How Energy-Efficient Air Compressors Can Reduce Your Carbon Footprint

July 31, 2024

Best Air Compressor for Trucks and Transportation

August 14, 2024Air Compressor Oil Filtration: Preserving Air Quality and Prolonging Equipment Life

Kaishan USA | August 7, 2024| Uncategorized

Smooth, shiny finishes like those on aircraft and cars require high-quality compressed air.

Four Things You Need to Know About Air Compressor Oil Filtration and How It Enhances Air Quality and Prolongs Equipment Life

Air compressors have come a long way since the bellows and primitive devices first used to compress air.

In fact, they are now developed with sophisticated technology that precisely machines parts, carefully matches lubricants and filter elements and reaches new heights of air quality, reliability, energy efficiency, equipment life and cost-effectiveness.

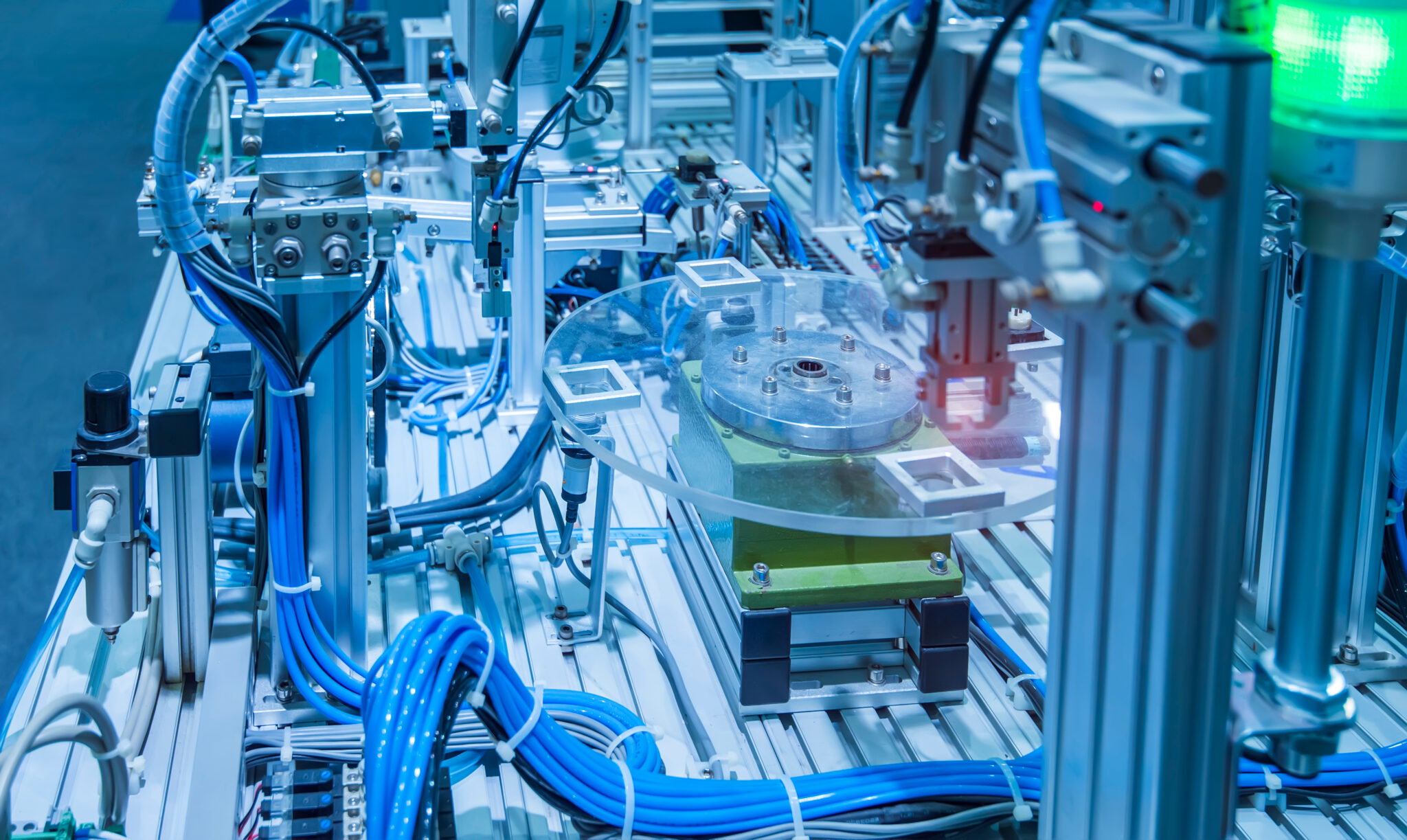

Air quality is crucial in a wide range of industries, including electronics, automotive, aerospace, healthcare and medical device manufacturing.

The robotic equipment used in automotive manufacturing requires high-quality air.

Unfortunately, many compressed air users are not aware of the advances air compressor manufacturers have made. As a result, they lack some critical information that can help them achieve the highest air quality. We offer four of those key information points below.

1. Maintenance is the Cheapest Thing You Can Do to Ensure High Air Quality

Since air compressor oil plays such a crucial role in air compressor operation, it’s essential to maintain fluid levels, change filters, replace oil and submit oil samples regularly. Changing your lubricant and filters with reputable OEM-approved products is the number one thing you can do to extend the life of your equipment. In our experience, lack of maintenance is the number one reason for compressor failures.

You’ll want to make sure to match your maintenance intervals to your operating and installation conditions. If you operate 24/7, you'll need more maintenance. And if your environment is hot or dirty, you should do your routine maintenance more frequently.

When you change the oil, drain the oil cooler completely to ensure no residual oil is left behind. Failing to drain your oil cooler completely is like mixing fresh milk with curdled milk; leaving even a small amount of the old oil can significantly impact the life of the new lubricant.

The good news? Kaishan KRSP and KRSP2 premium rotary screw air compressors have a separate drain point and atmospheric vent installed to make this process easy.

Our constant refrain with customers: Maintain these machines properly, and you will get a crazy number of years out of them. Changing your oil on time is the cheapest insurance you can get for any piece of equipment.

Doing it correctly and doing it often is the number one way to ensure your oil quality and prolong equipment life. An important part of that maintenance is oil sampling.

Oil Sampling

Fluid sampling is critical to the life of an oil-flooded rotary screw air compressor. Regularly sampling oil will tell you whether it is being exposed to excessive heat or taking in contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem, even avoiding an unplanned shutdown.

Perhaps even more significantly, oil sampling can help you identify significant variations even within your facility. We’ve seen occasions where one compressor gets 10,000 hours from a lube, while the same compressor at the other end of a factory needs an oil change after 4,000 hours. It’s all about the operating environment.

That’s why we consider oil sampling the most critical maintenance procedure for our compressors. We also require that our customers collect an oil sample and have it analyzed every 2,000 hours or every 1,000 hours for food-grade applications to maintain their warranty protection.

Oil sampling extends the life of the lubricant and your equipment. It verifies that your air compressor oil will last as long as expected and measures the level of contamination, lubricant oxidation and additive depletion. For more on oil quality and oil sampling, read “Choosing the Right Rotary Compressor Oil.”

Oil sampling provides a wealth of data about the performance of your air compressor oil. And we can also learn a lot about the condition of your compressor.

2. Air/Oil Separators Need to Be Like Goldilocks: Not Too Fast, Not Too Slow, Just Right.

The speed at which compressed air enters an air-oil separator is critical to the air quality. If the air is moving too fast, the fibers in the filter media won’t be able to capture the oil and remove it from the airstream. The air blows straight through, almost cleaning the filter media.

Conversely, if the air moves too slowly, it almost “walks” through the fibers. And the filter will not capture the oil.

In both cases, the oil will carry over, degrading air quality.

That’s why original equipment manufacturers like Kaishan match the air-oil separator elements with the specific gravity and velocity of the lubricants. Their goal is to engineer the fibers and the lubricant to perfectly optimize oil capture.

Using knock-off parts or cheap oil, then, throws that carefully engineered system out the window, resulting in oil carryover and loss of quality.

Even using a pirated oil filter or even one that is more porous than the OEM specifications can cause problems. Anything that passes through the oil filter can get trapped in your air oil separator element, causing clogging that will shorten the life of your air oil separator and reduce your air quality at discharge.

3. Using the Right Oil Pays for Itself

Kaishan worked with an expert global developer of industrial lubricants to formulate the air compressor oil we install in our compressors. Our KTL-8000 air compressor oil is a hydrologically stable synthetic with ester chemistry additives.

KTL-8000 has been specially formulated for Kaishan’s rotary screw air compressors, enabling them to overperform in any industrial setting. We strongly encourage every customer to use it in their Kaishan machines. For more information, download the KTL-8000 safety data sheet. We also offer food-grade lubricants and a PG (polyglycol) alternative for high humid conditions.

Long Life

Kaishan’s KTL-8000 lasts two times longer than mineral-oil-based products. From an environmental standpoint, you’ll use less oil and have less oily waste. We’ll also consume less energy manufacturing it, which benefits the environment.

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

It’s part of an overall strategy that allows Kaishan to offer industry-leading warranty protection. Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months. With our extended warranties (provided at no additional cost), we back our KRSP and KRSP2 screw compressors with a lifetime warranty on the airend.

As mentioned, our extended warranties require that you use genuine Kaishan industrial air compressor parts and sample the oil every 2,000 hours or 1,000 hours for food grade applications (see “Oil Sampling” section above). Your local service provider may want to customize the intervals if conditions are challenging.

Using generic or aftermarket parts/fluids will void the warranty.

Kaishan’s KTL-8000 air compressor oil.

4. You Can Get Burned Using Pirated Parts. So Can Your Facility.

If you use pirated parts not designed to the same specifications, you can get high oil carryover, which impacts your quality. You can permanently damage the machine, potentially even causing a fire.

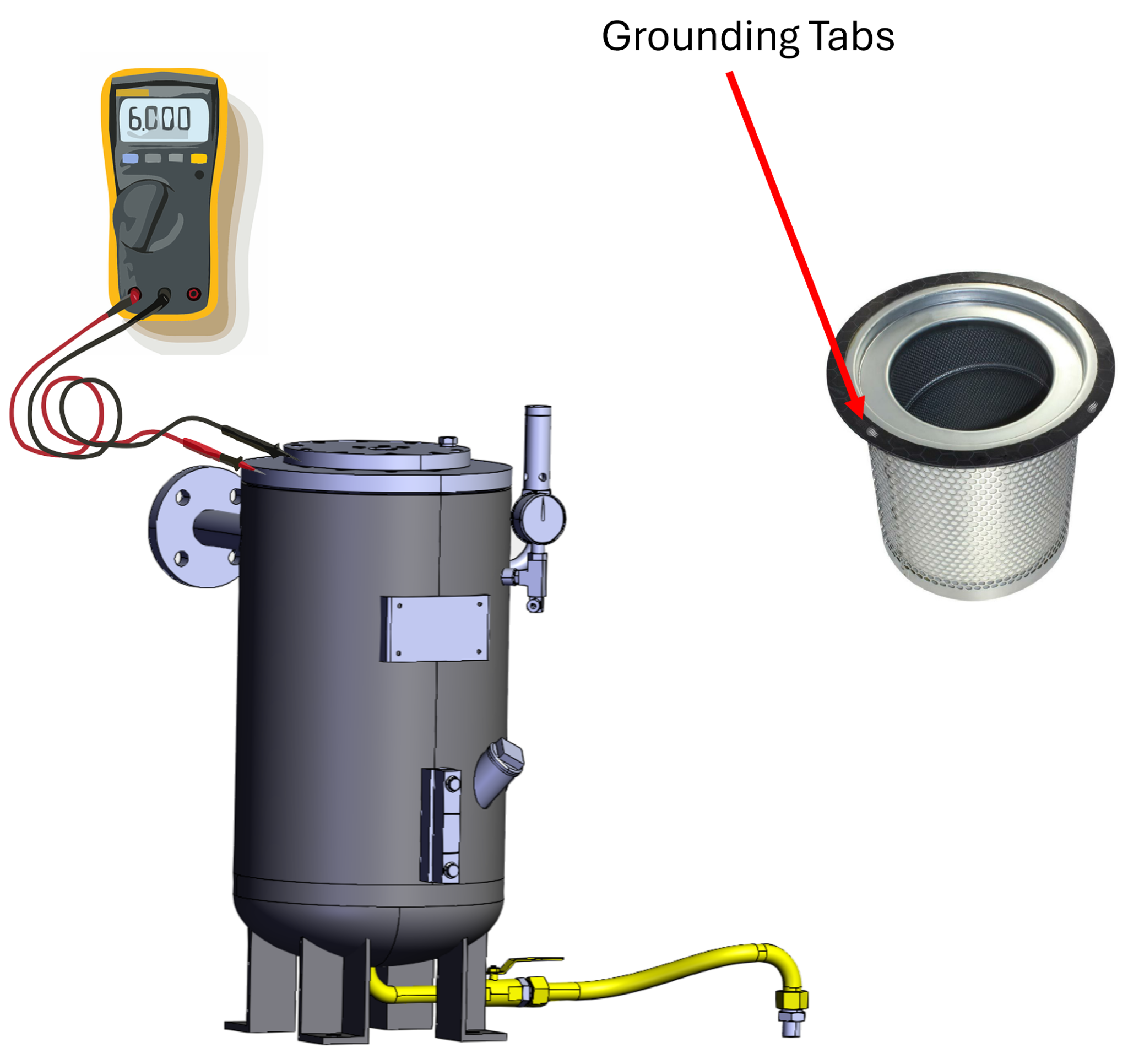

That’s what can happen when the air-oil separator in a rotary screw air compressor is not seated or grounded properly. The high volume of air flowing into the separator creates static electricity, causing sparks and, potentially, a fire. Not only can the machine be destroyed, but the facility as well.

And while rotary screw air compressors are remarkably safe—safer, in fact, than almost any other power source—they are not immune to user error. Even the best-engineered system in the world will experience a problem when it's not appropriately maintained.

And it all happens because someone is trying to save money and buys a gray-market or knock-off aftermarket part—in this case, an air-oil separator.

Kaishan designs its rotary screw air compressors so that the air-oil separator seats perfectly into the compressor, providing the required continuity and grounding.

Air-oil separators are designed to line up with the grounding tabs and clips that secure them in place and provide continuity so the separator has a path to the ground. An aftermarket separator is not intended to fit any specific OEM’s machine. As a result, it may not maintain the necessary continuity between the separator and the sump tank, which is grounded. The consequences can be devastating.

It’s one reason why OEMs require that you use their own industrial air compressor parts for warranty validation. Kaishan’s extended warranties require that you use genuine Kaishan industrial air compressor parts and sample the oil every 2,000 hours (see “Oil Sampling” section below). Using generic or aftermarket parts/fluids will void the extended warranty.

As Compressed Air Best Practices notes, any perceived short-term savings you realize by purchasing aftermarket parts could ultimately raise your lifecycle costs, resulting in higher energy use, increased downtime and more frequent replacements. “The money you save by purchasing generic parts is often the most expensive money you will ever save.”

For more information on the importance of using genuine OEM replacement parts, visit our parts and services page. Or read our blog post, “How to Maintain Your Air Compressor with Genuine Spare Parts.”

To avoid damage or premature wear, you should provide high-quality air to drive the pneumatic devices that are used throughout industry today.

Local Help

More and more companies are finding they no longer have expertise in-house to properly maintain and troubleshoot their compressed air systems. And few have the resources to purchase the latest technology or the need to train staff in its use. As a result, we strongly advise our customers to seek outside help when problems arise. Especially the loss of air quality or shortened equipment life.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Key Takeaways

-

- Maintenance is the cheapest way to ensure high air quality.

- Air/oil separators need to be like Goldilocks: Not too fast, not too slow, just right.

- Using the right oil pays for itself.

- You can get burned using pirated parts. So can your facility.

- The money you save by purchasing generic parts is often the most expensive money you will ever save.

Let Us Help

Maintaining your rotary screw air compressor and its filter elements is critical to the quality of the air you are delivering and the life of your equipment. Which in turn is essential for the efficiency and success of your operation. If you need help developing a comprehensive maintenance program, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text