Can Centrifugal and Rotary Screw Air Compressors Play Nice Together?

November 19, 2025

Water: The Compressor Killer

December 3, 2025Four Ways Engineered Compressed Air Systems Can Add Value in Your Operation

Kaishan USA | November 26, 2025 | Uncategorized

Facility managers developing robotic systems for advanced medical technology would benefit from the help of a compressed air professional in sizing and equipping their compressors.

The role of compressed air continues to grow in commercial and industrial facilities, as facility managers and production managers become increasingly aware of the advantages it offers as a power source.

While many view the growth of small, battery-powered hand tools as a potential threat, compressed air still offers critical advantages. Small electrical tools have a limited lifespan, require charging stations and frequent battery changes and may be easily damaged, resulting in thermal events and fires.

And they still are heavier than pneumatic hand tools, a disadvantage in repetitive motion and hard-to-reach applications.

Plus, pneumatic devices continue to be attractive in volatile atmospheres or settings, such as the semiconductor, electronics, life science and food and beverage industries, where clean air is paramount.

A Crucial Crossroads

As a result, many facilities find themselves at a crucial crossroads in their compressed air planning and utilization. Where the next stage of development requires engineering support.

It’s not surprising, really, in that many plants have grown up with what might be called point-of-use compressed air. When a major new application needed compressed air, they simply added a small, inexpensive compressor to provide the power.

Unfortunately, a scattering of isolated compressors is not very efficient. Nor is it reliable.

So, getting to the next level requires the engineered application of compressed air. For the most part, that’s beyond the skills of the typical plant maintenance staff.

Engineered Compressed Air Systems

A recent article in Plant Services magazine documents that skills gap, noting that “Many maintenance professionals lack the training and expertise to work with modern machinery.”

That applies to air compressors, which, as with most industrial equipment, have become more advanced with more precise machining and electronic controls.

We outline four critical initiatives below, where the next significant leap in industrial compressed air efficiency requires engineered compressed air systems. We’ll start with a compressed air systems design approach.

A Compressed Air System Design Approach

By transitioning from point-of-use units to a more systematic approach, facilities can enhance industrial compressed air efficiency and reliability. A single, larger compressor, after all, will always be more energy-efficient and cost-effective to operate, simplifying maintenance, for example.

Additionally, by moving compressors to an equipment room away from workers, a centralized capability reduces the noise level (especially for older reciprocating compressors) that can approach the 90-dBA recommended exposure limit set by the U.S. Occupational Safety and Health Administration (OSHA).

We often encourage customers to adopt a multi-compressor system approach involving base, trim and backup units:

- A base-load compressor meets your system’s minimum compressed air load. Its output does not fluctuate as demand changes. Instead, it runs at full capacity—or it turns off. Depending on your demand profile, you could have more than one unit to fulfill that base-load function. Many companies use a rotary screw compressor, but plants with significant air demand could find that a centrifugal air compressor is the most energy-efficient choice.

- A trim compressor handles fluctuations in demand above the base unit. Since the level of flow needed will rise and fall depending on the needs of your system, rotary screw compressors (such as our KRSP2 premium, two-stage rotary screw air compressors) equipped with variable-speed-drive air compressor are a natural for this application.

- A backup compressor is on standby if a base-load or trim unit goes offline. To fill in appropriately, it should be the same size as the base-load compressor.

Kaishan’s KRSP2 premium, two-stage rotary screw air compressors equipped with variable-speed drives are an excellent choice for trim compressors. They are also a good selection for base-load units.

Configuring your compressed air system in this way virtually assures reliability. For most companies, avoiding a day of downtime more than justifies the additional expense of an air compressor backup system, as carpet manufacturer Mannington Mills discovered.

For more on multi-compressor systems, read our blog post, “How a Multi-Compressor System Can Help You Reduce Compressor Downtime.”

Variable-speed-drive air compressors, mentioned above as trim units, are another excellent example of an engineered compressed air system solution available to facility managers.

Variable-Speed Drive Air Compressors

The application of VSD technology to rotary screw air compressor systems has enabled many companies to save significant amounts of energy. And energy savings are not the only benefit.

VSD compressors can earn rebates, allow soft starts and offer better control of your compressed air system. They are also an energy-efficient way to address rapid cycling.

However, they are not a good choice at the extremes—we encourage customers not to use a VSD compressor when the machine runs at 20% of its total capacity most of the time. Or more than 80%.

Variable-speed-drive air compressors earn rebates, allow soft starts and offer better control of your compressed air system. They are also an energy-efficient way to address rapid cycling. But they are not a good choice at the extremes.

We’ve seen more than one instance where the misapplication of a VSD has resulted in significant costs, far exceeding the savings the companies had hoped to achieve. Or even the rebates they earned. Therefore, it’s in your best interest to have a consultant help you determine whether the variable demand across your compressed air system matches the profile that makes a VSD a suitable choice for you.

For more on the pros and cons of VSDs, see our blog post, “How Variable-Speed Drive Rotary Screw Air Compressors Save You Money.”

Next, as you take your system to the next level, the sizing of your compressor is critical.

Accurate Sizing

Sizing may be the most crucial decision you make when purchasing a new air compressor. Time and again, experience has shown that the most serious air compressor problems stem from mistakes in sizing or application.

With rotary screw air compressor systems, especially, that means oversizing. Or over-buying. Trying to add more “muscle” to your system or anticipate future needs.

It may seem counterintuitive, but with rotary screw air compressor systems, “too much” is almost as bad as “not enough.” So, it’s essential that you don’t oversize your system.

Before you buy a compressor, make sure you have a clear understanding of your demand profile. Think of Goldilocks when sizing your compressor: not too much, not too little, just right. Your local compressed air consultant is a great place to start.

For a comprehensive compressed air sizing guide, download our white paper, “Demystifying Air Compressor Sizing.”

One last engineered compressed air system solution you’ll want to consider is the use of oil-free vs. oil-flooded compressors.

Oil-Free vs. Oil-Flooded Compressors

As facilities incorporate more advanced, sensitive technologies, they are under increasing pressure to develop oil-free compressed air systems. Especially if they are involved in or marketing to the food and beverage, electronics, healthcare or medical device industries.

The food industry needs compressed air that is clean and free of oil and other impurities.

In addition, Kaishan USA is offering facility managers two new, oil-free alternatives–the KROF oil-free rotary screw compressor and the KCOF centrifugal air compressor.

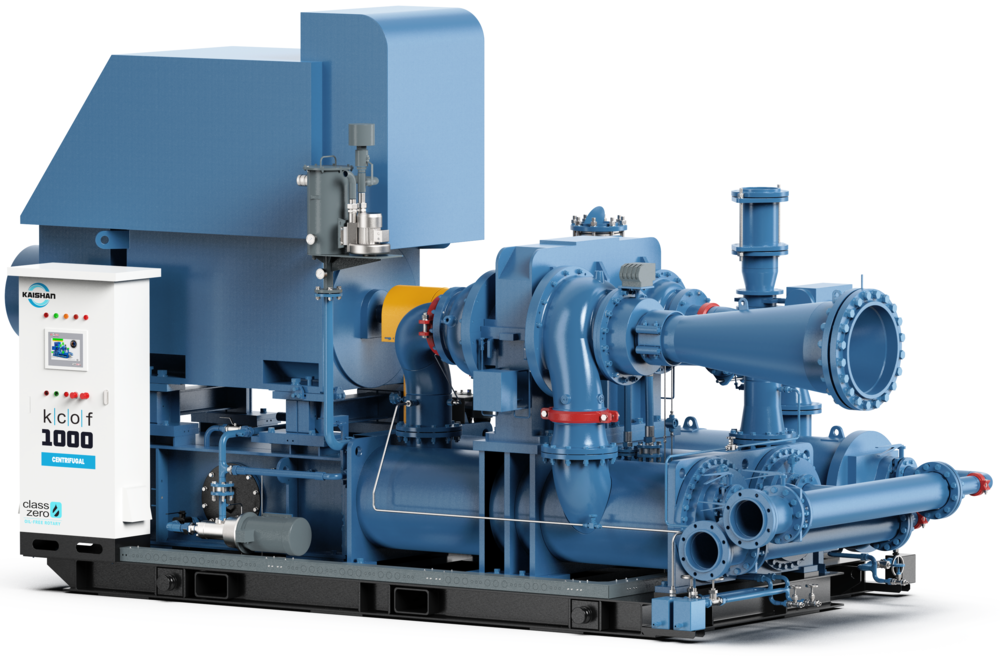

Kaishan KCOF: Centrifugal Air Compressor Efficiency, Reliability and Support

Kaishan’s KCOF centrifugal air compressor offers an exciting option for oil-free compressed air. It provides significant benefits in control capabilities, low maintenance and support:

Kaishan’s KCOF centrifugal compressors provide significant benefits in control capabilities, low maintenance and support. They range from 250 HP and 1,400 CFM to over 10,000 HP and 50,000 CFM. They are also available in a wide range of pressures, from 35 to 350 PSIG. Learn more by watching the KCOF video.

- State-of-the-art controls. Our KCOF centrifugals are equipped with a field-proven control and energy management software solution that offers dynamic machine and system throttling, as well as a full-flow range of operation. Kaishan offers a user-friendly open architecture that uses industry-standard Allen-Bradley PLC hardware.

- Easier maintenance. Like other centrifugal compressors, the KCOF requires less service inventory and minimal maintenance time. The KCOF features a self-cleaning inlet air filter as an option, reducing the need for filter changes in extremely dirty environments. As a result, filters do not clog as quickly. In addition, the KCOF has longer service intervals, requiring an oil change in many applications only after two years of continuous operation. Our coolers feature tube bundles constructed from corrosion-resistant stainless steel, with epoxy-coated water passages and housings, ensuring excellent reliability and long life.

- Unmatched parts availability. As one of the world’s few fully integrated manufacturers of centrifugal compressors, we offer unmatched parts availability. With five-axis machining centers to cut key parts such as impellers, no one delivers the parts you need as quickly. While other manufacturers make you wait weeks or months (!) for replacements, our parts often ship directly from our warehouse in days, if not hours.

KROF Oil-Free Rotary Screw Compressor

Kaishan’s new KROF oil-free rotary screw compressor, produces ISO 8573-1, Class 0 oil-free compressed air that safeguards the integrity of your products.

It is available in 100-, 125- and 150-PSIG models with integrated air or water cooling. And it’s perfect for challenging compressed air applications such as food and beverage, electronics, healthcare and medical devices.

Because of its inherent durability and long-lasting performance, Kaishan backs the KROF with an industry-leading five-year warranty on major components, including the airend.

Kaishan’s new KROF two-stage oil-free compressor is an excellent choice when you need uncontaminated, highly efficient, reliable air.

Best of all, it is the only oil-free compressor designed, engineered and manufactured in the U.S. for a global market. It is manufactured at our state-of-the-art 130,000-square-foot plant in Loxley, AL.

Admittedly, many facility managers have found that oil-free systems offer many challenges. Fortunately, there are other options.

Other Alternatives

As a result, if you are not in those sensitive applications, you may achieve significant savings with an oil-flooded rotary screw air compressor that typically has a lower lifetime cost than oil-free machines because it offers lower acquisition, maintenance and electricity costs.

An oil-flooded rotary screw air compressor offers several significant advantages, including:

- Performance advantages. Rotary screw air compressors enable you to run equipment and tools that need a lot of power. They are incredibly efficient and can handle a 100% duty cycle, providing a steady flow of clean, high-quality air.

- Operational advantages. Rotary screw air compressors are highly reliable and require less maintenance than other types of compressors. They can handle variations in demand and temperature extremes and are relatively safe. They have a compact footprint and generate less noise.

- Lifetime cost advantages. Rotary screw air compressors are known for their dependable operation, which means that you will have less downtime. They have a long lifespan and a relatively low total cost of ownership. Plus, they have better warranties than other types of air compressors due to their reliability, efficiency and long life.

Oil-flooded rotary screw air compressor systems can even be equipped with filtration that reduces oil levels to 3 PPM—not suitable for food or semiconductor applications. But it is acceptable for a wide range of other uses.

As with so many topics in compressed air, there are tradeoffs. Yes, oil-free compressors have a higher initial cost. However, because they are oil-free, there’s less need to process the discharge air. And the extra filtration required to clean up the air flow of an oil-flooded compressor adds pressure drop and requires more maintenance.

The one thing these advances have in common is that they require the support and expertise of a professional specializing in compressed air.

Kick-Starting the Process

Whether you’re taking a compressed air system design approach, considering VSDs, struggling with sizing or moving to oil-free air, your local air compressor consultant can help you make choices that will boost productivity, ensure rock-solid reliability and reduce your energy, maintenance and operating costs.

We work with a nationwide network of independent distributors, who can provide that kind of on-site help and consultation.

We partner with independent, local distributors because it's the best way to make sure you get expert guidance, faster response times and personalized support tailored to your needs.

Unlike large corporate suppliers, there's no red tape here; our distributors don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

They have factory-trained technicians and a deep understanding of industrial applications, helping you maximize industrial compressed air efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than just a product—you're getting a local partner who genuinely cares about your business and wants to see it succeed. Find a compressed air consultant near me.

Key Takeaways

Four ways engineered compressed air systems can add value in your operation:

- Taking a compressed air systems design approach

- Variable-speed-drive air compressors

- Accurate sizing

- Oil-free vs. oil-flooded compressors

Let Us Help

Taking your compressed air system to the next level can offer a wide range of advantages, cutting downtime, reducing costs and improving energy efficiency. If you need help analyzing the best ways to add value to your system, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

The Power of an Engineered System

Alright, welcome back to The Big Dog Podcast—where compressed air isn’t just a utility! it’s the heartbeat of how so many of us get things done. I’m Jason Reed, and with me as always is Lisa Saunders.Hey y’all! Good to be back. Today we’re digging into the real deal value you can get with compressed air systems—if, you know, you stop treating them like an afterthought and start thinking system-wide.

That’s it. I gotta say, after all the places I’ve walked through, there's one mistake I see over and over: these point-of-use compressors scattered everywhere. It's like every time someone needed air, they just tossed in another little compressor next to the new machine or workstation. Next thing you know, you’ve got a whole zoo in there, and none of them are working together. They’re loud, inefficient, barely reliable, and honestly—you end up spending more on repairs and energy than you save buying cheap upfront.

Yeah, I remember we hit on this in a few earlier episodes—people thinking, “Eh, I’ll just get what I need, where I need it.” But once you centralize your system, you open up so many options for, like, better control, lower maintenance, and way fewer headaches if something goes down. Mannington Mills, for example—they have their main base compressors, a trim unit to handle the peaks, and a backup ready to swing in if anything fails. That kind of redundancy saved them a huge chunk in downtime.

Exactly. Once you’re running a multi-compressor setup—base load, trim, backup—you stop worrying about a single compressor bringing the plant to a halt. And with proper design, you also get to put the whole setup in an equipment room, away from where people are working.

Which brings up another big point: noise! I stopped by a food plant last month, and they’d centralized their compressors—moved ‘em into a purpose-built space. The shop floor was actually quiet enough for workers to have a conversation, which, just for reference, is a rarity if you’ve ever been near a bunch of old reciprocating units. OSHA says 90 dBA is the recommended limit, and if you’ve got those things sitting right by your operators—yeah, good luck with that. But centralization handled the noise and improved workflow, since nobody had to weave around these old, rumbling compressors every time they needed something shipped or fixed.

It’s better for safety, better for maintenance access, and honestly—just better for sanity. And the reliability bump? Huge. Especially if you’re following what we talked about in Episode 8 with multi-compressor controls—load sharing, rotating units, all of which ups that system lifespan and keeps you up and running. So, engineered solutions? They’re not some sales pitch. They're what separates the shops crushing it on uptime and energy from everyone else struggling to patch things together.

Getting Smart: VSDs and Sizing

That ties right into what’s next—making your system smarter by picking the right tech and sizing. Let’s talk variable-speed-drive, or VSD, compressors for a second. They’re, like, the darling of the rebate and energy-saving crowd, but I’ve seen more than one place get burned by putting a VSD in the wrong spot. There was a packaging plant I toured—beautiful VSD rotary screw, fancy control panel, the works. Problem was, their demand profile was, um, not exactly what you’d want for a VSD. They ran it either at twenty percent or at ninety percent all the time—never in that sweet spot for VSDs to actually pay off. So, the savings they hoped for? Didn’t show up. Actually, cost them more in the end with extra service calls and headaches.I see that a lot. People just hear “VSDs save energy!” and buy one without really understanding whether it fits their plant. Like, if you’re always at the low or high end of its output, you’d be better off with a fixed-speed machine. You want that VSD to cover the ups and downs—not just sit idling or screaming at full tilt.

And then—sizing. I gotta admit, I love this topic because people screw it up all the time. You get folks thinking, "I might as well buy the biggest one I can—future-proofing!" But with rotary screw compressors, too big is almost as bad as too small. You end up with cycling issues, wasted energy, and a machine that never reaches its efficient running point. It’s the Goldilocks thing—not too much, not too little. Just right.

Absolutely. It’s one of the biggest pain points I see in the field. People overbuy, thinking they’re covering their bases, but it’s just money down the drain. There’s actually a sizing guide from Kaishan, and—full disclosure—I use it all the time because having a clear handle on your plant’s real air demand saves you a mountain of grief. And don’t get me started on undersizing, either—a short-cycling compressor is a maintenance nightmare. That rapid cycling beats up the machine and shortens the lifespan real quick.

So that’s why, if your demand keeps spiking or you notice your compressors cycling like crazy? Get someone in who actually lives and breathes compressed air. Even if it’s just for a consultation, they’ll help you figure out what actually fits, instead of guessing your way through. The stuff’s gotten technical—between electronic controls, VSDs, demand mapping, it really helps to have a compressed air pro in your corner who can run the numbers and make sense of it all.

Totally agree. Building on what we talked about in Episode 6—where we dug into BMS integration and data-driven troubleshooting—sometimes you just gotta admit it’s out of the usual maintenance crew’s skillset. No shame in calling for help.

Choosing Between Oil-Free and Oil-Flooded

And now for probably my favorite debate—oil-free versus oil-flooded compressors. Here’s where you really gotta weigh what matters most for your shop or plant. Oil-free is a no-brainer for stuff like food, beverage, electronics, medical…all those spots where any bit of oil vapor would be a disaster. Kaishan’s got the KROF oil-free rotary screw and the KCOF centrifugal—both bring in crazy clean air, and honestly, the reliability on the new models is solid, with things like low-maintenance self-cleaning filters and those super long service intervals. You need pharmaceutical-grade, or you’re feeding compressed air into sterile processes? Oil-free is pretty much your only option.Yeah, but for everyone else, oil-flooded rotary screws are the workhorses. I was at a metal fab shop just last quarter—they asked if they had to “upgrade” to oil-free for their main air, but when we dug into their actual needs, it was totally overkill. Oil-flooded is simpler, runs cheaper in the long haul, and you can slap on filtration to take care of most uses. They saved a bundle sticking with oil-flooded, no change in air quality that mattered for their process, and longer service intervals too. I mean, you can't use them in places like food or pharma lines, but for most stuff? You just don’t need to pay oil-free prices unless there’s a hard requirement.

That’s the tradeoff, right? Oil-free means a bigger upfront spend and more regular maintenance—but you skip the risk of contamination. Meanwhile, oil-flooded keeps costs way down, handles temperature swings, is incredibly reliable, and as long as you’re not feeding packaged lettuce or building semiconductors, oil levels down to 3 PPM are good enough for almost every other use. The Kaishan oil-flooded screws can even run a hundred percent duty cycle, so you get performance and a compact setup.

And don’t forget, with the new KROF and KCOF oil-free units, Kaishan’s making oil-free more accessible than before. But still, there’s always a balancing act—think upfront budget versus long-term reliability, downtime risks, and what’s really required for your specific application. No one-size-fits-all answer here.

You summed that up perfectly. If you’re still on the fence, it’s always worth talking to a compressed air expert who gets both worlds and isn’t just pushing you to the most expensive solution. The right answer is the one that matches your end goals, regulatory needs, and, frankly, your budget—without sacrificing reliability. Alright, Jason, I think we’ve about run out of time on this one. Big thanks to everyone listening—seriously, if you need help sorting through the oil-free versus oil-flooded debate, or want to talk system design, find your local air pro or reach out to Kaishan for advice. We’ll be back soon with another deep dive. Jason, signing off?

Absolutely. Thanks, Lisa—and thanks to everyone who stuck with us! We’ll catch you next time on The Big Dog Podcast. Take care, Lisa.

Later, Jason! And thanks everyone—stay sharp out there!

Random stat or

customer quote

textXXtext

text