Six Low-Cost Fixes for Compressed Air Optimization in Times of Economic Uncertainty

July 23, 2025

What Happens When the Pressure Is Too Low for Your Air Tools?

August 6, 2025How You Can Turn Your Compressed Air System into a High-Efficiency Profit Center

Kaishan USA | July 30, 2025 | Uncategorized

VSD-equipped, two-stage rotary screw air compressors are a great example of an investment that produces long-term benefits. One of our customers, Carlisle Construction Materials of Carlisle, PA, earned an $11,000 rebate from its utility company by adding an energy-efficient KRSP2 premium rotary screw air compressor.

Most of us consider compressed air a necessary expense. Not something that contributes to our bottom line.

But that assumption misses some tremendous opportunities:

First, as mentioned in our blog post, “Six Low-Cost Fixes for Compressed Air Optimization in Times of Economic Uncertainty,” there are many low-cost ways to optimize your compressed air system.

Second, and more importantly, there are several ways to make strategic investments in your rotary screw compressor that offer significant economic benefits.

These investments produce significant compressed air energy savings, cost reductions, performance enhancement and greater reliability.

We’ll start with an investment in two-stage rotary screw compressors.

Two-Stage Compressors

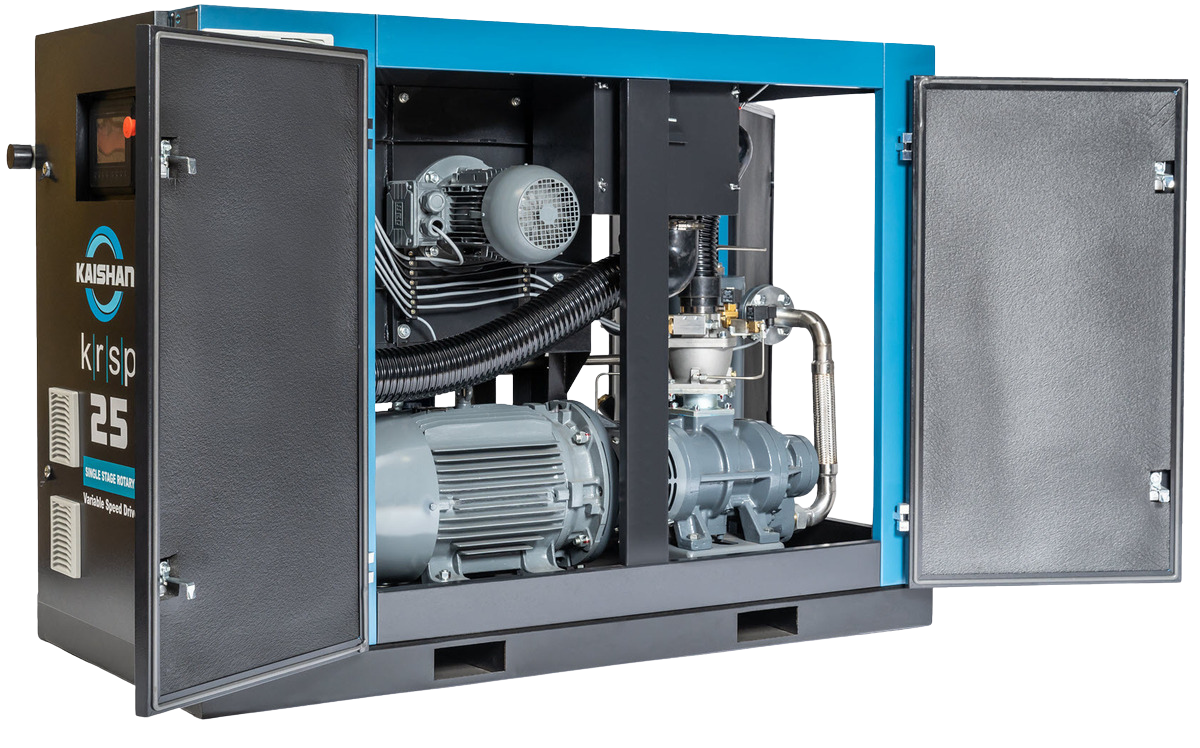

A single-stage compressor like Kaishan’s KRSP premium rotary screw air compressor generates a compression ratio of 7.8 to 1 to create 100 PSIG of pressure. It is one of the most cost-effective compressors on the market, and Kaishan backs it with an industry-leading lifetime airend warranty.

Kaishan’s KRSP single-stage rotary screw air compressors are among the most cost-effective options on the market.

However, a two-stage unit such as our KRSP2 premium rotary screw air compressor splits the workload into two separate stages:

- A first stage, generating a compression ratio of 2.8 to 1.

- A second stage, compressing to a similar 2.8:1 ratio.

By building on the pressure achieved in the first stage, the KRSP2 delivers more compressed air for less energy—up to 15% to 20% more flow than a single-stage compressor of the same horsepower. Paybacks on energy costs alone may be less than two to three years.

Kaishan’s KRSP2 two-stage rotary screw air compressor is one of the most energy-efficient machines on the market.

Equipping your KRSP2 with a variable-speed drive can add even more air compressor efficiency at partial loads. The VSD-equipped KRSP2 is so efficient that one of our customers, Carlisle Construction Materials of Carlisle, PA, earned an $11,000 rebate from its utility company.

Our VSD version of the KRSP2 is one of only a few two-stage units available in sizes as low as 30 HP. For more on the advantages of variable speed drives, see our blog post, “How Variable Speed Drive Rotary Screw Air Compressors Save You Money.”

In addition to compressed air energy savings, two-stage units offer several other benefits:

- Durability. By spreading the work over two stages, the KRSP2 experiences less mechanical stress and less heat, reducing wear and tear and extending the lifespan of its components. As a result, the KRSP2 is built to last.

- Cost-efficiency. Because a two-stage compressor generates more compressed air flow than a comparable single-stage unit, you may be able to use a smaller model. For example, you may be able to replace a 300-HP single-stage compressor with a 250-HP two-stage KRSP2. That could allow you to cut the initial cost gap to 15 to 20%. Plus, by manufacturing two-stage air compressors as small as 30 HP, Kaishan is making these units cost-effective for a much larger universe of industrial users.

- Lower operating cost. Reduced electricity costs and lower lifetime maintenance requirements result in lower operating costs for a two-stage compressor compared to a single-stage unit.

- Peace of mind. Because of their reliability, compressed air efficiency and long lifespan, Kaishan’s KRSP and KRSP2 rotary screw air compressors are backed by a lifetime warranty on the airend, the best in the industry.

An industry-leading lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

Those benefits last for years or even decades, quickly paying back the higher initial cost. For more on the benefits of two-stage compressors, read our blog post, “Five Critical Differences Between a Single-Stage and a Two-Stage Air Compressor.”

Another smart investment in your compressed air system builds in reliability, cuts cost and improves serviceability of your system by adjusting the way you have your compressors working together.

Multi-Compressor Configuration

While you may want to rely on a single compressor to handle all your compressed air needs, we often encourage customers to adopt a multiple-compressor system, including:

- A base load compressor to meet your system’s minimum compressed air load

- A trim compressor to handle fluctuations in demand above the base unit

- A backup compressor on standby if a base or trim unit goes offline

A multi-compressor configuration can virtually eliminate unplanned downtime, simplify maintenance and reduce electricity usage. You can also sequence two units to wear the consumables and hard items evenly across both units, ensuring they have similar load hours.

Some customers avoid using a trim unit by relying on a VSD air compressor to cover the variations in load. We strongly encourage these facilities to build in at least some form of backup. For example, adding a quick connection to a portable compressor, such as Kaishan’s KRSR portable electric rotary screw air compressor, allows for maintenance or emergency service if their compressor goes down.

For more on compressed air system design using a multi-compressor configuration, read our blog post, “How Energy-Efficient Air Compressors Can Reduce Your Carbon Footprint.”

Another wise investment is the use of remote monitoring, which gives you greater control over your compressed air system and increased insight into its operation.

AirWatch

Our AirWatch system uses a wireless-based cellular modem to enable real-time remote monitoring of your air compressor data. The wireless approach is a game-changer in that it avoids the nightmare of going through your IT department, enterprise software system and factory automation infrastructure.

Instead, you put an antenna on each compressor and link it to its own data hub, which accesses the internet through a cellular connection that only has to be within 330 feet of the unit. That allows you to circumvent the noise and interference often found on the factory floor.

With AirWatch’s cloud-based compressor monitoring software, you’ll access your unit in real time from a laptop, cell phone, tablet or desktop computer. You can:

- Set alarms

- See what maintenance is scheduled

- See current energy use

- Check readings for dew point, dryers, flow or pressure

- Change the time interval from day to week, to month to year

- Review trends

Plus, you can share access to that information with a distributor, consultant or even someone from our technical support organization. It’s almost like having a continuous audit.

Using our AirWatch remote monitoring system, you can give your distributor or compressed air consultant access to your compressed air system.

Best of all, our standard controller is the only one on the market that displays critical electrical information, such as amps and volts, on the screen. Even if you don’t monitor the system remotely, you can determine if there’s a problem simply by looking at the screen—if it usually runs at 100 amps and suddenly it's running at 120, you know your compressor is using more energy than normal.

There are plenty of ways to invest intelligently and strategically in your compressed air system. The best place to start is with your local compressed air consultant.

Ready to Turn Your Compressed Air System into a Profit Center? Help Is Close By.

If you want to make strategic investments in your compressed air system, your local compressed air professional can help. They can analyze your system and suggest improvements that will produce benefits for years or decades. And they can run the numbers and help you justify the costs to top management.

They’re just the partner you need to make strategic choices. That’s why we partner with a nationwide network of independent distributors. There’s no better way to provide the skilled, professional advice you need, on-site, to help you make these critical decisions.

They offer expert guidance, faster response times and personalized support tailored to your needs. And it’s not just about selling compressors—their goal is to build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they’re all about maximizing air compressor efficiency and minimizing downtime. So, when you buy through Kaishan USA, you're getting more than a product—you're getting a local partner who cares about your business. And wants to help it succeed.

Key Takeaways

There are several ways to make strategic investments that deliver significant economic benefits, including the following:

- A two-stage model, such as our KRSP2 premium rotary screw air compressor delivers up to 15% to 20% more compressed air for less energy with a payback of two to three years.

- Configuring your compressed air system in a multi-compressor arrangement can virtually eliminate unplanned downtime, simplify maintenance and reduce electricity usage.

- Our AirWatch system uses a wireless-based cellular modem to allow real-time remote monitoring of your air compressor data.

Let Us Help

Making a strategic investment in a rotary screw compressor is a great way to improve the operation of your compressed air system and turn it into a profit center. If you need help identifying the best alternatives, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Unlocking Efficiency With Two-Stage Compressors

Alright, welcome back to The Big Dog Podcast! I’m Jason Reed, and as always, I’m here with Lisa Saunders. Today, we’re talking about something that, honestly, I think gets overlooked way too often—how you can actually turn your compressed air system into a profit center. Not just a cost you gotta swallow every month.Yeah, and I love this topic because, let’s be real, most folks just see compressed air as a necessary evil. But there’s so much opportunity if you know where to look. And, Jason, I know you’re a big fan of two-stage rotary screw compressors, so let’s start there. What’s the big deal with these?

So, here’s the thing. A two-stage rotary screw compressor, like Kaishan’s KRSP2, splits the workload into two steps. Instead of one big push, you get a first stage and a second stage, each handling part of the compression. That means less mechanical stress, less heat, and—this is the kicker—up to 15 to 20 percent more airflow compared to a single-stage of the same horsepower. That’s not just a little bump. That’s a game changer for a lot of plants.

And the payback period is actually pretty quick, right? I mean, we’re talking two to three years just on energy savings alone. I visited a plant last year—this was before they made the switch—and they were running a single-stage system that just couldn’t keep up. They were constantly fighting pressure drops, and the maintenance headaches were nonstop. Once they upgraded to a two-stage, it was like night and day. The reliability went up, and their energy bills went down. I think they were kicking themselves for not doing it sooner.

Yeah, and it’s not just about the energy. You get durability, too. The KRSP2, for example, spreads the work out, so you’re not beating up your components. That means less wear and tear, and Kaishan actually backs it with a lifetime airend warranty. That’s pretty rare in this business.

And let’s not forget Carlisle Construction Materials. They put in a KRSP2 with a variable speed drive and ended up getting an $11,000 rebate from their utility company. That’s real money back in your pocket, not just savings on the bill. It’s one of those stories that makes you realize, hey, this isn’t just theory—it’s happening out there.

Exactly. And with VSDs, you’re getting even more efficiency at partial loads. So, you’re not just saving when you’re running full tilt. You’re saving all the time. That’s what makes these investments so smart. And, honestly, with two-stage units available as low as 30 horsepower now, it’s not just for the big guys anymore.

Right, it’s opening up options for a lot more facilities. And, you know, if you’re still running a single-stage and wondering if it’s worth the switch, just look at the numbers. The payback is there, and the long-term reliability is hard to beat.

Maximizing System Performance With Smart Configurations

So, let’s talk about system configuration. Because, honestly, even the best compressor can’t save you if your setup is all wrong. I’ve seen it too many times—folks relying on a single compressor for everything, and then when it goes down, the whole line stops. That’s a nightmare.Yeah, and that’s where multi-compressor setups come in. You’ve got your base load compressor handling the minimum demand, a trim compressor for those peaks, and a backup ready to go if something fails. It’s like having a safety net, but it also lets you sequence the workload so you’re not wearing out one machine faster than the others.

Exactly. And, you know, I had a customer—this was a while back—who thought they could get away with just a VSD unit covering all the load swings. No backup, no trim. Well, guess what? Their main compressor tripped out during a critical run, and they were scrambling to get a rental in. It almost cost them a full day of production. That’s a lot of money down the drain for something that’s totally preventable with the right setup.

And it’s not just about downtime. With a multi-compressor configuration, you can actually reduce your electricity usage. You’re only running what you need, when you need it. Plus, maintenance is way easier—you can take one offline without shutting down the whole system. It’s just smarter all around.

And if you’re using a VSD-equipped unit, like the KRSP2, you can even skip the trim in some cases, but you still need some kind of backup. Even if it’s just a quick connection for a portable unit, you gotta have a plan. Otherwise, you’re just rolling the dice.

Yeah, and I think a lot of people underestimate how much flexibility you get with the right configuration. It’s not just about avoiding disaster—it’s about running leaner, saving money, and making maintenance a whole lot less stressful. And, honestly, it’s one of those things we keep coming back to on this show: plan ahead, and your system will pay you back.

Remote Monitoring and the Future of System Control

Alright, so let’s get into remote monitoring, because this is where things get really interesting. Kaishan’s AirWatch system, for example, uses a wireless cellular modem, so you can check your compressor data in real time from your phone, your laptop, whatever. No more fighting with IT or dealing with factory network headaches.Yeah, and that’s huge. You can set alarms, track maintenance schedules, see your energy use, and even share access with your distributor or tech support. It’s almost like having a continuous audit running in the background. And, honestly, it’s saved a lot of folks from some nasty surprises.

I’ve got a story about that, actually. There was a plant manager I talked to who got a late-night alarm on his phone—turns out, the compressor was pulling way more amps than usual. He caught it before it turned into a major failure. If he hadn’t had remote monitoring, he probably wouldn’t have known until the next morning, and by then, it could’ve been a disaster. Sometimes it’s the little things that make the biggest difference.

And even if you don’t have remote access, Kaishan’s standard controller shows you critical info right on the screen—amps, volts, all that. So, if you see something out of whack, you can jump on it fast. No more guessing games.

It’s all about having the right information at the right time. And, you know, as we’ve talked about in past episodes, the more you know about your system, the better decisions you can make—whether it’s maintenance, upgrades, or just day-to-day operation.

Absolutely. So, if you’re looking to turn your compressed air system from a cost center into a profit center, start with the right equipment, set up your system smart, and keep your eyes on the data. That’s how you stay ahead of the game.

Alright, that’s gonna do it for this episode of The Big Dog Podcast. We’ll be back soon with more ways to make your compressed air system work for you. Jason, always a pleasure.

You too, Lisa. Thanks for listening, everybody. Catch you next time.

Random stat or

customer quote

textXXtext

text