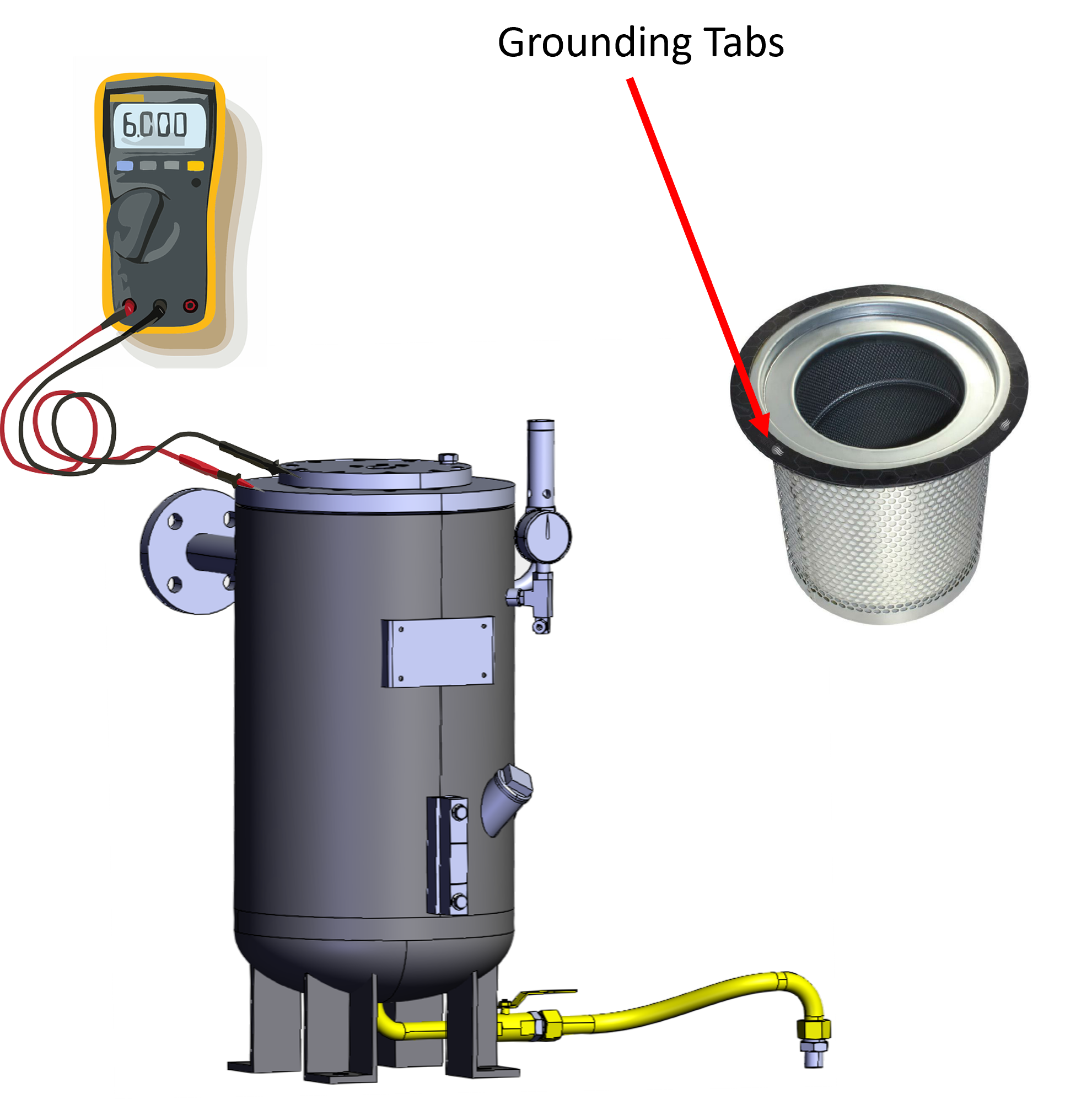

That’s what can happen when the air-oil separator in a rotary screw air compressor is not seated or grounded properly. And the high volume of air flowing into the separator creates static electricity, causing sparks and, potentially, a fire. Not only can the machine be destroyed, but the facility as well.

And while rotary screw air compressors are remarkably safe—safer, in fact, than almost any other power source—they are not immune to user error. Even the best engineered system in the world will experience a problem when it's not appropriately maintained.

And it all happens because someone is trying to save a little money and buys a gray-market or knock-off aftermarket part—in this case, an air-oil separator.

Kaishan designs its rotary screw air compressors so that the air-oil separator seats perfectly into the compressor, providing the required continuity and grounding.

Air-oil separators are designed specifically to line up with the grounding tabs and clips that secure it in place and provide continuity so the separator has a path to ground. An aftermarket separator is not intended to fit any specific original equipment manufacturer’s machine. As a result, it may not maintain the necessary continuity between the separator and the sump tank, which is grounded. And the consequences can be devastating.

It’s one of the reasons why original equipment manufacturers (OEMs) require that you use their own industrial air compressor parts for warranty validation.

Use Genuine Kaishan Parts

Our compressors and parts have been engineered as an integrated system, with all the elements working together to optimize performance and productivity. Even the slightest variations could reduce life expectancy, reliability, energy consumption and air quality.

We strongly recommend that you use genuine Kaishan industrial air compressor parts to maintain the integrity of your air compressor system and allow it to achieve the performance level you expect.

Plus, in the same way we’re taking advantage of the latest materials and technologies in enhancing the performance of our products, we’re also applying the latest advances to our parts.

Generic aftermarket parts might replace stainless steel with aluminum, lowering the performance of your compressor and failing to meet the air quality required for food and beverage applications.

Using our recommended industrial air compressor parts will allow you to achieve the following benefits:

-

- Longer life expectancy. Our parts are engineered and manufactured specifically to support and enhance the performance of your compressor. That longevity extends not only to the compressor but to its components and the end-use tools it serves.

- Part quality. Our parts conform to stringent specifications and go through the same quality-control testing as our compressors.

- Performance. All our industrial air compressor parts meet the same high standards, delivering the high-quality air expected in industries such as processing, semiconductor and electronics. Generic aftermarket parts might replace stainless steel with aluminum, lowering the performance and changing a part’s size, weight and cost. Or an air intake filter might have a higher micron rating and fewer pleats, giving it a shorter service life. And it could allow small particles to continue into the air stream.

- Drop-in replacement. Genuine Kaishan parts are designed exactly the same as the parts they are replacing and are fully compatible with your machine. As a result, they are easy to identify, order and install.

- Consistency. Your Kaishan compressor is a completely integrated system with all its industrial air compressor parts working in concert to achieve your performance and production goals.

- Easier to use. Because they are drop-in replacements, Kaishan industrial air compressor parts fit precisely and do not require modification or adjustment.

- Air quality. From air intake to air-oil separation, our parts are designed to enhance the life of your compressor and the quality of the air it delivers. Our separator elements, for example, are designed for the specific gravity and blend of our lubricants, ensuring maximum separation and the highest quality of air.

- Reliability. Genuine Kaishan parts allow our rugged rotary screw air compressors to deliver industry-leading durability and reliability that customers have counted on to keep their operation running and slash downtime.

- Productivity. By maintaining quality air delivery and reducing downtime, using genuine Kaishan industrial air compressor parts supports your productivity goals.

- Energy savings. Using the right filter materials and other Kaishan industrial air compressor parts ensure your compressor will function the way it’s designed, building cost efficiencies and cutting costly, unplanned downtime.

- Cost savings. Your short-term, money-saving, generic aftermarket parts could ultimately raise your lifecycle costs, resulting in higher energy use, increased downtime and more frequent replacements. As Compressed Air Best Practices notes, “The money you save by purchasing generic parts is often the most expensive money you will ever save.”

- Safety. OEM parts have been designed and tested to meet the compressor’s designed operating specifications and comply with industry safety standards and all applicable state and local regulations. The potential for injury to staff, damage to equipment and financial liability dwarfs any additional cost.

If you need help determining when your compressor needs attention, see our blog post, “Four Signs Your Air Compressor Needs Parts and Service.”

Lubrication

Lubricants are another potential problem area. We’ve had customers mix lubricants from different sources, causing significant foaming that plugs up the unit. That can only be remedied by flushing the compressor, a time-consuming and expensive process.

And there are other problems with lubrication. OEMs typically specify normal operating conditions when they set maintenance intervals—for example, 2,000 hours for oil sampling. But facilities using food-grade lubricants should do oil sampling every 1,000 hours of operation. And plants with temperature extremes or dirty, dusty environments should do the same. (For more on caring for your compressors in extreme weather, read our blogs “17 Tips to Keep Your Rotary Screw Air Compressor Running in the Summer Heat” and “Using an Air Compressor in Cold Weather.”

Sample oil in your air compressor every 2,000 hours. More often, if you use food-grade lubricants or your environment is hot, cold or dusty.

If the sample report says the oil is breaking down, you should change the oil to protect your compressor. If that happens, your compressor oil might only give you 4,000 hours of operation instead of the normal 8,000-hour maintenance interval. For more on maintenance intervals, see our blog post, “The Ultimate Guide to Rotary Screw Compressor Maintenance.”

Other Parts

We even see problems with parts on some of the end-use equipment serviced by our compressors. We’ve had instances when customers’ sandblasting equipment was not getting enough pressure from our compressor.

The problem was not with our compressor but with the nozzle on the sandblaster. Because of the abrasion inside the nozzle, the sandblaster that needed just 200 CFM will need 400 or 500 CFM in a few months. It’s much easier to replace the nozzle than it is to buy a new air compressor.

Unsurpassed Warranties

As mentioned above, almost all compressor manufacturers, including Kaishan, require that you use their original OEM parts to maintain warranty eligibility and ensure that your air compressor system operates at the expected performance level and safety.

Because of their reliability, efficiency and long life, Kaishan rotary screw air compressors have the best warranties in the industry. Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months. With our extended warranties (provided at no additional cost), Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

Kaishan’s KRSP and KRSP2 screw compressors are backed by an unmatched lifetime airend warranty.

As mentioned, our extended warranties require that you use genuine Kaishan industrial air compressor parts. Use generic or aftermarket parts/fluids and you sacrifice the warranty.

Local Help

Kaishan USA works with a nationwide network of independent distributors, who can help you obtain the industrial air compressor parts you need or assist you in any area of compressor operation and maintenance. These factory-trained air compression experts have an investment in their local communities, and they have staff members who are skilled in all areas of compressor operation and maintenance.

Key Takeaways

-

- Purchasing non-OEM parts will not save money long term and may lead to avoidable thermal and safety events.

- Most compressor OEMs require that you use their own parts for warranty validation.

- Genuine Kaishan industrial air compressor parts allow our rugged compressors to deliver industry-leading durability and reliability.

- Using the right filter materials and other Kaishan quality parts ensures your compressor will function as designed.

- Plants using food-grade lubricants or those with temperature extremes or dirty, dusty environments will need to adjust maintenance intervals, such as oil sampling every 1,000 hours of operation.

Let Us Help

Obtaining industrial air compressor parts for your rotary screw air compressor is critical to maintaining and operating your compressed air system and all the processes that rely on that system. If you need help finding OEM replacement parts for your compressor, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Our compressors and parts have been engineered as an integrated system, with all the elements working together to optimize performance and productivity.