How to Design and Prepare for an Industrial Air Compressor Installation

August 9, 2023

Compressed Air Solutions: The Core of Railways and Locomotive Operations

August 23, 202317 Tips to Keep Your Rotary Screw Air Compressor Running in the Summer Heat

Kaishan USA | August 16, 2023 | Uncategorized

When you’re evaluating your compressed air needs in preparation for next summer’s demands, we recommend that you plan for your worst-case conditions.

It may seem odd to be talking about preparing for summer heat now. But the best time to get ready for hot weather is before it happens. So it may be too late for this summer, but it’s not too soon to get started for next year.

Heat brings out the worst in air compressors for a lot of reasons. First, the compression process generates heat by itself. Heat that must be removed with cooling equipment. Plus, hot air carries more moisture. So high temperatures mean your equipment will work harder.

We recommend that you plan for the worst-case situation. Think summer in Texas, with high humidity and triple-digit temperatures. Prepare for that worst case, and you’ll be ready, no matter what happens.

We’ll start with a high-level view of your system, then dive into the details with a 17-point pre-summer checklist.

Major Concerns

The typical commercial or industrial operation adds capabilities all the time—an expansion to do painting, a room conversion to add a new specialty, some new air tools. It all adds up. Any of those things could require more flow or greater pressure than your current system can handle.

And sometimes, the opposite is true. Your compressor may have been sized with “room to grow” or purchased to handle end uses that have since been removed from the system. It may seem counterintuitive, but with air compressors, “too much” is almost as bad as “not enough,” wasting energy, reducing equipment lifetime and requiring more maintenance.

Your pre-summer review of your compressed air system is a great time to take a broader look at your system and determine if it’s meeting your needs. The two critical elements affected by changes in system demands are sizing and air flow.

Size

Are your compressor, dryer and cooling equipment sized correctly for your worst-case ambient temperature conditions?

Because the air in summer is thinner, you may need to oversize your compressor and cleanup equipment by as much as 10% to 15% to make up the difference in output. Dryers, filters and separators should be sized for the hottest day of the year, using correction factors provided by the manufacturer.

Pay special attention to your dryer. The higher the inlet temperature, the more you need to oversize the dryer. If your compressor room is 110°F and you have mediocre coolers, for example, you’re passing 130°F air through to your dryer. So, following the manufacturer’s correction factor, you need to add dryer capacity, incurring costs and increasing energy consumption.

Air Flow

Air circulation through your compressor enclosure is critical to hot-weather operation. You can use several possible configurations to move air through your equipment room.

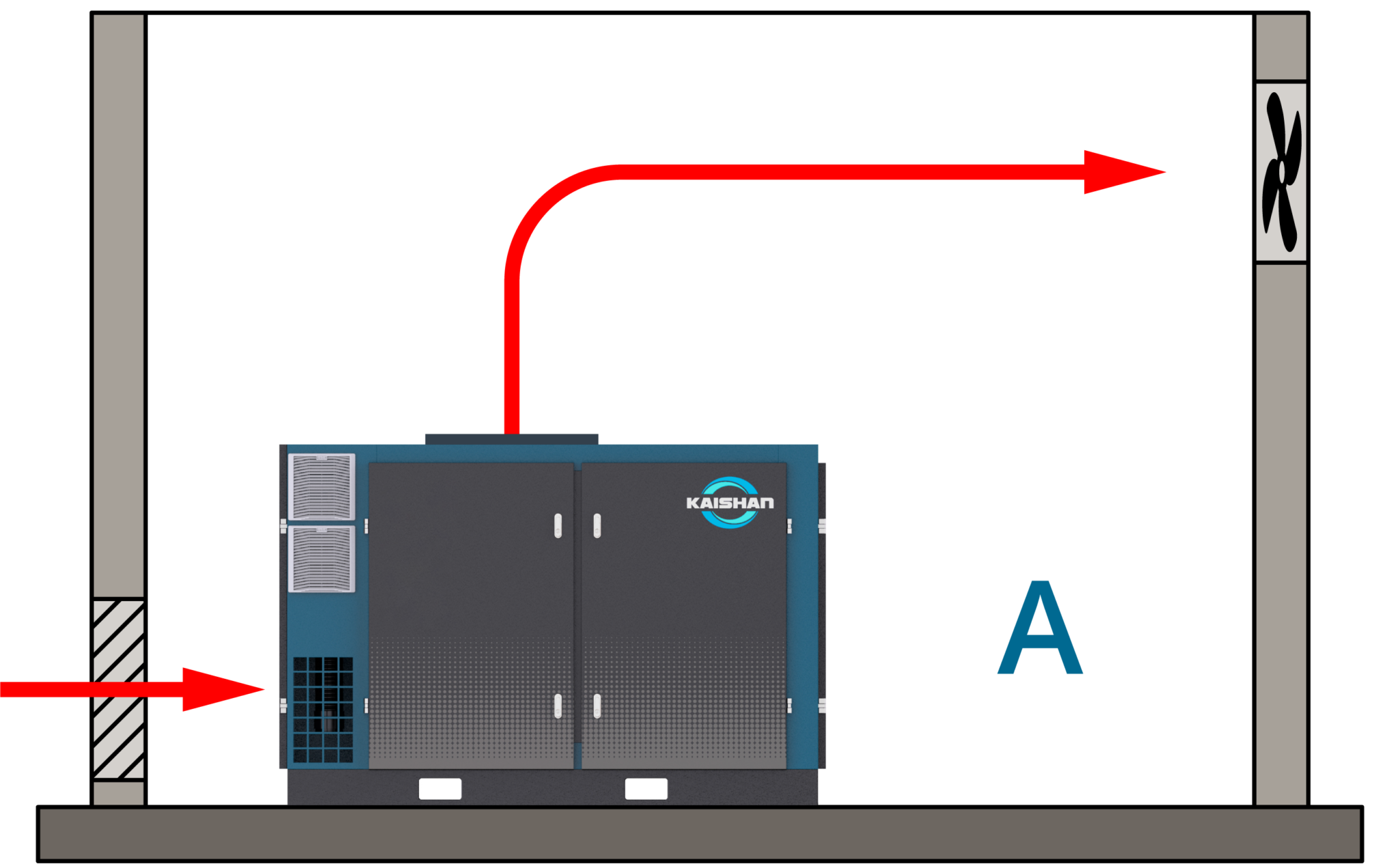

For smaller compressors, louvered inlets and outlets in your compressor room may provide enough air flow through your enclosure to remove the heat generated in the compressor. But it all depends on the ambient conditions.

Depending on ambient conditions, you may only need louvered inlets and outlets to keep your smaller compressor cool.

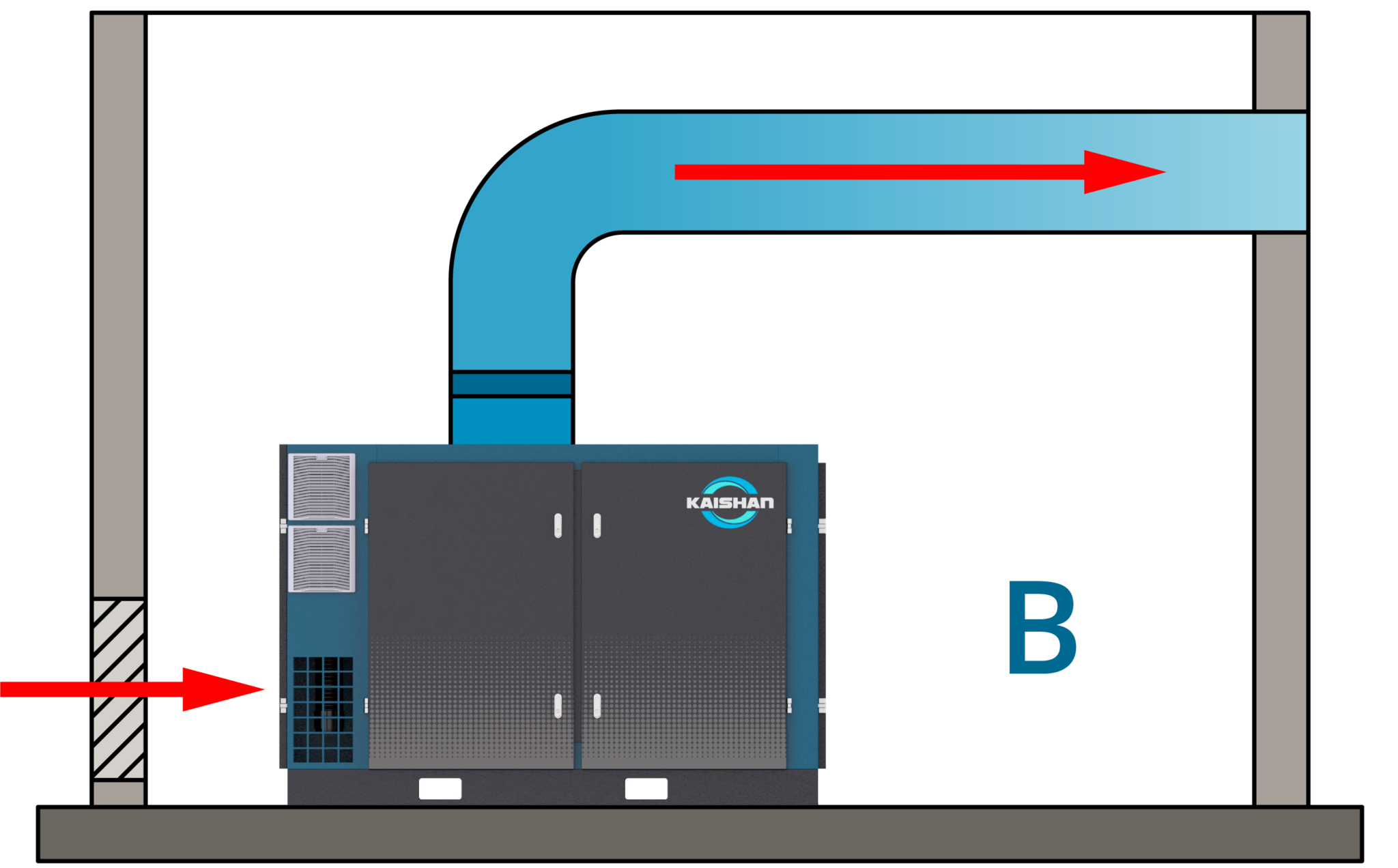

Compressors larger than 25 HP usually require forced ventilation, but every site is different. An exhaust fan pulls the air through the ductwork and blows it outside.

Consult a qualified heating and air conditioning professional in your area for sizing, designing and installing duct works.

For larger units (25 HP and above), you may need a fan and ductwork to remove heat.

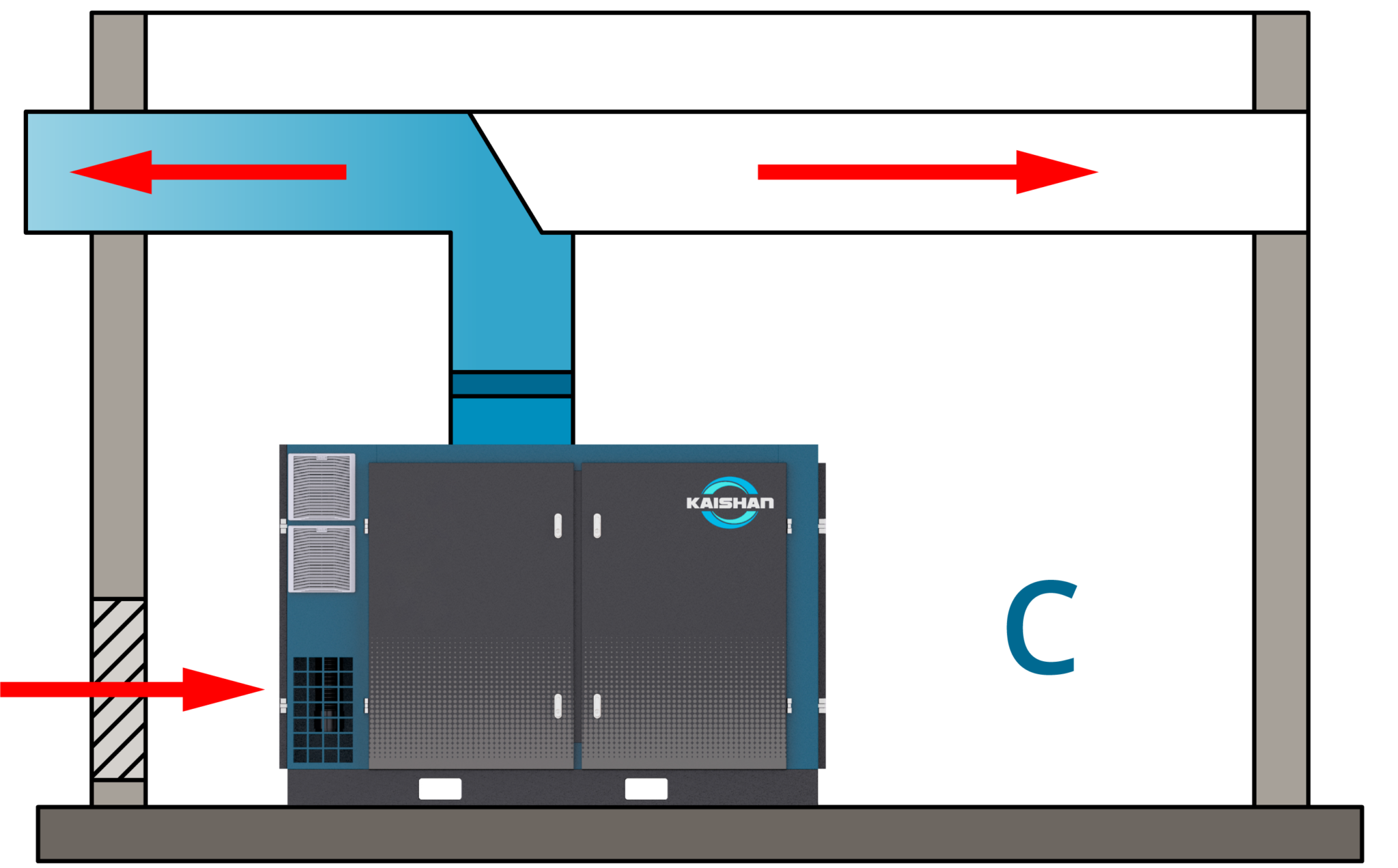

In northern climates, it’s also possible to save significant amounts of energy by recovering the heat removed from the compressed air system in the winter. A damper directs the air toward an outside vent in the summer, and in the winter, the air goes toward space heating or preheating other operations.

Using heat recovery, you can recover most of the heat your compressor generates, especially in cooler, northern climates.

We recommend doing preventive maintenance (“PM”) on your air compressor in the spring to make sure it’s ready for the summer heat.

Get Your Preventive Maintenance Done in the Spring

Many companies like to do comprehensive preventive maintenance in the fall because things usually slow down a little before the end-of-year holidays.

But we always encourage our customers to do their PM in the spring so your system is in optimal condition before the hot weather pushes it to its limits.

Industry research has proven that a proactive maintenance strategy can help you reduce maintenance costs by as much as 70%.

A good preventive maintenance program will help you avoid unplanned downtime, saving you time and money.

The goal of preventive maintenance is to anticipate problems before they happen, addressing compressor issues that could worsen and lead to a shutdown. A good preventive maintenance program thus will pay for itself in lower service and replacement costs, reduced energy consumption (not to mention lower utility bills) and fewer costly shutdowns. The result? Fewer instances of lost production time and the associated labor and overtime costs.

Here's a good checklist you can use to guide your springtime PM.

Pre-Summer Maintenance Checklist

Compressor Oil

-

- Change compressor

- Change oil filters to remove metal filings, calcium and other materials in the oil and prolong its useful life.

- Draw an oil sample and send it to a qualified lab for analysis. Most manufacturers, including Kaishan, require oil sampling for extended warranties.

Oil Separator

4. Change the oil separator.

5. Replace drop-in air/oil separators at 8,000 hours or annually. Spin-on separators should be changed every 4,000 hours or six months.

Compressor Motor

6. Change motor grease at manufacturer-recommended intervals.

Traps and Drains

7. Remove any scale, rust, dirt or other solids from condensate traps and drain points.

8. Ensure that all drains are operating correctly, including the drains on the moisture trap, filtration, dryers and tanks. Test each one to be sure.

Filters

9. Change your inlet filter.

10. Inspect all other air filters (like intake or panel filters), replacing them as needed.

Coolers

11. Deep clean coolers, especially exposed surfaces like the heat exchanger fins, to remove dust and dirt. Make sure you are blowing out your coolers on a regular basis as well.

Valves

12. Clean and service valves, making sure thermal valves are working properly.

13. Inspect belts and couplings. Swap out as they begin to show wear.

Electrical

14. Inspect your electrical cabinet, removing dirt and dust buildup. Make sure fans are running and clean any filters inside the cabinet. Verify all electrical connections are secure.

Ductwork

15. Inspect the ductwork, making sure it is clean and free of obstructions.

16. Make sure thermostatic controls are working correctly.

Dryer

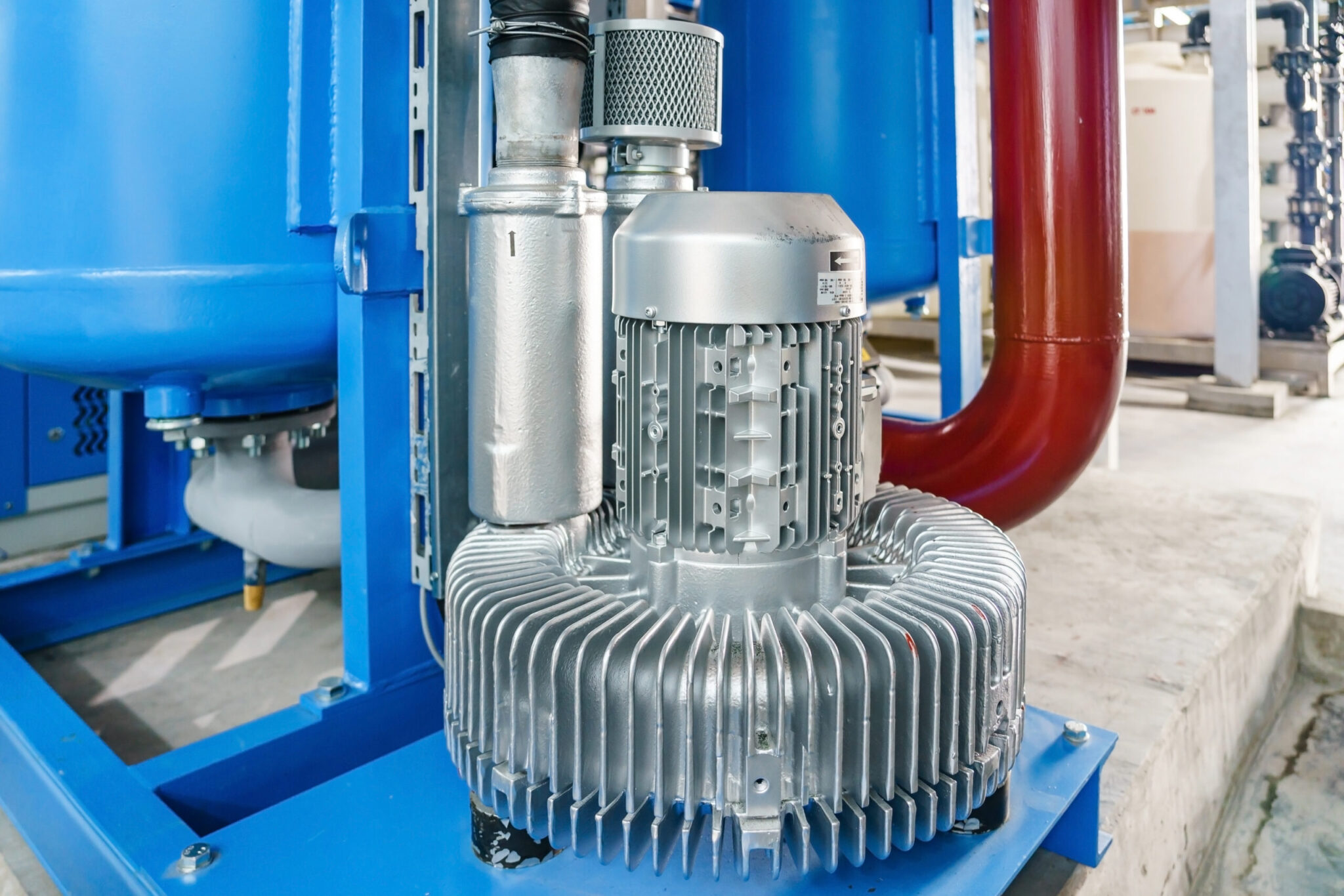

17. Service your dryer, checking fluid levels, and making sure it is properly ventilated. Clean dirt and debris from filters and confirm that traps ad drains are clear.

Keep dryers well-ventilated and free of dirt and debris.

Local Help

If you have questions about pre-summer service, Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in using leak-detection technology on a daily basis.

If you need help planning your pre-summer maintenance, check with your air compressor professional.

Key Takeaways

-

- Heat brings out the worst in your compressor.

- Plan for the worst-case conditions.

- Size matters.

- Pay special attention to ventilation.

- Do your PM in the spring.

Let Us Help

Getting your air compressor ready for the heat of summer is critical to the operation of your compressed air system and all the processes that rely on that system. If you need help with your spring preventive maintenance or any air compressor issue, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Heat brings out the worst in air compressors for a lot of reasons.