Stitching It All Together: Air Compressors in the Textile Manufacturing Sector

December 20, 2023

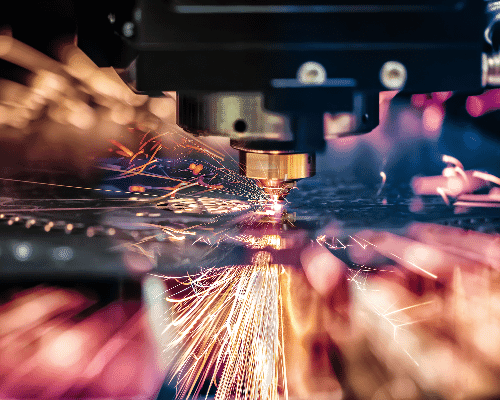

How Industrial Air Compressors Improve Laser Cutting Performance

January 3, 2024Variable-Speed vs Fixed-Speed Air Compressors

Kaishan USA | December 27, 2023 | Uncategorized

Use of a VSD air compressor may allow you to cut energy use and save money.

Deciding to install a VSD air compressor is a major step for any facility. On the positive side, VSD compressors can save energy (and significant amounts of money), earn rebates, allow soft starts and offer better control of your entire compressed air system.

But there are many concerns. VSD air compressors cost more than their fixed-speed counter parts. And, like any electronic device, they can be sensitive to harsh, demanding environments (see the “VSD: The Cons” section below).

Let’s start with the basics.

Fixed- and Variable-Speed Air Compressors: The Background

First, a little background on fixed and variable-speed drive.

A fixed-speed compressor operates at the same speed continuously, cranking along at the same RPM, no matter what the system’s demand. And, unless you change the pressure, the compressor’s output of CFM will also remain the same.

A VSD air compressor, on the other hand, is equipped with a variable frequency drive or inverter that allows it to adjust its motor speed or RPM (and thus its CFM) to match the real-time demand for compressed air. When the demand drops, the inverter dials back the motor operation to a lower speed (and lower CFM). It thus consumes proportionately less energy (and money), creating a relatively linear output-to-input efficiency curve.

VSDs are an extremely energy-efficient way to address rapid cycling, which occurs when your air compressor switches back into the loaded state before the transition to the no-load state is complete. If that happens too frequently, it can cause increased wear and reduce compressor reliability and lifespan.

VSDs are recommended when the compressor operates at a load between 30% and 80% of its total capacity most of the time. They are not recommended when your compressor is running at 100% load most of the time as the VSD drive itself has some losses (that can be overcome by optimizing tip speeds). But they are very valuable as a trim compressor complementing a base load compressor (see “System Reconfiguration” section below).

Variable-speed drives complement rotary screw air compressor technology exceptionally well.

VSD: The Pros

The major benefits of VSD technology include energy savings, rebates, soft starts and improved control.

Energy Savings

When operating with no load, a fixed-speed compressor still consumes 30-70% of full-load energy. A VSD air compressor, on the other hand, requires almost no energy input, simply shutting down when no load is required.

That can add up to real money:

-

- Annual energy usage will drop by 33%, according to the Compressed Air & Gas Institute, with individual manufacturers placing the savings as high as 70%.

- Annual cost savings as much as $17,208, according to a recent American Society of Mechanical Engineers study analyzing case studies across multiple industries.

- Payback period at two years although the ASME estimated average VSD paybacks at two to five years.

Rebates

Utilities in several states offer rebates to companies that install VSDs or variable frequency drives. And California at one time had a VSD mandate, although it has since been repealed.

Because of the energy savings mentioned above, VSDs may help companies achieve their sustainability goals.

Soft Starts

VSDs allow the compressor to ramp up to full speed gradually, preventing a high in-rush current (up to six times as high as operating current) that fixed-speed compressors draw during startup. They automatically control acceleration and deceleration to reduce peak amps, thus avoiding utility company penalties for increased power demand. Utilities levy these costs to discourage spikes in usage that can overload the power grid.

This soft start capability saves energy and reduces the startup stress on compressor components. It lengthens the life of the motor by decreasing inrush current, which causes the coils to heat up and reduces the life of the insulation. It thus extends the lifespan of your equipment.

Better Control

By allowing more finite control of your compressor, VSDs will enable you to calibrate the output to match compressed air demand, enhancing efficiency and performance.

In addition, you can control the pressure more tightly, keeping the pressure band—the gap you set between load pressure and unload pressure—to +/- 1.5 PSIG, according to CAGI. With a fixed-speed unit, that pressure differential will have to be much higher.

That’s a lot of wasted energy, especially if your plant needs 100 PSIG and you're compressing up to 130. The rule of thumb is that for every 2 PSIG increase in pressure, the energy consumption goes up by 1%. You can conserve energy by using a VSD air compressor and setting the header pressure as low as possible.

VSD: The Cons

Before you go all-in on the benefits VSDs offer, it’s essential that you know some of the drawbacks, including the following concerns.

Initial Expense

Variable-speed compressors are more costly, so facilities with lower levels of compressed air use may not find them to be cost-effective.

Size Matters

Variable-speed drives are not very cost-effective for smaller applications, which often operate under relatively consistent load conditions, diminishing the efficiency gains that VSDs offer. Considering the initial investment, the payback period through energy savings may be too long for smaller units.

Equipment Failures

Like any electronic device, variable speed drives add an additional component that could impact system reliability. They require regular monitoring and maintenance, especially in challenging environments.

VSD air compressors perform best in environments that do not have excessive heat, dust, dirt or airborne contaminants.

Harsh Environments

While VSDs can save money in the right application, you should know the challenges they face in many industrial environments. Dust, dirt and airborne contaminants could clog the VSD’s heat sink, causing it to overheat. As a result, we do not recommend installing VSDs where the unit would be near a welding operation, for example, which adds conductive material to the ambient air. Hot temperatures also are a concern.

Maintenance

As a result of a VSD’s sensitivity to heat and airborne contaminants, we recommend increased maintenance to ensure the device’s cooling systems are performing correctly. More training may be required.

When to Use a VSD Air Compressor … and When Not To

You should consider a VSD:

-

- When demand varies more than 20%

- When demand varies significantly between shifts

- When demand varies seasonally

- When you need to operate within a tight pressure band

You should avoid using a VSD:

-

- When you have little to no variation in demand

- When you can operate continuously at full speed

- When you have an inconsistent power supply

- When you have an environment that is hot, dirty, dusty or wet

VSD Alternatives

VSDs are not the only way to save energy and reduce the risk of rapid cycling in your compressed air system. Other items in the system designer’s bag of tricks include modulation and system reconfiguration. Wye-delta and solid-state starters also help reduce inrush currents to mitigate power company penalties.

Modulation

To combat rapid cycling, we often propose modulation that adjusts the inlet valve to a partially open position. As mentioned previously, variable-speed drives are a more energy-efficient way to address this issue but cost more up front.

While modulation has traditionally been viewed as a waste of money and energy, it may be more cost-effective than VSDs for some users. The key is to balance that potential cost with the negatives of rapid cycling.

Neither modulation nor VSDs, however, take the place of an appropriately sized compressor and storage tank. It’s a best practice to have both wet and dry storage to remove moisture and maintain stable header pressure. For more on tank storage, see our post, A Quick Guide to Accurately Size Air Compressor Tanks.

While VSD air compressors can help cut energy use and prevent rapid cycling, deploying multiple compressors in a network to handle the variations in compressed air demand may be more reliable.

System Reconfiguration

Typically, our customers want one machine to take care of the entire compressed air system in their facility. And they want one device to maintain, which seems a lot simpler, or maybe two, with one as a backup.

It's typically more reliable and energy-efficient, however, to deploy multiple compressors in a network to handle the variations in compressed air demand.

Here’s an example. Typically, we find wide variation in usage, depending on what’s happening in a plant. Suppose you need 1,000 CFM on the first shift, 600 on the second shift, but only 200 for the third. The first two are okay, but the last is a problem, no matter how you do it.

Many manufacturers advocate use of VSDs to operate more efficiently. But, in our view, you're much better off buying three units–one for base loading, one to trim, and another one for backup. And rotate the three continuously. Here’s how that works:

-

- A base load compressor. As it sounds, the base load compressor is designed to meet your system’s minimum compressed air It is not intended to fluctuate in output as demand changes. Instead, it is run full bore—at 100% capacity—or turned off. When you only need a small amount of capacity, significantly below the base load—like weekends, holidays or a minimal third shift—we recommend meeting that need with a trim compressor.

- A trim compressor. Trim compressors are designed to handle fluctuations in demand above the base unit. Since the level of flow needed will rise and fall depending on the needs of your system, rotary screw compressors are a natural for this application. Equipping them with a variable-speed drive makes them more cost-effective and energy efficient. In fact, VSD air compressors are ideal for trim units.

- A backup compressor. We recommend completing your system with a backup compressor, which can be on standby if a base or trim unit goes offline. To fill in appropriately, it should be the same size as the base load compressor.

Together, the three compressors have you covered in your likely demand profiles.

Considering a VSD air compressor? Ask your air compressor professional to conduct an audit.

Questions? Ask for an Audit

Most facility managers will benefit most by working with an air compressor professional to evaluate their VSD air compressor options. Our nationwide network of independent distributors, can provide on-site help and consultation, conducting an air audit to determine the most cost-effective approach. These factory-trained compressed air experts have staff members who are skilled in conducting audits and installing and operating advanced air compressor technology.

Key Takeaways

-

- Deciding to install a VSD air compressor is a significant step for any facility.

- The positives include energy savings, rebates, soft starts and better control of your compressed air

- The negatives include initial cost, sensitivity to harsh environments, and the need for heightened maintenance.

- You should consider a VSD air compressor when demand varies more than 20%, especially between shifts or seasonally. Or when you need to operate within a tight pressure band.

- You should avoid using a VSD air compressor when you have little to no variation in demand, when you can operate continuously at full speed, when you have an inconsistent power supply or when you have an environment that is hot, dirty, dusty or wet.

- For rapid cycling, alternatives to VSDs include modulation and system reconfiguration.

- If you are considering deployment of a VSD air compressor, it would be wise to have a compressed air professional perform an audit.

Let Us Help

Installing a rotary screw air compressor with VSD technology can be a major decision for your operation. If you need help evaluating your options, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text