- Filter by

- Categories

- Tags

- Authors

- Show all

- All

- Air Compressor

- air compressor for truck

- Air Compressor Not Building Pressure

- air compressor oil

- Air Compressors

- best air compressor

- Compressed Air

- compressed air demand

- Compressors

- Industrial

- Industrial Air Compressor

- industrial vacuum pumps

- Maintenance

- rotary screw air compressor

- Screw Compressors

- Two-Stage Air Compressor

- Vacuum

September 10, 2025

Categories

We’ve written many blog posts about money-saving ways to optimize your compressed air system. [...]

Do you like it?

September 3, 2025

Categories

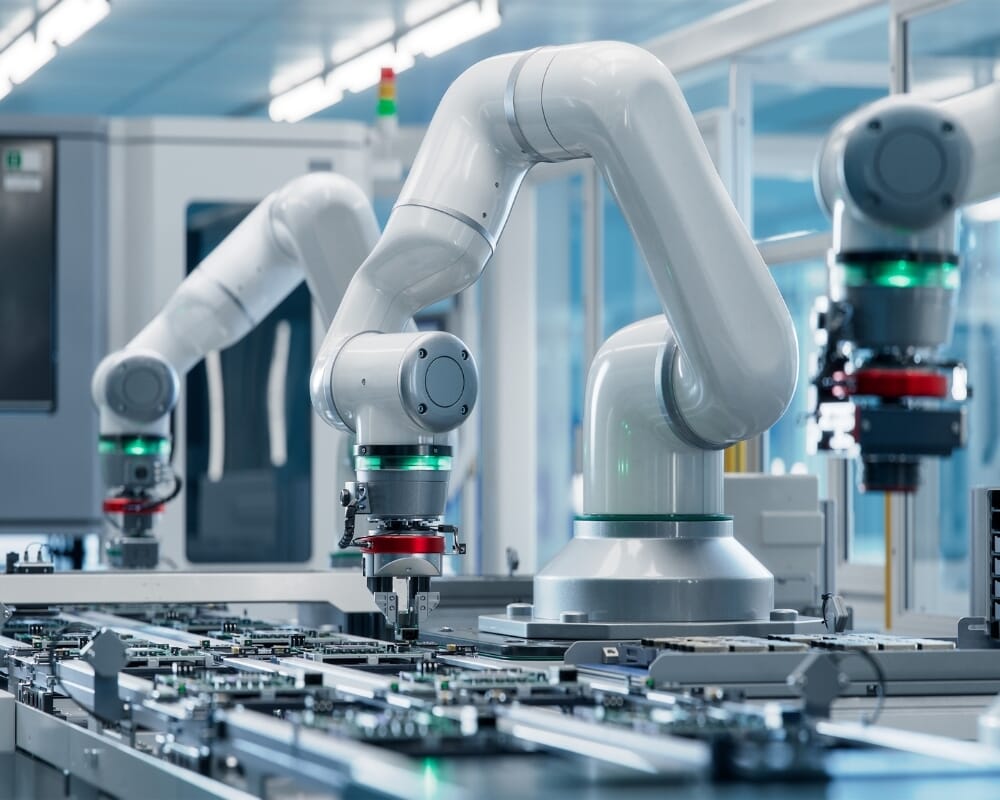

Unplanned downtime now costs the world’s largest manufacturers $1.4 trillion annually, 11% of their revenue, according to Siemens. [...]

Do you like it?

August 27, 2025

Categories

Centrifugal compressors like Kaishan’s KCOF are an essential power source in today’s industrial economy. [...]

Do you like it?

August 20, 2025

Categories

When you’re purchasing major pieces of equipment, most industrial buyers know to look at the big-ticket items, such as overall energy efficiency, maintenance and equipment lifespan, that drive total cost of ownership decisions. [...]

Do you like it?

August 13, 2025

Categories

Rotary screw compressors move through cycles of loading and unloading to meet your system’s demand for compressed air. [...]

Do you like it?

August 6, 2025

Categories

If your compressed air system is not delivering the 90-PSIG or 100-PSIG your impact wrench requires, it will operate more slowly. [...]

Do you like it?

July 30, 2025

Categories

Most of us consider compressed air a necessary expense. Not something that contributes to our bottom line. [...]

Do you like it?

July 23, 2025

Categories

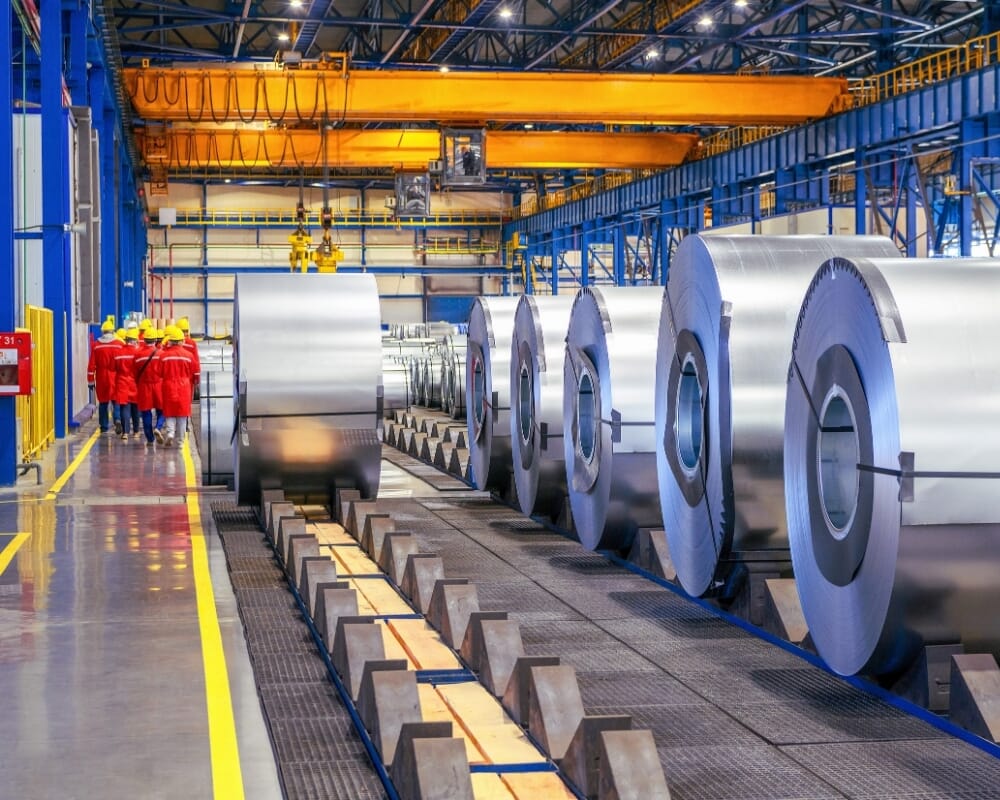

The vast majority (70%) of all industrial plants have compressed air systems, according to analyst Markets and Markets. [...]

Do you like it?

July 16, 2025

Categories

You’ve probably heard the many reasons why you should only use OEM air compressor parts to maintain your air compressor. [...]

Do you like it?