The Bond Between Air Compressors and Renewable Energy

May 22, 2024

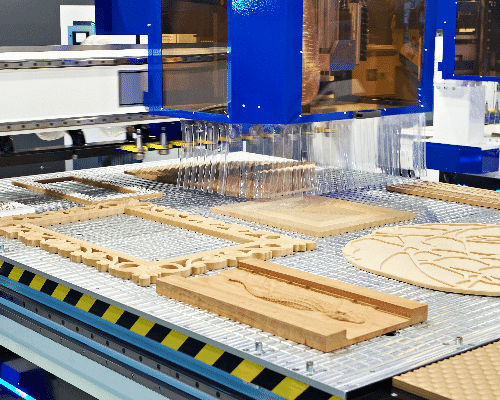

Industrial Vacuum Pumps Prove Their Value in Woodworking

June 5, 2024Choosing the Right Air Compressors for Electric Car Battery Manufacturing

Kaishan USA | May 29, 2024 | Uncategorized

Compressed air plays a significant role in producing batteries for electric vehicles.

Industrial air compressors and related technologies play a critical role in the rapidly developing field of manufacturing electric vehicle batteries.

Compressed air provides the power behind the pneumatic devices that move, lift and handle delicate EV battery components like electrodes. And vacuum systems based on air compressor technology are in place at every step.

In addition, both technologies are involved in one of the most crucial finishing steps—removing gases from the battery cells in the activation stage.

And many companies use compressed air to generate the nitrogen they need, saving cost and eliminating supply chain and quality control issues.

How did compressed air become so crucial in such a cutting-edge enterprise? Compressed air and the tools it drives offer some compelling advantages.

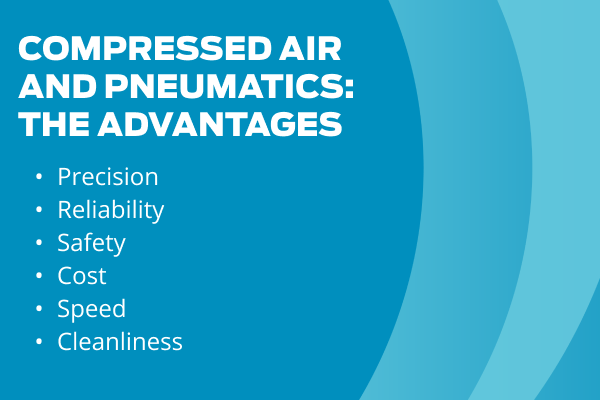

Advantages of Compressed Air and Pneumatics

-

- Precision. Compressed air powers the pneumatic tools that allow EV battery manufacturers to control their processes with pinpoint accuracy. They lift fragile electrode sheets. Assemble battery enclosures. Apply rivets and seals. And remove gas from battery cells.

- Reliability. Compressed air systems have a long track record of reliable operation.

- Safety. Air-powered tools run cooler. They don’t generate sparks, fires or electrical shocks. They also don’t become overloaded or overheated. And they don’t stall, avoiding the problems those conditions cause in the workplace.

- Cost. Pneumatic tools have simple designs, no batteries or motors and fewer moving parts, so they’re less expensive to acquire.

- Cleanliness. Compressed air is a clean and proven technology that helps eliminate reliance on fossil fuels and minimize carbon emissions. See more on oil-free air below.

- Speed. Lightweight and flexible, automated pneumatic tools are capable of high-speed operation, enabling high throughput with remarkable accuracy and repeatability. For more detail on the larger benefits of pneumatics, see our blog post, “Air-Powered Tools: The Seven Benefits and uses of Pneumatic Tools.”

As a result, industrial air compressors and the pneumatic tools they drive play an essential role in the manufacture of EV batteries.

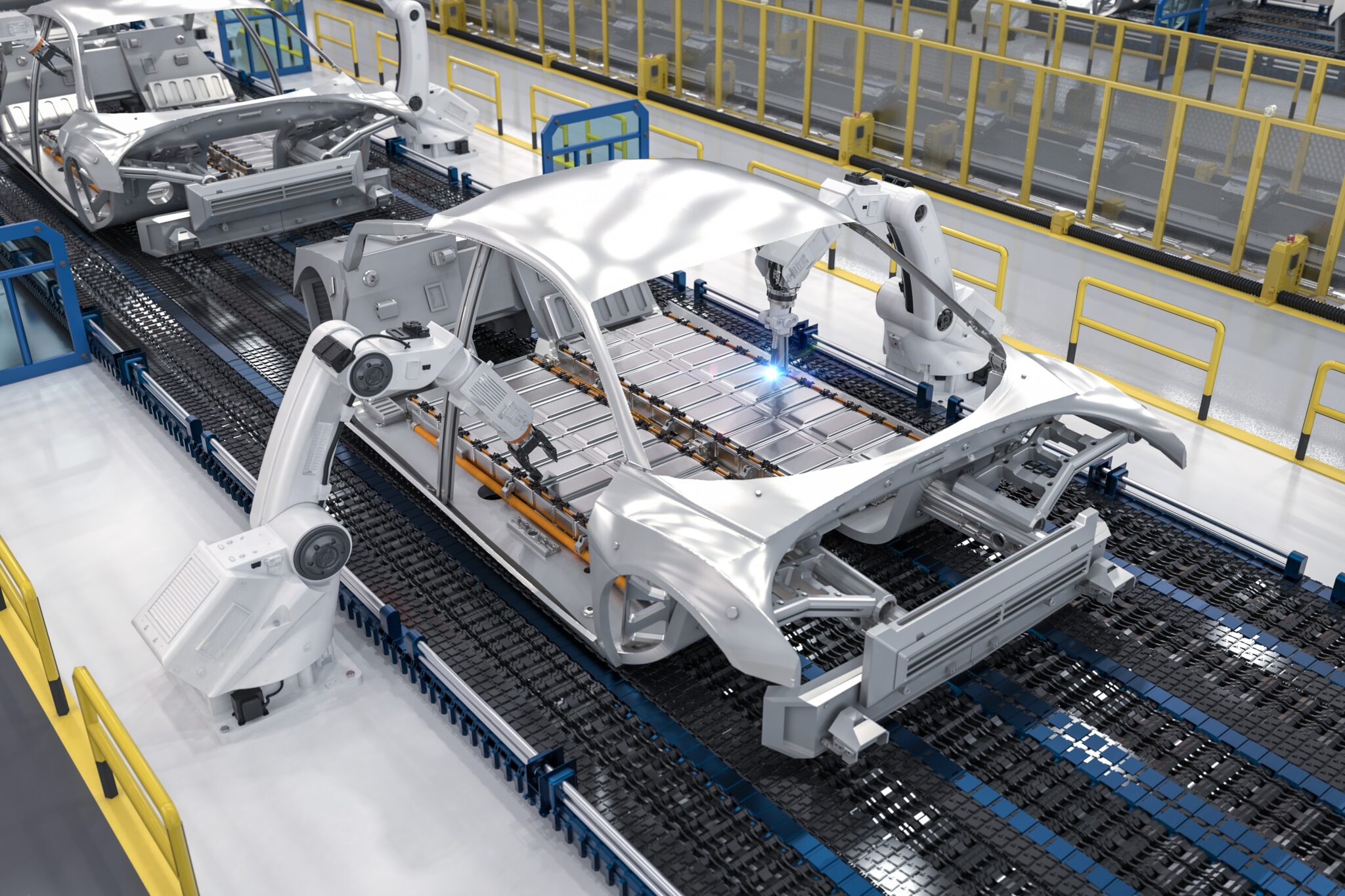

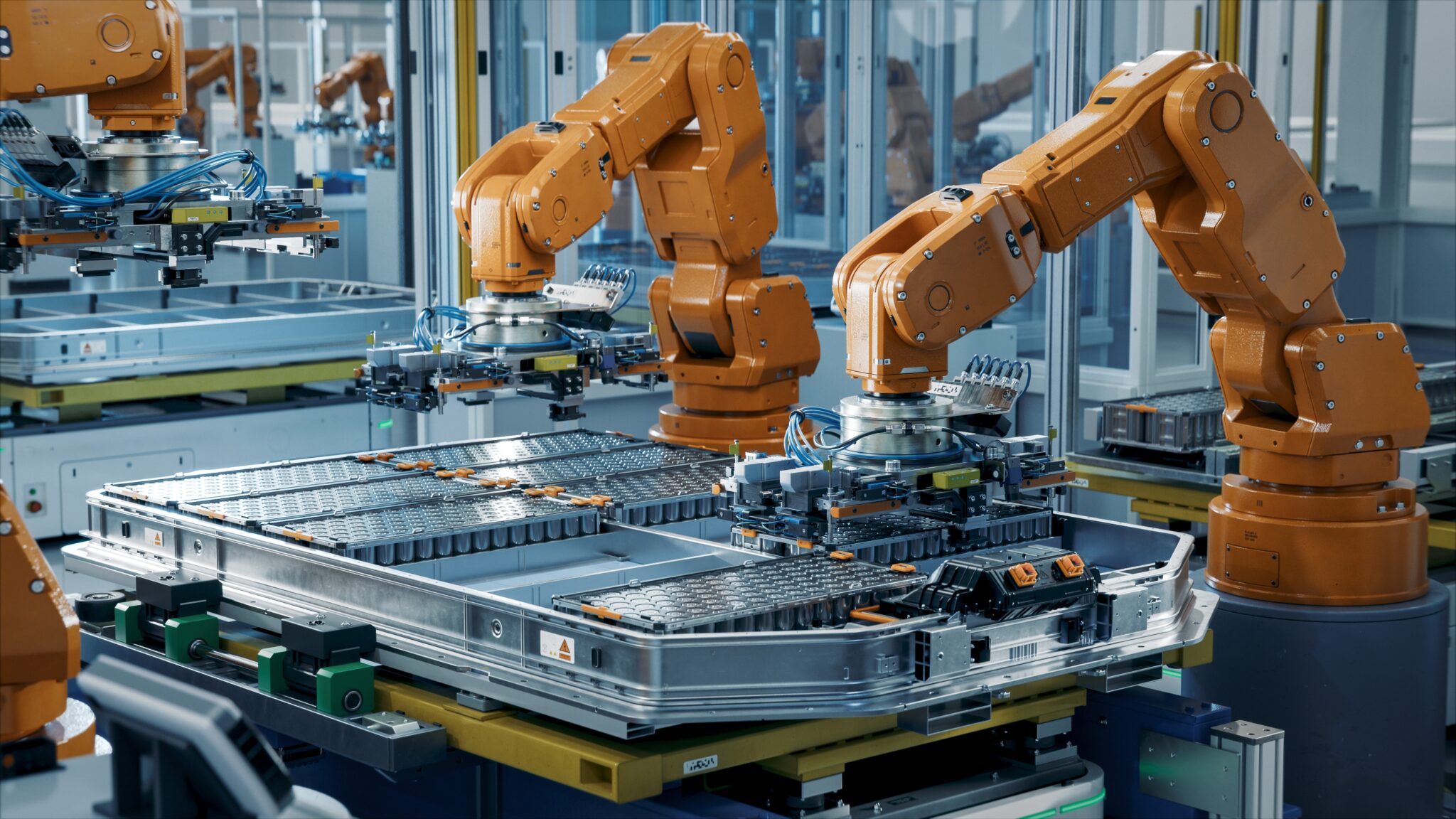

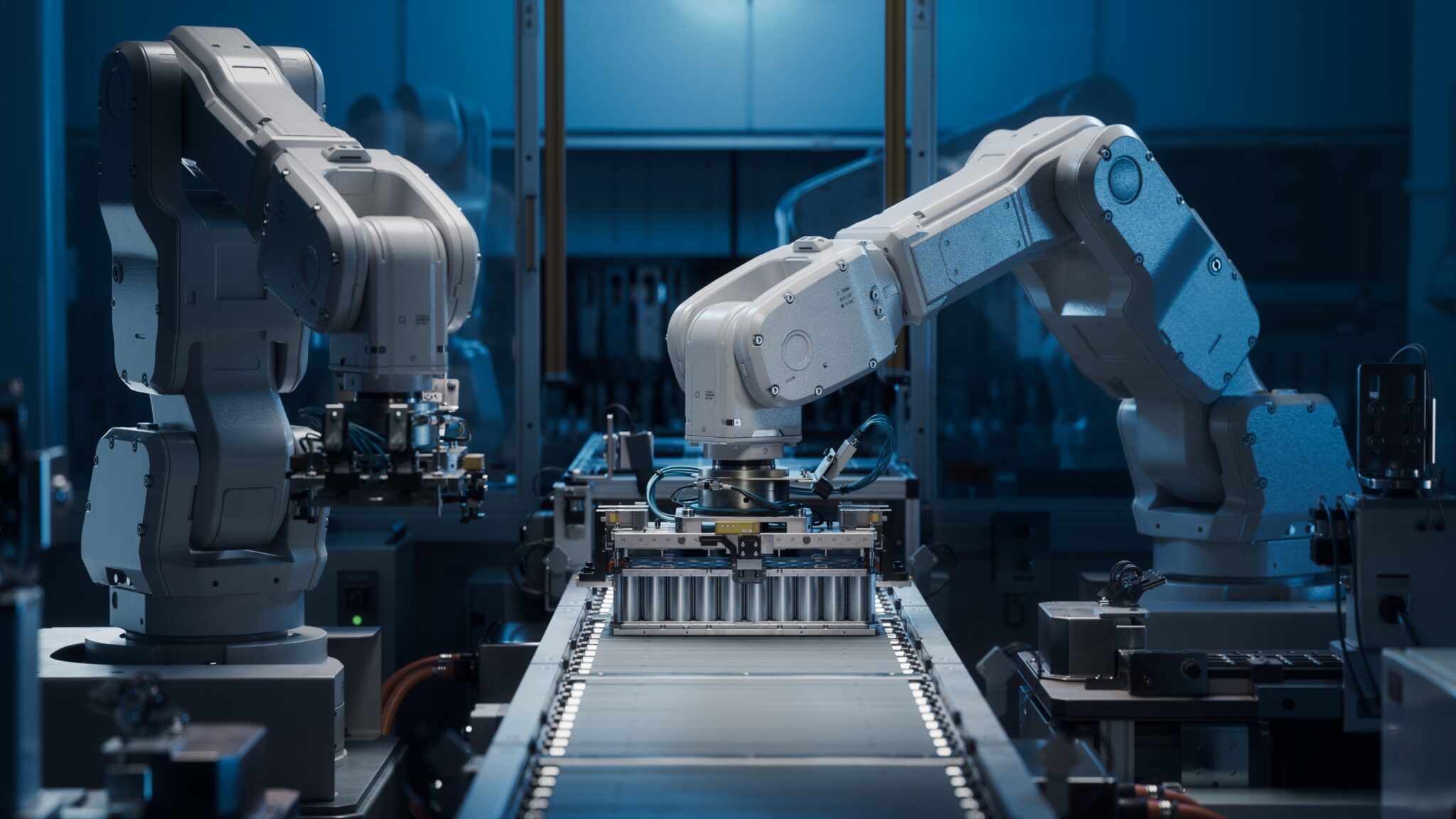

Pneumatics and robotics do much of the material handling in automated EV battery manufacturing plants.

Industrial Air Compressors in EV Battery Manufacturing

As a newly evolving industry, EV battery manufacturing relies heavily on automation. And most of that automation is run by pneumatics.

Compressed air and pneumatics are used in the following steps or processes in EV battery manufacturing:

-

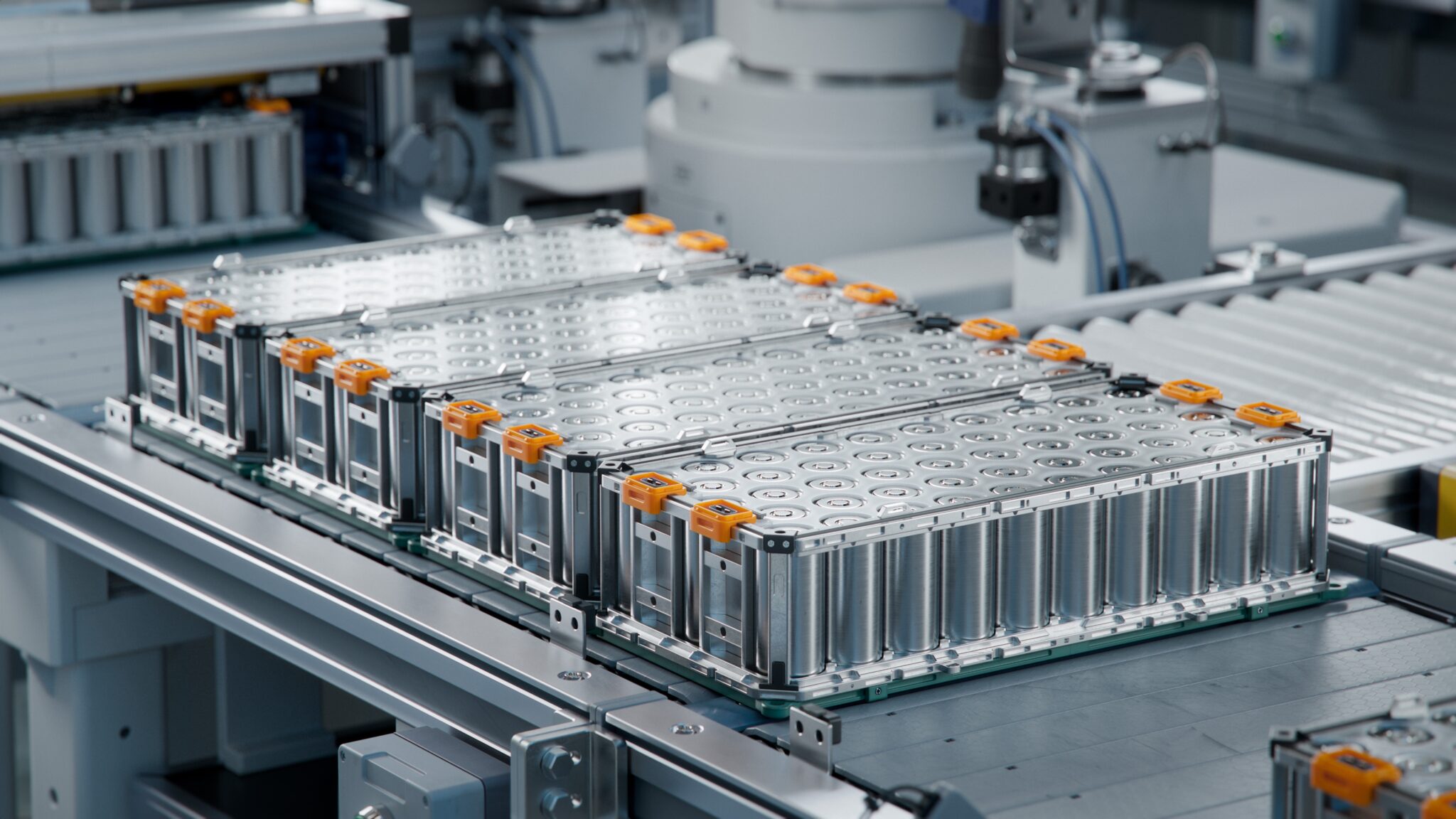

- Handling and assembly. Handling systems driven by compressed air allow careful movement and placement of delicate electrodes, battery cells and other components. During cell assembly, pneumatic suction devices move individual electrode sheets and put them in the cell enclosure. Pneumatic tools rotate, pick up and place cells in modules. Pneumatic riveters and sealing applicators allow efficient assembly of battery casings. And pneumatic grippers pick up the assembled batteries when they’re completed.

- Spot welding. Pneumatic spot welders apply pressure and heat with great precision to create strong, reliable bonds within the EV battery cells.

- Degassing. During the activation phase of battery production, hollow lances, moved in place by pneumatic actuators, puncture the battery cells to allow gas bubbles to be removed. This step is critical in preventing the formation of any gaps or voids between the electrodes and the electrolyte that would limit the battery’s ability to charge and discharge efficiently.

- Testing. Pneumatics powers the testing equipment that ensures the batteries meet quality standards.

Lithium-ion battery modules on the production line.

EV battery manufacturers are also harnessing the power of compressed air to generate nitrogen.

Generating Your Own Nitrogen

Some EV battery manufacturers are choosing to develop their own nitrogen-generating capabilities to avoid the uncertainties of relying on outside vendors.

EV battery manufacturing requires an inert environment that is dry (with dew points as low as -80°C) and free of carbon dioxide. Some companies have chosen to develop their own nitrogen-generating capacity, using compressed air to power that equipment.

In-house nitrogen-generating equipment offers several benefits:

-

- Supply-chain issues. You can avoid the uncertainties of supply and delivery by developing your own nitrogen-making capabilities. The practice became mainstream after the COVID-19 pandemic, as facilities found themselves without the needed materials because of supply chain issues.

- Cost. After the initial investment, companies save as much as 80% of their nitrogen costs with a two-year payback.

- Space savings. Storing the bottles of nitrogen you’ll need to ensure a steady supply usually takes a lot of dedicated space.

It may take a lot of dedicated space to store enough nitrogen to meet your needs. That’s why so many laser-cutting operations have decided to make their own nitrogen.

-

- Quality. Most operators find it easy to establish and set the level of purity they need for their specific tasks.

- Safety. You avoid the risks associated with handling and storing high-pressure cylinders.

- Sustainability. Generating your own nitrogen is an energy-saving solution that reduces waste. As a result, it has less environmental impact than traditional tank delivery and storage.

- Steady supply. Facilities with in-house, 24/7 nitrogen generation don’t have to worry about delays, bad weather, delivery problems, storage or safety.

- Logistics. Having your own nitrogen-generating capacity in-house will eliminate the need to monitor inventory and schedule deliveries. Or the need to find a second source if your primary supplier experiences problems.

Having your own generating capacity may mean you don’t have to worry about bad weather, delays or supply chain issues disrupting your supply of laser-cutting gases.

We discuss the use of compressed air to generate your own nitrogen in greater detail in our blog post on laser cutting, “How Industrial Air Compressors Improve Laser Cutting Performance.”

Both compressed air systems and nitrogen-generating capabilities work best with an industrial air compressor closely matched to a specific need. That’s why selecting the right compressor for your application is so important.

Choosing the Right Industrial Air Compressor

There are many different types of industrial air compressors, but most manufacturers find rotary screw air compressors are the best choice because of their reliability, efficiency and long life.

Rotary screw air compressors are known for producing steady streams of high-quality compressed air and handling large-capacity loads. And they are backed by the industry’s best warranties—Kaishan’s KRSP and KRSP2 screw compressors are backed by an industry-leading lifetime warranty on the airend.

For applications such as EV battery production, our new KROF oil-free compressor provides the high-quality air you need.

Kaishan KROF: Changing the Rules of the Oil-Free Game

Kaishan’s new oil-free compressor, the KROF, sets new standards for reliability, efficiency and warranty protection, producing ISO 8573-1, Class 0 oil-free compressed air. It is available in 100-, 125- and 150-PSIG models with integrated air or water cooling.

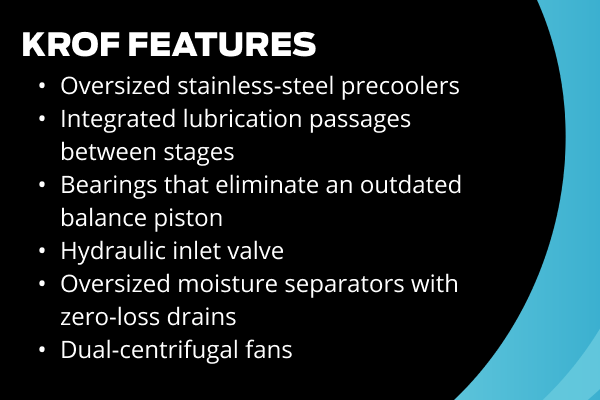

The KROF has robust features that make it the best choice for demanding oil-free applications:

-

- Oversized stainless-steel precoolers on each stage that lower temperatures for both intercoolers and aftercoolers.

- Integrated lubrication passages between stages to ensure proper lubrication and reduce leak points, service requirements and lifetime costs.

- Bearings that eliminate the need for an outdated balance piston and require no maintenance to achieve proper thrust loading.

- Hydraulic inlet valves to increase reliability in contaminated environments.

- Oversized moisture separators equipped with reliable, zero-loss drains that prevent moisture from passing between stages and handle contamination better than traditional, orifice-style drains.

- A dual-centrifugal fan to reduce noise.

Best of all, it is the only oil-free compressor designed and engineered in the U.S. for a global market. And it is manufactured at our state-of-the-art, 65,000-square-foot plant in Loxley, AL (soon to be expanded to 130,000 square feet).

Industry-Leading Warranty

Because of its built-in Kaishan reliability and longevity, Kaishan backs the KROF with an industry-leading five-year warranty on major components, including the airend.

Kaishan’s new KROF two-stage oil-free compressor is an excellent choice when you need uncontaminated, highly efficient, reliable air.

With the increasing emphasis on sustainability and carbon neutrality in many industries, you’ll want to consider the lifetime carbon footprint when purchasing an oil-free air compressor. If your organization is trying to go green, the KROF air can help you achieve your goals.

Local Help

Industrial air compressors, nitrogen-generating capabilities and vacuum pumps are critical to an EV battery manufacturing facility. And Kaishan is one of the few manufacturers who supply both vacuum technology and industrial air compressors, including our oil-free KROF rotary screw air compressor.

Selecting the right equipment will require careful analysis of your exact application. Kaishan’s nationwide network of independent distributors, can provide on-site help and consultation to select the right equipment for your plant. They can service your industrial air compressor, nitrogen generation and vacuum systems without a problem. And they have staff members skilled in applying and using advanced technology.

Key Takeaways

-

- Industrial air compressors play a critical role in manufacturing electric vehicle batteries.

- Compressed air powers pneumatic tools that move, lift and handle delicate EV battery components.

- Vacuum systems (based on air compressor technology) are in place at every step.

- Compressed air offers compelling advantages, including precision, reliability, safety, cost, speed and cleanliness.

- Kaishan’s new KROF oil-free industrial air compressor sets new standards for reliability, efficiency and warranty protection.

- Some companies save money and ensure a steady supply by using compressed air to power their nitrogen-generating equipment in-house.

Let Us Help

Choosing the right industrial air compressor for your application can play a significant role in the success of your EV battery manufacturing operation. If you need help deciding on the right vacuum pump or air compressor (for pneumatics and nitrogen generation), get in touch with the experts at Kaishan. Contact us today.