Laser Cutting

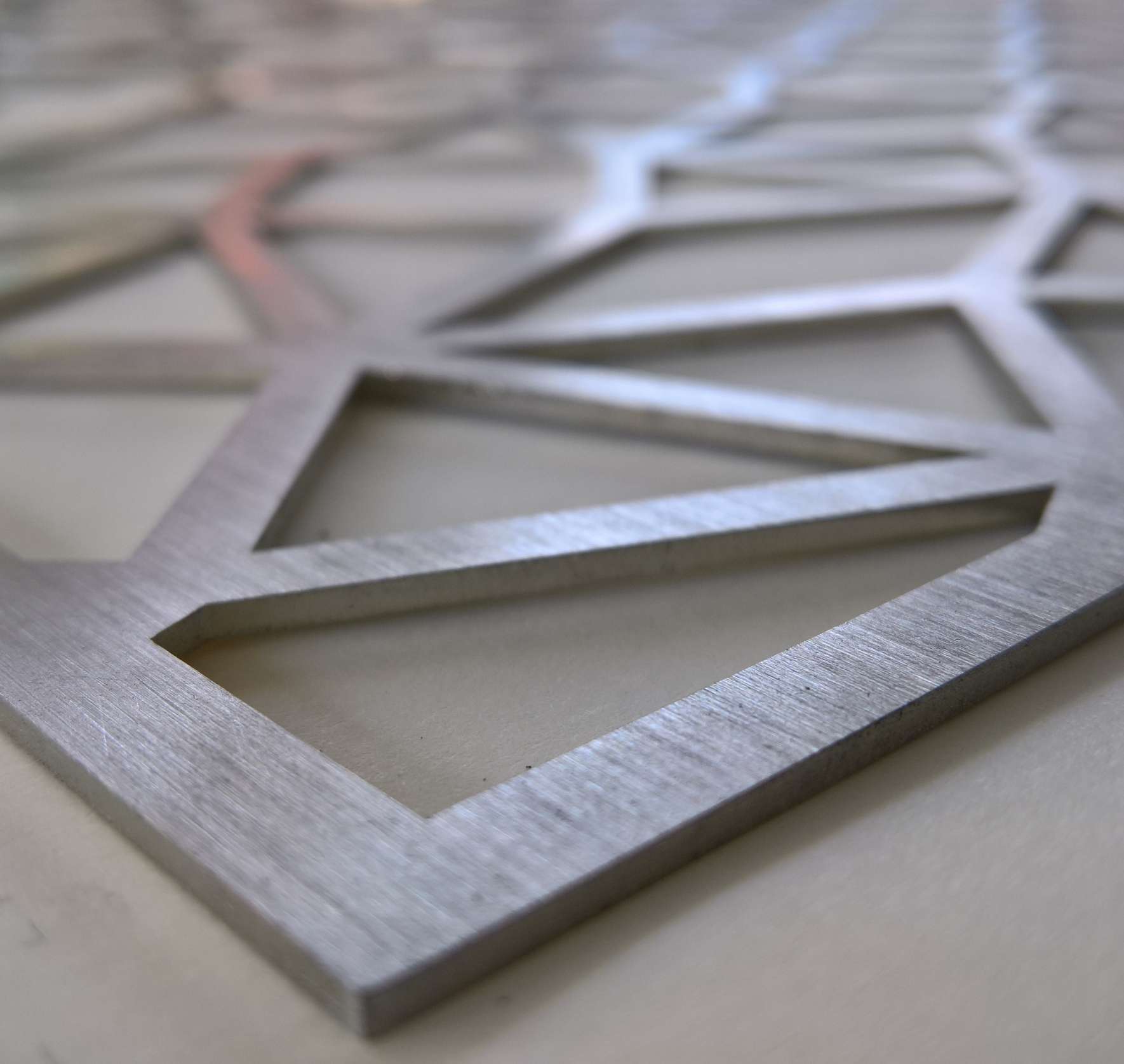

Companies that use laser cutting need a reliable air compressor. Any material wasted during the laser cutting process represents added cost and highlights inefficiencies. Auxiliary gasses, such as compressed air, can be used to reduce material waste during the cutting process. Compressed air blows smoke and cutting residue away from the beam path and operator sight line. The pressure, stability, and capacity of the air compressor directly affect metal laser cutting quality.

Kaishan USA supplies laser cutters with quality air compressors that can improve the performance of your laser cutting tools. Kaishan air compressors are engineered with features like high-efficiency electric motors to deliver a reliable source of compressed air while in use. Our high-quality air compressors ensure your operators cut with precision and waste less material.

Engineered to deliver the performance you expect

Laser cutting engineers and operators rely on Kaishan USA to deliver compression-powered air assistance that improves their cutting process. Whether they are cutting through wood, steel, or other materials, Kaishan is proud to provide laser cutters with:

KRSB Air Compressors with IE3 premium efficiency motors for long operating life Read More >

KRSD Air Compressors with safety features to reduce OSHA risk and injury Read More >

The laser cutting industry can utilize Kaishan USA compressors to improve laser cutter operator performance while maintaining proper safety standards.

Interested in learning more about Kaishan compressors? Contact us here.