Eight Myths Debunked about Industrial Rotary Screw Air Compressors

July 19, 2023

Twelve Critical Differences Between Rotary Screw and Piston Air Compressors

August 2, 2023Hot Weather Impacts on Air Compressor Systems

Kaishan USA | July 26, 2023 | Uncategorized

Summer heat can significantly impact your air compressor system, making the incoming air hotter, thinner and more moisture-laden.

Although it’s not directly related to comfort conditioning or refrigeration, your air compressor system has to work much harder in the summer months.

In fact, hot weather is a trifecta of trouble for your compressed air system:

-

- Hotter. The added summer heat makes your compressor’s cooling system work harder, reduces the compressor’s capacity and increases the temperature of discharge air. The hotter discharge air means your dryer does not work as efficiently.

- Thinner. Hotter air is also thinner, so your compressor produces less air flow (CFM). That makes your system work harder to maintain header pressure.

- More water. Hotter air carries more water, making life tough on refrigerated air dryers. Specifically, the moisture load doubles for every 10°F rise in temperature.

As a result, you’ll want to take some essential steps—now and before next summer—to counteract the heat.

What You Should Do Right Now

Check several key components to ensure your system can handle the summer heat.

-

- Air flow. Make sure all vents are open. Verify fans are functioning if used for moving air in your equipment room. When you walk into the room, does it feel hot? If so, you have to improve the air flow. See the discussion of vents in the “What you Should Do Before Next Summer” section below.

- Heat exchangers. Make sure your heat exchanger coils are clean and free of dust and debris.

- Filters. Fortunately, if you have a Kaishan compressor, its control system will monitor the pressure differential in your compressor’s intake air, oil and air filters and notify you of any problems. But your compressor’s controls do not check the filters in your downstream equipment, so you’ll want your team to be checking the differential pressure (DP) gauges in your downstream devices. Differential pressures in the red zone indicate a filter is clogged and is wasting energy.

Your team should watch the differential pressure (DP) gauges on all downstream equipment filters.

-

- Drains. The increased moisture in the air means more water must be removed from the system, most of which ends up in the drains. Inspect the moisture trap drain and the drains in all your tanks, filters and dryers. Dirt and debris often accumulate in drains, causing them to become stuck. Stuck in the open position, the drain will leak air. And a closed drain will allow moisture and other impurities to pass through, contaminating your compressed air and possibly damaging production equipment.

- Sampling. Changing the compressor oil and sending out a sample for testing before the heat of the summer months is crucial for a number of reasons. Primarily, this preventive maintenance step can help identify potential problems before they occur, thereby enhancing the operational efficiency and longevity of your equipment. The summer heat can intensify the strain on the compressor, accelerating oil degradation. By sampling the oil, you can determine if the oil is still providing adequate lubrication, if the viscosity has changed, or if there's the presence of harmful contaminants or wear metals that can adversely affect the compressor's performance. Consequently, sampling or changing the oil not only safeguards the compressor against potential summer heat-related issues but also significantly reduces downtime and repair costs.

Most of all, you’ll want to complete your preventive maintenance before the temperatures start to rise. That way, you’ll start the season with your system fully prepared. And you’ll have a chance to identify any problems before they result in a shutdown.

What You Should Do Before Next Summer

Long-term, you should review your vent configuration and equipment sizing and take any actions needed to reduce the effects of summer heat.

Vents

Air circulation through your compressor enclosure is critical to hot-weather operation. You can use several possible configurations to move air through your equipment room.

-

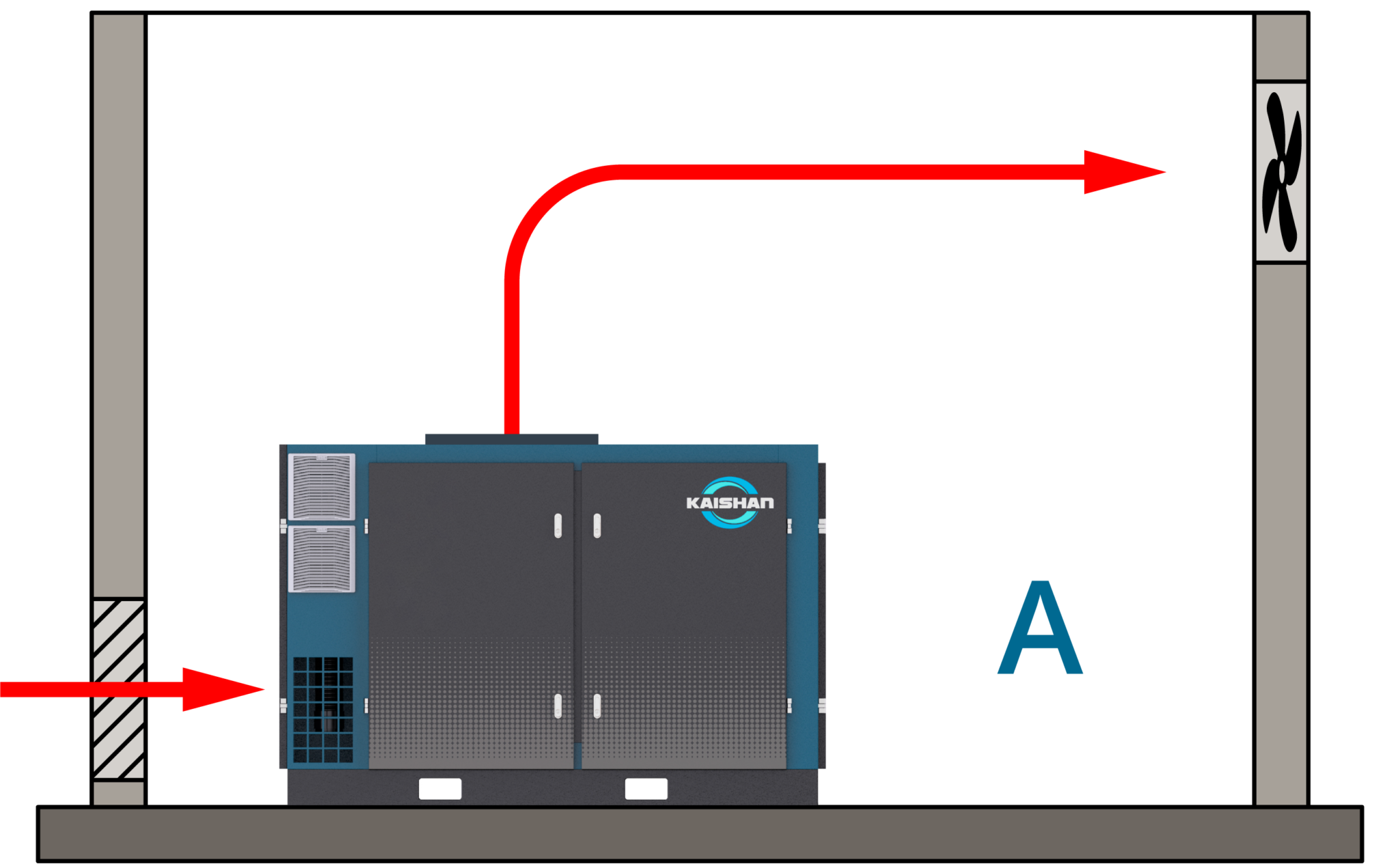

- Louvered vents. For smaller compressors, louvered inlets and outlets in your compressor room may provide enough airflow through your enclosure to remove the heat generated in the compressor. But it all depends on the ambient conditions. Consult a qualified heating and air conditioning professional in your area for sizing, design and installation of ductwork.

Depending on ambient conditions, you may only need louvered inlets and outlets to keep your smaller compressor cool.

-

- Forced ventilation. Compressors larger than 25 HP usually require forced ventilation, but every site is different. An exhaust fan pulls the air through the ductwork and blows it outside. Unfortunately, it’s not as simple as it looks, especially in small compressor rooms with low ceilings. If you add bends and curves to reach the outlet, you build up back pressure in the ducts—a 90° turn, for example, is like adding 30 feet of straight ductwork. So just adding a few zigs and zags creates a lot of resistance, resulting in heat building inside of the compressor.

- Forced ventilation. Compressors larger than 25 HP usually require forced ventilation, but every site is different. An exhaust fan pulls the air through the ductwork and blows it outside. Unfortunately, it’s not as simple as it looks, especially in small compressor rooms with low ceilings. If you add bends and curves to reach the outlet, you build up back pressure in the ducts—a 90° turn, for example, is like adding 30 feet of straight ductwork. So just adding a few zigs and zags creates a lot of resistance, resulting in heat building inside of the compressor.

For larger units (25 HP and above), you probably need a fan and ductwork to remove heat.

-

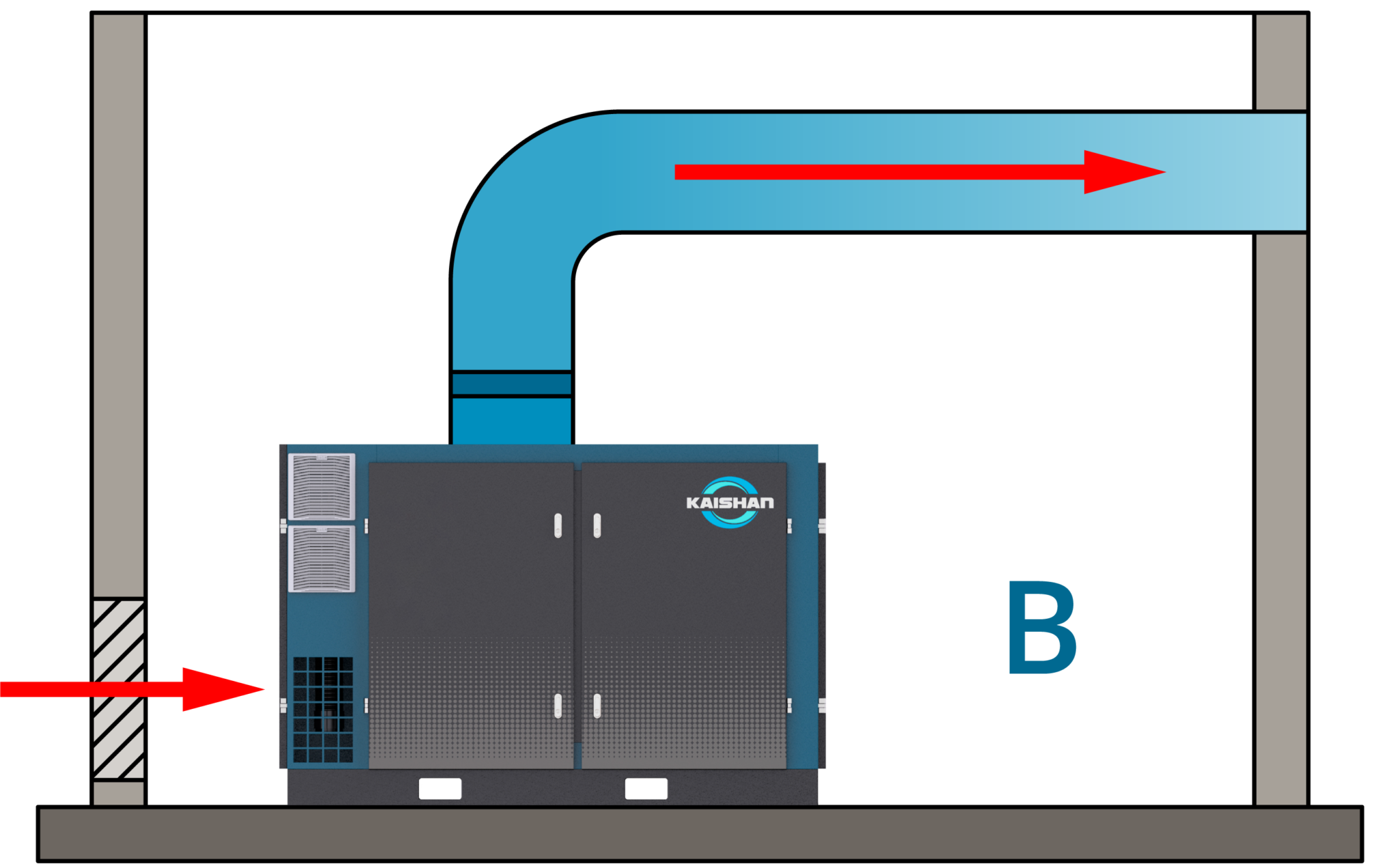

- Heat recovery. In northern climates, it’s possible to save significant amounts of energy by recovering the heat removed from the compressed air system in the winter. A damper directs the air toward an outside vent in the summer, and in the winter, the air goes toward space heating or preheating other operations.

It’s also possible to recover most of the heat your compressor generates, especially in cooler, northern climates.

Equipment Sizing

As mentioned above, you’ll need to size your compressor, dryer and cooling equipment for your worst-case ambient temperature conditions.

-

- Compressor. Because the air in summer is thinner, you may need to oversize your compressor by as much as 10% to 15% to make up the difference in output. Admittedly, that’s not as important as the correction factor for atmospheric pressure (basically, elevation above sea level), which can be as high as 30% to 40%. But it is significant, and both the compressor and the cleanup equipment must be oversized to compensate for the hot weather.

- Cleanup equipment. All cleanup equipment, including dryers, filters and separators, should be sized for the hottest day of the year, using correction factors provided by the manufacturer. Especially the dryer. The higher the inlet temperature, the greater the need to oversize the dryer. For example, if your compressor room is 110°F and you have mediocre coolers, you’re passing 130°F air through to your dryer. So, following the manufacturer’s correction factor, you need to add dryer capacity, incurring cost and increasing energy consumption.

How Kaishan Helps

We have taken several steps to ensure our rotary screw air compressors do well in even the most challenging environments. Major enhancements include:

-

-

- Oversized coolers. Kaishan designs its units to handle hotter environments by oversizing the coolers. We design most of our units to withstand temperatures as high as 122°F, while many of our competitors list 104° to 115°F as their maximum temperatures.

-

Kaishan oversizes coolers on most of its line, including this KRSP125 premium rotary screw air compressor to accommodate ambient temperatures of 122°F (50°C).

-

- Spacious packaging. We also design our packages to be more spacious with more air flow. Spacing out the internal components allows them to cool more efficiently. As a result, our compressors are not the most compact on the market, but they handle hot weather better than machines with tighter spaces. And they’re easier to service.

- Robust lubricants. Kaishan's OEM lubricants have undergone rigorous testing in a range of extreme environments, from the frigid polar regions to the scorching heat of deserts, ensuring their resilience and efficiency in varying weather conditions. This proven performance record makes Kaishan's OEM lubricants a trusted choice for reducing downtime and increasing operational productivity, regardless of weather conditions.

We design Kaishan compressors to be more spacious, allowing air to circulate freely. And making service easier—a repair that takes an hour in our more service-friendly compressors could require several hours of downtime on a more compact unit.

Local Help

If you need expert help in coping with the summer heat, Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in helping you prepare your air compressor system for any weather extremes.

Key Takeaways

- Summer is hard on air compressors. Hot weather makes your air compressor system work much harder.

- Hotter. Summer heat raises the temperature of the discharge air, which means it requires more treatment.

- Thinner. Your system has to work harder to maintain header pressure because the air is thinner.

- More water. Hotter air holds more moisture and thus makes refrigerated air dryers work harder.

- Things to do now. Make sure vents are open, and heat exchangers are clean and free of dust. But also check filters and test or change oil.

- Do before next summer. Review your venting configuration to ensure that air is flowing freely. And make sure all your equipment is large enough to handle the summer heat.

- How Kaishan helps. We oversize our coolers, designing our units to handle higher temperatures. And our service-friendly design allows more air flow through the compressor.

Let Us Help

Keeping your rotary screw air compressor cool during the heat of summer is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help preparing your compressed air system for hot temperatures, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Although it’s not directly related to comfort conditioning or refrigeration, your air compressor system has to work much harder in the summer months.