Six “Gotchas” That Turn Low Sticker Prices into High Lifetime Costs

August 20, 2025

Mt. Morris Tire Center

August 26, 2025CASE STUDY:

KAISHAN USA AND DIVERSIFIED AIR SYSTEMS KEEP STARTUP FROM DESTROYING $300,000 MACHINE

Fire Roasted Crust Company

Wexford, PA

The Situation

Fire Roasted Crust Company recently began producing artisan-style pizza crusts for sale through a broadline food distributor. In fact, the company recently concluded a deal to distribute its products through a large central Pennsylvania convenience store chain with almost 100 locations.

To facilitate expansion, the company acquired an assortment of new and used equipment from around the world, but neither partner knew a lot about compressed air.

“We knew nothing,” said Jason de Wolfe, company co-founder and president.

The Challenge

They worked with a bakery engineer to develop their baking process and found a cheap compressor at a local home center. However, they soon discovered that their $1,200 retail purchase would do more harm than good.

“Little did we know our equipment would be destroyed,” Jason said, if they used the bargain-basement unit Their process needed dry air at the right pressure, and just one piece of that equipment cost $300,000.

The Solution

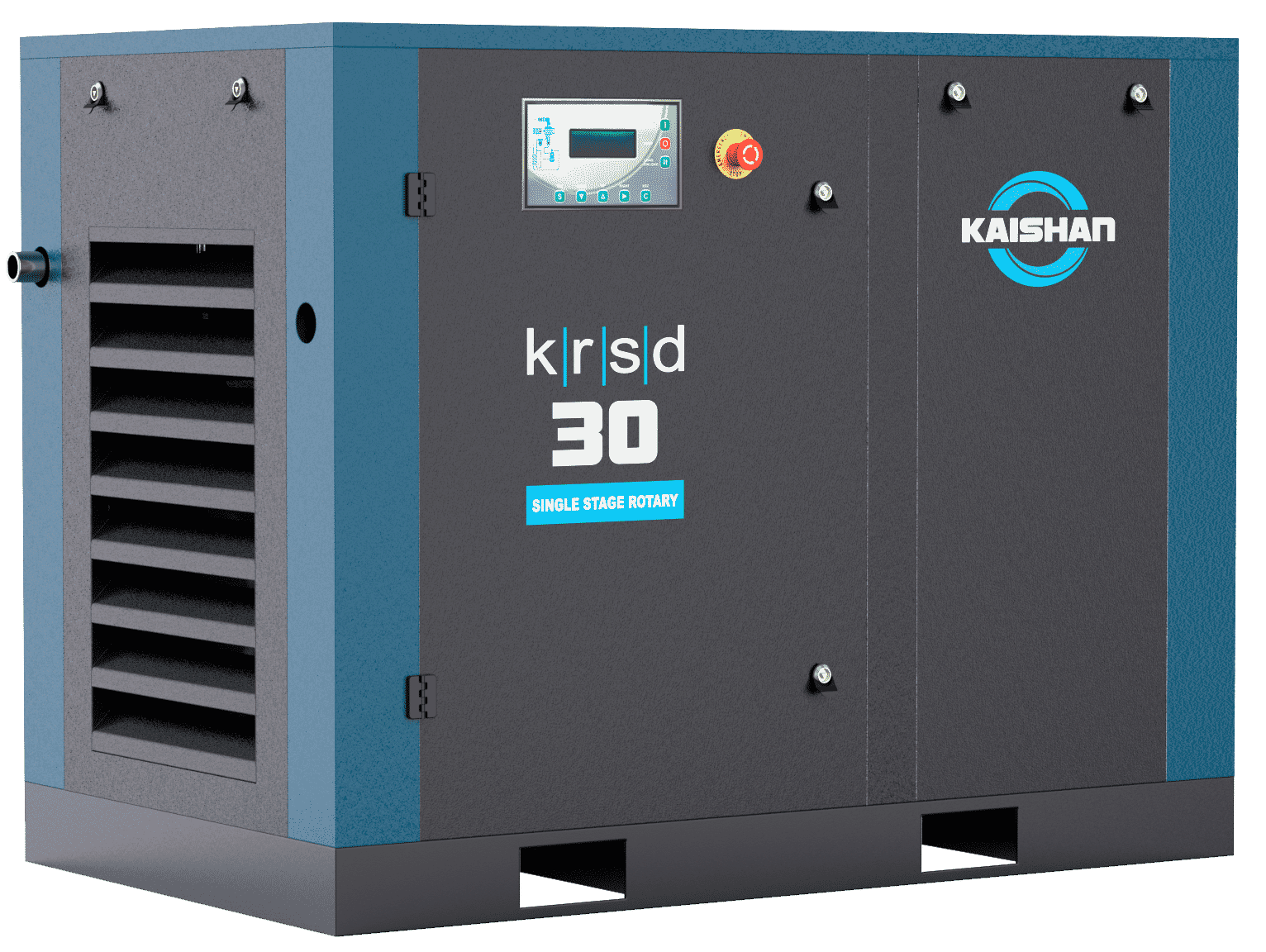

After speaking with a few other potential suppliers, Jason started working with Carl Rademacher, a sales rep for Diversified Air Systems, an independent Kaishan distributor. Jason reviewed the choices Carl presented and purchased a 30-HP Kaishan KRSD direct drive rotary screw air compressor with a variable-speed drive.

Before you shout “oil-free only,” remember—oil-free is required only when air touches the food. In this case, it doesn’t. The compressed air just keeps the oven belt tight, making it incidental contact. With food-grade oil, extra filtration and state inspection approvals, this setup passed with flying colors.

The Results

- STARTUP-FRIENDLY

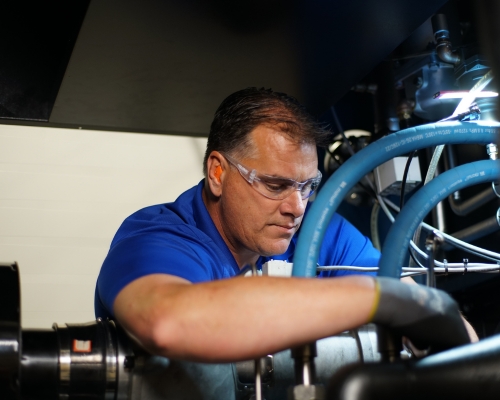

Jason said his new company needed Diversified’s professional guidance and support.

“If you walk through my building and I can’t trust you, then I know that you’re going to cost me more money,” he said. “We’re a startup where every dollar came directly out of my wallet. We didn’t even have bank funding, so every dollar mattered.” - SAVINGS ON ELECTRICITY COSTS

“The more efficient it is, the leaner your operation is,” Jason said. “It’s always going to be more profitable.”

The VSD will enable the company to keep its energy costs under control. Plus, the new system that Carl

designed will recover most of the heat of compression, using the energy for space heating during the winter. - IT’S ALIVE!

Perhaps the biggest surprise was that the dough he was working with was actually a living object, sensitive to temperature and humidity. “Dough is not metal. It is not plastic. It’s alive,” Jason said. “So, it is sensitive to everything you do.”

That made the selection of the compressed air system even more critical. - THUMBS UP ON TRUST

Jason said he started in the oil and gas industry, where “the vendor was a punching bag.” He found in Carl and Diversified a vendor he could trust. One that would go above and beyond the call of duty, even for a startup.

“We needed to be consulted, advised and ultimately supported for this operation because we didn’t know what we were doing,” Jason said. “I can tell you that, you know, that did happen. So, I give it a thumbs up.”

“We needed to be consulted, advised and ultimately supported for this operation because we didn’t know what we were doing. I can tell you that, you know, that did happen. So, I give it a thumbs up.”

— Jason de Wolfe, President, Fire Roasted Crust Company

More case studies:

Random stat or

customer quote

textXXtext

text