Electric Portable Air Compressors: A Smart Alternative to Diesel

January 7, 2026

When To Use a VSD on a Rotary Screw Air Compressor

January 21, 2026State-of-the-Art Manufacturing of Oil-Free Rotary Screw Air Compressors

Kaishan USA | January 14, 2026 | Uncategorized

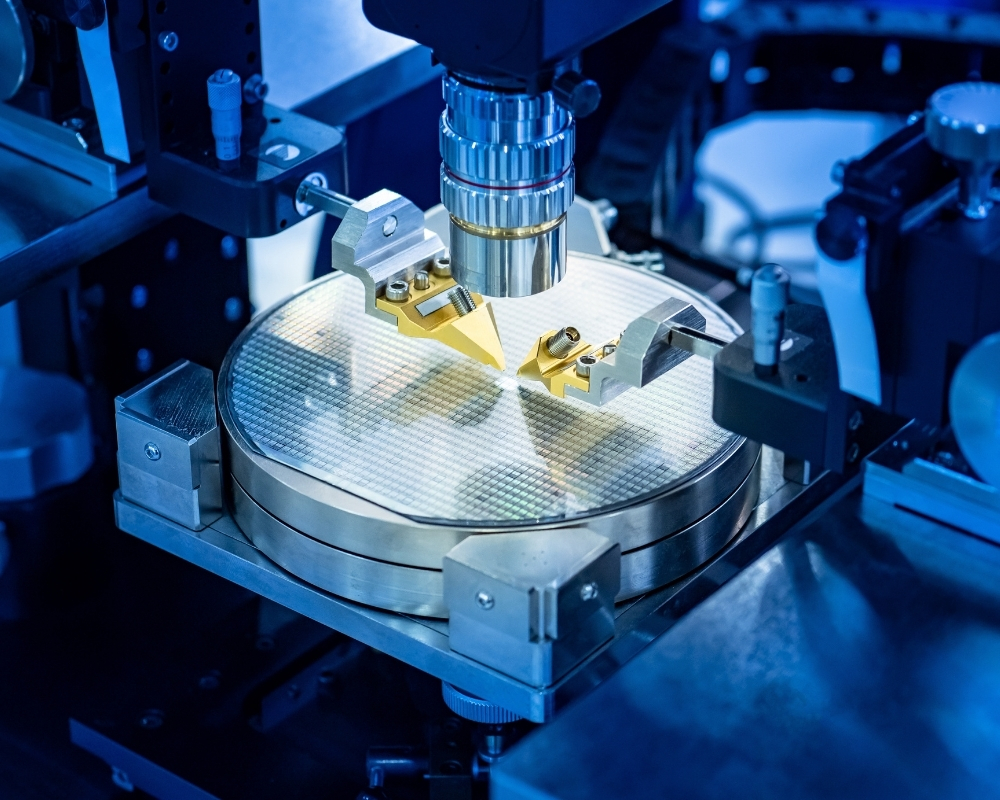

Semiconductor fabrication requires the cool, clean and dry compressed air that comes from oil-free air compressors, such as Kaishan’s KROF two-stage, oil-free, rotary screw air compressor.

If you manage compressed air systems in a facility that demands clean, dry air—such as electronics, food and beverage, healthcare/life science and semiconductor industries—you already know “oil-free” isn’t just a spec on a datasheet. It’s a daily discipline. Almost a way of life.

Oil-free rotary screw air compressors must deliver ISO 8573-1 Class 0 air without the safety net of oil lubrication in the compression chamber. That ups the stakes on design, materials, manufacturing and maintenance. For a maintenance manager or plant manager, it means reliability has to be engineered from the first cut of metal to the last bolt torqued:

- First, there’s precision machining. In an oil-flooded rotary screw compressor, oil fills microscopic clearances and helps seal the gap between the rotors. Oil-free is different. There’s no oil in the compression chamber, so tolerances must be tighter and rotor profiles must be perfect. Low-friction materials, such as PTFE coating on corrosion-resistant steel rotors, reduce wear during startup and shutdown when condensate can form.

- Then there’s air compressor heat management. Oil-flooded machines typically run about 100°F above ambient. Oil-free units run significantly hotter—with a discharge temperature about 300°F above ambient—so the cooling system has to work smarter. Oversized precoolers, efficient interstage coolers and smart airflow or water circuits are essential to protect components, preserve clearances and maintain efficiency.

- Advanced filtration is another must-have. Without oil to help trap contaminants, the intake filtration and downstream separation strategy carry a heavier load. High-efficiency media protect the rotors, bearings and valves from dust and wear particles while helping the entire system run cleaner.

- Precision synchronization of the rotors is nonnegotiable. Without a film of oil between the male and female rotors, the timing gears and helix geometry must mesh perfectly. Any drift in timing or thrust loading risks contact, heat and accelerated wear.

- Finally, this level of performance demands skilled personnel—designers, machinists, assemblers and technicians who understand how high-temperature, high-speed, oil-free compression behaves in the real world. This craftsmanship is backed by data, metrology and experience.

Let’s explore how Kaishan designs and builds the KROF two-stage, oil-free rotary screw air compressor to meet those challenges head-on and make life easier for maintenance teams.

Manufacturing Excellence

The oil-free portion of Kaishan’s manufacturing center of excellence in Loxley, AL, is purpose-built for oil-free rotary screw air compressors. The designers and engineers who developed the Kaishan KROF “factory of the future” sit steps away from the production floor, shortening feedback loops and accelerating innovation.

Kaishan’s manufacturing center of excellence in Loxley, AL, is purpose-built for oil-free rotary screw air compressors.

This site manufactures the KROF’s airends and rotors for global distribution, which means every process—from rotor machining to final testing—has been standardized for world-class consistency and quality.

The Loxley team focuses on the details that matter over the long haul: clean assembly environments, calibrated inspection equipment and rigorous quality gates. The facility’s test stands verify performance under load, validating pressure and temperature before shipment. This discipline translates to fewer surprises at startup and fewer callbacks during the first years of service, lowering total cost of ownership.

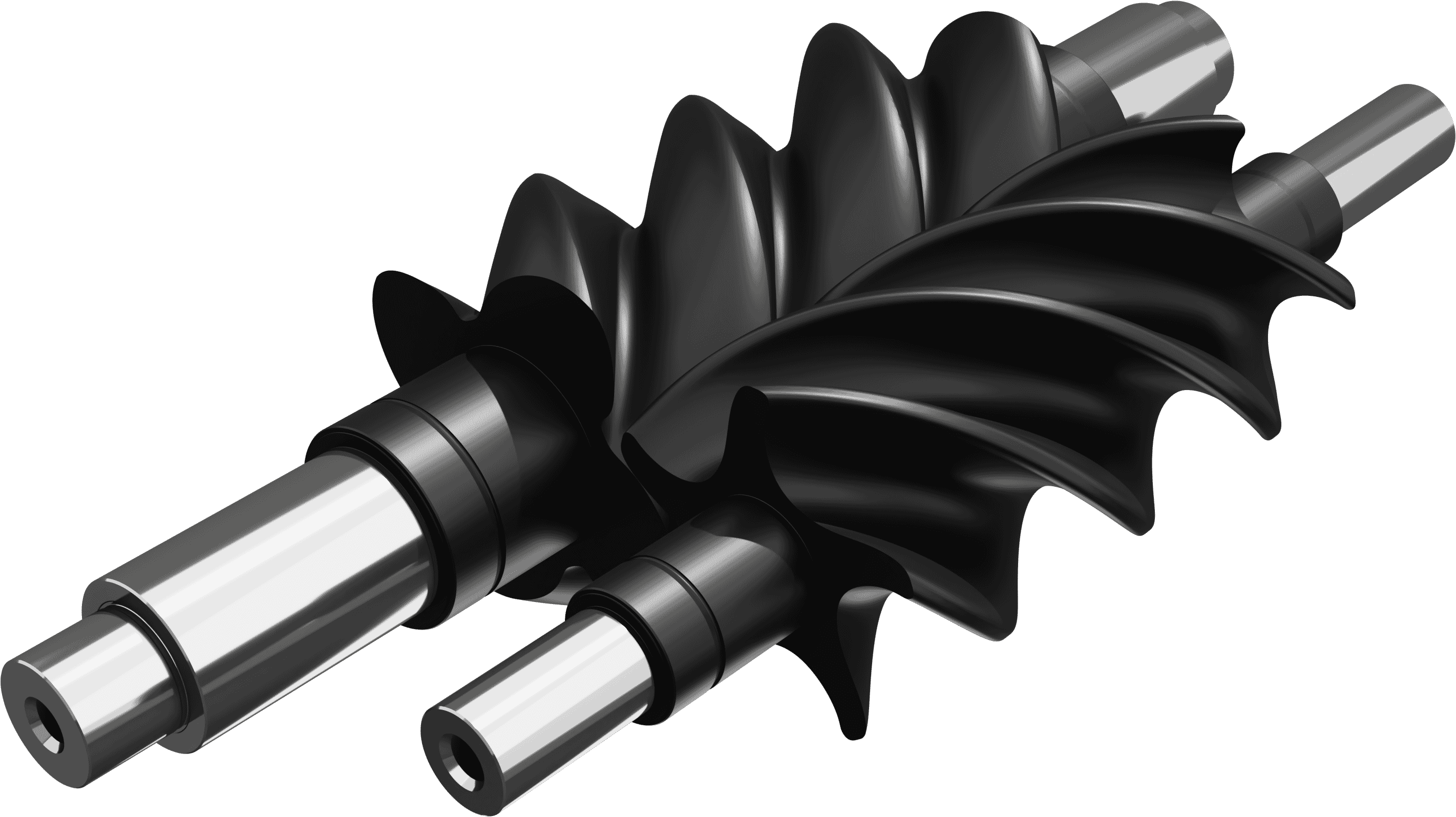

Precision processes only get you so far without precision parts, which is why the Kaishan KROF’s rotors are engineered and machined to exceptionally tight tolerances.

Machined to Tight Tolerances for Oil-Free Performance

The Kaishan KROF’s two intermeshing rotors are machined to micron-level precision. The geometry—diameter, profile and twist—is engineered to maintain an optimal seal across a wide temperature range, including the high thermal loads typical of oil-free compression. As the compressor accelerates to supersonic tip speeds and internal temperatures rise to 300°F above ambient, the rotors expand exactly as designed to preserve gap control and efficiency without metal-to-metal contact.

The rotors on the KROF are machined to micron-level precision and coated with an in-house blend of PTFE to ensure they preserve gap control and don’t touch when they’re spinning at supersonic speeds.

Material selection matters. Kaishan uses corrosion-resistant steel with a PTFE coating to protect rotors during shutdowns (when condensate can form). The coating reduces friction at startup, supports long-term stability of clearances and guards against corrosion that could otherwise erode efficiency and increase risk.

Because oil isn’t present in the compression chamber to help seal or carry away heat, custom tooling and super-precise inspection equipment are required to ensure every rotor meets spec. Timing gears and rotor helix geometry must synchronize perfectly to maintain thrust and radial stability throughout the full operating envelope.

Advanced oil-free rotary screw compressors need equally capable cooling, which is where the KROF’s air and liquid systems stand out.

Advanced Air Compressor Heat Management with Oversized Precoolers and Intercoolers

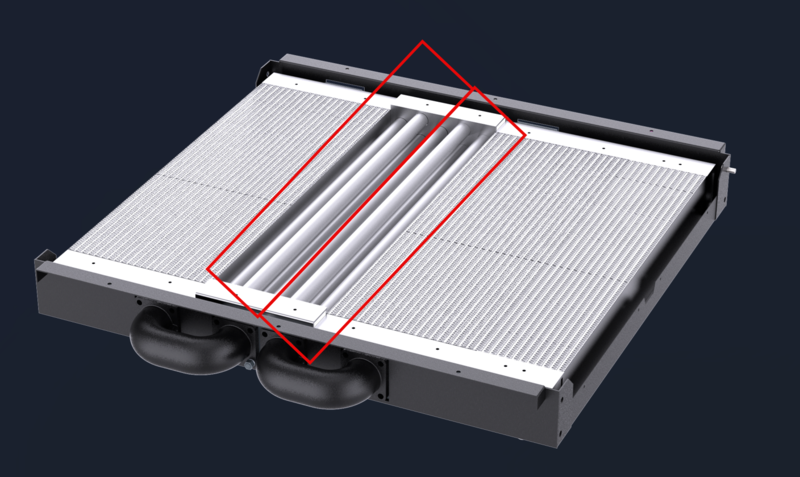

Oil-free compression runs hot, so the Kaishan KROF’s cooling architecture is designed to absorb and reject heat efficiently at every stage. Air-cooled models feature stainless-steel precoolers that take the first-stage discharge from roughly 400°F down to about 50°F above ambient. That temperature drop protects components and sets up the interstage for success.

Air-cooled KROF compressors feature stainless-steel precoolers that take the first-stage discharge from roughly 400°F down to about 50°F above ambient, protecting components and setting up the interstage for success.

Interstage coolers continue the job, reducing the air temperature to within 5°F-10°F of ambient before the second stage. Lower inlet temperatures improve compression efficiency, increase the density for the next stage and reduce thermal stress. Oversized moisture separators with reliable, zero-loss drains ensure condensate is removed effectively between stages, preventing moisture carryover that could challenge the second-stage airend.

A liquid-cooled Kaishan KROF model simplifies the path by eliminating the need for a precooler. Liquid cooling provides highly stable thermal control, which can be a significant advantage in high-duty-cycle or high-ambient environments.

With heat under control, the airend’s internal force balance becomes the next critical design lever for long-term reliability.

Airend Design That Eliminates the Balance Piston

Many oil-free airends attempt to counteract linear forces with a balance piston. That design uses discharge air to pressurize a diaphragm at the discharge end of the housing, preloading the bearings to resist the natural axial forces generated as the rotors “climb” over one another. The problem is that diaphragms can leak. Lose preload, and bearing life suffers—eventually risking airend failure.

The airends for our KROF two-stage, oil-free rotary screw air compressors are manufactured in our state-of-the-art facility in Loxley, AL.

Kaishan takes a different approach. The KROF’s gears and rotor helix are engineered to counteract linear forces within the airend itself, eliminating the need for a balance piston. Advanced bearings achieve proper thrust loading without maintenance, removing a potential failure point from the system. Fewer service items mean fewer surprises and less downtime.

This design philosophy—simplify, then engineer for durability—pays dividends for maintenance teams. With fewer parts to fail, the KROF delivers predictable performance and longer service intervals, reducing total lifecycle cost.

With the foundation set, let’s look at the complete package and how the KROF checks all the boxes for demanding oil-free applications.

The Kaishan KROF: Two-Stage, Oil-Free Performance, Built for Reliability

The KROF produces ISO 8573-1 Class 0 oil-free compressed air to safeguard product integrity in sensitive applications. At its core is a two-stage design, with each stage driven by a pinion gear from a single, robust bull gear. That drivetrain is coupled to a high-efficiency drive motor, keeping the mechanical layout simple and effective. Models are available in 100-, 125- and 150-PSIG with integrated air or water cooling.

Kaishan’s KROF two-stage, oil-free, rotary screw air compressor is machined to micron precision.

Key features for maintenance and plant teams:

- Two intermeshing, PTFE-coated rotors machined to micron precision for stable, oil-free sealing

- Oversized stainless-steel precoolers on each stage that reduce temperatures for intercoolers and aftercoolers

- Integrated lubrication passages between stages to reduce leak points, simplify service and lower lifetime costs

- Advanced bearings that eliminate the need for an outdated balance piston while maintaining proper thrust loading

- Oversized moisture separators with zero-loss drains that handle contamination better than orifice-style drains

- A dual-centrifugal, electronically commutated fan that reduces noise and improves cooling efficiency

- Exclusive Ultra-Web air filters that remove small particles and protect the airend from wear

Backed by Kaishan’s commitment to reliability in rotary screw air compressors, the KROF carries an industry-leading five-year warranty on major components, including the airend. With precise engineering and high-quality output, it’s a dependable workhorse you can count on to drive productivity over the long haul.

For maintenance managers, serviceability matters. Kaishan USA stocks complete stages and critical components to allow quick parts replacements when needed. That reduces lead times, simplifies maintenance planning and keeps your system running with minimal interruption.

Learn more by downloading the brochure or watching the video on the KROF product page.

When it’s time to evaluate options or plan a project, local expertise can make all the difference in selecting, installing and maintaining the right oil-free system.

World-Class Expertise, Available Locally

Choosing the right oil-free compressor is a team effort. Your facility’s duty cycle, ambient conditions, air quality targets and service model shape the best solution. If you’re weighing options or need a second set of eyes on your system, connect with a local compressed air professional to determine whether the Kaishan KROF is right for your application. You can start with your local Kaishan distributor.

Kaishan USA partners with a nationwide network of independent distributors who provide on-site support and consultation when you need it. These factory-trained compressed air experts service complete systems with confidence and bring the latest technology to every job.

We work with independent, local distributors because it serves you best. There’s no corporate red tape—just expert guidance, fast response and support tailored to your plant. They don’t simply sell compressors. They build relationships, helping you select the right system, keep it maintained and get parts quickly when you need them.

With factory-trained technicians and deep industrial experience, they help you boost efficiency and cut downtime. When you choose Kaishan, you get more than a product. You get a local partner invested in your success.

Key Takeaways

- Oil-free compression removes the sealing effect of oil, so precision machining, rotor synchronization and PTFE-coated surfaces are critical.

- Air compressor heat management is essential; the KROF uses oversized precoolers and efficient interstage coolers to control high discharge temperatures.

- Advanced filtration protects rotors and bearings from particles that oil would otherwise capture in flooded designs.

- Kaishan’s Loxley, AL facility is a manufacturing center of excellence with stocked stages for faster service and reduced downtime.

- The KROF’s airend design balances linear forces without a balance piston, reducing the risk of component failure and simplifying maintenance.

- A simple, robust two-stage drivetrain powered by a single bull gear improves reliability and efficiency.

- Local Kaishan distributors provide on-site expertise to help you evaluate, specify and maintain the right oil-free system.

Let Us Help

Getting oil-free compressed air can be critical to a wide range of processes and your entire operation. If you need help finding the right oil-free rotary screw air compressor, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Building Clean Air: Oil-Free Manufacturing Precision

Alright, welcome back to The Big Dog Podcast—Lisa Saunders here with Jason Reed, and today we're digging into how oil-free rotary screw compressors are really changing the game when it comes to reliability and air purity. I mean, nobody wants to talk specs for the sake of specs, right Jason? But in industries like semiconductors and healthcare, oil-free is...well, it’s non-negotiable. It’s kind of like—it’s not just something you tick on a datasheet. It’s a whole mindset, every single day.Yeah, you nailed it, Lisa. You know, I was just at a plant the other week—electronics manufacturer, right? I was talking to their maintenance manager and he tells me, flat out, “One oil leak, Jason, just one, and the whole line shuts down.” Like, done until the root cause is tracked down. It’s wild, but it made sense. In electronics, or semiconductors, you’ve got to have that ISO 8573-1 Class 0 air. There’s no room for mistakes—every little thing, from the precision machining on the rotors to the final filtration, has to be dialed in. Otherwise, you’re gambling with massive downtime and scrap.

Exactly. And building on what we talked about in that intake air episode, you can’t just throw a filter at it and call it “oil-free.” The air itself has to move through these compressors that are designed from the ground up for zero contamination. That means Kaishan’s KROF uses super tight tolerances in the machining, PTFE coatings—it’s like, if oil flooded compressors use oil to fill those microscopic gaps, with oil-free you’re relying on flawless metalwork. There’s nowhere to hide a mistake.

Yeah, and that means quality control’s totally next level. If you look at how the KROF comes together at Kaishan’s Loxley, Alabama facility, it’s not just some assembly line with a checklist. The engineers are right there on the floor next to the folks machining the rotors. It shortens those feedback loops and, I mean, it’s what you want if one minor flaw means you’re in for a costly repair call later on.

And for those industries—semis, med devices, electronics—it’s a daily reality. I saw a visual the other day; they called it a “way of life,” not just a spec. That’s spot on. It’s what drives all those skilled machinists—the part of manufacturing you never see but definitely feel when the air is pure and the process lines keep running. Honestly, if you’ve got oil-free in your process, there’s zero wiggle room for sloppiness.

Managing the Heat: Advanced Cooling and Rotor Engineering

So, shifting gears—and this part’s huge for reliability—you can't talk oil-free rotary screw without talking about heat. With oil-flooded machines, the oil’s basically doing double duty—sealing and cooling. But oil-free? That discharge temperature’s, like, about 300 degrees over ambient sometimes. That’s where that whole “oversized stainless-steel precooler” thing matters. KROF has these massive precoolers to drop the stage-one temps fast, and efficient intercoolers so when the air hits stage two, it’s not just cooked and useless. I always say, you want to make a maintenance manager’s life better, start by managing the heat.Right—and I’m glad you mentioned that, because I think a lot of people overlook the role of advanced cooling in cutting down service calls. When you keep your components cooler and protect your clearances, there’s way less thermal stress—and that just means things last longer. And those rotors? They’re running at supersonic speeds, and Kaishan coats them with PTFE on corrosion-resistant steel. That helps keep friction down during startup, but also, it helps resist corrosion from moisture if there’s any condensate during shutdown. It’s like, every part of the process tries to head off a future failure.

It’s funny you mention service calls—let’s talk about Kaishan’s Loxley plant. Their whole model is about standardizing quality. Like, every airend and rotor, they’re made there, right next to R&D. So every time they find a tweak to improve cooling, it gets rolled out globally. Means you get the same level of quality if you’re in Loxley or, y’know, halfway across the planet. And it’s validated—nobody’s shipping out a unit without full-pressure and temp testing under load. Kinda takes the surprise out of commissioning day, which is nice.

Yeah, and it’s not just air-cooled, either—liquid cooled KROF models sort of eliminate the need for that bulky precooler but offer super-stable thermal control. That matters a ton if you’re running in high-duty or just brutal ambient temperatures. Plus, the oversized moisture separators and zero-loss drains between stages? Totally key; we talked about water issues back in our Moisture Mayhem episodes, and this is the kind of thing that actually prevents those nightmares later on.

Simplifying Reliability: Airend Innovations and Serviceability

Alright, let’s get into the guts of the KROF—the airend. There’s this classic design problem: most oil-free airends try to balance the axial forces with a balance piston, right? But those diaphragms can leak, and when that happens, you lose your preload on the bearings, which pretty much spells doom for your airend. Kaishan just ditched the whole piston—engineered it out entirely. Now, their rotors and gears are set up to stay balanced by themselves. That cuts out a whole category of failure, so less can go wrong, which is exactly what you want if you’re the one getting called at 2 a.m. when stuff breaks.I love that, because if you’re managing maintenance, you want fewer surprises and faster fixes. Not everyone’s got time to hunt down a bunch of rare parts; you just want reliability and easy access. Kaishan thought about that too—oversized moisture separators, those advanced bearings, and simple service access to the whole airend. And I think it’s brilliant that they stock complete stages at their distributors, so if you do need a new stage, you don’t have to wait weeks or play the “backorder game.”

Oh, let me tell ya, I’ve seen this play out. There was this food production plant—big operation, needed oil-free for obvious reasons. Their KROF was due for a stage swap. Tech from their local Kaishan distributor rolls in, gets the new stage on in under an hour. I was kinda shocked how fast it was—kept their downtime so low they barely noticed. For a busy plant, that’s a win. Means you’re not blowing your production schedule every time you need to swap a major part.

Absolutely, and that’s where having local support is such a huge deal. We’ve said it before—reliability isn’t just about good engineering. It's about making sure parts and expertise are never far away. Alright, we’re gonna wrap up this episode, but if you want more hands-on knowledge about oil-free systems—or have a gnarly maintenance problem, honestly—make sure to get in touch with your local Kaishan distributor or drop us your questions at Kaishan USA. Jason, always a pleasure talking shop—

Right back at you, Lisa. Thanks, everyone, for listening to The Big Dog Podcast. Don’t forget to hit that subscribe button—plenty more no-nonsense compressed air talk coming your way. Catch ya next time!

Random stat or

customer quote

textXXtext

text