Ten Need-to-Know Rotary Screw Air Compressor Maintenance Tips

March 6, 2024

The History Of Air Compressors

March 20, 2024Ultimate Guide: What is a Rotary Screw Compressor?

Kaishan USA | March 13, 2024 | Uncategorized

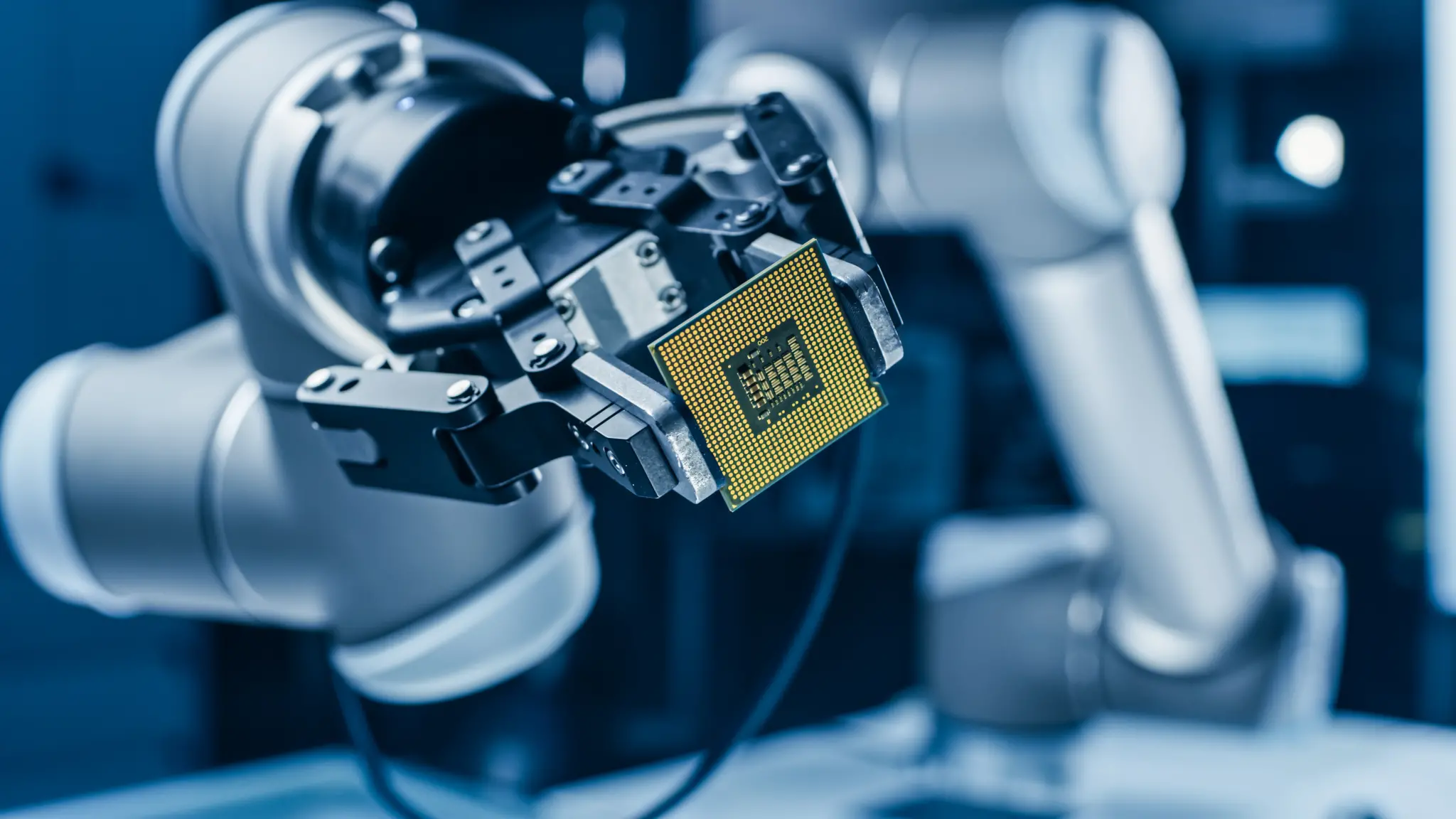

Rotary screw air compressors are the best choice for a variety of applications, such as electronics, where high-quality air is essential.

Most users today know the different types of compressors and how they work and function.

They know that reciprocating compressors are inexpensive, the perfect machine when you have a small number of air tools that you use sporadically.

And they probably have heard about large centrifugal units, which are efficient. But, because of their high initial cost, they only cost-effective for high-volume applications with fairly stable demand. Plus, they have a limited pressure range (unless you go to a multistage unit).

The Real Difference

The critical distinction, however, is the difference between heavy-duty industrial air compressors, like those used in most industrial plants. And commercial air compressors, like those you might see at a hardware store or home center.

In general, a commercial unit will be lighter in weight. It will have components made of composites and plastics. And, in many cases, it will be a reciprocating compressor.

Industrial compressors, on the other hand, are beefier. More heavy-duty. Intended for continuous use—round the clock, if needed.

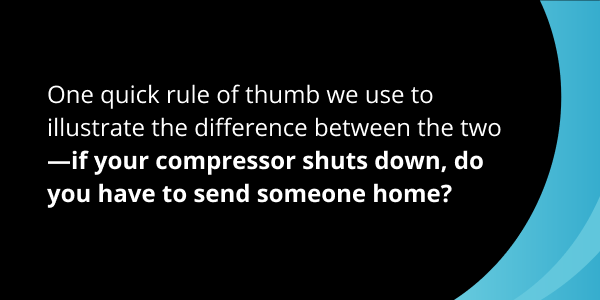

One quick rule of thumb we use to illustrate the difference between the two—if your compressor shuts down, do you have to send someone home?

If the answer is no. If a compressor shutdown is just an inconvenience that won’t cost you money, a commercial compressor is probably fine for your application.

If the answer is yes. If a shutdown will mean you’ll lose product or productive time in your plant, you’ll want an industrial compressor.

In most cases, that means a rotary screw air compressor.

Rotary Screws: The Air Compressor of Choice for Most Applications

Rotary screw air compressors are generally the compressor of choice for most industrial applications.

Rotary screw compressors have two rotors that revolve in a compression chamber and pressurize the air until it reaches the desired pressure. The rotors never touch and don’t wear, so they last a long time, creating long-term reliability that has become one of the hallmarks of rotary screw compressors.

Oil-lubricated rotary screw air compressors rely on oil to lubricate the bearings, seal off the air flow between the rotors and the stator and remove the heat of compression, keeping the compressor and the air flow cooler. Oil-free machines, like our KROF, are an exception designed to offer food processors the benefits of rotary screw technology without introducing oil to the pressurized air flow. They are also used in semiconductor fabrication and other sensitive applications.

Even food and beverage producers can use rotary screw air compressors, thanks to oil-free units like our KROF two-stage premium rotary screw air compressor that produces ISO 8573-1, Class 0 oil-free compressed air.

Advantages of Rotary Screw Air Compressors: A Review

Rotary screw air compressors appear in so many industrial applications because of a broad range of advantages:

-

- Performance Advantages. Rotary screw air compressors enable you to run equipment and tools with high horsepower requirements. Plus, they are based on a simple, time-tested design that enables impressive efficiency. They can handle a 100% duty cycle; as a result, we recommend setting up your compressed air system so that they operate as close to full load as possible. Rotary screw compressors provide a steady flow of clean, high-quality air without the pulsations that sometimes occur with other types of compressors, especially reciprocating or piston compressors.

- Operational Advantages. Because they have fewer moving parts, rotary screw air compressors are highly reliable and require less maintenance. They can handle variations in demand and temperature extremes and are relatively safe. They have a compact footprint and generate less noise.

- Cost Advantages. Rotary screw air compressors are known for their dependable operation, which means that you will have less downtime. They have a longer lifespan and a relatively low total cost of ownership. Plus, they have better warranties than other types of air compressors because of their reliability, efficiency and long life. In fact, Kaishan’s KRSP and KRSP2 premium rotary screw air compressors are backed by an industry-leading lifetime warranty on the airend.

Kaishan backs its KRSP and KRSP2 rotary screw compressors with an unmatched lifetime airend warranty, recognizing their reliability, efficiency and long life.

In short, they meet the needs of a wide variety of applications.

Disadvantages

Admittedly, rotary screw compressors have some disadvantages. They have a higher initial cost than smaller horsepower reciprocating compressors. And while they don’t need service often, they occasionally require the skills of advanced maintenance professionals. Plus, they’re designed for a full load, not intermittent use.

When to Use Recips

Lighter-duty reciprocating compressors have their place. They are perfect for businesses, such as oil-change shops, tire-repair centers and smaller dry cleaners, with an intermittent need for compressed air. In those cases, a smaller reciprocating compressor may fit the bill, providing compressed air efficiently at a lower price point. With slightly less maintenance, since a recip has less oil and needs oil changes less frequently.

Reciprocating or piston compressors have traditionally been the ideal choice for applications such as automotive repair shops, which use air tools intermittently.

According to the Compressed Air & Gas Institute (CAGI), “Small, air-cooled reciprocating compressors, 3 HP to 30 HP, are ideal for intermittent service similar to those compressors commonly used in an auto body/tire repair operation.”

But they do have some downsides. They can only operate at a half-duty cycle, meaning you need extra capacity and storage to maintain your operation while the machine is in its cooling-off cycle. And they’re noisy.

Over the years, however, we’ve found that customers fall in love with rotary screw compressors because they are reliable, energy-efficient and quiet.

Rotary Screw Air Compressors in Commercial Applications

At this point, there currently aren’t many rotary screw compressors that work well in the smaller size and scale of the commercial compressor market. As mentioned previously, they are designed for continuous use. Turning them on and off usually allows water to condense out of the air flow. And that water will ultimately cause problems with the bearings. And operating at low loads will cause water to build up in the system and cause high oil carry-over issues.

Once again, CAGI says, “Installing an intermittent-duty compressor into a continuous demand is a recipe for early equipment failure. Likewise, installing a continuous-duty compressor into an intermittent application results in premature failure of the compressor due to rapid cycling as well as very inefficient operation.”

That’s why we currently advise customers who have more sporadic compressed air needs to buy a small reciprocating compressor.

When to Use a Rotary Screw Air Compressor

You’ll find rotary screw air compressors meet the challenges of industrial applications, working well in the following situations:

-

- You need a constant flow of compressed air at a consistent pressure level. They are typically used in industries that require a large volume of compressed air, such as general manufacturing, construction, oil and gas, food and beverage, life sciences, semiconductor fabrication, textile and power generation. Or even a larger automotive shop where the use is more constant.

Applications such as sandblasting that need high pressure and high air flow are perfect for rotary screw air compressors.

-

- You need high pressure and high flow in an application like sandblasting. For more on sandblasting, read our blog post, “Best Screw Compressors for Sandblasting.”

- You have rugged conditions, including temperature extremes. Rotary screw air compressors are used widely throughout the mining, oil and gas and metallurgy industries, providing a reliable, consistent fourth utility (joining electricity, gas and water) in challenging environments. The only issue is that compressors drawing in ambient air loaded with dust and dirt require extra filtration and more frequent oil changes.

- You need high-quality air, free of impurities and moisture. Think industrial painting, semiconductor fabrication, or electronics assembly plants. And, with oil-free units like Kaishan’s new KROF two-stage rotary screw air compressor, you can even provide compressed air that has direct contact with food and beverage products.

- You’re looking for a low total cost of ownership. Adding up the energy efficiency, rugged reliability, extended lifetime and warranty protection, rotary screw compressors are a long-term bargain for virtually any industrial application.

Local Help

If you need assistance in determining whether a rotary screw compressor is right for your facility, Kaishan can help. We work with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. These factory-trained air compression experts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in advanced technology.

Key Takeaways

-

- For the most part, facilities use one of the three major types of compressors: reciprocating, centrifugal or rotary screw compressors.

- The most important distinction is between industrial and commercial air compressors.

- Our quick rule of thumb illustrating the difference between industrial and commercial air compressors—if your compressor shuts down, do you have to send someone home?

- Reciprocating compressors are perfect for businesses, such as tire-repair or oil-change shops, that need compressed air intermittently.

- For industrial users, rotary screw compressors offer several advantages, including performance, operational and cost benefits.

- Rotary screw air compressors work best in applications needing a constant flow of high-pressure, high-quality air.

Let Us Help

Selecting the right air compressor is critical to the operation of your compressed air system and all the processes that rely on that system. If you’re not sure if a rotary screw air compressor is suitable for your application, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Most users today know the different types of compressors and how they work and function.They know that reciprocating compressors are inexpensive, the perfect machine when you have a small number of air tools that you use sporadically.