Optimizing Rotary Screw Compressors for Seasonal Temperature Swings

May 28, 2025

How the Right Air Compressor Enables the Soft Touch that Makes Pneumatics So Valuable

June 11, 2025Altitude Considerations: High-Elevation Operation of Rotary Screw Compressors

Kaishan USA | June 4, 2025 | Uncategorized

Like an athlete training to perform at higher elevations, you must prepare for altitude effects on compressors.

When 19-year-old Jim Ryun broke the world record for the one-mile run in 1966, one of the marquee events in track and field, it looked like he had a lock on Olympic gold in two years. By the time he reached the starting line in 1968, he was the world record holder in the 880-yard run and the one-mile run, as well as the metric equivalents for those distances.

Unfortunately, he finished second in the metric mile (1,500 meters) and did not place in the 800-meter event. He was hit by a double whammy: Mexico City’s 7,300-foot altitude and wily Kipchoge Keino, who grew up and trained in Kenya, where 7,000-foot altitudes are routine.

If one of America’s premier middle-distance runners experienced problems, we shouldn’t be surprised by the altitude effects on compressors. Let’s talk about the impact of altitude on rotary screw compressors.

What Happens at Higher Elevations

- Less density. As you go higher in elevation, there’s less air and fewer air molecules per cubic foot.

- Lower air pressure. In the same way that the weight of the water generates crushing pressure at the deepest part of the ocean, the weight of the air above generates air pressure. So, the higher you are, the less air you have above you, and, hence, you have less air pressure.

Those factors, combined, have a significant impact on your compressor.

Altitude Effects on Compressors

High-altitude air affects your compressor’s efficiency and performance, as well as its capacity to produce air pressure and flow. We’ll start with the impact on flow.

Less Flow

With less density and fewer air molecules available, an air compressor in Denver can capture and compress less air and deliver less flow than the same compressor in Houston.

That difference can be significant. Let’s say, for instance, that you have added up all rated flows your end users need, and you determine that you’ll need your compressor to deliver 1,000 CFM. That’s great if you’re at sea level. Say, New Orleans.

But if you’re somewhere in Colorado at 10,000 feet, there are fewer air molecules to compress. So, that same compressor that gave you 1,000 CFM in New Orleans will only give you 600 CFM. You’ll need a compressor capable of delivering 1,500 or 2,000 CFM at sea level to meet all your requirements.

Higher elevations, like this one in Colorado, can be picturesque. But they pose challenges for compressed air systems.

Recognizing the significant impact elevation has on compressor capacity, compressor manufacturers have adopted standards to allow “apples-to-apples” comparisons of their models and those of other manufacturers, taking site conditions out of the equation:

- Actual CFM (ACFM): the volume flow rate of the discharge of the air compressor, measured at the inlet, at sea level elevation (atmospheric pressure of 14.7 PSIA), 36% relative humidity and an ambient temperature of 68°F. It is the measurement manufacturers use to describe the capacity of their compressors.

- Standard CFM (SCFM): the mass flow rate of the discharge of the air compressor on your site. It recognizes that few real applications meet the “ideal” conditions for calculating ACFM. So SCFM factors in the altitude, ambient temperature and relative humidity of your specific location.

Only the compressor is rated in ACFM. Dryers, filters and all downstream equipment are rated in SCFM.

Less Pressure

Lower ambient air pressure means your compressor must work harder to generate the pressure you need. If the air pressure is 14.69 pounds per square inch in New Orleans and 12.22 in Denver, your compressor has to make up the difference. For the most part, an air tool in Denver needs the same 80 PSIG of pressure it requires in Miami.

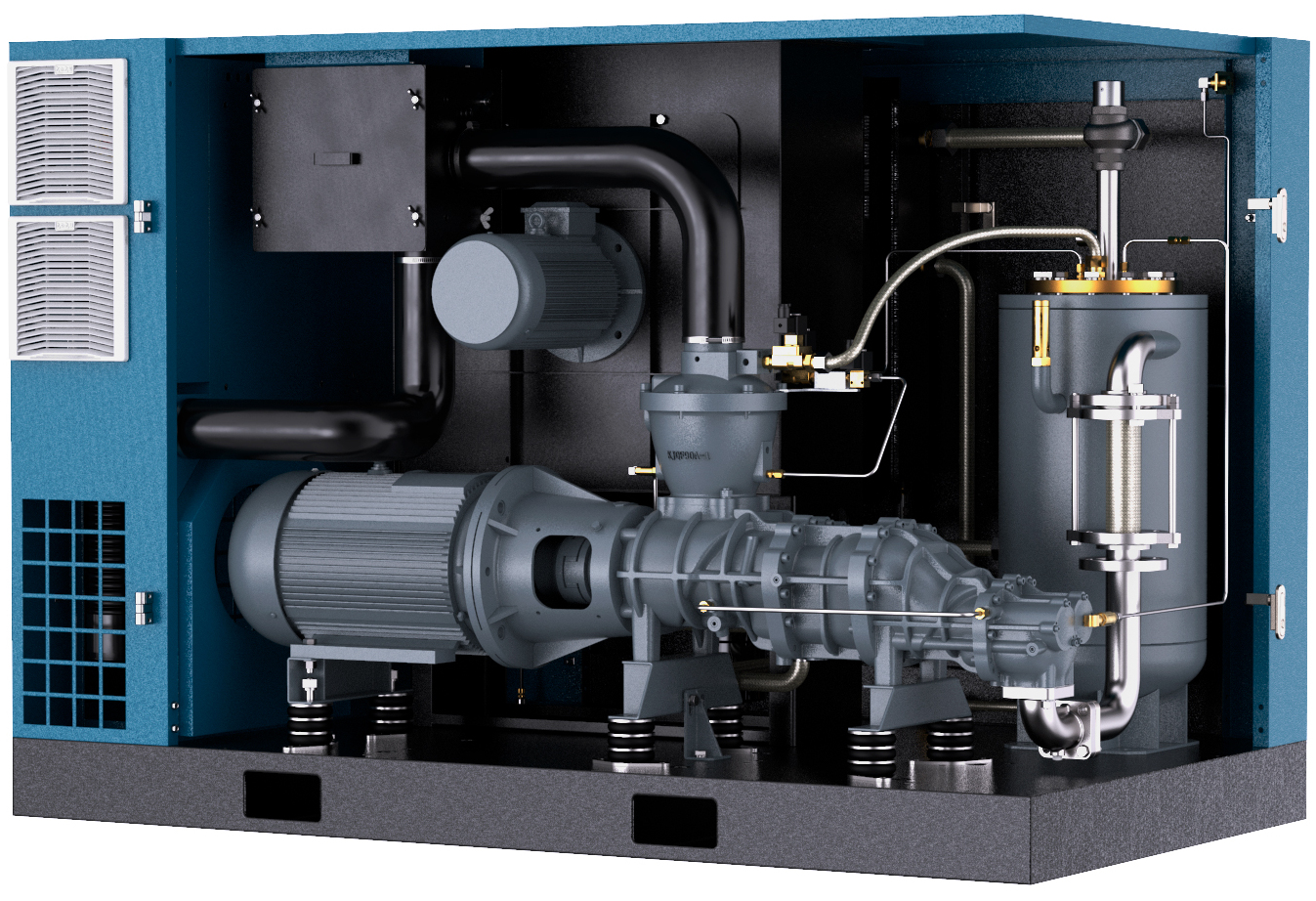

Altitude even impacts two-stage units like Kaishan’s KRSP2 premium rotary screw air compressor, requiring higher compression ratios, especially in the first stage.

More Heat

Because fewer air molecules enter at a lower pressure, your compressor at altitude will have to work harder and generate more heat to produce the same amount of pressure and flow as at sea level.

Less Cooling

Because the air is less dense, there are fewer air molecules to remove heat. Once again, your compressor must work harder to maintain the target temperature.

Impact on Your Compressor’s Components

The effects of altitude are not limited to your compressor and the airend. They will also change the performance of your motor and cooling equipment.

More Motor

Your compressor will need a larger motor to do the increased work required to generate the pressure and flow. As with the compressor, the motor will generate more heat and have less cooling capability, so you will need a motor rated for high altitudes.

Larger Air Intake

Because the air is thinner at higher elevations, you may need to increase the size of your air inlet valve to bring more air molecules.

You may need to increase the size of your air inlet valve to compensate for the thinner air at higher elevations.

Cooling Equipment

As mentioned, altitude will impact the cooling capabilities of an air-cooled machine (but not a water-cooled compressor). You’ll need to oversize your fans and heat exchangers.

Electrical Components

Even your electrical components will be impacted. Your starters and other electrical equipment must be oversized to dissipate heat into thinner air.

If you use the same components at 10,000 feet as you use at sea level, your system may overheat.

High-Altitude Compressors?

Do we have high-altitude compressors? Not really, but there are a host of steps we can take to make sure your compressor runs well at higher elevations, including:

- Increasing compressor size. The higher the elevation, the larger the compressor. Your local compressed air consultant can help you calculate the capacity you’ll need.

- More cooling. Fans and heat exchangers need to be sized to account for the reduction in cooling capacity at higher altitudes.

- Larger motor, starter and drives.

- Larger electrical components.

Altogether, these combined impacts could require as much as a 40% increase in compressor capacity at higher altitudes, according to Compressed Air Best Practices.

We recently sold a compressor to a Colorado gold mine where they could have used a 200-HP compressor if they were at sea level. But because they were at 11,000 feet, we had to specify a 350-HP unit with a 400-HP cooler pack, larger fan, heat exchanger, motor, starter and drive. We oversized everything, and it’s been running well.

Local Help in Getting Altitude Right

Sizing a compressor to account for your elevation illustrates the value your local compressed air consultant can offer. They know your area and the unique challenges of delivering compressed air.

Your local compressed air professional can help ensure that your air compressor is sized correctly for your elevation.

Kaishan USA is fortunate to work with a nationwide network of independent distributors, who can provide on-site help and consultation to answer any questions about how your particular elevation will impact the operation of your compressed air system.

We choose to partner with independent, local professionals because it's the best way to ensure you have access to factory-trained air compression experts who can service your air compressor system without a problem. They offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they know how to maximize efficiency and minimize downtime. When you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see it succeed.

Key Takeaways

- Altitude has a significant impact on the operation of your compressed air system.

- The air is less dense at higher elevations, and the air pressure is lower.

- Lower ambient air pressure means your compressor will have to work harder to generate the pressure you need

- Your compressor must work harder and generate more heat at higher elevations to produce the same pressure and flow.

- In addition to its effects on the compressor and the airend, altitude will also change the performance of your motor and cooling equipment.

- Even your electrical components must be oversized at higher altitudes to dissipate heat.

- Sizing a compressor to account for your elevation illustrates the value your local compressed air consultant can offer.

Let Us Help

Making sure your rotary screw air compressor is sized and equipped for your altitude is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help adapting your compressed air system to your elevation, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Why Altitude Changes Everything

Welcome back to The Big Dog Podcast! I’m Jason Reed, here with Lisa Saunders. Today we’re talking about something that gets overlooked way too often—altitude. Not the kind you get on a plane, but the kind that messes with your rotary screw compressor when you’re up in the mountains.Yeah, and it’s wild how much elevation can throw a wrench in your system. I mean, you’d think air is air, right? But once you get up a few thousand feet, it’s a whole different ballgame. Less air density, lower pressure—your compressor just can’t grab as much air as it does at sea level.

Exactly. It’s like, you take a compressor that’s rated for 1,000 CFM in New Orleans, and you drop it in Denver—suddenly you’re only getting, what, 600 CFM? That’s a huge hit. And people don’t realize it until their tools start choking out or production slows down.

And that’s where those ratings come in—ACFM versus SCFM. I always mix these up, but, uh, ACFM is what the manufacturer says the compressor can do at sea level, right? Like, perfect conditions. SCFM is what you actually get at your site, factoring in your altitude, temperature, humidity—all that real-world stuff.

Yeah, you got it. ACFM is the lab number, SCFM is the real number. If you’re not looking at SCFM, you’re basically guessing. And that’s how people get burned.

I had this plant manager in Denver—he called me, totally frustrated. They’d just installed a brand new compressor, and it wasn’t keeping up. Everyone was blaming the machine, but nobody had factored in the altitude. Once we ran the numbers for Denver’s elevation, it all made sense. They needed a bigger unit, not a repair.

Happens all the time. People forget that the air’s just thinner up there. It’s not the compressor’s fault—it’s physics. You gotta size for where you are, not where you wish you were.

Engineering for Thin Air

So, let’s talk about what actually happens inside the compressor at altitude. It’s not just about less air going in—the whole system has to work harder, right?Yeah, and it’s brutal. The compressor’s gotta spin faster, run hotter, just to hit the same pressure you’d get at sea level. And because the air’s thinner, it can’t cool itself as well. So you get more heat, less cooling, and everything’s under more stress.

And it’s not just the compressor, either. Motors, fans, even the electrical components—they all have to be oversized. Standard specs just don’t cut it when you’re, like, 8,000 or 10,000 feet up.

Right. I mean, we had this job at a gold mine in Colorado, up at 11,000 feet. Normally, a 200-HP compressor would’ve done the trick. But at that altitude? We had to go with a 350-HP unit, plus a 400-HP cooler pack, bigger fan, bigger everything. If we’d stuck with the standard setup, it would’ve overheated and shut down in no time.

That’s a massive jump. And it’s not just about throwing more horsepower at the problem, either. You have to look at the whole system—air intake, cooling, even the starter and drives. If you miss one piece, the whole thing can fall apart.

Yeah, and you can’t just order a “high-altitude compressor” off the shelf. It’s all about customizing—oversizing the right parts, making sure the system can handle the extra load. Otherwise, you’re just setting yourself up for trouble.

Getting Sizing and Support Right

So, how do you actually get it right? I mean, if you’re running a plant up in the mountains, what’s the move?First thing—don’t guess. You gotta size your compressor for your actual site conditions. That means factoring in your elevation, your temperature, your humidity. If you just go by the catalog, you’re gonna end up short.

And that’s where local consultants come in. I know it sounds like a sales pitch, but honestly, having someone on-site who knows your area makes all the difference. Kaishan’s distributor network is built for this—they’ve got people who actually understand what it’s like to run equipment at altitude.

Yeah, and I’ve seen what happens when folks skip that step. There was this facility up in the mountains—didn’t bother with a local expert, just ordered what they thought they needed. Compressor kept shutting down, overheating, constant downtime. They ended up spending way more fixing it than if they’d just sized it right from the start.

It’s one of those things where you really can’t afford to cut corners. The right support means you get a system that actually works, not just on paper, but in your real-world conditions. And if something goes wrong, you’ve got someone local who can help—fast.

Bottom line—altitude changes everything. If you’re not planning for it, you’re asking for trouble. But if you get the sizing and support right, your system’s gonna run smooth, no matter how high up you are.

Alright, that’s a wrap for today. If you’re dealing with high-altitude headaches, don’t go it alone—reach out to your local experts, get the right advice, and keep your plant running strong.

Thanks for tuning in to The Big Dog Podcast. Lisa, always good talking shop with you.

You too, Jason. See you next time, everyone.

Take care, folks. Don’t let that thin air catch you off guard.

Random stat or

customer quote

textXXtext

text