Kaishan is the foremost expert in air compression technology, with more than 60 years of experience in manufacturing air compressors. So, it’s safe to say that we have seen it all. Kaishan is dedicated to educating current and future customers about all aspects of a compressed air system.

From air compressor guides to compressor room design, you can find content to better understand compressed air systems and how they can suit your application. Our air compressors can operate in harsh environments, improve uptime, and reduce maintenance and operational costs.

Learn more about how you can trust Kaishan air compressors for any application. Check out our blog below to see how our air compressors can fit into your application.

One of the most dangerous misconceptions that undermines cost-effective operation of compressed air systems is the belief that compressed air is free. [...]

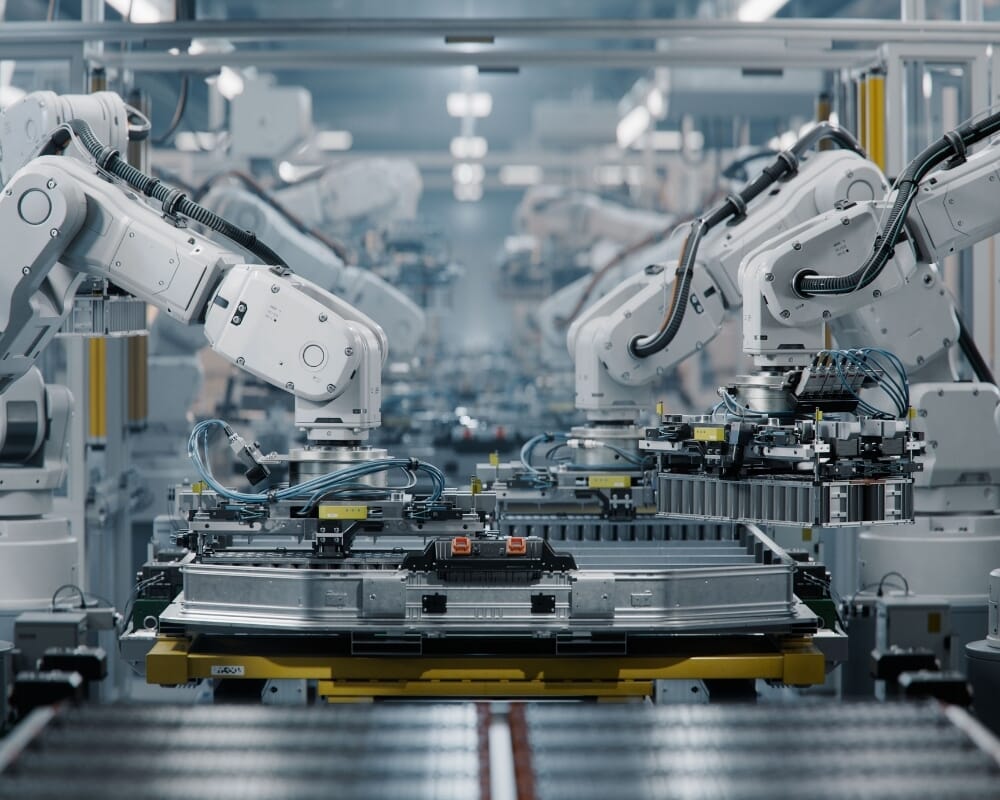

If you’re responsible for keeping a plant running, you already know that compressed air is a necessity. [...]

Almost everyone in today’s industrial environment has heard about variable-speed drives. And for good reason. [...]

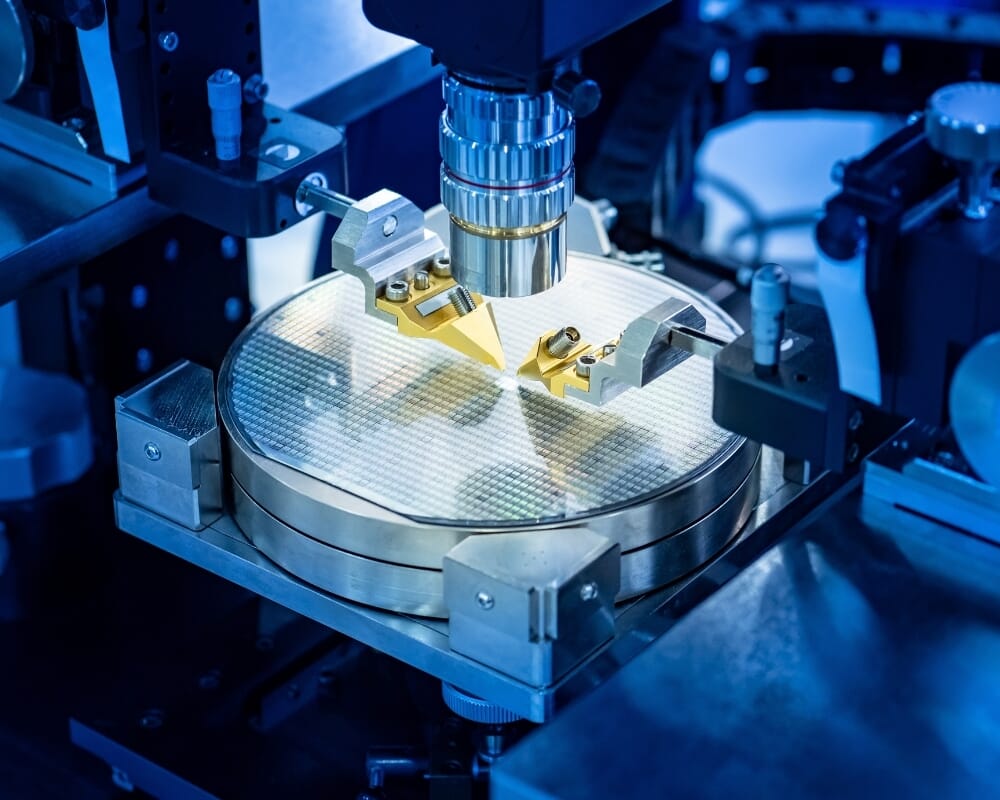

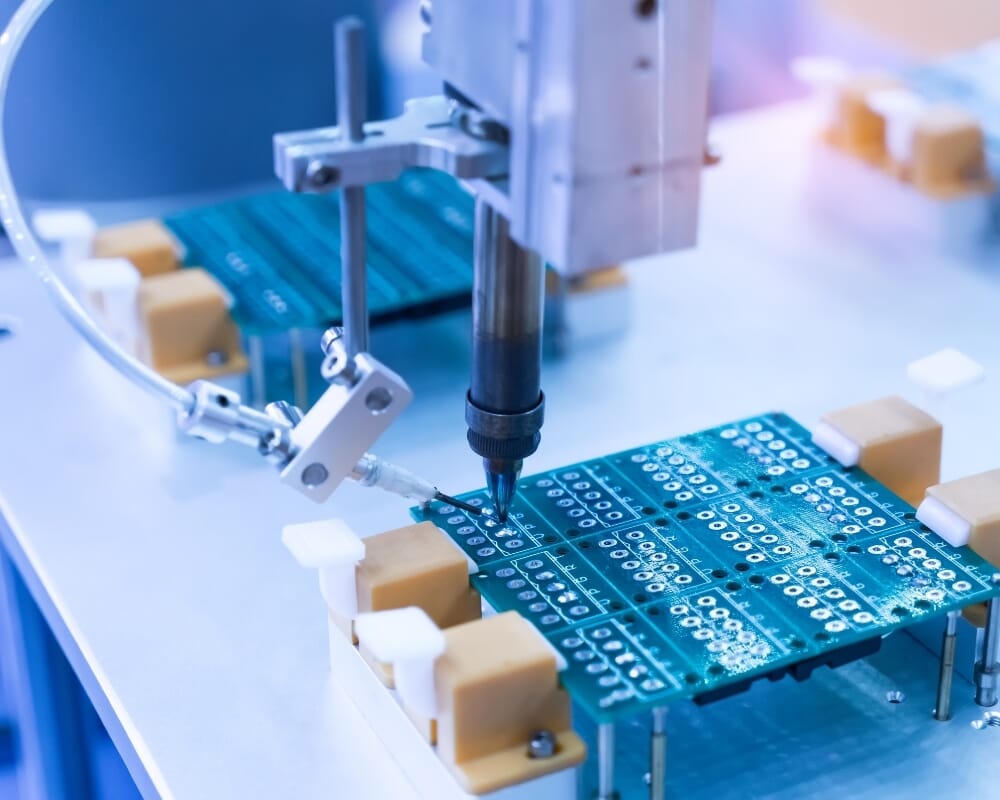

If you manage compressed air systems in a facility that demands clean, dry air—such as electronics, food and beverage, healthcare/life science and semiconductor industries—you already know “oil-free” isn’t just a spec on a datasheet. It’s a daily discipline. [...]

For years, when a plant needed temporary air—during a shutdown, a planned maintenance window or a sudden breakdown—the default has been to call the rental house and tow in a diesel portable compressor. [...]

Compressed air keeps your plant moving. But it tends to fly under the radar until something goes wrong. [...]

Maintenance managers are constantly looking for ways to optimize compressed air system efficiency while keeping costs in check. [...]

During the early days of the electronics revolution, the phrase garbage in, garbage out, or GIGO, was popular with the computer set. [...]

Whether you’re talking about a rotary screw air compressor or a centrifugal air compressor, the presence of water is a serious issue, causing rust, damage and compressed air contamination throughout your machine. [...]