Air-powered Tools: The Seven Benefits and Uses of Pneumatic Tools

February 21, 2024

Ten Need-to-Know Rotary Screw Air Compressor Maintenance Tips

March 6, 2024Choosing the Right Rotary Compressor Oil

Kaishan USA | February 28, 2024 | Uncategorized

Choosing the right rotary compressor oil will help you keep your air compressor functioning at peak performance.

Any oil-flooded rotary screw air compressor has an oil lubrication system that seals the compression cycle, lubricates components and removes the heat of compression, lowering your system’s operating temperature.

Oil reduces friction and wear, controlling contamination and protecting your unit’s components from oxidation and corrosion.

It’s so central to the operation of your compressor that we consider rotary compressor oil the lifeblood of your system. And it’s why we place so much importance on selecting the right oil for our compressors.

And while it’s true that oil-free units do not rely as much on oil, they still use oil to lubricate components and to lower the operating temperatures in the stage cooling jackets (keeping casting temperatures lower).

Importance of the Right Oil

Kaishan worked with an expert global developer of industrial lubricants to formulate the rotary compressor oil we install in our compressors. Our KTL-8000 rotary compressor oil is a hydrologically stable synthetic with ester chemistry additives.

KTL-8000 has been specially formulated for Kaishan’s rotary screw air compressors, enabling them to overperform in any industrial setting. We strongly encourage every customer to use it in their Kaishan machines.

Why Synthetic?

We chose a synthetic blend over a mineral-oil product to improve the thermal and oxidative stability, giving the oil much longer life. It has a higher viscosity index, enabling it to handle a wider range of temperatures than mineral oil. And it lessens the formation of sludge, which can negatively impact compressor performance. The longer life alone gives it significant cost advantages over mineral oil.

Our main oil is a blend of polyalphaolefin and polyol ester formulated with antioxidants, liquid additives that combine with the base oil to prevent oxidation. Oxidation produces acids that cause varnish or solids to form in the oil.

KTL-8000 rotary compressor oil has a low dissolved-water content, helping prevent corrosion in a compressor’s bearings. Its thermal stability means less oil carryover into your compressed air flow.

Long Life

Kaishan wanted KTL-8000 to be bulletproof and last at least as long as specified. In fact, it lasts two times longer than mineral-oil-based products. From an environmental standpoint, that means you’ll use less oil and have less oily waste. We’ll also consume less energy manufacturing it, which is beneficial to the environment.

The goal? To ensure that your rotary compressor oil never causes a problem or shutdown in your facility. We don’t want our oil to be the cause of a premature compressor failure. View the safety data sheet.

We also offer a PG (polyglycol) alternative for high humid conditions.

An unmatched lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

It’s part of an overall strategy that allows Kaishan to offer industry-leading warranty protection. Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months. With our extended warranties (provided at no additional cost), we back our KRSP and KRSP2 screw compressors with a lifetime warranty on the airend.

As mentioned, our extended warranties require that you use genuine Kaishan industrial air compressor parts and sample the oil every 2,000 hours (see “Oil Sampling” section below). Using generic or aftermarket parts/fluids will void the warranty.

If you need help determining when your compressor needs attention, see our blog post, “Four Signs Your Air Compressor Needs Parts and Service.”

Kaishan’s KTL-8000 rotary compressor oil.

KTL-8000 Rotary Compressor Oil

-

- 100% synthetic multi-functional blend

- Formulated for no sludge or varnish formation at elevated pressure and discharge temperatures over 212°F or 100°C

- Formulated with additives that work in combination to prevent mild wear, corrosion and oxidation

- Exhibits outstanding thermal, oxidative and hydrolytic stability in applications designed for extended drain intervals

- Demulsible

- Low pour point and high viscosity index

- Low foaming

- Low water-containing fluids

View the safety data sheet.

Maintenance and Oil Changes

Since rotary compressor oil plays such a crucial role in compressor operation, it’s essential to maintain fluid levels, change filters and replace oil regularly. Drain the old oil from the system when you do an oil change. Make sure to drain the oil cooler completely to ensure no residual oil is left behind. Leaving a small percentage of the old oil can significantly impact the life of the new oil. The good news? Kaishan KRSP and KRSP2 premium rotary screw air compressors have a separate drain point and atmospheric vent installed to make this process easy.

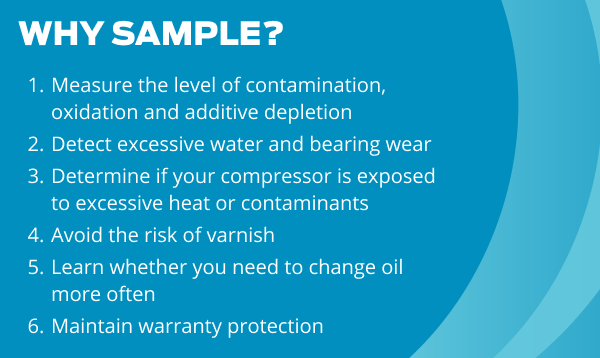

Oil Sampling

Fluid sampling is critical to the life of an oil-flooded rotary screw air compressor. Sampling oil regularly will tell you whether it is being exposed to excessive heat or is taking in contaminants. It can also detect excessive bearing wear, allowing you to be proactive when you uncover a problem, even avoiding an unplanned shutdown.

That’s why we consider oil sampling the most important maintenance procedure for our compressors. And we require that, to maintain their warranty protection, our customers collect an oil sample and have it analyzed every 2,000 hours or every 1,000 hours for food-grade applications.

There are two critical readings you’ll see in your oil analysis:

-

- Viscosity by ASTM D 445 measures the thickness of the fluid. We expect viscosity to increase as you use your compressor. That’s how the oil keeps possible contaminants in solution, preventing varnish or solids from “dropping out” of the fluid.

- Total acid number indicates how much acid has formed. Once again, we expect it to increase as the oil ages.

Oil sampling extends the life of the lubricant and your equipment. It verifies that your rotary compressor oil will last as long as expected, and also measures the level of contamination, lubricant oxidation and additive depletion.

It’s especially critical if you expose your compressor to excessive heat or contaminants or if your air compressor does not run often enough—when it’s lightly loaded, condensate collects and causes rusting issues. In these situations, oil life can be decreased, so it is critical to follow the sample recommendations to avoid the risk of varnish.

Oil sampling provides a wealth of data about the performance of your rotary compressor oil. And we can also learn a lot about the condition of your compressor.

It gives us hard data to estimate how long your oil will remain effective in your application and how often you should change it. Make sure to change your oil before it is no longer effective.

In addition to the conditions of the rotary compressor oil, the analysis gives us critical insight into the operational conditions of your compressor, indicating high levels of wear or corrosion. For example:

-

- If the oil is becoming dirtier, there might be some concerns with the quality of the air you’re drawing into your compressor.

- If the compressor starts running warmer or if we see the total acid number increase more quickly than expected, there might be issues with the temperature of the compressor’s environment or an indication that the cooling system needs service.

- If metal fines are detected in the sample, it indicates future bearing failure; since the rotors never touch, you’ll only find metal in an oil sample if there is bearing failure.

- If water is detected in the sample, it indicates the system is short-cycling and may not have time to exceed the pressure dew point temperature.

It's an all-encompassing review of the lubricant and its integrity, and it can give you insight into the compressor’s operation and its environment.

Your local professional can help ensure you have the right rotary compressor oil and maintenance plan for your compressor.

Local Help

If you need help determining the right rotary compressor oil for your compressor, check with our nationwide network of independent distributors. One of our local distributors can provide on-site help or consultation. These factory-trained air compression experts can service your air compressor system without a problem. And they have staff members skilled in using advanced compressed air technology.

Key Takeaways

-

- Oil is the lifeblood of your rotary screw air compressor.

- Our rotary compressor oil is specially formulated for Kaishan rotary screw air compressors.

- Our KTL-8000 synthetic lubricant lasts two times longer than mineral-oil-based products.

- Draw a fluid sample and have it analyzed every 2,000 hours to maintain warranty protection.

- Two critical readings in an oil analysis are the viscosity and total acid number.

Let Us Help

Using the right rotary compressor oil in your rotary screw air compressor is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help determining which lubricant is right for you, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text