End-of-Life Decisions for Rotary Screw Air Compressors

May 21, 2025

Altitude Considerations: High-Elevation Operation of Rotary Screw Compressors

June 4, 2025Optimizing Rotary Screw Compressors for Seasonal Temperature Swings

Kaishan USA | May 28, 2025 | Uncategorized

To ensure continuous operation without downtime, industrial facilities should prepare their compressed air systems for temperature extremes.

Air compressors are uniquely tied to atmospheric conditions, perhaps more than most other industrial equipment.

In many ways, they are at the mercy of the TV weatherperson, mainly because the raw material they start with is ambient air. Wintry weather brings the risk of freezing lines, sluggish oil and water condensation, while summer brings heat that can damage equipment across your entire compressed air system.

The first thing you need to do is determine what air compressor temperature range you are dealing with year-round. Very few people in the U.S. have the extremes: tropical conditions, with annual lows never going below 50°F or arctic conditions with temperatures never going higher. In most cases, it’s between 10°F in winter lows and 95°F in summer highs.

As a result, most American companies cope with seasonal extremes, highs and lows. We’ll address the key concerns for both extremes, starting with the cold.

Dealing with Winter’s Icy Blasts

Rotary screw air compressors are more efficient in the cold. Because of the density of the air, it takes less energy to compress it, and bringing in cooling air helps offset some of the heat generated during compression.

But freezing weather—anything below 35°F-40°F—introduces serious concerns. Like most other mechanical devices, from computers to cars, air compressors experience adverse impacts when freezing temperatures arrive. Especially when parts of the compressor or compressed air system are exposed to the elements.

Specific concerns include:

- Oil viscosity. Oil gets thicker as it gets colder, creating more drag for the motor of an oil-lubricated rotary screw compressor. If not addressed, the current will increase, causing breakers to trip and shut off the power. And your compressed air supply.

- Seals and hoses. Rubber and other elastomer materials become harder and less flexible in the cold, increasing the risk of cracked hoses and leaking seals.

- Water condensation. As temperatures drop, the air’s ability to hold moisture declines, causing water to condense. In some places, especially condensate traps, it will freeze and create blockages, making your compressed air system less efficient. Dryers work harder to remove water from the air, and, ultimately, some will get through, damaging work product and end-use equipment and corroding pipes or exposed metal. Plus, if you have a desiccant dryer, you may have to replace the beads.

- Water freezing. Water reaches its peak density at 39.2°F—meaning it expands as it gets warmer than 39.2°. It also expands as it cools. All that expansion and contraction can wreak havoc, breaking water hoses and fittings. That’s a special problem for water-cooled machines.

Pipes freeze, ice blocks drains and seals become more brittle in colder temperatures.

Fortunately, the industry has developed approaches to keep your compressed air system operating despite the cold weather, holding energy and repair costs in check.

Low-Ambient Temperature Compressors

Kaishan has developed a true cold-weather air package for its special low-ambient temperature compressors. These units include:

- An electrical enclosure heater to keep the electrical elements warm enough to prevent condensation, corrosion, stuck contents and other damage.

- A sump heater to stop compressor oil from thickening in the separator tank and enable easier starting. It also reduces energy consumption when the compressor is running.

- Trace heating/insulation to prevent condensation and freezing along pipes or other surfaces.

Trace heating involves attaching an electrical heating element to winterize pipes or other surfaces to keep them from freezing.

- Independently controlled thermostats to manage the compressor’s immediate environment more effectively.

All those elements are managed and powered through the control system, so no extra work or cost is required.

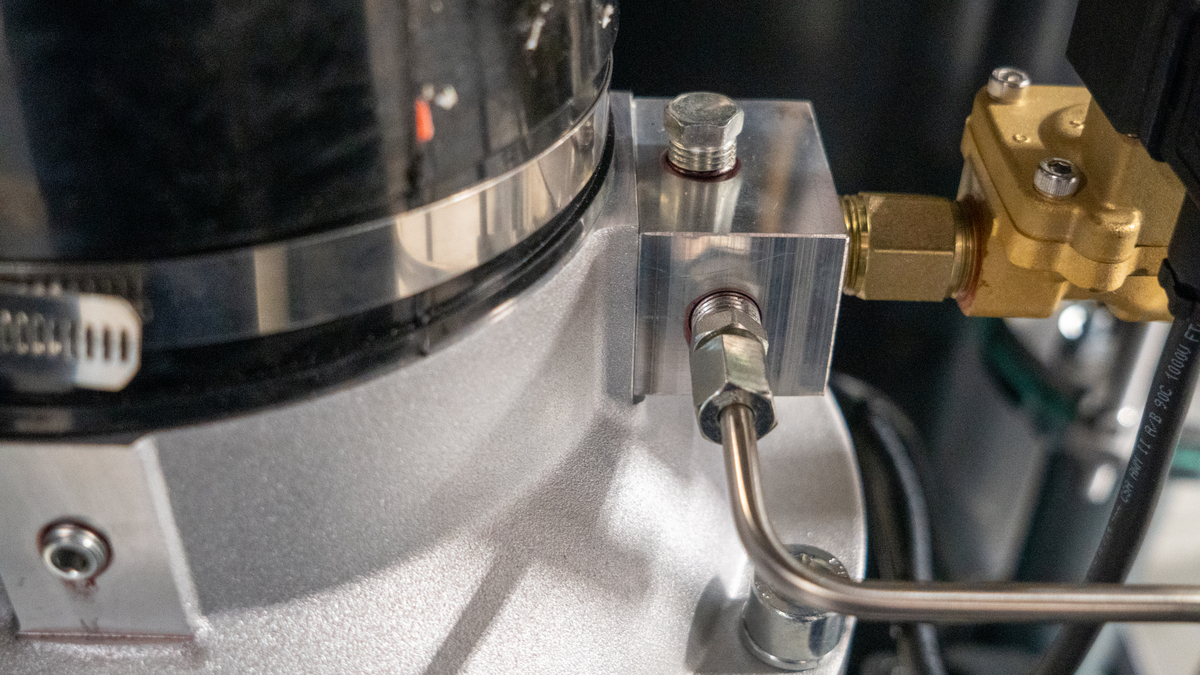

While most of our competitors rely on copper, brass or steel (which corrodes over time), Kaishan compressors have more robust stainless-steel pipes and fittings. In addition, all our liquid-cooled compressors use glycol, rather than water, as the cooling medium, to reduce the risk of freezing.

We use stainless-steel pipes and fittings in all our rotary screw air compressors.

For more on dealing with cold temperatures, with special emphasis on ways to maintain or upgrade your system to prevent winter problems, read our blog post, “Using an Air Compressor in Cold Weather.”

Compressors also have significant challenges in the summer weather, because they generate so much heat.

Dealing with the Heat

Elevated outdoor temperatures can negatively impact air compressor efficiency. If it’s already hot outside, that heat must be removed, or your compressed air system efficiency will suffer.

How hot is too hot?

The ambient air that enters your system, presumably at 70°F, will reach 175°F-200°F in an oil-lubricated screw compressor before it is cooled, according to Air Compressor Guide. You’ll need cooling and drying equipment to condition that air down to a more manageable level. However, it will still be 10°-20°F higher than your incoming air.

As a result, if it’s hot outside and your intake air is at 110°F, you will struggle to get the compressed air you send downstream below 120°-130°F.

And that will kill a lot of equipment throughout your compressed air system. For more on the negative impact of heat, read our blog post, “The Impact of Temperature on Air Compressor Efficiency.”

Kaishan Advantages

Most competitors only rate their compressors at 104°F (40°C), then want to charge more for units that can handle higher temperatures. Unfortunately, we see many industrial applications that run much hotter, in the range of 115°F (46.1°C), so our oil-flooded units are rated for a running temperature of 122°F (50°C).

In addition, we use Class F insulation on the main motor, rated to withstand a maximum temperature of 155°C, to ensure the insulation will withstand the heat of a typical application. You’ll also want to consider the heat impact on auxiliary motors running fans.

The key thing to remember is that if you go too far beyond the rating, you’ll risk burning out the motor. The rule of thumb is that every 10°C you operate a motor above the insulation rate cuts the insulation’s service life in half, according to Machine Design magazine.

The Special Heating Challenge for Oil-Free Compressors

Cooling the airend is even more of a challenge with an oil-free compressor, because they do not use oil as a cooling agent (although gear oil floods the jackets in the airend to help cool the discharge air and keep the housing temperatures lower).

Heat creates special challenges for the oil-free rotary screw air compressors serving the food and beverage industry.

As a result, an oil-free machine runs much hotter than its oil-lubricated cousin—the ambient air that enters your system at 70°F will reach 350°F in an oil-free rotary screw air compressor. That presents quite a cooling challenge.

Kaishan equips its KROF two-stage oil-free rotary screw air compressor with oversized coolers and high-temperature, stainless-steel pre-coolers. As a result, the KROF is built to withstand temperatures of 115°F (46.1°C), the highest temperature range we customarily find in U.S. facilities.

We equip our KROF two-stage oil-free rotary screw air compressor with oversized coolers to remove heat and it is built to withstand temperatures of 115°F (46.1°C).

Variable-Speed Drives

The sensitive electronics of variable-speed drives make them particularly vulnerable to high temperatures. There are three options:

- Do nothing. Some customers do nothing and take their chances. That can be expensive.

- Pay for an upgrade. Others pay more and get an upgraded VSD that can withstand heat. That is expensive as well.

- Go remote. We prefer a remote VSD, which involves locating your VSD device in a climate-controlled area, such as a server room or data center, or somewhere cooler than a typical factory floor. Typically, we say the maximum distance is 40 feet, but longer distances are possible with appropriate filters. See your distributor for details.

Another VSD-related issue is that VSDs gain heat in turn-down mode. If you are considering an oil-free compressor equipped with a VSD, you should discuss that heat gain with your equipment manufacturer.

One last consideration when dealing with heat is to review your entire compressed air system. It’s imperative that you have enough storage.

The Compressed Air & Gas Institute (CAGI) recommends up to 10 gallons per CFM of system capacity. Most facilities have a combination of wet and dry storage, with a third of storage capacity as wet storage and two-thirds as dry.

To handle any temperature extremes, it’s imperative that you have enough compressed air storage.

For more on storage, see our blog post, “A Quick Guide to Accurately Size Air Compressor Tanks.”

Maintenance

No matter the weather conditions, it’s always smart to adopt good maintenance practices to keep your system functioning properly. We encourage all our customers to develop several different levels of maintenance:

- Regular cleaning and inspection of filters and drain traps, removing any obstructions and replacing clogged filters.

- Oil sampling, ensuring your oil has the remaining life to keep the compressor properly lubricated, thus reducing operating temperature.

- Preventive maintenance, doing routine procedures like oil changes and filter replacements regularly.

- Predictive maintenance, closely monitoring data from sensors located throughout your compressed air system and taking action to deal with problems before they become serious.

After all, good maintenance is preferable to unplanned shutdowns, which can result in lost production time and ruined processes and materials.

For more information on preventive and predictive maintenance, see our blog post, “The Differences Between Air Compressor Preventive Maintenance and Predictive Maintenance. And Why You Should Care.”

Beating the Heat Is a Team Effort

The larger (and more mission-critical) your compressed air system, the more you will benefit from having a compressed air consultant’s advice and assistance. From sizing ductwork to helping you set up good maintenance practices, a professional’s advice can help you deal with heat problems that could otherwise damage your equipment or cause unplanned downtime.

We have developed close partnerships with a nationwide network of independent distributors. They have the experience and skills to offer expert advice and help you prepare for the temperature swings you can expect in your region.

Beyond dealing with seasonal variation, they can help you maintain and optimize your system, enhancing air compressor performance and compressed air system efficiency.

We’ve chosen to work with these independent, local businesses because we know there’s no better way to ensure you have the expert guidance, faster response times and personalized support you deserve. For them, it’s not just about selling compressors. It’s about building relationships that ensure you get the right system, reliable service and quick access to parts when you need them most.

The goal? Helping you maximize efficiency and minimize downtime. When you buy through Kaishan, you're getting more than a product—you're getting a local partner who cares about your business and wants to see you succeed.

Key Takeaways

- Air compressors are uniquely tied to atmospheric conditions, perhaps more than most other industrial equipment.

- The first thing you need to do is determine what air compressor temperature range you are dealing with year-round.

- Rotary screw air compressors are more efficient in the cold. But cold weather introduces some serious concerns regarding oil thickness, cracked seals and water condensation and freezing.

- Kaishan has developed a true cold-weather air package for its special low-ambient temperature compressors.

- Elevated outdoor temperatures can hurt air compressor efficiency. Heat has to be removed, or your compressed air system efficiency will suffer.

- Our oil-flooded compressors are rated for a running temperature of 122°F (50°C), significantly higher than competitors’ products.

- We build our KROF two-stage oil-free rotary screw air compressor to withstand temperatures of 115°F (46.1°C), significantly higher than other oil-free units.

Let Us Help

Dealing with changing seasons is critical to the operation of your rotary screw air compressor, your compressed air system and all the processes that rely on that system. If you need help getting ready for changing weather, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Surviving the Freeze

Alright, welcome back to The Big Dog Podcast! I’m Jason Reed, here with Lisa Saunders, and today we’re talking about something that, honestly, gets overlooked until it’s too late—weatherproofing your air compressor. Specifically, what happens when winter hits hard.Yeah, and I mean, it’s not just about being cold, right? Cold weather can really mess with your compressed air system. I always thought, “Hey, machines like the cold, don’t they?” But it’s way more complicated than that.

Yeah, it’s true—rotary screw compressors are actually more efficient in the cold because the air’s denser, so you get more bang for your buck. But, and this is a big but, once you drop below, say, 35 or 40 degrees Fahrenheit, you start running into real problems. Oil thickens up, seals get brittle, and water starts condensing and freezing in all the wrong places.

Right, and I always forget—oil viscosity, that’s the big one, isn’t it? When it gets cold, the oil gets thicker, so the motor has to work harder. That can trip breakers, shut down the compressor, and suddenly you’re scrambling to get production back online.

Exactly. And it’s not just the oil. Rubber seals and hoses, they get stiff, start cracking, and then you’ve got leaks. Plus, water condensation is a nightmare. It freezes in the lines, blocks drains, and if you’ve got a desiccant dryer, you might be replacing beads way more often than you want.

So, what do you actually do about it? I mean, you can’t just cross your fingers and hope for a mild winter.

Nope, that’s a recipe for downtime. The best setups I’ve seen use a few key things: electrical enclosure heaters to keep the controls from freezing up, sump heaters to keep the oil warm, and trace heating on pipes so you don’t get ice blockages. And, honestly, insulation everywhere you can put it. Kaishan’s low-ambient package does all that—plus, they use stainless steel pipes, which hold up way better than copper or brass in the cold.

I love that you brought up trace heating. I always thought it was just for, like, water pipes in old houses, but it’s a lifesaver for air systems too. And those independently controlled thermostats—they’re not just a luxury, right? They actually help you dial in the right temp for each part of the system.

Yeah, and let me tell you, I saw this firsthand at a plant in the Midwest. They had this brutal cold snap—condensate lines froze solid, and production was about to grind to a halt. They brought in a Kaishan low-ambient setup, with all the heaters and insulation, and it kept everything running. No more frozen lines, no more emergency shutdowns. It was, uh, kind of a game changer for them.

That’s the thing—people don’t realize how much downtime costs until it happens. And it’s not just the compressor, it’s the whole process that gets thrown off. So, prepping for winter isn’t optional if you want to keep things moving.

Beating the Heat

Alright, so we’ve survived the freeze—now let’s talk about the other extreme. Summer. High-ambient temperatures can be just as brutal, maybe even worse in some ways.Yeah, heat’s a silent killer for compressors. If your intake air is already, say, 110 degrees, by the time it’s compressed, you’re looking at discharge temps of 175, 200 degrees, easy. That’s rough on everything—motors, oil, seals, you name it.

And it’s not just oil-lubricated units, right? Oil-free compressors run even hotter. I read that the air can hit 350 degrees inside an oil-free rotary screw. That’s wild.

Yeah, oil-free is a whole different animal. You need oversized coolers, high-temp insulation, and, honestly, you gotta make sure your system is rated for those temps. Kaishan’s oil-flooded compressors are rated up to 122 degrees Fahrenheit, which is higher than most competitors. Their oil-free KROF units can handle 115 degrees, and they use Class F insulation on the motors—so you’re not burning out windings every summer.

That’s a good point. And, uh, I actually saw this go wrong on a factory tour in Texas. They had a VSD unit—variable speed drive—sitting right out on the shop floor, no climate control. It failed in the middle of a heat wave. Turns out, those electronics are super sensitive to heat. If you don’t put the VSD in a cooler, climate-controlled spot, you’re just asking for trouble.

Yeah, VSDs are finicky. You can pay for a heat-rated upgrade, but honestly, just put it in a server room or somewhere cool. And don’t forget, VSDs actually generate more heat when they’re running in turn-down mode, so you gotta plan for that too.

So, best practice—keep your VSDs remote if you can, and always check the max distance with your distributor. And, uh, don’t forget about storage. The Compressed Air & Gas Institute says you want up to 10 gallons per CFM of system capacity, with a mix of wet and dry storage. That helps buffer those temperature swings and keeps your system stable.

Yeah, and don’t skimp on cooling. Oversized coolers, high-temp insulation, and regular checks on your auxiliary motors—those fans are working overtime in the summer. If you push your system past its rating, you’re just cutting the life of your motor in half. Literally—every 10 degrees Celsius over the insulation rating, you lose half the service life. That’s not a scare tactic, that’s just physics.

It’s easy to forget how much heat impacts the whole system. And, honestly, a lot of failures I’ve seen could’ve been avoided with better planning—just thinking ahead about where you put the equipment and how you cool it.

Design, Maintenance, and Expert Partnerships

So, we’ve talked about surviving the cold and beating the heat, but honestly, none of that matters if your system design is off. You can have the best compressor in the world, but if you don’t have the right setup, you’re still at risk.Yeah, system design is everything. Multiple compressors, proper storage, backup units—if you’re running just one compressor with no backup, you’re rolling the dice. I always say, base, trim, and backup. That’s the gold standard. It keeps you running, even if something goes down, and makes maintenance way less stressful.

And maintenance—don’t get me started. You need a checklist: clean your filters, check your drains, sample your oil, and keep an eye on your sensors. Predictive monitoring is huge. It’s not just about fixing things when they break, it’s about catching problems before they cost you real money.

Yeah, and I know it sounds like a lot, but it’s way cheaper than unplanned downtime. I mean, a shutdown in the middle of a production run? That’s a nightmare. Regular cleaning, oil sampling, and just walking the floor—those little things add up to big savings.

And if you’re not sure where to start, partner with a local expert. Seriously, consultants and distributors know the climate, they know the equipment, and they can help you size your system right. It’s not just about selling you a compressor—it’s about building a relationship so you get the right advice, fast service, and support when you need it.

Yeah, I mean, nobody wants to be stuck renting a diesel backup because they didn’t plan ahead. That’s expensive, it’s dirty, and it’s just not sustainable. Working with a local partner means you’re ready for whatever the weather throws at you, and you’re not scrambling when things go sideways.

So, bottom line—design your system for year-round reliability, stay on top of maintenance, and don’t be afraid to ask for help. That’s how you keep your compressed air system running strong, no matter what the forecast says.

Alright, that’s gonna do it for this episode. Lisa, always good talking shop with you. And for everyone listening, stay ahead of the weather, keep your system tight, and we’ll catch you next time on The Big Dog Podcast.

Thanks, Jason. And thanks to everyone tuning in—don’t forget, we’ve got more episodes coming, so stick with us. Take care, everybody!

Random stat or

customer quote

textXXtext

text