The History Of Air Compressors

March 20, 2024

Energy Efficiency Unleashed: The Advantages of Rotary Screw Air Compressors

April 3, 2024How Does a Rotary Screw Industrial Vacuum Pump Work?

Kaishan USA | March 27, 2024 | Uncategorized

Vacuum technology plays a vital role in food and beverage processing, helping keep food products fresh.

New developments in industrial vacuum pump technology have changed the rules of the game for rough vacuum applications.

Thanks to the development of variable-speed drives and the addition of variable-discharge port technology, centralized vacuum systems have become a cost-effective alternative to the point-of-use vacuum pumps serving so many individual uses in a typical industrial plant.

These are typically applications in the low or rough vacuum range, 15 to 29.9 inches of mercury (.5 to 1 bar or 381 to 760 Torr). Advanced processes such as particle accelerators or surface analysis tools typically require higher vacuum levels.

First, we need to introduce industrial vacuum pump technology to illustrate how these two developments deliver such significant benefits in rotary screw vacuum pumps.

How a Rotary Screw Vacuum Pump Works

A rotary screw vacuum pump draws air into a compression chamber through an inlet filter and inlet valve. The turning of the pump's rotors compresses the air to a low pressure and then releases it to the atmosphere, creating a vacuum on the inlet.

Before the air is released into the atmosphere, a sump tank with an air/oil separator element removes the small amount of oil the air picks up in the compression chamber. The oil captured from the separator returns to the pump airends.

For more details on industrial vacuum pumps, read our blog post, “Industrial Vacuum Pumps: Applications and Benefits.”

The two critical advances mentioned above make rotary screw vacuum pumps even more efficient.

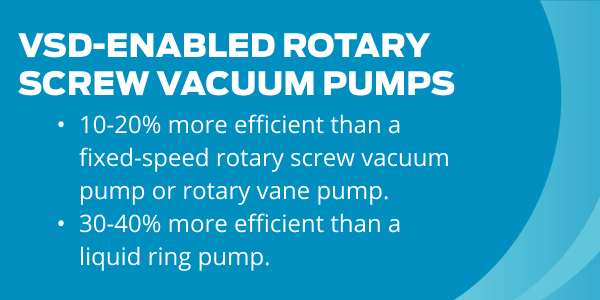

Variable-Speed Drive

A rotary screw vacuum pump is almost a textbook application for a variable-speed drive. As the vacuum level rises, the VSD speeds up the rotors to take advantage of the "extra" motor horsepower available. It thus increases the flow and decreases power consumption at the required vacuum levels.

As a result, VSD-enabled vacuum pumps are 10-20% more efficient than a fixed-speed rotary screw vacuum pump or rotary vane pump and 30-40% more efficient than a liquid ring pump.

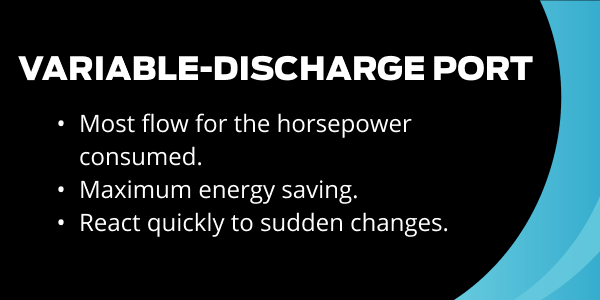

Variable-Discharge Port

Most other vacuum pumps on the market today have a fixed discharge port, with a compression ratio established by the manufacturer. So, when you select a pump, you have to choose the pump size based on either the volume you need at startup or the level you will want at the desired vacuum. So, you must choose whether to sacrifice efficiency at the beginning or the end of the process.

A variable-discharge port alters that dynamic, adjusting the size of the discharge port as the vacuum level changes. Opening it and thereby discharging more air from the chamber creates a stronger vacuum. Closing it reduces the vacuum pressure achieved by the pump.

The variable-discharge port makes the change on the fly, increasing the pump’s volumetric efficiency and performance. It also allows a rotary screw vacuum pump to operate efficiently at any point within its range, making it especially beneficial for applications where the vacuum level varies over time.

Kaishan’s KRSV: Both VSD and Variable-Discharge Port

Kaishan’s KRSV is the only vacuum pump on the market to offer both VSD capability and a variable-discharge port. From woodworking, printing, glass production and ceramics to medical and laboratory applications, the KRSV can improve a wide range of industrial processes while reducing both maintenance and electrical costs.

This design delivers the greatest efficiency in CFM per horsepower—providing you with the most flow for the horsepower consumed at every vacuum level and thus keeping electricity consumption stable.

You start the pump with the discharge port wide open to achieve maximum flow. Then, the variable-discharge port slowly closes as the vacuum level rises. The device balances the compression ratio and maintains it in an ideal range. Thus, the compression ratio stays at an optimum level at all pressures.

Another advantage is that the variable-discharge port can react quickly when the vacuum dramatically decreases, which might happen if several processes come online simultaneously.

When a variable-discharge port is coupled with a variable-speed drive, the pump will achieve maximum flow and energy savings at any level within its operational range.

VSD and Variable-Discharge Port, the Combination

A variable-discharge port gives you a quick response when you start it up, enabling you to achieve a high level of flow for the horsepower consumed. It combines with the variable-speed drive to give you great flow and energy savings at all vacuum levels. Equipped with both VSD capability and a variable-discharge port, Kaishan’s KRSV gives you an unequaled operational range (a turndown capability at 80% to 90% of maximum), helping you avoid the need for blow-off.

Rotary screw vacuum pumps that combine variable-speed drive with a variable-discharge port achieve even greater efficiency and long operating life. A rotary screw vacuum pump can often run for 100,000 hours before you need a significant repair—a huge benefit compared to other vacuum pump technologies.

Rotary Screw Vacuum Pumps: Benefits Summary

-

- Low energy consumption. Pumps equipped with VSDs and variable-discharge ports optimize the energy required to perform at various vacuum levels, thereby increasing overall efficiency.

- Low maintenance costs. The lower maintenance costs cut the total cost of ownership for rotary screw vacuum pumps.

- Automatic alerts. The pumps automatically alert you when performance falls below a specified threshold. Sophisticated microprocessor controls allow you to fine-tune machine operation to meet your needs.

- Low noise. Many rotary screw vacuum pumps are quiet enough to hold a conversation nearby.

Their main disadvantage is that they are sensitive to unwanted liquids and solids. Even some gasses. They also have a higher upfront cost; however, their total cost of ownership makes them an attractive alternative.

Rotary screw vacuum pumps are known for outstanding reliability and longevity. And our KRSV rotary screw vacuum pump combines a variable-speed drive with a variable-discharge port, making it highly efficient over a wide range of pressures and operating flows. It also has an external oil pump to prevent overheating.

An External Oil Pump Prevents Overheating

Several of our competitors have VSD vacuum pumps. However, with those products, the oil flow changes as the speed of the pump changes.

When the pump slows down and the speed of the airend decreases, the oil flow decreases as well. Their oil pump flow is directly proportional to the speed of the input shaft. So as their unit slows down, so does the oil flow.

As a result, the vacuum pump may overheat and suffer serious damage because of lack of lubrication on the airend bearings.

Kaishan’s KRSV, on the other hand, maintains oil pressure throughout its speed range.

Applications such as woodworking, where a worker may use vacuum-powered equipment sporadically, can benefit from a rotary screw vacuum pump with an external oil pump.

If you need a steady vacuum most of the time, overheating may not matter. But it can be an issue in an application such as woodworking, where a worker may cut a piece of wood one minute, then stop their equipment before resuming work again a few minutes later. Another application would be agriculture, where you might be moving materials out of silos.

Vacuum equipment that moves material in an agriculture operation may need an external oil pump to avoid overheating.

Combining All Three Options

Rotary screw vacuum pumps equipped with a VSD, variable-discharge port and an oil pump deliver tremendous advantages when compared to the smaller rotary vane vacuum pumps many plants use today.

First, you will have to repair or replace rotary vane pumps often, usually every 40,000 hours, at a cost that’s 60% of the purchase price. As mentioned, a rotary screw vacuum pump will last at least 100,000 hours before any significant maintenance is required.

Plus, without the VSD, a rotary vane pump or even another rotary screw vacuum pump will not be able to handle partial loads. The KRSV, on the other hand, can scale down to 10% of full load, matching the vacuum output to the CFM demand from the plant and saving significantly on energy costs. We had one recent plant where the savings on energy costs alone delivered a payback in nine months!

As a result, plants that centralize their vacuum systems can save on electricity bills and frequent, avoidable maintenance costs—ending high energy costs and the constant repair and replacement of multiple rotary vane pumps. And substituting instead an industrial-strength vacuum capability that matches the rough vacuum needs of all your equipment.

Local Help in Optimizing Vacuum Performance

The best approach is to bring in an expert to help you determine whether a centralized vacuum capability would benefit your organization. Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained industrial vacuum pump experts can analyze your needs and make recommendations to optimize vacuum delivery throughout your plant.

Key Takeaways

-

- Several significant developments are changing the rules of the game in industrial vacuum pump technology.

- VSD vacuum pumps can help you match vacuum flows to your plant’s demand.

- Variable-discharge ports change the size of the discharge port, maximizing volumetric efficiency at multiple vacuum levels.

- Kaishan’s KRSV is the only vacuum pump on the market today offering a VSD and a variable-discharge port.

- Oil pumps can help prevent overheating by maintaining consistent oil flow independent of vacuum pump speed.

- These advances combined can help you lower electricity and maintenance costs.

Let Us Help

Finding the right industrial vacuum pump for your operation can help you save money, cut downtime and reduce maintenance costs. If you need help finding the right pump for your application, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text