Precision Rehab Manufacturing

August 26, 2025

Centrifugal Air Compressor Sizing

August 27, 2025CASE STUDY:

KAISHAN USA AND AIRMATIC COMPRESSOR HELP GLOBAL FRAGRANCE MAKER HIT THE SWEET SPOT FOR ENERGY SAVINGS

Robertet Fragrances

Mount Olive, NJ

The Situation

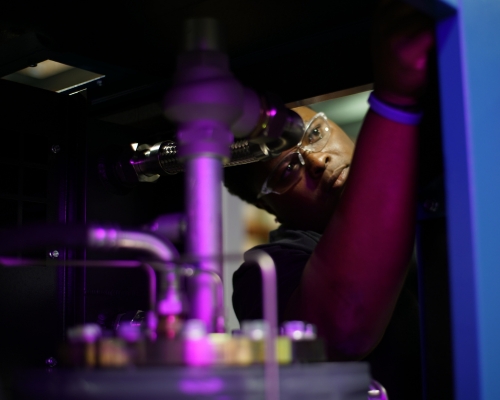

One of the world’s leading companies in the fragrances, flavors and natural raw materials industry since 1850, Robertet Fragrances uses compressed air in a wide range of applications, including a large dispensing system with a critical pressure threshold.

“We have a dispensing system that uses spring-loaded valves that need 120 PSIG to open,” said engineering manager Paul Edworthy. “If we have any dip, we won’t be able to operate this machine.”

The Challenge

Robertet’s existing 50-HP compressor and 30-HP backup were proving inadequate because of the varying air flow requirements. “We could keep up under normal operation, but if our main compressor were to fail, the backups would not be able to keep up,” Paul said. The backup unit even had to kick in when demand peaked.

When replacement parts were required, the lead time was as long as three weeks.

The Solution

The company had an existing relationship with an independent Kaishan distributor, Airmatic Compressor Systems of Carlstadt, NJ, and wanted to be proactive about updating its system for greater reliability. Having clean, dry air was essential for Robertet’s mixing process. “We can’t have water getting into our equipment,” maintenance supervisor Don DiBello said. In addition, Paul wanted greater flexibility. “We wanted a machine that had a high turndown ratio,” he said. “It was the biggest thing for us just because of the sporadic nature of our demand curve. It has a lot of high peaks and low troughs.”

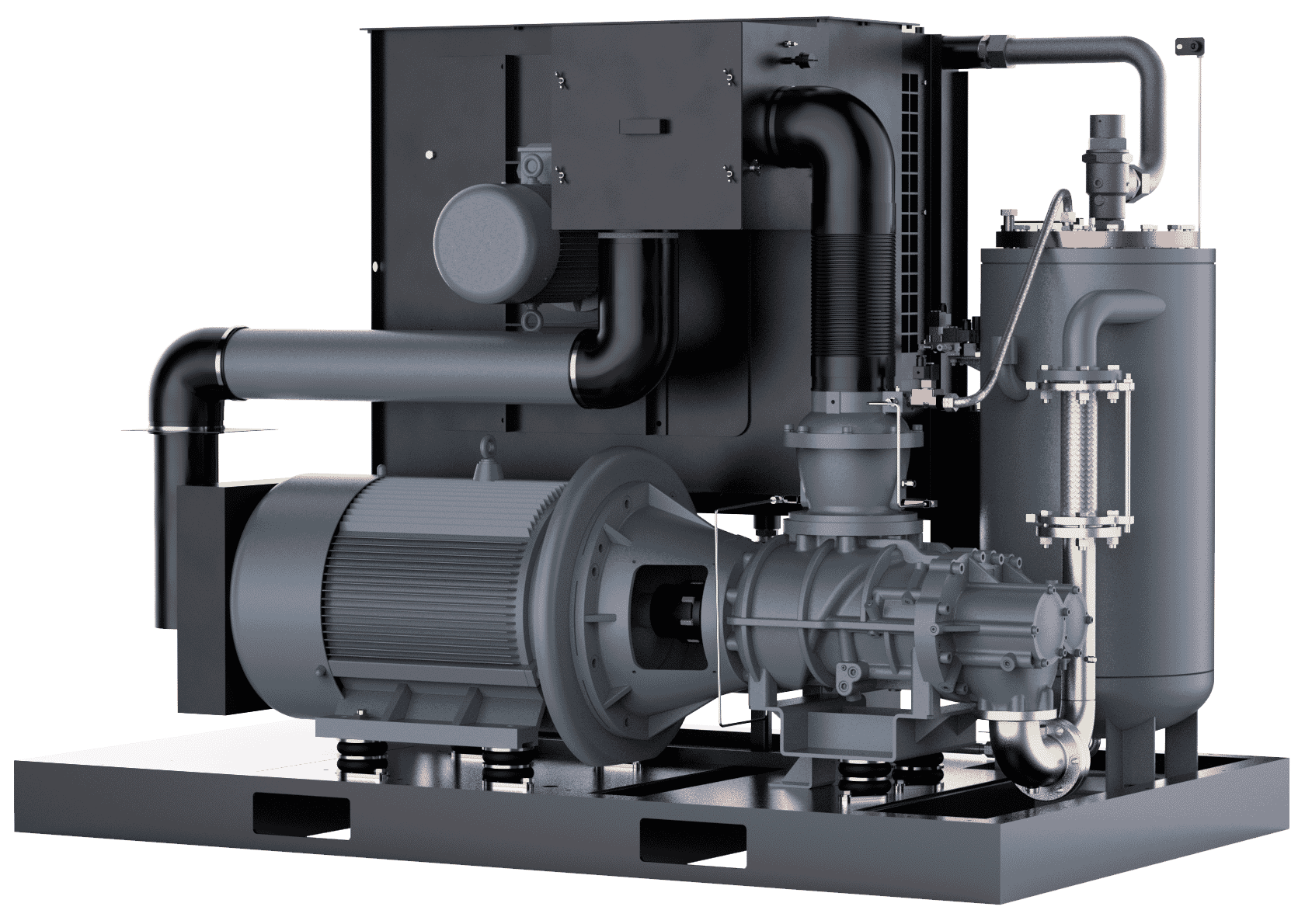

Airmatic’s Tom Sullivan, a systems specialist, conducted a compressed air audit and discovered that Robertet needed more capacity. He recommended a 75-HP Kaishan KRSP premium rotary screw air compressor with a variable-speed drive.

The Results

- IN THE “SWEET SPOT”

The existing 50-HP unit had a variable-speed drive. But since it was running at full capacity most of the time, it was neither saving money nor energy. Robertet’s new 75-HP KRSP, on the other hand, is in the 60% “sweet spot” for optimal VSD operation, saving significantly on energy use and electricity cost. - “DOING ITS JOB”

The Kaishan KRSP is “doing its job,” Don said. And Robertet is overjoyed with the outcome. - SEAMLESS OPERATION

Robertet has the Kaishan KRSP linked to its building operating system, and the Airmatic team does the regular maintenance. - A CONFIDENCE-INSPIRING TEAM

Although he was not familiar with the brand, Don said he asked some of the Airmatic service techs who

work on their equipment about Kaishan. After hearing their enthusiastic endorsement, he said, “I was on board.”

"The KRSP is doing its job."

—Don DiBello, Maintenance Supervisor, Robertet Fragrances

More case studies:

Random stat or

customer quote

textXXtext

text