Summer Tips For Air Compressors

May 1, 2024

The Complete Guide to Air Compressor Sizing

May 15, 2024What Kind of Air Compressor Do I Need?

Kaishan USA | May 8, 2024 | Uncategorized

In applications where your compressed air comes in direct contact with food and beverage products, oil-free machines, such as our new KROF two-stage rotary screw air compressor, are a logical choice.

There are many different kinds of air compressors, but most industrial facilities, use one of three main types—reciprocating, centrifugal or rotary screw air compressors.

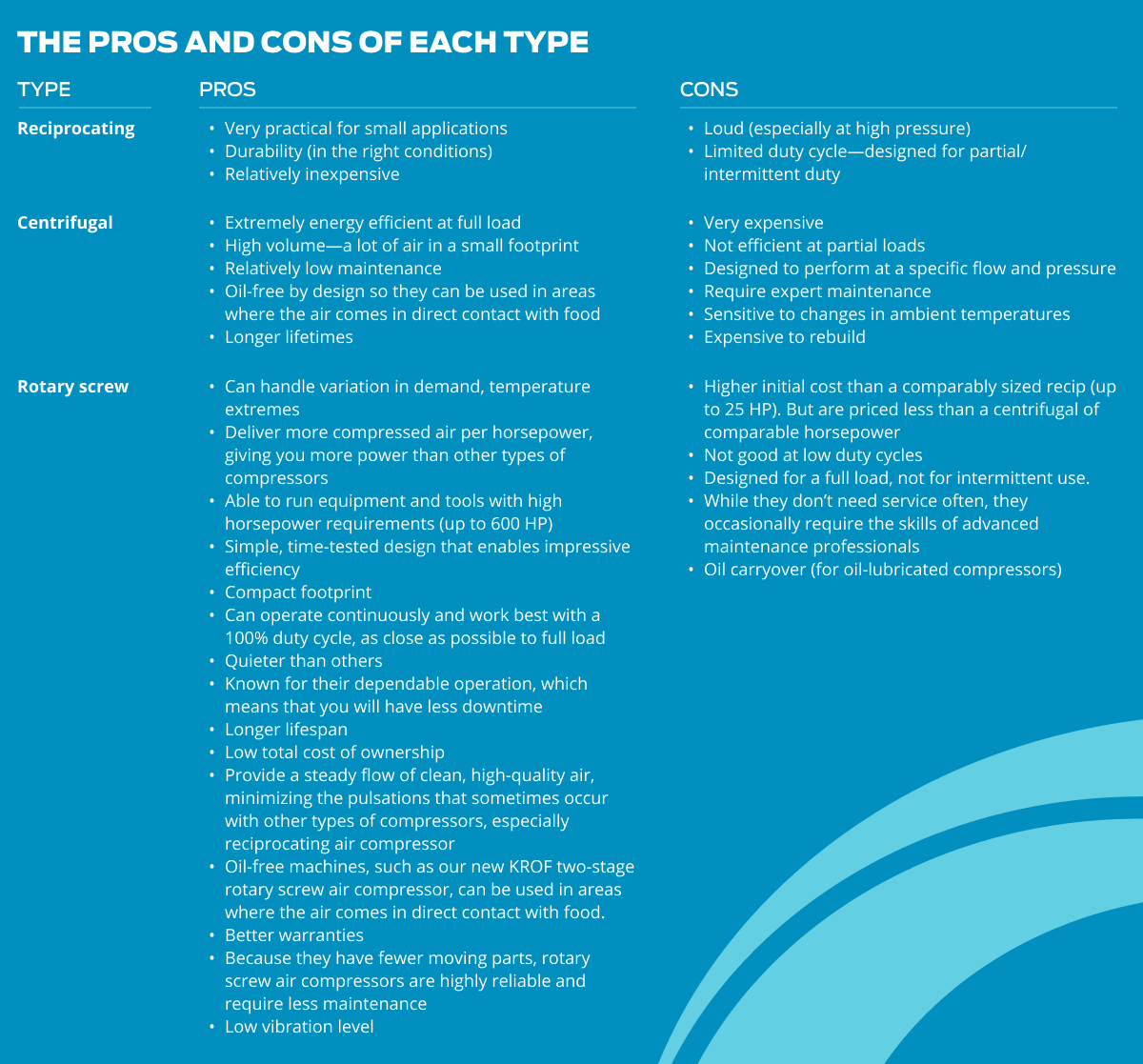

Each offers some unique benefits, depending on the application:

Reciprocating Compressors

A reciprocating piston compressor acts like an automobile engine, drawing air into a compression chamber as it moves in one direction, then compresses it when it reverses and moves in the opposite direction. Single-stage reciprocating compressors have a limited duty cycle, working best with intermittent or partial duty. They typically run best at 50% duty cycle or less. That’s 30 minutes in an hour. Run it longer, and you risk damaging your compressor and shortening its life. As a result, to properly size a recip, you need to consider a compressor with a larger horsepower rating to give the pump time to cool down.

Multiple-stage recips can get much larger (up to 1,000 HP) and are more energy-efficient than single-stage compression for high-pressure applications. However, they are becoming less common because they have a higher initial cost and require reinforced foundations and more extensive maintenance.

Centrifugal Air Compressors

Centrifugal compressors have an impeller that sucks in and compresses air. A diffuser plate then slows down the air, increasing the pressure. Extremely efficient, especially at high volumes with steady demand, centrifugal compressors can produce a lot of air from a small footprint and are very durable. And they are oil free.

Rotary Screw Compressors

Rotary screw compressors have two rotors that rotate through a compression chamber and pressurize the air until it reaches the desired pressure. They range in size up to 600 HP. Because they have fewer moving parts, rotary screw compressors are more reliable than other types of compressors. They can handle a 100% duty cycle—as such, we recommend setting up your compressed air system so that they operate as close to full load as possible. In addition, they are very energy efficient and good at variations in demand. Best of all, they deliver high-quality air, meeting the needs of many different applications.

Here’s a quick summary of the advantages of each type.

When to Use Each Type

When to Use Recips

Lighter-duty reciprocating compressors are perfect for businesses with an intermittent need for compressed air, such as oil-change shops and tire-repair centers. In those cases, a smaller reciprocating compressor may fit the bill, providing compressed air efficiently at a lower price point. And maintenance is minimal because a recip has less oil than other types of compressors. You need to do oil and air filter changes periodically. And, since small amounts of oil do blow by the rings of the pistons, you do need to add oil on occasion and provide downstream air treatment to get clean air.

Reciprocating or piston compressors have traditionally been the ideal choice for applications such as automotive repair shops, which use air tools intermittently.

According to the Compressed Air & Gas Institute (CAGI), “Small, air-cooled reciprocating compressors, 3 HP to 30 HP, are ideal for intermittent service similar to those compressors commonly used in an auto body/tire repair operation.”

When to Use Centrifugals

Extremely efficient, especially at high volumes, centrifugal compressors can produce a lot of air from a small footprint and are very durable. And they are oil free. Unfortunately, centrifugals are more efficient than other types of compressors down to 300 HP but may not be practical. Because of their initial cost, they are only feasible in larger applications (400 HP and above) with relatively stable pressure and flow demands.

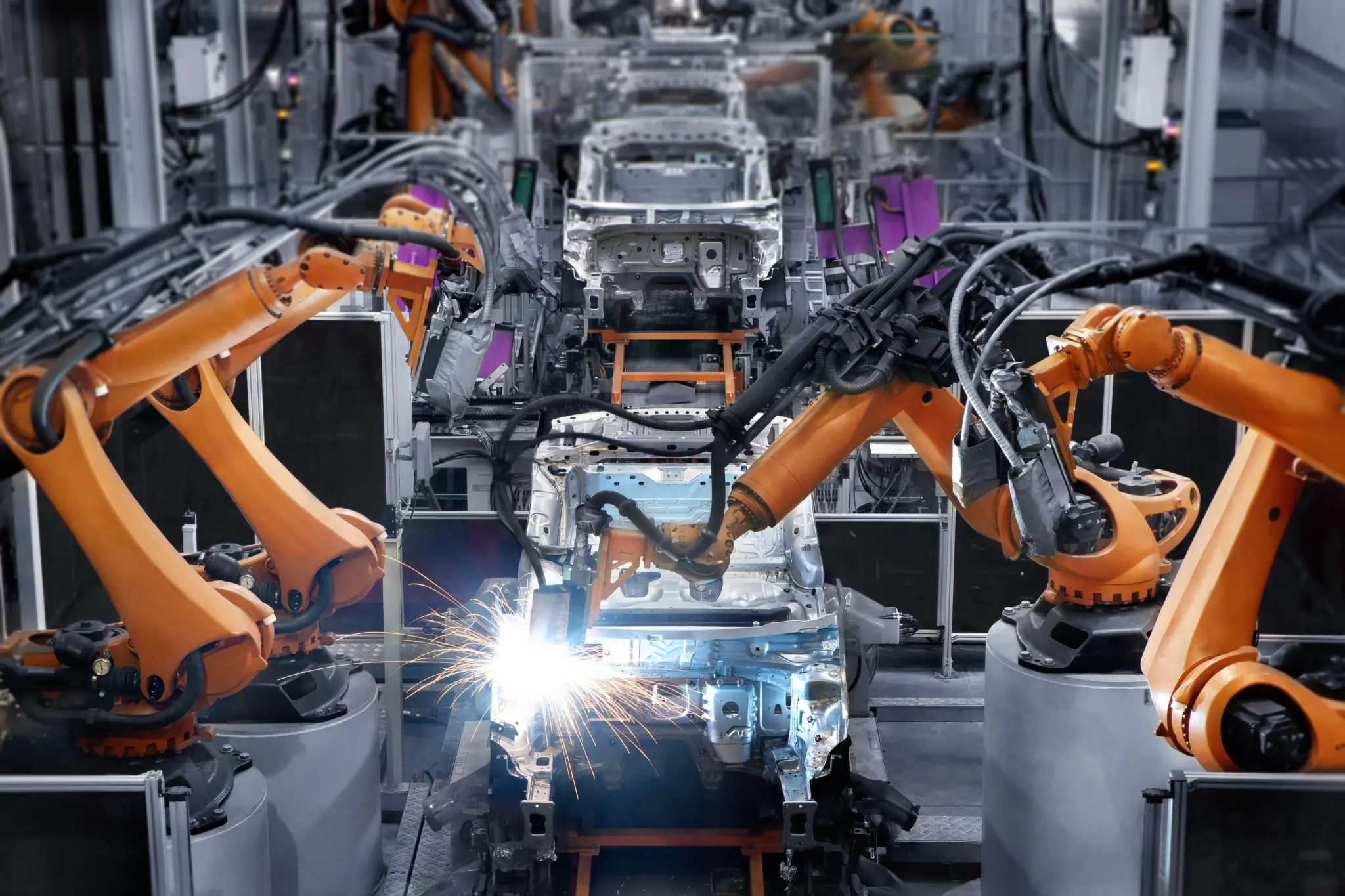

Large automotive assembly plants usually have enough need for compressed air that large centrifugal air compressors are cost-effective.

When to Use a Rotary Screw Air Compressor

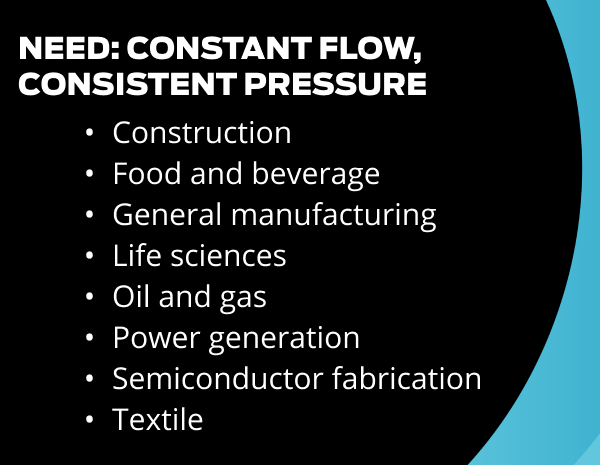

You’ll find rotary screw air compressors meet the challenges of many different industrial applications, working well in the following situations:

-

- You need a constant flow of compressed air at a consistent pressure level. They are typically used in industries that require a large volume of compressed air, such as general manufacturing, construction, oil and gas, food and beverage, life sciences, semiconductor fabrication, textile and power generation. Or even a larger automotive shop where the use is more constant.

- You need a constant flow of compressed air at a consistent pressure level. They are typically used in industries that require a large volume of compressed air, such as general manufacturing, construction, oil and gas, food and beverage, life sciences, semiconductor fabrication, textile and power generation. Or even a larger automotive shop where the use is more constant.

Applications such as sandblasting that need high pressure and high air flow are perfect for rotary screw air compressors.

-

- You need high pressure and high flow in an application like sandblasting. For more on sandblasting, read our blog post, “Best Screw Compressors for Sandblasting.”

- You have rugged conditions, including temperature extremes. Rotary screw air compressors are used widely throughout the mining, oil and gas and metallurgy industries, providing a reliable, consistent fourth utility (joining electricity, gas and water) in challenging environments. The only issue is that compressors drawing in ambient air loaded with dust and dirt require extra filtration and more frequent oil changes.

- You need high-quality air, free of impurities and moisture. Think industrial painting, semiconductor fabrication, or electronics assembly plants. And, with oil-free units like Kaishan’s new KROF two-stage rotary screw air compressor, you can even provide compressed air that has direct contact with food and beverage products.

- You’re looking for a low total cost of ownership. Adding up the energy efficiency, rugged reliability, extended lifetime and warranty protection, rotary screw air compressors are a long-term bargain for virtually any industrial application.

Large metalworking plants often use rotary screw air compressors to power a wide range of end-use applications.

Generally, a centrifugal air compressor is most cost-effective for high-volume applications (above 2,500 CFM) common in many larger applications, but rotary screw air compressors are better for lower volumes.

Rotary Screw Air Compressors—the Best Choice for Most Applications

Because of their reliability, efficiency and long life, rotary screw air compressors are the industrial air compressors of choice for most applications. Even major manufacturers with thousands of employees usually select rotary screw machines because their facilities are too large to make centralized units practical. In addition, rotary screw air compressors are known for producing steady streams of high-quality compressed air and handling large-capacity loads. And they are backed by the industry’s best warranties—Kaishan’s KRSP and KRSP2 screw compressors are backed by a lifetime warranty on the airend.

Over the years, we’ve found that customers fall in love with rotary screw compressors because they are reliable, energy-efficient and quiet.

Local Help

Selecting the right air compressor for your application is essential to the success of any organization. That’s why we recommend that you work with your local air compressor professional to select the right air compressor for your operation. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation. These factory-trained air compression experts can service your air compressor system without a problem.

Key Takeaways

-

- Most companies choose either reciprocating, centrifugal or rotary screw air compressors for their compressed air needs.

- Lighter-duty reciprocating compressors are a good choice when compressed air is needed intermittently.

- Centrifugal compressors are most cost-effective for applications needing high volumes of compressed air at a relatively stable pressure and flow.

- Because of their reliability, efficiency and long life, rotary screw air compressors are the industrial air compressors of choice for most applications.

Let Us Help

The right air compressor can make a big difference in the operation of your compressed air system and all the processes that rely on that system. If you need help choosing the right air compressor, get in touch with the experts at Kaishan. Contact us today.