How to Choose the Right Rotary Screw Air Compressor for Your Business

January 31, 2024

Seven Strategic Ways to Reduce Expenses from Compressed Air

February 14, 2024How Many CFM Do I Need? Air Pressure by Different Applications

Kaishan USA | February 7, 2024 | Uncategorized

Robotic welders rely on pressure (PSIG), but not that much flow (CFM), to execute their precise movements.

Unfortunately, many of the terms used to describe the delivery and capacity of compressed air—pressure (measured in PSIG), flow (CFM) and even horsepower (HP)—are used interchangeably. All those terms, of course, are relevant to every application.

Some confusion is understandable, mainly because some uses, like pneumatics, focus on one of the measures more than the others. So, with pneumatics, most users are focused on having pressure, while flow is not as much of an issue.

As a rule, you need enough pressure (PSIG) to do the work your system needs to accomplish. And you need enough flow (CFM) to transfer the total energy you need for the tool’s particular task at the pressure you need.

Equipment manufacturers usually tell you how much pressure and flow their machines or tools require. But that may be a challenge for older equipment, where manuals are not available. In that case, you may need an air audit performed by an air compressor professional. (For more information on when to ask for an audit, read our blog post, “When to Do a Compressed Air Audit, When to Do an Assessment.”

So, any discussion of one parameter, in this case, CFM, probably needs to start with an explanation of the terms and how they relate.

Flow (or CFM)

CFM stands for cubic feet per minute, specifying the amount of compressed air that flows through your system. You may also hear other measurements of flow used internationally, like cubic meters per minute (m3/min), liters per minute (L/min) and liters per second (L/s). See our calculator to convert among the different units of measure.

CFM is a measure of the amount or volume of compressed air your compressor is producing. Air tools typically specify the CFM they need, and compressors will tell you how many they deliver. A higher CFM air compressor gives you more power and greater versatility in the number of applications you can service and the volume and pressure those applications will require.

Wastewater treatment plants need higher air volumes (or CFM) but little pressure to generate air bubbles during the aeration stage.

Applications That Need High Flow (CFM)

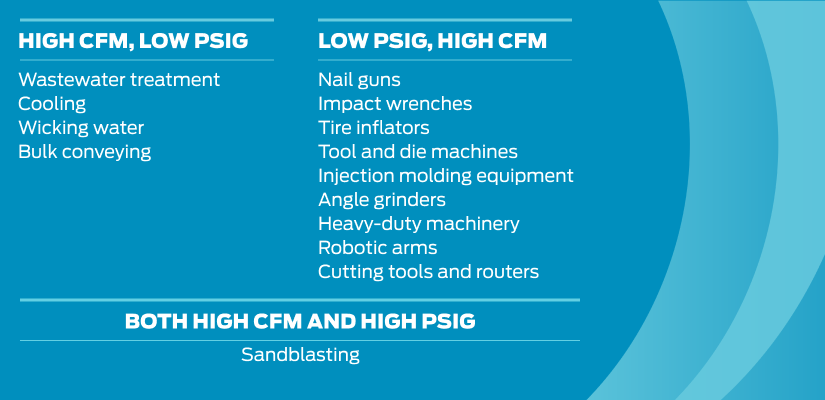

Sometimes, you’re just blowing on things, so you need more air, but low pressure will suffice. Applications include:

-

- Wastewater treatment, where the emphasis is on aeration

- Cooling, cleaning, or simply blowing air over a tool or piece of equipment to remove heat or debris

- Blowing water or sawdust off a surface

- Bulk conveying of powders, pellets or resins, where pressure is not as much of a factor

Pressure (or PSIG)

PSIG stands for pounds per square inch gauge and measures the system pressure, the force your end-use application needs to perform a task. Having more PSIG available enables you to do more work with less effort. Most air tools need between 80 and 90 PSIG of pressure.

Once again, you will hear other measurements of pressure used internationally, like bar and kilopascals (kPa). See our calculator to convert among the different units of measure.

Applications That Need a Standard Range of Air Pressure

On the other hand, some applications need more pressure, but not much flow. They include:

-

- Pneumatics, like nail guns, impact wrenches or tire inflators

- Tool and die machines

- Injection molding equipment

- Auto body shops’ impact wrench

- Heavy-duty machinery like presses and other large pieces of industrial equipment

- Robotic arms

- Cutting tools and routers

A few applications, like sandblasting, require significant amounts of pressure (100 PSIG) and flow (up to 300 CFM, depending on nozzle size) because you are moving a lot of weight and a lot of volume at the same time. For more on the specific needs of sandblasting, read our blog post, “Best Screw Compressors for Sandblasting.”

Sandblasting is the ultimate power hog, requiring high pressure (PSIG) and high CFM air compressors.

The real challenge for compressed air systems is providing both types of needs in the same operation, perhaps even with the same machine.

Compressed air experts have many tools to deal with varying demands. But, in all cases, the solution requires a complete understanding of the plant’s needs. What we call the demand profile.

Factor In Your Uses

A common mistake is to overestimate the power you need.

Suppose you have ten tools that all require 5 CFM of flow. You may think that means you need 50 CFM of flow. But you probably don’t.

Here’s why: the ten tools not usually work at once. Some may be in continuous use, but most are probably “intermittent.” So, rather than needing the entire 50 CFM mentioned above, you only need 10 CFM. That’s called the “use factor.”

With each tool, you’ll want to ask if you are using it continuously, like sanding a part, or only sporadically, as you might for tightening lug nuts on tires. And which tools are running simultaneously?

You’ll want to weigh those different choices in calculating your flow and pressure needs:

-

- CFM is additive, so you’ll add all the continuous uses and allow for the intermittent ones. If you have two tools drawing 5 CFM of flow, you need 10 CFM to cover those tools. Then, you have five other tools, each also requiring 5 CFM of flow, that only operate 20% of the time. So. you’ll only add another 5 CFM (5 tools, each 5 CFM, time 20%). And your total is 10 + 5 or 15 CFM.

A formula might look like this:

[Tools #1 CFM + Tool #2 CFM + … Tool #n CFM] x [Use factor %] = Additive CFM - Pressure is not additive, but set by the highest use. Let’s say you have ten tools needing 80 PSIG and one drawing 90. That means you’ll need 90 PSIG of pressure (allowing for any pressure loss from the compressor to the point of use). And you’ll equip the tools requiring less with pressure-reducing valves or regulators. But you don’t set your operating pressure higher than you need it. That wastes energy, causes leaks, generates heat and increases wear.

- CFM is additive, so you’ll add all the continuous uses and allow for the intermittent ones. If you have two tools drawing 5 CFM of flow, you need 10 CFM to cover those tools. Then, you have five other tools, each also requiring 5 CFM of flow, that only operate 20% of the time. So. you’ll only add another 5 CFM (5 tools, each 5 CFM, time 20%). And your total is 10 + 5 or 15 CFM.

One added thought: rather than waste energy with pressure-reducing valves or regulators, it may be more cost-effective to meet a this need by installing a dedicated compressor like our KRSL low pressure series rotary screw air compressor.

The Relationship Between CFM and PSIG

Most air compressors are designed to deliver a fixed amount of output. For example, 100 CFM at 100 PSIG. You do have some flexibility. But it comes at a cost, reflecting the relationship between flow and pressure: when you increase the pressure, you decrease the flow. And vice versa.

The inverse relationship between CFM and PSIG causes all kinds of confusion. If you’re not getting enough pressure at one of your key applications, for example, you’ll naturally want to go back to your air compressor and jack up the pressure. But that almost never works. By increasing the pressure, you reduce the flow because the issue was not with the pressure in the system. Ideally, if your compressor is adjusted to deliver 85 PSIG, the pressure throughout your system is at that level. It’s the flow that is reduced as you deliver air to end-use tools (or as your system leaks). So the problem is not with the system pressure, but the flow.

Your mechanic may say they are not getting enough pressure to power their impact wrench. But boosting the pressure at the compressor probably won’t work. It most likely will result in even lower pressure to their tool.

Let’s say your system is set at 85 PSIG, and you bump it up to 90, hoping to get that extra pressure you need. Then, because of that inverse relationship, you’ll have less compressed air flow and it will be at a higher temperature. So, all those regulators you had set to decrease the 85 PSIG down to 80 will now have to reduce the pressure an additional 5 PSIG. Costing you even more flow.

And then there’s the leaks. All those tiny gaps leaking air throughout your system are under more pressure. They begin to leak even more air, reducing flow further and adding to your energy use.

The result is less compressed air volume (and lower pressure) at the end of the line.

Your maintenance team will likely not believe it, but the best way to get more pressure at the end of the line is often to lower the pressure at the air compressor. That boosts CFM and delivers more air flow to the tool. And it’s at the desired pressure. Admittedly there are some variations for different types of compressors:

-

- Turning down the pressure on a fixed-speed compressor will help reduce artificial demand in the plant and reduce the power draw, while slightly increasing the CFM output.

- For a variable-speed compressor, you can change the maximum RPM to keep the power draw the same while gaining CFM at the lower pressure.

- If it's a belt drive, you can change the pulleys to get more CFM at a lower pressure (speeding up the airend).

And Don’t Forget Horsepower (HP)

Another critical determinant of system capacity is the compressor horsepower (HP), a measure of an air compressor’s motor performance. Specifically, the power output of the motor that drives a high-CFM air compressor. The more horsepower, the more capacity the compressor has to deliver compressed air at the required CFM and PSIG. You need enough horsepower (HP) to generate all that energy.

In general, adding compressors with more horsepower to your system increases the power of your system, allowing it to produce more CFM. That doesn’t mean, by the way, that you can add a larger horsepower motor to an existing compressor to get more CFM. It doesn’t work that way.

Local Help

Need help determining how to get the flow and pressure you need throughout your system? We can help. We work with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts can work with you to calculate your demand for compressed air and know the capacity you need.

Key Takeaways

-

- There is confusion over the terms CFM, PSIG and HP.

- They are not interchangeable.

- CFM (flow) is additive.

- PSIG (pressure) is not.

- CFM and PSIG have an inverse relationship.

Let Us Help

Knowing how much capacity you need in your rotary screw air compressor is critical to the operation of your compressed air system and all the processes that it powers. If you need help calculating your CFM needs, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Unfortunately, many of the terms used to describe the delivery and capacity of compressed air—pressure (measured in PSIG), flow (CFM) and even horsepower (HP)—are used interchangeably. All those terms, of course, are relevant to every application.