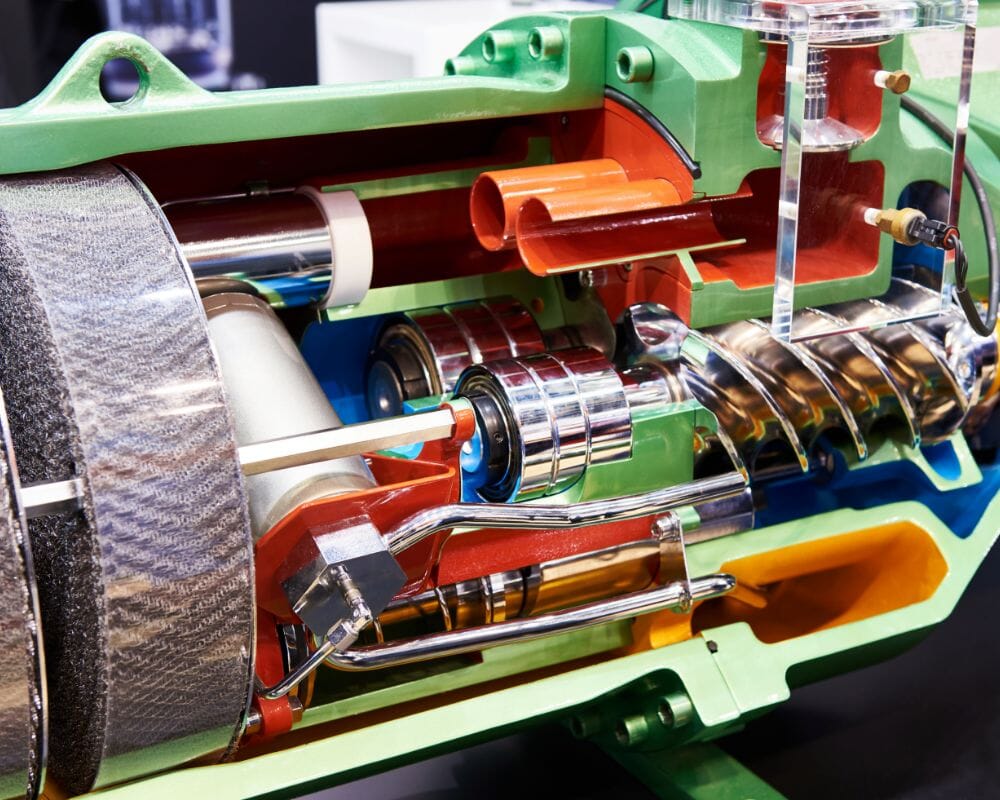

Key Parts Of A Rotary Screw Air Compressor

June 5, 2018

What Are The Different Types Of Air Compressors?

September 6, 2018SURPRISING USES FOR ROTARY AIR COMPRESSORS

Kaishan USA | June 20, 2018 | Rotary Air Compressors

It is almost impossible to imagine a world without air compressors. These machines do what few others can, powering countless pieces of equipment and operations big and small with their high-pressure outputs and workhorse-like capacities. They exist across industries and perform specialized tasks. They are high-functioning yet mechanically undemanding, with many operational around the clock.

Equally impossible to imagine is a stagnant list for air compressor uses. When considering how you can use an air compressor, the answers point more to: what can you not do, given the right accessories and a little creativity?

In fact, air compressor uses are so varied, and so dynamic and reliable, that they have been likened to the backbone of industrial infrastructure. At the very least, these machines work seamlessly to deliver highly pressurized, high-energy compressed air for a range of job tasks or functions. Yet what you can use air compressors for may ultimately surprise you, as these machines do not stop at routine business.

All air compressors will have some form of these three stages, and all air compressors will ultimately deliver high-pressure air streams—either in controlled spurts or 24/7—across industrial applications. All air compressors flows are measured in actual cubic feet per minute (ACFM), adjusted for machine inlet conditions, and some machines can even store pressurized air in tanks and chambers for later usage. The overall output produced by each device is measured in the typical mechanical unit of power: HP.

There are dozens upon dozens of uses for air compressors. Some you may have heard of before, while the creativity of others may surprise you. These types of compressors are common in high-power and around-the-clock industrial applications, as well as for smaller commercial or even personal tasks. Dividing the uses for air compressors into these two categories helps focus our discussion.

In fact, the uses of compressed air in daily life showcase the true versatility and nature of these machines. These surprising uses for compressed air can be found in businesses like construction, utilities, manufacturing, and mining, as well as in resorts, automobiles, garages, and backyards. We explore all these surprising applications, and more, below.

Industrial Uses Of Air Compressors

The world of industry has long relied upon the safe, energy-efficient, and high-output capabilities of air compressors. When managed properly, these provide a near-constant flow of controlled air streams only restricted by maximum temperatures and machine operating pressures. Most industrial rotary screw compressors can run around the clock as long as temperatures do not exceed 120 degrees Fahrenheit (49 degrees Celsius) and their parts are cooled and lubricated with oil, water, or additional air injection. Industrial compressor units typically range from 10 to 500 HP.

With all this in place, the most common industries to utilize these compressors are as follows:

1. Construction

Construction industries use air compressors for a range of pneumatic tools and equipment. Depending on the construction task at hand, variable flow streams will be needed and rotary screw air compressors will be found in jackhammers, nail guns, and compactors.

This industry’s air compressor uses also cover powering other portable tools, as compressors offer a mobile power source that will not overheat or unexpectedly surge. In both indoor and construction sites, this is an essential safety element.

The construction industry cites these compressors as the most efficient sources for bulk drilling, handling, and lifting operations. They power dozens of these equipment types across various sectors like infrastructure development, road building, demolition, as well as commercial and residential projects big and small.

2. Manufacturing

Perhaps no industry relies on the multifaceted nature of compressed air as much as manufacturing. From plastics and metal fabrication to food, beverage, and pharmaceutical packaging, rotary screw equipment not only enhances manufacturing productivity—it lies at the core.

In food and beverage and pharmaceutical manufacturing, contaminant-free and tightly sealed products are mandatory. Rotary screw equipment delivers that clean seal while also powering things like conveyor belts, sprayers, presses, and packaging.

Applications of this equipment also extend to plastics and other molding and shape manufacturing. Steady and robust air streams provide product finishes as well as formings and cleanings.

3. Agriculture

Farming operations require long days and heavy, expensive machinery. Some of the machines that sit at the heart of agriculture include tractors, sprayers and pumps, and crop conveyors, all of which are powered by various air compressors.

Other contemporary agriculture machinery, like those used in dairy farms and greenhouse ventilation, require compressed air to distribute steady, clean air.

Compressed air can also be shot through pipes and irrigation systems to properly winterize them in colder agricultural regions, waterproofing their interiors and maintaining their quality and longevity.

4. Energy Sector

Oil drilling has found particular functionality in air compressors. In oil rig operations alone, dependable and safe drilling equipment is imperative to the safety of the crew. Even the smallest malfunctioning part or stalled power source can interrupt operations or put the entire crew at risk.

Beyond extracting oil, other rig tasks need secure and controlled energy sourced through air compressors. Compressors are unique in their spark-free delivery and stable outputs, which are a priority in operations as delicate and isolated as oil rigs.

5. Heating, Ventilation and Air Conditioning (HVAC)

Rotary screw models are frequently built into the air-sourcing and heat pump systems of HVAC units. These parts routinely perform what is known as vapor compression refrigeration, wherein the rotary screws compress air vapors, raising their temperature and modulating the all-important refrigerant cycles that signal the cooling of HVAC systems. This relationship is the central function of several HVAC units and allows for their personalized temperature adjustments.

Whether HVAC units control the climate of large-scale warehouses or cozy residential apartments, they rely on numerous rotary screw systems and air compressors daily.

Unique Uses Of Compressed Air

The large-scale, high-output industrial uses for compressed air are what tend to come to mind when people think of these machines. That's no surprise. However, while industrial rotary screw air compressor uses still dominate the market, they aren't the only sectors where you will find positive-displacement rotors hard at work.

What can you use air compressors for outside of industrial applications? What's more, even within these go-to, designated operations, are there surprising applications and manipulations? Find out below.

Surprising Uses Of Industrial Compressors

The following industries fly under the radar when it comes to compressor usage, yet compressors often sit at the center of many of their everyday functions.

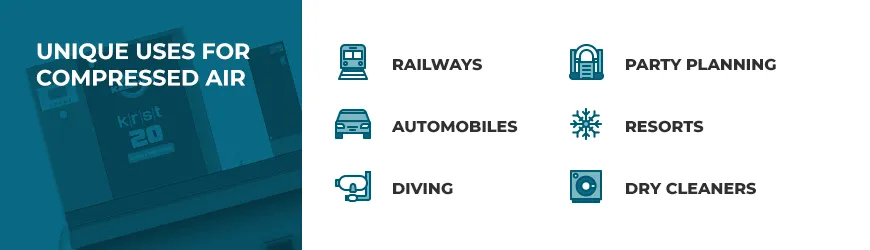

1. Railways

Rotary screw equipment offers exciting technology for railways. They are especially useful for train and subway air brake systems, which need the stable, direct, and reliable flows rotary screws can best deliver. Without compressed air, locomotives and subway systems across the world would find themselves unable to brake safely—a nightmare scenario for this industry.

In addition to that essential air brake system, contemporary air compressors help open and close automatic train doors as well as assist in their suspension systems. Both the people or cargo onboard would experience bumpy rides without tailored suspension manipulation running throughout steering and movement controls, and doors would need to be manually opened through an emergency shut off if these compressors malfunctioned.

To sum it up, air compressors make sure your train gets you from point A to point B effortlessly. They fuel the commutes of millions worldwide—and you likely never even knew it.

2. Automobiles

Many are familiar with compressed air usage in inflating tires. While this is undoubtedly a popular, mainstream, and professional function, air compression for body shops and automobile mechanics goes well beyond properly inflated tires.

Automobile repair shops use air compressors for auto body work, especially repainting cars. Yet these garages and their professionals do not stop there. This equipment is found in automobile tools like hoses and couplers, blow guns, brushes, dryers, and lubricators. These tools are cordless and battery-free. They have a range of sizes, do not require hassled storage, and are simple to train mechanics on. Any working garage with an auto-body reputation will have these air compressor pneumatic tools and more, all in order to elevate the speed and quality of their work.

3. Diving

While many do not think of diving as a profession in itself, it's surprising to learn how many careers depend upon safe diving: on its training, security, equipment, and related services—none of which could be rendered without air compressors.

Scuba diving and related recreational forms use filtered compressed air in their tanks to breathe while underwater. Compressed air is stored in diving cylinders that can fluctuate as required during specific dive depths, with dependable high- and low-pressure variations.

Other professions require compressed air stored away in safety tanks as well. Firefighters need clean filtered air when inside smoky or burning buildings, and many municipalities have divers and underwater crime scene investigators amongst their police or criminal-justice task forces.

Underwater welders, submarine workers, and marine contractors are additional professions that require the routine use of compressed air diving tanks.

4. Party Planning

From backyard birthday parties to large-scale corporate events, party planning is hardly a frivolous endeavor. The entertainment sector in particular needs to be able to inflate party materials.

Bouncy houses and other inflatable equipment are party staples that require compressed air. No other machine can deliver an air stream that is equal parts steady, dense, and fast. Not to mention, other entertaining and engaging activities—like paintball—require compressed air to re-pressurize guns and fill up equipment CO2 stores.

5. Resorts

Ski resorts and lodges have air compressors on-hand to help create their all-important snow, without which these resorts turn inoperable. During unfavorable weather or busy times of the season, when the snow gets swept away or dangerously packed, snow machines generate human-made mounds to supplement the slopes. These machines work by combining water with pressurized air, which then gets deposited straight onto natural snow or ice to maintain its composition. It's a relatively cheap and creative solution for this industry’s weather woes.

Snow machines can even be employed at home for some unforgettable backyard fun. Using a smaller-HP air compressor and a few other household items, you could be well on your way to building your own snowmaker.

6. Dry Cleaners

Your local laundromat likely has air compressors tucked away in its cleaning rooms. Accommodating a range of sizes and pressurizations, these air compressors can de-wrinkle, press clothes, spot treat, and recover solvents from the most delicate materials that their normal washing machinery cannot handle. Dry cleaning air compressor systems are tailored based on the laundromat’s scale and cleaning capacity, and can be manipulated to achieve full-service operation.

And since air compressors are so energy-efficient, upgrading certain machines and processes to include them can save dry cleaners up to 25 percent on their utility bills and overall operating costs.

Surprising Uses Of Compressed Air In Daily Life

Complementing its other uses, air compressors are just as savvy and surprising in daily life as they are in large-scale operations. Consider the following everyday uses for rotary screw air compressors and related mechanisms. You may find that you already have most of these tools tucked away somewhere in your home.

1. Carpentry and Furniture

From novices to the most seasoned carpentry craftsmen, carpentry and furniture building would be made much more difficult without air compressors. While most are familiar with certain pneumatic tools that are specially designed to be powered by compressed air, such as nail guns, many are still surprised by just how many tools are built for pressurization purposes.

Sandblasters help prepare surfaces for treatment, remove excess rust or dust, and remove other imperfections from wood and metal alike. Air sanders utilize air compression as well and, unlike other electric or mechanical sanders, do not overheat. This makes these tools great for continuous and detailed usage, where low air outputs are needed but steady streams of reliable air treat wood and other materials with care. There are dozens of other carpentry tools that utilize air compression, some of which even come with their own specialty attachments.

2. Pressure Washing

The size and tank capacity of pressure washers will vary—but their power will not. From 80-gallon industrial units to home power washers perfect for heavy-duty outdoor cleaning, compressed air pressure washers make these jobs as easy as pressing the “on” button.

Pressure washers are perfect for cleaning siding, brick, sidewalks, decks, and patios in commercial and residential properties. They are user-friendly, fast, and labor-saving, drastically reducing the time it would take to clean these outdoor areas manually. They also allow you to skip buying harsh chemicals or cleaning treatments that may be ill-suited to sitting around in daily life, or hiring an expensive third-party cleaning service.

3. Crafting

Crafting is a mainstay among uses of compressed air in daily life. From nail and staple guns for airbrushing and spray paint to air-blow guns for final project clean up, crafting projects can reach the next creative level, given the right tools. These tools are often hand-held and pneumatic, getting rid of electric cords and other dangerous nuisances so that craft projects can be the sole focus.

Compressed air crafting tools are perfect for daily life as well, since they are typically lightweight and easy to use. Most crafting air compressor tools will apply less than 30 pounds-per-square-inch of pressure: strong enough for dynamic uses but not too dangerous to keep in an average workstation or private storage. You can easily extend your crafting kits, too, through compressor accessories and tool fittings.

4. Pumping Inflatables

Inflators and compressed air pumps are simple in design but masterful in application. In your daily life, you are bound to have some inflatables to pump up, from pool accessories and bike tires to air mattresses and sports equipment.

Even though these tools are small, do not mistake their size for their usage. Such pneumatic tools can provide superior airflow for the above activities and more. Plus, they typically carry a long shelf life and are commercially accessible should you need additional parts, attachments, or new gear.

5. Yard Work

The tools we associate with yard work are typically manual, without many frills or design specialties for daily use. Yet landscapers, groundskeepers, gardeners, contractors, and crafty homeowners have found air compressor uses for their yard or property work, significantly decreasing the time and energy they have to put in to maintain a beautiful green space.

New hoses can be bought and attached to air compressors, making them perfect for sweeping and removing leaves and debris from the yard. These higher-power hoses can even move puddles of water that have pooled in inconvenient places. For commercial properties and businesses, this is a great way to keep your storefront clean, welcoming, and accessible with minimum work required.

What is more, compression sprayers can be added to your hardworking kit to easily spread weed killers. This is especially attractive for larger yards or property administrators looking to keep their grounds in the best possible shape themselves—without contracting expensive services.

Contact Kaishan For Your Air Compressor Needs

In both residential and commercial uses, across industrial and everyday life, it's hard to ignore the versatile and surprising uses these durable tools in their various forms provide.

We are engineering the future of air compressor and rotary-screw technology to be bigger and better than ever before. See how we can team up today to make that future a reality for you. Get in touch with one of our product specialists or spend time exploring our complete product catalog to see how we can help solve all your air compressor needs.

Random stat or

customer quote

textXXtext

text

It is almost impossible to imagine a world without air compressors. These machines do what few