Four Applications of Industrial Vacuum Pumps in Food and Beverage

May 31, 2023

Four Reasons Your Plant Needs a Backup Air Compressor

June 14, 2023Air Compressor Safety: 8 Essential Tips

Kaishan USA | June 7, 2023 | Uncategorized

Make sure all your people understand compressor basics. And require that everyone who operates your compressors has been thoroughly trained.

As the term “fourth utility” implies, compressed air joins electricity, water and natural gas as fundamental services in an industrial facility. Well-maintained air compressors and their associated equipment provide almost every industry with much-needed power that is remarkably safe.

At the same time, as with the other utilities, compressed air deserves to be handled with respect. Accidents can happen. But many can be avoided if companies follow some basic safety practices. We offer several of the basics below.

1. Comply with the Regulations

You’ll want to ensure you comply with air compressor safety regulations (1910.166–1910.168) enforced by OSHA. Following safety guidelines to follow when using an air compressor is critical.

Safety is no accident. Make sure your workers all have the appropriate PPE when they are working around your compressor.

2. Protect Your People

Your people should have all appropriate personal protective equipment, including goggles, masks, gloves (rubber or leather), steel-toed shoes and leather or PVC aprons.

3. Train, Train, Train

Too many accidents happen because operators and nearby workers aren’t aware of air compressor best practices. It’s in every company’s best interest to require that everyone who operates your equipment has been appropriately trained in compressed air basics and operating procedures. And make sure all your equipment operators have taken the safety training. If you need training materials, check out our safety video.

If you upgrade your equipment, it’s a great idea to have a training session with operators, so they know how your new devices should operate. And know what the warning signs are.

4. Maintain, Maintain, Maintain

An aggressive preventive maintenance program is one of the most critical parts of your safety program.

Some safety highlights of a proactive maintenance program include:

-

-

- Follow your manufacturer’s recommendations. Every equipment manufacturer provides detailed instructions on maintaining your air compressor. Failing to heed those instructions could expose your team to unnecessary hazards. Plus it might invalidate your warranty.

- Lubrication. We often say that oil is the lifeblood of your compressor. It is not the place to cut corners or pinch pennies. Once again, follow your manufacturer’s guidance on the appropriate oils for your application—the wrong oil can lead to a thermal event or catastrophic machine failure.

- Disconnect power before servicing. Shut down your compressor and disconnect it from the power source. Lock the electrical switch in the open position and tag it so no one restarts your compressor by mistake. The objective is to deenergize all stored energy, isolating the compressor from the plant and removing all sources of potential energy. Be especially careful about VSD units, which have capacitors and can store energy even after disconnected.

- Obvious wear. To prevent injury and downtime, you should replace worn-out components immediately.

- OEM parts. Only use parts authorized by your manufacturer. Almost all compressor manufacturers require that you use their original OEM parts to maintain your warranty eligibility and ensure that your air compressor system achieves the expected performance level. And safety.

-

For more on maintenance, read our blog post, “Air Compressor Maintenance” or watch our compressor maintenance video.

5. Know the Hazards

Once again, compressed air technology is remarkably safe. But there are several hazards that can impact workers.

-

-

- Electricity. Ensure all outlets are grounded, and you’ve followed the manufacturer’s instructions regarding electrical connections.

- Fumes. Compressors powered by gas or diesel will produce dangerous fumes, so you will want to use them outdoors only. And make sure they are not near any HVAC or air compressor air intakes.

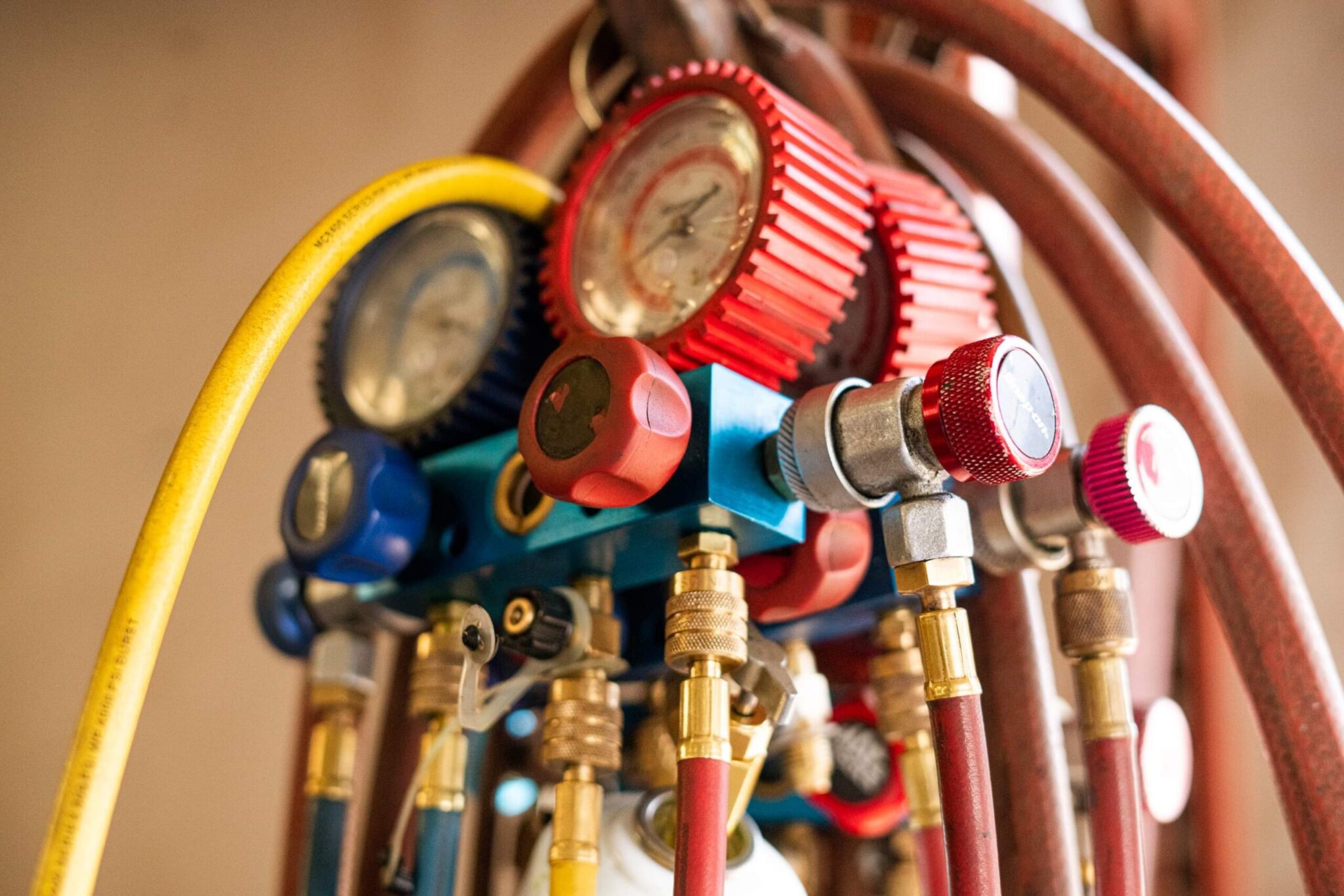

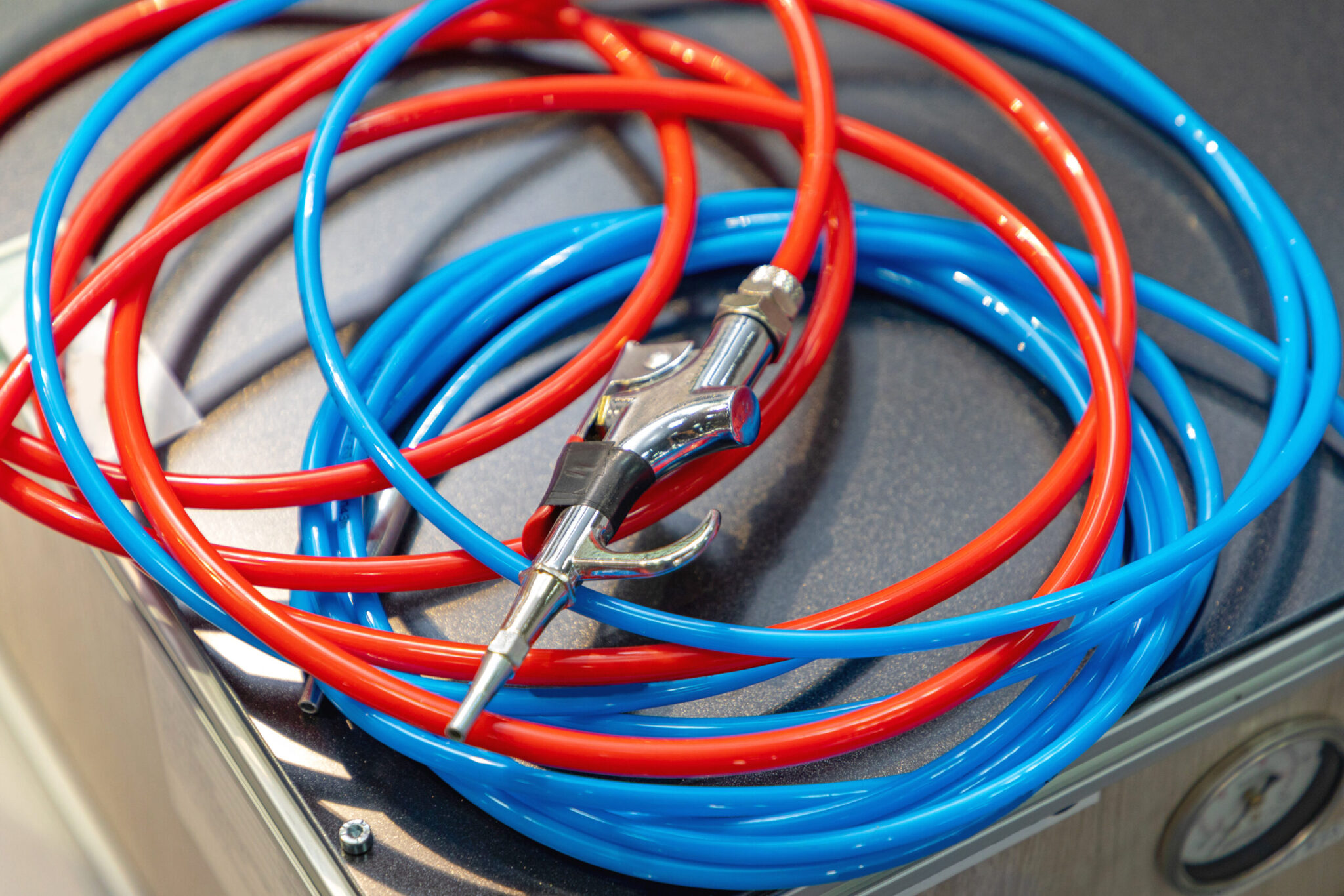

- Hoses. Always shut off the compressor and know how to release air from air compressor systems safely before disconnecting hoses. If a hose is cut or disconnected and starts whipping around, do not try to grab it. Instead, shut off the compressor and release the pressure before trying to contain the hose. And don’t forget the tripping hazards posed by hoses and electrical cords stretched across the floor.

- Flying debris. The air pressures are high enough that all kinds of foreign materials and objects can become airborne and cause injury.

- Noise. A noisy compressor can cause hearing loss. The Journal of the American Medical Association estimates that 20.3% of Americans (48.1 million people) experience hearing loss in at least one ear. For more on controlling noise from compressors in your plant, read our blog post, “Benefits of a Quiet Air Compressor For Your Plant.”

-

6. Set Up Your Equipment Properly

One way to avoid safety hazards is to set up your compressor and related equipment properly. Key points to address before you crank up your system:

- Air source. Make sure the incoming air is clean and dry. And check screens or filters to see if they are clogged or dirty.

- Pressure ratings. Verify that all system components, including hoses, pipes, fittings and other supporting equipment, are rated for your compressor’s maximum air pressure.

- Relief valves. Do not adjust, bypass or remove relief valves.

- Drain valves. Keep drain valves away from moisture. They should be at least a foot and a half above ground.

- Shutoff valve. You’ll want to make sure you can reach the shutoff valve easily.

- Guards. Any moving parts, like flywheels, belts and pulleys, need effective guards.

- Ventilation. See that all workspaces have good air circulation.

- Humidity. You don’t want your workplace to get too humid. If levels start creeping up, improve air circulation or add a dryer to your compressed air system.

You’ll want to check all the air connections and follow best practices for how to start an air compressor safely.

7. Get Off to a Good Start

It’s a good idea to create a checklist your operators should follow before they begin operation. Items would include:

-

-

- Oil. Add oil if needed, being careful not to overfill the reservoir.

- Lubrication. Lubricate every pneumatic tool, following the manufacturer’s guidelines.

- Fuel level. One of the drawbacks of using diesel compressors is the inconvenience of stopping when the fuel level gets low and allowing the compressor to cool down before adding more. That’s one of the reasons why we recommend replacing diesel compressors with electrically-driven models.

- Air filter. Check the air filter before you start up. Clean or replace it if it’s dirty or clogged.

- Air connection. Inspect the air connection and make sure it’s secure.

- Tools. To avoid surprises, you’ll want to ensure that none of your end-use tools have their trigger pulled before startup.

- PPE. Make sure to use personal protective equipment, especially hearing protection.

-

Before startup, check end-use tools to ensure none have their trigger pulled.

8. Other Things to Avoid

-

-

- Don’t use compressed air for breathing. Intake air can include environmental contaminants and pollutants like carbon monoxide that are concentrated in the compression process. As a result, we encourage companies to ensure proper airflow and ventilation in all workplaces. And we always tell our customers not to use compressed air from their system for breathing equipment like hoods and masks.

- Don’t use compressed air to clean clothing or human skin. It’s probably a great idea to cover this subject as one of the first items in your basic training course.

- Don’t use compressed air to pressurize a vessel. Like emptying oil from a gearbox that is not designed to handle pressures that high.

- Horseplay. Even though compressed air is relatively safe, you need to follow the guidelines mentioned here. Failing to do so can lead to serious injury and death.

-

Have Safety Questions? Don’t Hesitate to Ask.

Better safe than sorry. If you have questions about air compressor safety, get in touch with your air compressor professional immediately. We work with a nationwide network of independent distributors, who have the skills and experience to provide on-site help and consultation. These factory-trained air compression experts have an investment in their local communities and help you operate your air compressor system safely.

Immediately check with your air compressor professional if you have any questions about the safe operation of your equipment.

Key Takeaways

-

-

- Remarkably safe. Well-maintained air compressors and their associated equipment provide almost every industry with much-needed power that is remarkably safe.

- Accidents can happen. That’s why compressed air deserves to be handled with respect.

- PPE. Your people should have appropriate personal protective equipment, including goggles, masks and gloves.

- Training. Require that everyone who operates your equipment has been properly trained in compressed air basics and operating procedures. And make sure everyone who operates the equipment has taken the safety training.

- Maintenance. Following an aggressive preventive maintenance program is one of the most critical parts of your safety program.

- Hazards. Follow your manufacturer’s recommendations. Make sure all electrical hazards are grounded. Shut off power before disconnecting hoses.

- Startup. Give your operators a checklist to follow when they start up their machines, checking fluid levels, filters and air connections. And make sure end-use tools don’t have their trigger pulled before you start up.

-

Let Us Help

Operating your air compressor system safely does not have to come at the expense of your productivity. In fact, safe operation is the only way to ensure long-term success of your facility.

If you have questions or need help setting up a safety program, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

As the term “fourth utility” implies, compressed air joins electricity, water and natural gas as fundamental services in an industrial facility.