What Are The Different Types Of Air Compressors?

September 6, 2018

Air Compressors In Food And Beverage Production

October 4, 2018WORKING PRINCIPLES OF TWO-STAGE AIR COMPRESSORS

Kaishan USA | September 20, 2018 | Rotary Air Compressors

With so many models of air compressors in the market today, it can be difficult to understand them all. First, however, it would be good to establish that all air compressors work on basically the same principle: they transform power from a source—such as an electric motor, gas, or diesel engine—into pressurized air, which is then stored and ready to be released to drive machinery such as production and construction equipment.

How Does A 2-Stage Air Compressor Work?

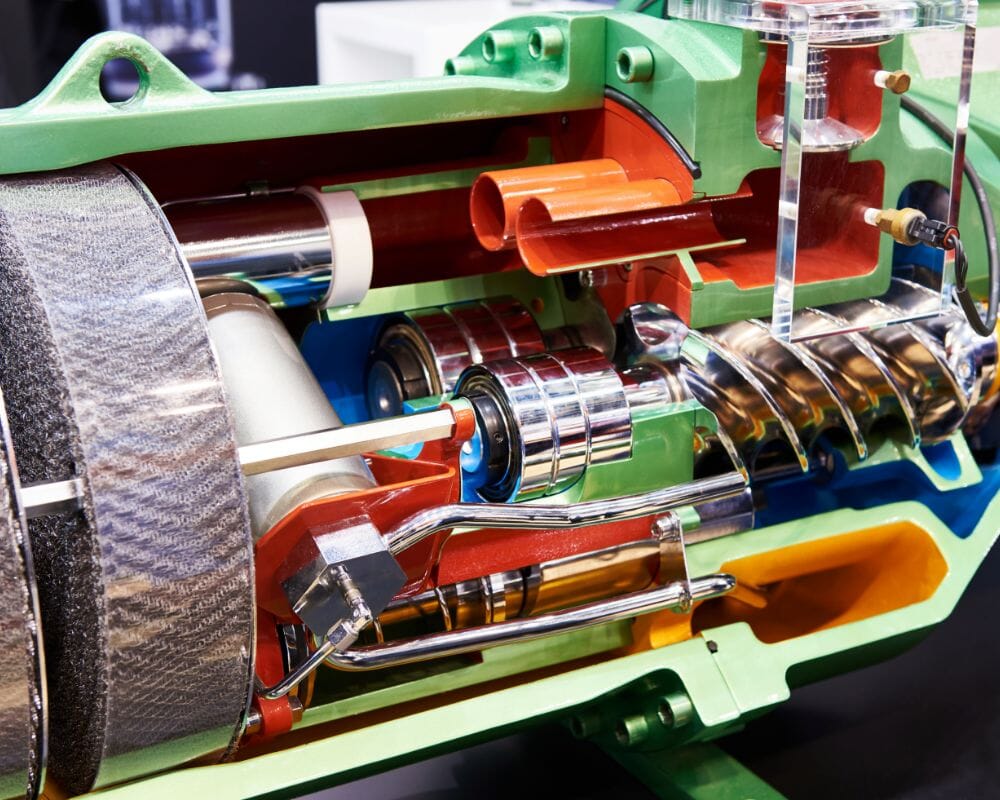

Now that we have established the basic operating principle of all air compressors, let us address the 2-stage air compressor theory. Unlike single-stage air compressors that typically use a piston or rotary screw to draw air from an external intake and pressurize it once, 2-stage compressors repeat the pressurization of the air they take in twice. Naturally, this means there are two cylinders to store the pressurized air, as well as double the mechanisms to draw air in and pressurize it.

There are several differences between single-stage and 2-stage compressors. In the single-stage process, air is compressed, used and replenished at the speed with which a single piston or screw can draw in more air and pressurize it. In contrast, 2-stage air compressors work on the principle that after the first stage of pressurization, a second stage of pressurization allows for a higher pressure of stored air. This process is prized by those requiring higher sources of pressurized air, typically above 100 PSI, as well as the quick and continuous replenishment of air.

2-Stage Rotary Screw Air Compressors

Valued for their ability to produce higher pressure and faster recovery of stored pressurized air, 2-stage air compressors are often used to drive equipment that is critical to mass production where reliability is crucial—for example in general manufacturing, automotive, aerospace, food and beverage, and glass production. Of all 2-stage compressors, those that operate by means of rotary or twin helical screws are by far some of the most popular and trusted models in use today.

Especially in industrial applications like those just mentioned above, 2-stage rotary screw air compressors are often preferred over reciprocating or piston-driven models. The reason for this is that the rotary design is more efficient, requires less maintenance, and runs more quietly. Putting all of the benefits together, 2-stage rotary screw compressors offer more uptime for applications that require non-stop continuous operation.

Why Choose Kaishan Rotary Screw Compressors?

At Kaishan Compressor, we have been manufacturing single-stage and 2-stage rotary screw air compressors for over 60 years. We strive for continual improvement and innovation in everything we do. That is why all of our air compressors are low noise, low maintenance, and consume less energy, reducing your cost of ownership while maximizing the reliability and performance you get from our products.

Kaishan’s air compressors serve the mission-critical needs of a variety of industries, including electronics, chemical, petrochemical, general manufacturing, automotive, aerospace, food and beverage, and many more.

To learn more about rotary screw air compressors, contact us today.

Random stat or

customer quote

textXXtext

text

With so many models of air compressors in the market today, it can be difficult to understand them all.