Air Compressor Guide

June 5, 2018

Surprising Uses For Rotary Air Compressors

June 20, 2018KEY PARTS OF A ROTARY SCREW AIR COMPRESSOR

Kaishan USA | June 05, 2018 | Air Compressor Information, Rotary Air Compressors

When it comes to modern-day, industrial-grade machinery, few products are more important or versatile than rotary screw air compressors. These units flex their mechanical muscles for a range of demanding industry tasks, without which an unimaginable number of industries would encounter operational challenges.

Rotary screw air compressors have a unique design history that sets them apart from other compressor types. Their list of parts, applications, processes, and technical usage can sometimes make even the most industry-savvy engineer pause to consider how to best fix, adjust, or maintain the machine’s functionality.

We have put together a rotary screw air compressor guide to help navigate the features and accessories that bring rotational compressors to life and sustain them, day after day.

What Is A Rotary Screw Air Compressor?

As their name suggests, air compressors work to do one thing: compress air. Once the air is condensed into a concentrated form, compressors—across mechanical types—must then supply that air smoothly and consistently, without spurts or interruptions. They are imperative to both small and large-scale businesses and industries, for machines to generate power and perform functions. In fact, up to 30 percent of industrial jobs could not be completed without the high-density, high-pressure air pumped by rotary screw compressors—literally making or breaking several industrial production lines and service types, if these compressors malfunction or go neglected.

Rotary screw compressors rely on the movements of two paired spiral rotors or rollers to create their streamlined airflow. Each rotor is spiral in design and responsible for taking in air and fluid, and for moving and pressurizing these elements right from their initial intake. The screws rotate together to compress air, trapping and holding it within their curved divots and preventing its release.

It is these interlocking rotors and their insulation design that creates highly pressurized air. As the rotors rotate, they move the gas farther along the chamber. Most rotary screw chambers become smaller near their discharge side, squeezing and consolidating trapped air into its highly pressurized final state. They then open into a discharge chamber, where air can be stored in pressure-retaining tanks or released immediately in its new, concentrated form.

The overall design runs parallel to what you find in most positive-displacement machines. These designs rely on capturing and converting gases or fluids on a larger, intake side while releasing them from a smaller, more condensed exit cavity. They are less likely to fuel direct, on-and-off mechanical tasks in favor of smooth and continuous, high-volume air compression operations.

How Rotary Screw Air Compressors Work

Rotary screw air compressors take the science of potential energy and convert it into measurable, mechanical output. At their most basic, rotary screw compressors function through the following steps:

- 1. An opening valve suctions external gas inside the twin compressor chambers. Inside these chambers are two screw rollers which, when the machine is on, rotate at high-speeds to compress air between them.

- 2. As the rollers spin, they trap and isolate air between roller divots and move it down the chamber.

- 3. The chamber gets smaller and smaller farther away from the opening valve. As such, the amount of room the trapped gas can fill begins to decrease, yet the amount of gas stays the same. At a constant temperature, volume and pressure are inversely related, so as the volume decreases, the pressure increases.

- 4. Pressurization builds as air is condensed.

- 5. The build-up of air causes the compressor’s discharge valve to open, which moves the now-pressurized air into or out of a holding tank for its mechanical application.

- 6. You now have the desired compressed air.

- 7. Electric operating systems called control schemes manage the outputs of rotary screw compressors. They can be programmed and tailored to slow down or speed up rotation speeds, delivering the amount of compressed air as needed.

- 8. Control schemes come in a different modulations and adjustments, all of which affect the rotary screw compressor’s final operating capacities.

Note that—like their cousins, the reciprocating air compressors—rotary screw units can contain multiple “stages.” These stages tell you how many times trapped air is funneled through circulating chambers before reaching a holding tank, becoming denser each time. Overall, multi-stage rotary screw air compressors produce a higher pound-per-square inch (PSI) final air stream at a more efficient rate.

Two Types Of Rotary Air Compressors

There are two models of rotary air compressors in the market today: oil-injected or oil-free.

- Oil-injected rotary air compressors use oil on chamber cylinder walls and bearings to keep machine parts lubricated and running smoothly. This is known as an “oil bath” or “oil flooded” lubrication maintenance. This type of compressor requires more routine maintenance but will run more efficiently in the long run. At Kaishan Compressor, we currently focus on selling only oil-injected rotary screw air compressors due to their high efficiency and longer running time.

- Oil-free rotary air compressors, on the other hand, do not flood their compression chambers with oil. Bearings and other machine parts come with lubrication treatments and anti-corrosive materials. Though this type tends to be more expensive and prone to noise than its oil-injected counterparts, there is no need to worry about oil contamination.

List Of Rotary Screw Air Compressor Parts

While these air compressors come in a diverse set of builds and applications, their basic makeup is the same. Every compressor relies on a shared and fundamental list of parts, as well as a common formula for how those parts interact. This crossover of basic parts and functions makes it easier to understand and apply different compressor models to your manufacturing, production, or processing needs.

The following is a list of the compressor’s components:

- Part 1: Rotors/Rollers. There are few elements as critical as rotors. They are the centralized components of the compression process, without which, air compressors cannot function or exist normally. Rotors or rollers come in pairs and are built inside cylinders. When turned on, rotors rotate at high, smooth, sweeping speeds, creating the pipeline for suctioned air to move through, be compressed, and then exit in an ultra-pressurized form.

- Part 2: Compression Cylinder. These compressor models include mainline compression cylinders, which house their all-important rollers. Collected air runs through a cylinder’s chambers and into the interlocking, spinning rotors. The number of cylinders contained in a unit determines how many “stages” the particular unit has, as well as the level of pressurization it can generate.

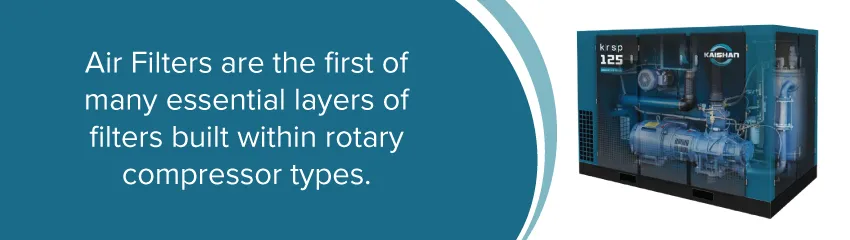

- Part 3: Air Filters. Air filters are the first of several essential layers of filters built within this type of compressors. The inlet air filter rests just inside the compressor’s opening valve, attracting dust, moisture, and air particles that would be damaging to the inside of the machine. Other air filters may be set within chamber components for additional cleaning and protective layers.

- Part 4: Oil Filters. In the case of oil-lubricating compressors, oil filters are placed both within rotating chamber walls and near discharge valves, in order to properly sift oil lubrication from compressed air. Liquid lubrication also provides the cooling needed for compression machines, which produce high heat that is unsafe for optimal air and machine capacities.

- Part 5: Bearings. Bearings sit at both rotor ends and help rotors stay securely in place, rotating evenly and properly balancing their loads. They are typically anti-friction and anti-corrosive, with several design modifications based on the size, scale, and output expectations of the compressor unit—whether oil-lubricating or oil-free.

- Part 6: Suction Valve. The suction valve sits atop most compressing units and is responsible for initial retrieval of raw gas. At a cue given by the unit’s system stage control, the suction valves open to allow air to rush inside, where it mixes and is trapped within the interlocked twin rotors.

- Part 7: Discharge Valve. Likewise, discharge valves sit at the opposite end of the suction valve and cue the end of the compression cycle. They receive the now-pressurized air and release it into a holding or storage tank, or out of a discharge pipe for immediate application.

- Part 8: Motor. The compressor motor powers the rotations of the rollers at automatic and adjusted settings, which in turn powers the entire compression capabilities of the machine.

- Part 9: System Control. Given their multi-control scheme settings, operators need a system control display, in order to read and gauge a unit’s health and overall output. A system control displays and monitors the various components of a compressor, as well as its operating, idling, or stopping parameters. In high-capacity, automatic units working nearly 24/7, the gauge allows safe and procedural pressures to be monitored, with or without human oversight.

- Part 10: Storage Tanks. The storage tank receives the condensed air from the discharge valve. The condensed air is stored safely here and its pressure is maintained until use.

- Part 11: Separators. In oil-injection compressors, separator tanks are employed as another line of defense against oil and gas mixtures damaging the purity of your final compressed gas stream.

- Part 12: Gaskets And Seals. Pressurizing systems work only when they themselves are air-tight. Gaskets and seals address this overall concern, ensuring that a compressor is locked, sealed, and leak-free at every nook and cranny, both interior and exterior.

It is imperative to understand, monitor, tweak, and maintain each of part of a compressor’s system. A single dysfunctional element—even a seemingly small one like a dirty air filter—can lead to huge issues: at the very least temporarily halting production and at the very worst causing serious chaos for your bottom line.

How Each Rotary Screw Air Compressor Part Works

An in-depth guide to compressor parts and functions would be incomplete without describing how each component works. After all, the functional details and fluid interactions of a unit complete the one-of-a-kind, powerful pressurization process within these positive displacement machines.

1. Rotors/Rollers

Interlocking twin rollers lie at the heart of a functioning compressor. They perform the motion these mechanical units derive their name from and are nestled securely inside lined cylinders where their complementary rotations occur.

When a machine is powered on and its stage programmed, rotors kick into gear, receiving suctioned air through the opening valve. Through a connective distribution system of bearings, belts, and a motor drive, rotors are connected to a compressor’s motor and begin spinning. Air is sucked into the space between the rotors as this spinning starts and is compressed as the spinning continues.

Once the grooves reach the end of a rotation length, the air contained within them is transformed into its fully compressed state. It is then pushed out through a discharge valve or nozzle and into the final storage tank.

The above process is the primary mechanical function of these compressors, from single-stage to the most complex, multi-cycled automated industrial units.

2. Compression Cylinders

Cylinders act as the mainframe for your compressors. Since the all-important rotors sit directly inside them, cylinders are built to snuggly fit the dimensions of the main body of the individual compressor unit and are lined and fitted to be readily replaced when damaged. With most professional or industrial-grade screw air compressors, you will find multiple-cylinder or staged units with hyper-pressurization functionality and storage capacities.

Since cylinders provide the stage where rotary-driven pressurization takes place, it is important that each of them is secure, air-tight, and productive. Compression cylinders remain stationary, yet they work with moving and rotating parts inside and outside their chambers. They also contain oil-lubricating hoses and distribution systems in oil-injecting units in order to keep chamber temperatures healthy and functional.

Cylinders come in a range of types, from single-cylinder machines propelled by a single motor drive to multi-cylindered, multi-powered compressors with dual-acting stages designed for maximum, around-the-clock output.

Cylinders often come equipped with cooling techniques, particularly ones that kick in during peak compression. Cast iron and steel are the most prominent cylinder materials.

3. Air Filters

Air filters are a regulatory maintenance and oversight component of a working compressor.

For oil-injected units, air filters clean and compound both moisture and oil-related residue left behind from the cooling injection and opening valve processes. Regularly checking and replacing air filters is vital to the machine’s health and performance.

For oil-free units, air filters are located near the entry suction or intake valves. They are the most commonly used maintenance filters, as they are a primary line of defense from naturally occurring pressurized air impurities.

4. Oil Filters

Like air filters, oil filters are long, cylindrical additions to larger, industrial-grade compressors. They have a two-fold purpose: to clean and maintain the gas purity of compressed air and to help with down-the-line cooling and lubrication functions of the oil separator and the entire machine.

Belt-and-pulley oil distribution systems run parallel to those within the design of the oil separator. Contemporary oil or fluid filters come with spin-on installation, making them easier to assess and replace. This saves you time and money down the road, preventing major or emergency compressor repairs.

You will find most oil filters installed with bypass valves as well. These are triggers that alert when internal operating temperatures are too hot or oil filters are too jammed, thus allowing a rush of raw oil to enter the compression chamber without first penetrating the oil filters.

5. Bearings

Similar to crankshafts and crossheads in other air compressor machines, bearings work to reduce friction, balance part movements, and keep the overall compressor temperature regulated—with components less likely to wear out.

There are multiple bearings installed in key places, though perhaps none more important than the radial-load bearings and the axial bearings. The former assists in the machine’s smooth rotations and horizontal circular roller motions, all while running quietly. The latter keep the perpendicular, complementary spinning of the twin rollers balanced and in-load, thereby also contributing to noise reduction.

6. Suction Valves

The suction or input valve works as the compressor’s opening. It is triggered by the programmed stage settings of your machine to open and close when those same settings signal it to close or to remain open continually, thus contributing to the efficiency of rotary screw units.

Suction valves can come in a number of configurations. These take into account different design elements to maximize airflow and streamline type. Most suction valves come in 1 of 3 types, however: the poppet valve, the plate valve, or the ring valve. Each consists of its own concentric layers in different shapes, which come together to create ideal air flows for operation type.

7. Discharge Valves

The discharge valves, which constitute the endpoint of the compressor system’s air end, provide steady and safe release for freshly concentrated air.

Whether these discharge valves release into a storage container or get connected to air hoses for immediate use, they act as critical regulatory agents. Malfunctioning or misfiring discharge valves are not only a danger to your machine but to nearby personnel and the immediate work environment as well.

8. Motors

The most common motors are electrically powered, though gas and even hybrid fuel types are increasingly being developed. On account of its often large-scale, around-the-clock use, this type of compressor requires an equally large-scale and reliable motor: one which can configure two or more power sources.

However, it is important to remember that motor productivity is not as simple as the mantra “bigger is better.” The HP produced and maintained by large motors often courts efficiency problems. Test your motor frequently to ensure that it is safe and productive, and to gauge the overall health of your compressor.

Several contemporary models contain motor-reading “smart” technology and gauges, all of which help to safely and productively power your machine.

9. System And Stage Control

The system and stage control, as its name indicates, controls, monitors, and tracks the compressor’s performance. It is the quickest way to assess functionality and system checkpoints across multiple unit features. Familiarizing yourself with your system, learning to “read” it, and training operators to use it properly are all important parts of the overall maintenance of your model.

Certain unit designs have internal sensors that automatically switch off the motor when the storage tank is nearly full or when the programmed cycle is complete. This is a fundamental “smart” technological safety feature that has been activated for unmanned, high-capacity equipment.

10. Storage Tank

Almost all compressor varieties come with a storage tank. Storage tank capacities vary in size and scale, though for professional and industrial applications, storage tanks are substantially larger. This sizing feature is intuitive and practical, as large industrial tanks offer attractive reserve features and allow longer rest times for the unit motor.

11. Oil Separator

Since many of these models, by design, must infuse oil into their compression chambers to cool and lubricate parts, it is equally important to install a separator that can filter and clean out excess oil from newly compressed air.

This is where oil separators come in handy for oil-injecting rotary screw units. High temperatures are the natural byproduct of the intensity of these machines. As such, oil and other coolant fluids are necessary to contribute to the performance of the machine, yet should not be part of the final, gaseous product.

Oil separators ensure that there is little to no oil residue in the pressurized air. Oil separator types and levels can be modified and installed as a machine ages or when separator functionality needs boosting.

12. Gaskets And Seals

The air-tight design and seamless, high-efficiency productivity of air compressors are achieved through perfection in the smallest details. Specifically, details like bearing rings and chamber linings are placed around the bearings or compression cylinders in order to ensure that compressed gas does not leak out into other compressor parts. These sliding seals can be self-lubricated or oil-injected, thereby reducing the natural friction between rotors and their surrounding cylinders.

Other details, like rider loops or wear rings, are added to horizontal cylinder bands. This adds yet another barrier to friction build-up and ensures a smooth and seamless transfer of all gear and rotary motion types.

Maintaining Your Rotary Screw Air Compressor Parts

There are a few key strategies to be followed when it comes to maintaining your compressor parts. Overall, maintenance should be seen as an extension of your operational policies—and not as a burdensome afterthought or a rare chore.

Maintenance checks range from the daily to the situational. It can seem overwhelming to maintain simple dislodged parts, not to mention the unavoidable wear and tear that comes with continuous, industrial compressor running and use. But if you desire to achieve the maximum possible unit durability, cost-efficiency, and compressor life cycles, unit maintenance is a necessity—not a choice. Here are a few strategies you can implement today in order to successfully maintain your compressor parts:

- Air Filter Checks: Air filters and their accompanying elements will be some of the most commonly replaced parts on your compressor list. Daily inspections are ideal, and it is not advisable to go longer than a week between checkups for frequently powered units. Most air filters can be cleaned for optimal and easy maintenance, though complete filter replacement will eventually be required.

- Oil Filter And Separator Inspections: If your rotary screw air compressor machine is oil-injection lubricated, daily oil level inspections will keep frictional wear and tear at bay.

- Regular Stage Control Testing: A compressor stage controller monitors the entire machine. It not only provides safety readings like tank capacity, load, and speed settings or temperature checks, but also automatically controls the production system. Check pre-set limits and levels regularly to ensure that your motor shuts off or runs at low-capacity when healthy, and correctly reads pressure levels as well.

- Rotor Compression Inspections: Since rotors are the heart of your compressor’s very existence, regularly inspecting and testing their productivity is essential. You can use belt tension gauges to measure their activity levels, and then compare the test numbers to what rotors should be producing as per your unit manual. High readings mean that motor bolts, among other items, should be loosened. Low readings mean that these elements need tightening.

- Routine Maintenance And Cleaning Schedules: You should do an in-depth, complete system maintenance check and cleaning every few weeks for peak rotary screw compressor performance.

Benefits Of Rotary Screw Air Compressors

The uses of rotating screw air compressors are many. So, too, are the benefits.

- Safety And stability: Rotary screw air compressors power several machines and systems that operate under extreme conditions or temperatures or pose too many risks with standard electrical power sourcing. While other systems can experience frequent electrical overloading and temperature-related malfunctions—even fires and explosions—air compressors hold up well in such conditions, from furnace-like heat to extreme cold.

- Efficiency: The highly steady and easily adjustable nature of rotary air compressors makes them one of the most efficient and versatile power sources on the market. Typical applications run on automated modes, making your production systems as smooth and seamless as possible.

- Cost-Effectiveness: While certain large-scale, multi-cylindered compressors may have higher up-front building and installation costs, you save time and energy in the long run. Overall production costs decrease in most manufacturing and industrial applications when utilizing cutting-edge, well-maintained rotary screw air compressor machines.

- Storage: Consistently accessing and utilizing stored energy is a challenge across industries. The ease at which pressurized air can be stored means you have a constant source upon which to rely. In cases of volatile or fluctuating usage, these storage reserves offer an easy and efficient in-house solution.

Kaishan Compressor brings you a variety of industrial compressor products and over six decades of experience in the industrial and construction equipment manufacturing industry. Contact our experts to see how we can make our award-winning compressor products work for you.

Random stat or

customer quote

textXXtext

text

When it comes to modern-day, industrial-grade machinery, few products are more important or versatile