Benefits of a Quiet Air Compressor for Your Plant

December 28, 2022

Industrial Vacuum Pumps: Applications and Benefits

February 1, 2023Four Signs Your Air Compressor Needs Parts and Service

Kaishan USA | January 4, 2023 | Uncategorized

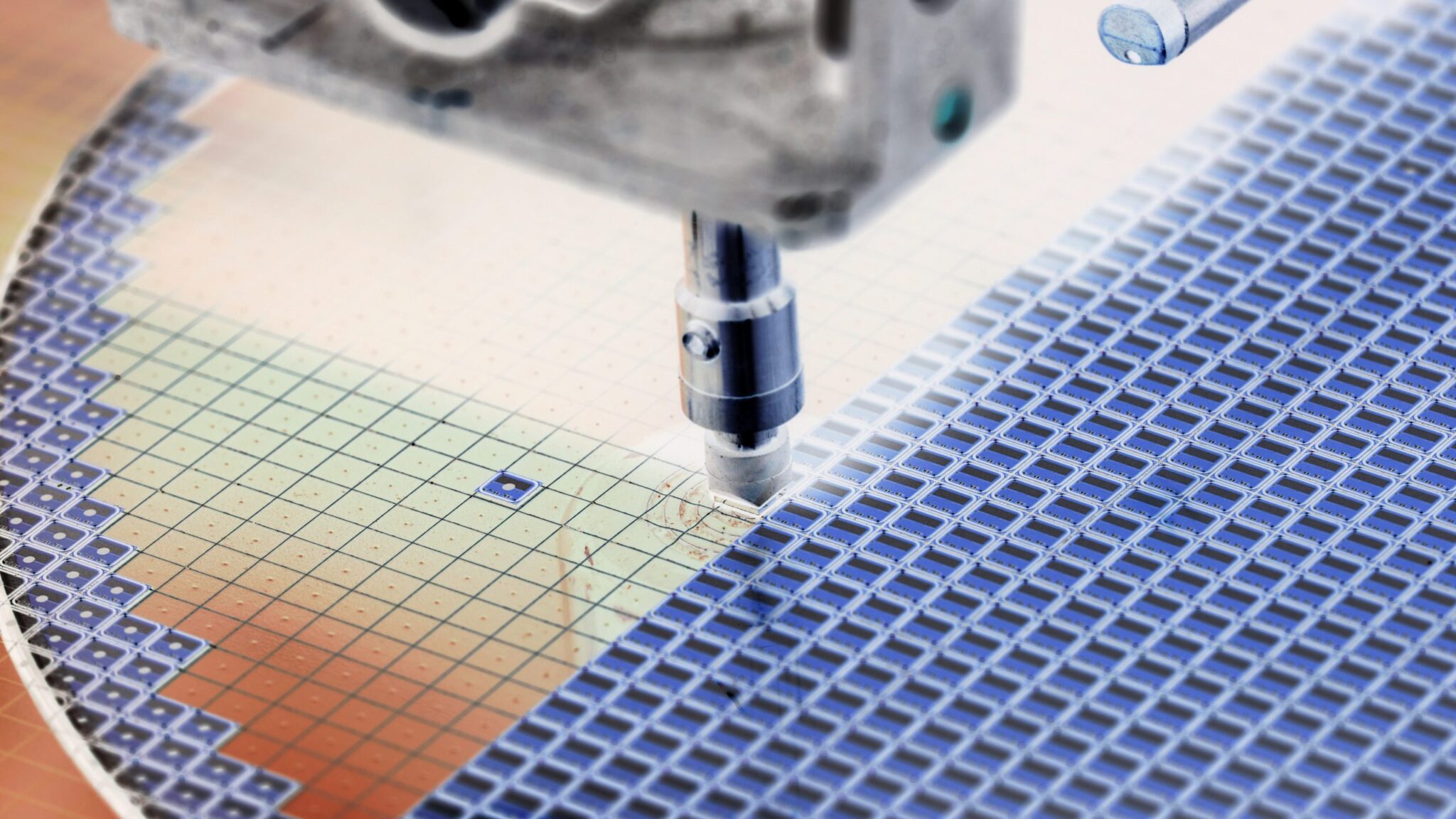

Maintaining air compressors in the semiconductor fabrication industry requires constant monitoring and replacement of key industrial air compressor parts to meet stringent air quality requirements.

Companies in an extremely wide range of industries rely on air compressors to power all kinds of tasks and functions. As a result, air compressors are found in all kinds of facilities and settings in industries as wide-ranging as food processing, life sciences and semiconductor fabrication.

Maintaining those compressors in such diverse settings, environments and use profiles can be challenging.

Fortunately, your air compressor probably has settings reflecting the best practices for routine maintenance of key service items:

- Oil sampling every 2,000 hours, which is required by most manufacturers, including Kaishan

- Oil filters replaced every 2,000-4,000 hours to extend the life of your system

- Air filters updated every 4,000 hours to maintain and improve the quality of the air your system provides

- Separators changed out every 8,000 hours, including lubricant, to keep your air compressor lubricated and prevent contamination

If you’re in a relatively clean environment, you may be able to go slightly longer on some of these issues. But remember this warning: when things start going bad, they go bad quickly.

In addition, most air compressor users have pressure indicators measuring pressure before and after the separators. Anything above a two-pound drop is a problem—making your compressor work harder than necessary.

And you’re not only damaging your compressor, but you’re also wasting energy (and money)—the more pressure differential you have, the more energy you’re wasting. Remember the general rule of thumb: every two pounds of pressure you’re losing is costing you 1% in power. If you have a clogged filter, you’re wasting an extra 5% on your energy bill.

Food and beverage companies have stringent quality regulations their systems must meet, including the use of USDA- and NSF-approved food-grade fluids.

The Key Issue: What Is Your Environment Like?

The setting in which your compressor is operating will drive the maintenance requirements.

If your air compressor is located in a hot room, for example, you will need to perform maintenance more often than the schedule listed above.

Similarly, if it’s in an area where there is a lot of dust and dirt, you will need to check thefiltersand do other maintenance more frequently.

To meet life sciences and healthcare industry regulatory requirements, you must carefully maintain your compressed air system.

Troubleshooting

If you’re experiencing problems, especially poor performance, you can follow this process to address your issues.

-

-

- First, you should do check of inlet and outlet temperature to determine the differential.

- Second, check the thermal valve. Is it stuck in a fixed position? Unfortunately, that's not something that’s easy to spot. You should either check the temperatures of the lines coming in and out of the thermal valve or take the valve out and test it, by heating it up in a pot of water or oil.

- Third, make sure your filters are not clogged.

- Fourth, make sure the inline check valve is opening to keep air from escaping and to prevent oil carryover.

-

If none of those steps resolve your issue, you may have an electrical problem. Many of those are a little more complicated because they may originate upstream from your compressor—like the unstable voltage, for instance.

Use Genuine Kaishan Parts

Most manufacturers require use of original OEM parts to maintain product warranties. We strongly recommend that you use genuine Kaishan parts to maintain the integrity of your air compressor system and allow it to achieve the performance level you expect.

Plus, in the same way we’re taking advantage of the latest technologies in enhancing the performance of our products, we’re also applying the latest advances to our parts. Using our recommended parts will allow you to achieve the following benefits:

-

-

- Longer life expectancy. Our parts are engineered specifically to support and enhance the performance of your compressor. That longevity even extends to the end-use tool your compressor is servicing.

- Air quality. Not only the life of your compressor but also the quality of the air you are delivering is at stake.

- Reliability. Think of your compressor as a completely integrated system and the parts as the independent elements that work in concert to achieve your performance and production goals.

- Productivity. By maintaining quality air delivery and reducing downtime, using genuine Kaishan parts supports your productivity goals.

- Energy savings. Using the right filter materials and other Kaishan quality parts ensures your compressor will function the way it’s designed, and building cost efficiencies and cutting costly, unplanned downtime.

-

Working with an Air Compressor Professional

When you are working with any of the electrical issues mentioned above or even to ensure your air compressor system is working at an optimum level, it may make sense to develop a relationship with an air compressor system maintenance professional.

Many companies are finding that they no longer have the kind of expertise they need in-house to deal with more advanced equipment.

And, when you go beyond routine maintenance, additional costs of hiring a pro may well be offset by preventing downtime and savings in energy costs. Especially when you consider that reducing compressed air loss from the normal 40% to 50% range to 20% or less can easily save you tens of thousands of dollars annually in energy costs.

Bring in a professional anytime you see a drop in performance you just can’t explain. Or when one of the troubleshooting tips mentioned above takes care of the problem.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed. Thesefactory-trainedair compressorexperts have an investment in their local communities and can service your air compressor system without a problem. And they have staff members who are skilled in using advanced technology on a daily basis.

From routine oil sampling to major compressor repair, our network can handle any air compressor service request to ensure the reliable operation of your equipment. Service your air compressor system without a problem.

Kaishan works with a network of independent distributors who can help you develop a program of leak detection.

Whether you establish a formal maintenance contract or simply an informal handshake agreement, you will benefit from having a compressed air professional available. It may take the form of a monthly walk-through of your plant or a regular series of inspections. But you and your company will benefit from having a relationship you can count on, both in the short term and in the long term.

Key Takeaways

-

-

- If you’re in a relatively clean environment, you may be able to go slightly longer on routine service items like replacing filters.

- Every two pounds of pressure you’re losing cost you 1% in power.

- Using genuine Kaishan parts will help you improve your compressor’s longevity, assure air quality and reliability, boost productivity and save energy.

- Bring in a professional anytime you see an unexplained drop in air compressor performance. Or when none of the normal troubleshooting tips take care of the problem.

-

Let Us Help

Maintaining your rotary screw air compressor is critical to the operation not only of your compressed air system but also of all the processes that rely on that system. If you need help setting up a regular schedule to replace your industrial air compressor parts, get in touch with the experts at Kaishan. Contact us today.

Random stat or

customer quote

textXXtext

text

Companies in an extremely wide range of industries rely on air compressors to power all kinds of tasks and functions.