Ways to Measure Air Compressor Performance and Know if You Need an Audit

June 19, 2024

Five Key Applications of Rotary Screw Vacuum Pumps in the Food and Beverage Industry

July 3, 2024Single Stage vs 2 Stage Air Compressor: Five Critical Differences

Kaishan USA | June 26, 2024 | Uncategorized

Reliable, energy-efficient air is essential in many industries—especially those like medical device manufacturing. However, deciding whether to use a single stage vs 2 stage air compressor can greatly impact performance and cost.

Single-stage and two-stage air compressors have been industry staples for years. Despite this, many end-users aren’t fully aware of the critical differences between an air compressor single vs two stage setup—beyond the fact that two-stage units generally cost more. These differences can determine whether investing in a two-stage model is worthwhile.

Especially the ones that determine whether a two-stage model is a worthwhile investment. The two look very similar, but they are quite different internally:

-

- A single-stage compressor like Kaishan’s KRSP premium rotary screw air compressor uses one compression chamber to compress air to the desired pressure, generating a compression ratio of 7.8 to 1 to create 100 PSIG of pressure. Our KRSB is one of the most cost-effective compressors on the market, and Kaishan backs it with an industry-leading lifetime airend warranty. Learn how it works in this video.

Kaishan’s KRSP single-stage rotary screw air compressors are among the most cost-effective options on the market.

-

- A two-stage air compressor like the KRSP2 premium rotary screw air compressor [Link: https://kaishanusa.com/krsp2-two-stage-rotary-compressors/] splits the workload into two separate stages, dividing that work into a first stage of 2.8 to 1, followed by a second stage of 2.8 to 1. Plus, before the second stage, the air passes through an interstage cooling step, removing some of the heat of compression and building efficiency. This video shows it in action. [Link to: https://www.youtube.com/watch?v=bwwVOw5f7b0]

There are five critical reasons why our two-stage air compressor is a better value.

1. A Two-Stage Compressor Is More Energy Efficient

A two-stage air compressor, such as Kaishan’s KRSP2 premium rotary screw air compressor, splits the workload into two separate stages. This approach is at the heart of the difference between single and two stage air compressors when it comes to energy efficiency. Here’s how it works:

But first, a contrast.

Consider a single-stage unit, like Kaishan’s KRSP premium rotary screw air compressor, which generates a compression ratio of 7.8:1 to reach around 100 PSIG. It’s one of the most cost-effective compressors available and comes with an industry-leading lifetime airend warranty. This is a key factor when you’re evaluating a single stage vs two stage air compressor

But, as mentioned, the KRSP2 divides that work into a first stage of 2.8 to 1, followed by a second stage of 2.8 to 1. Plus, before the second stage, the air passes through an interstage cooling step, removing some of the heat of compression and building efficiency.

By building on the pressure generated in the first stage, the KRSP2 generates more compressed air for less energy. The bottom line? A two-stage air compressor generates up to 15 to 20% more flow than a single-stage compressor of the same size (HP). Paybacks on energy costs alone may be less than two to three years.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

Variable-Speed Drive

Equipping your KRSP2 with a variable-speed drive can add even more efficiency at part loads. Our VSD version of the KRSP2 is one of the only two-stage units that are available in sizes as low as 30 HP.

For more on the advantages of variable speed drives, see our blog post, “How Variable Speed Drive Rotary Screw Air Compressors Save You Money.”

2. It’s More Reliable and Long-Lasting

Using two stages inherently lowers mechanical stress. Less heat is generated overall, reducing wear and tear on critical components. In a two-stage vs single stage air compressor comparison, this distinction often leads to longer service intervals and fewer unplanned repairs. For instance, Kaishan’s KRSP2 spreads the workload across two stages: four discharge bearings in the first stage and three in the second. In a typical single-stage unit, only two bearings handle the entire thrust load—which can lead to quicker wear.

Lower forces and more bearings result in longer life. The KRSP2 is built to last, enabling us to offer an industry-leading lifetime airend warranty.

An industry-leading lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

3. You May Not Need as Large a Compressor

Because a two-stage compressor often delivers 15–20% more CFM than a comparable single-stage machine, you may be able to step down to a smaller model. For example, you could replace a 300-HP single-stage unit with a 250-HP two-stage KRSP2—narrowing the initial cost difference, while still maintaining required airflow.

This is a key factor when you’re evaluating a single vs two stage compressor: the ability to match compressor horsepower to your specific CFM needs can yield both upfront and long-term savings.

It’s all about matching the compressor horsepower-to-CFM ratio that fits your needs.

4. You’ll Enjoy Lower Operating Cost

Reduced electricity usage, lower long-term maintenance requirements, and fewer part replacements make a two-stage rotary screw compressor less expensive to run over time than a single-stage unit. This difference in a single stage vs 2 stage air compressor can significantly impact your operational budget, especially for energy-intensive applications.

You can save even more money by using the KRSP2’s increased air flow to select a compressor with a lower horsepower rating. Need help determining how much flow you need? See our blog post, “How Many CFM Do I Need? Air Pressure by Different Applications.”

5. You Have a Lower Total Cost of Ownership

Yes, a two-stage system comes with a higher initial price tag. Yet, for many users, the difference in a single stage vs two stage air compressor’s total ownership costs lies in lower energy usage, reduced downtime, the option of sizing down, and less frequent part replacement. Over time, these factors can make the total cost of ownership (TCO) for a two-stage unit notably more favorable.

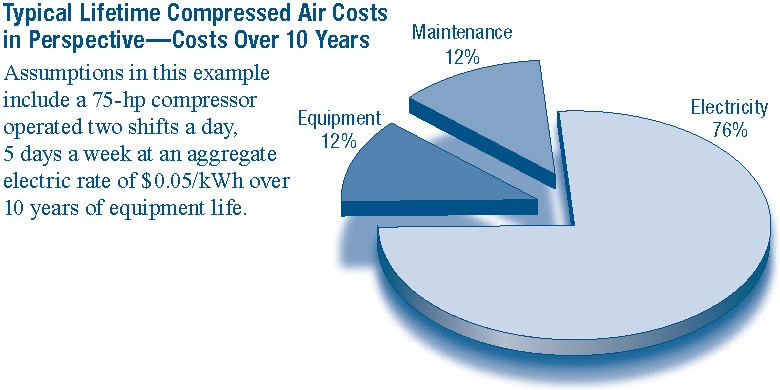

And remember, acquisition costs amount to only 12% of the total cost of ownership, according to the U.S. Department of Energy. You pay the initial cost one time. You’ll be paying the power and maintenance costs for the life of the compressor.

The U.S. Department of Energy estimates that the cost of purchasing an industrial air compressor is only 12% of the lifetime cost of owning and operating a compressed air system.

When to Use a Two-Stage Rotary Screw Air Compressor

Because of the initial cost, we find that two-stage air compressors are most attractive in the following situations:

-

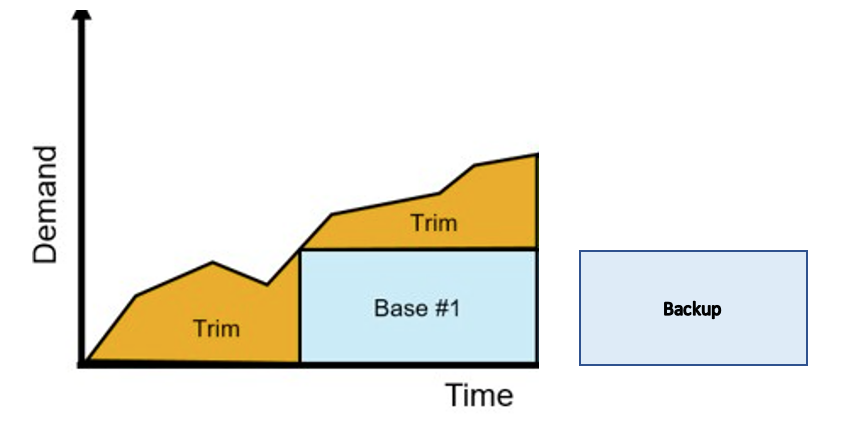

- As a base-load compressor in a two- or three-compressor configuration, running at 100% full-load capacity. For more on increasing reliability and energy efficiency with a three-compressor system, view our blog post, “Everything You Need to Know About Sizing Industrial Air Compressors for Manufacturing.”

In a three-compressor system, starting from left, a trim compressor handles the load on weekends, holidays or a limited third shift. Then, in the center, when you’re operating at normal levels, a base unit such as the KRSP2 comes on and immediately goes to full capacity. The trim unit, usually a VSD air compressor, then kicks in as needed to handle fluctuations in demand. An additional backup unit is in place should one of the other units fail.

-

- Mass production applications where reliability is critical, such as general manufacturing, automotive, aerospace, food and beverage and glass manufacturing.

- Companies looking for an environmentally friendly unit with high energy efficiency and long lifespan.

Because of their reliability and efficiency, two-stage rotary screw compressors like the Kaishan KRSP2 premium rotary screw air compressor are an excellent choice for base load compressors.

In fact, by manufacturing two-stage air compressors as small as 30 HP, Kaishan is making these units cost-effective for a much larger universe of industrial users.

Local Help

If you’re considering moving to a two-stage rotary screw compressor, it’s probably a good idea to work with your local compressed air professional to evaluate your compressed air system and determine the potential benefits. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed.

Key Takeaways

-

- A two-stage compressor can deliver up to 15–20% more airflow within the same horsepower range as a single-stage unit.

- This added efficiency often allows you to size down—potentially reducing both upfront and long-term costs.

- Because a two-stage air compressor generates more airflow than a comparable single-stage machine, it can pay for itself quickly through energy savings.

- Operating costs (electricity, maintenance, replacement parts) typically remain lower with two-stage compressors.

- Ultimately, when deciding between two stage vs single stage air compressor setups, remember that total cost of ownership heavily favors two-stage models for many industrial applications.

Let Us Help

Deciding whether you can benefit from a two-stage rotary screw air compressor is an essential step for your compressed air system and all the processes that rely on that system. If you need help deciding if a two-stage compressor would be right for your operation, get in touch with the experts at Kaishan. Contact us today.