How Often Should an Air Compressor Cycle?

August 13, 2025

Fire Roasted Crust Company

August 26, 2025Six “Gotchas” That Turn Low Sticker Prices into High Lifetime Costs

Kaishan USA | August 20, 2025 | Uncategorized

Looking for a great price on an air compressor? Make sure to read the fine print that can turn today’s fantastic deal into tomorrow’s nightmare.

When you’re purchasing major pieces of equipment, most industrial buyers know to look at the big-ticket items, such as overall energy efficiency, maintenance and equipment lifespan, that drive total cost of ownership decisions.

But everyone loves a low price. Currently, many air compressor manufacturers are offering their products at extremely low rates. One competitor is offering a "buy one, get one" deal.

Unfortunately, the products with the cheapest price may not deliver the lowest cost of ownership. Sometimes, a few hidden provisions can lurk in the details, making a seemingly irresistible deal a lot pricier.

Savvy buyers can save themselves a lot of trouble and headaches if they watch out for “gotchas” such as the ones below.

We’ll start with one notorious example, blue-light specials.

Gotcha No. 1: Blue-Light Specials

One of the popular commercials of the 1990s had a now-defunct retail chain promoting “blue-light specials.” Whether they had stock that was past its due date or purchased a train-car load of clunkers, we were offered a great deal on something we didn’t need, didn’t want, couldn’t afford or all of the above.

The same thing can happen with air compressors. What if you don’t need what’s on special? What if you need an oil-free compressor, such as our KROF two-stage, oil-free rotary screw air compressor? Or what if an energy-efficient air compressor, such as Kaishan’s KRSP2 two-stage rotary screw air compressor would pay for itself in savings in just two years?

If you need an oil-free unit, Kaishan’s KROF two-stage oil-free compressor is an excellent choice for uncontaminated, highly efficient and reliable air.

To use a technical term, you’re S-O-L (s--t outta’ luck).

The Solution: Buying the Right Air Compressor

The best advice is to decide what you need before you buy. If you’ve settled on a brand, make sure it offers a product mix that covers all the options you might consider. Then, when you know what will meet your needs the best, shop on price.

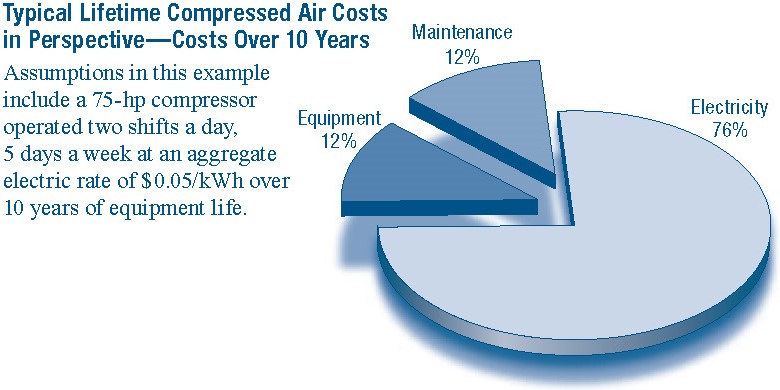

Remember, according to well-established industry and government research, the initial price of your compressor is 12% of the total cost of ownership, while electricity is 76%. So, buying on initial cost alone can be penny-wise and pound-foolish.

Industry and government research indicates that the initial price of your compressor is 12% of the total cost of ownership, while electricity is 76%.

We provide more information in our blog post, “What Kind of Air Compressor Do I Need?”

Next, we’ll discuss service contracts.

Gotcha No. 2: Service Contracts

One little-known fact is that many manufacturers of industrial equipment break even on initial costs but generate their real profits from aftermarket sales, especially oil. Some original equipment manufacturers may even sell their products at a loss.

Some manufacturers of rotary screw compressors, for instance, charge unbelievably low prices–even offering “buy-one, get-one” deals. But that “free compressor” is anything but free, requiring customers to sign up for service contracts requiring:

- Monthly or annual payments that add thousands to the total cost of ownership

- Use of company-owned service outlets with high labor costs to perform all maintenance and repairs

- Replacing worn components and supplies with OEM parts that are marked up significantly

That tactic may be based on a well-understood reality of corporate finance—that initial costs come out of a capital expense budget, while service contracts, parts and maintenance costs fall under operating expenses.

But knowing that really doesn’t help, does it? The best approach is to look at the fine print.

The Solution: Read the Service Contract

Make sure you understand the full cost of any service contract that offers an unbelievably low price. Things like expenses and costs for monthly or annual fees. Or maintenance performed by company-owned service teams or an OEM-approved contractor.

And then there is the cost of the parts.

Gotcha No. 3: Parts Costs

Once again, some OEMs view lubricants and parts as golden opportunities for profit. Parts are set at the OEM’s discretion, if not specified as part of your sales contract.

Needless to say, all manufacturers, including Kaishan, require that you use their OEM parts, components and lubricants, to “Preserve Your Compressor’s Design Integrity by Using OEM Parts.”

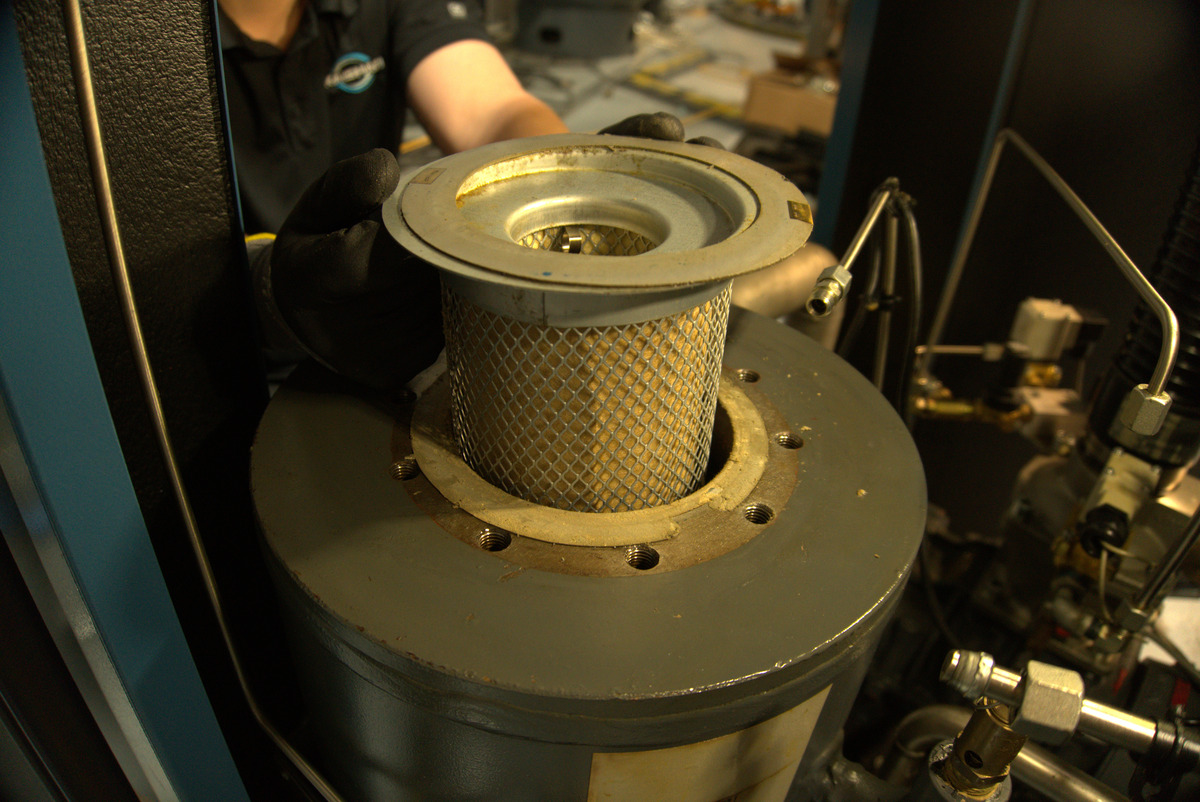

Air-oil separators are one of the most critical replacement parts in a rotary screw air compressor and replacing one with an off-brand part can result in fires, explosions and even injuries to workers. For details, read our blog post, “Preserve Your Compressor’s Design Integrity by Using OEM Parts.”

But that doesn’t mean we have to lock you into hefty fees.

The Solution: Ask for the Details

Ask the manufacturer for a five-year, line-by-line quote on every service item—consumables, hard goods and oil. Compare costs for the pricier repair components, such as coolers, motors, airends and drives, especially.

As mentioned, like other manufacturers, Kaishan requires that you use our OEM parts and lubricants, but we charge reasonable prices. We think it’s stupid to give people a financial incentive to use aftermarket or pirated parts. As a result, we make it as cost-effective as possible to use ours.

After all, no one wins if you use an aftermarket filter to save $10, then either starve your airend or send particles downstream. That’s not how to lower the total cost of ownership and maximize the value of your equipment investment.

And it’s not just the cost of parts that can be a problem. It’s their availability.

Gotcha No. 4: Parts Availability

Many compressor manufacturers do not have significant parts inventories in this country. Or anywhere, for that matter. So, when you need a component, they may have to order it from a supplier, wait for that company to make and ship it to them, then send it to you.

In today’s globalized economy, the OEM, their suppliers and you may all be in different countries or even on different continents. So your motor, drive or cooler may need to go through customs and incur tariffs or other fees. And we wonder why it sometimes takes weeks or even months to get a replacement.

That can translate into significant costs for downtime. Your OEM’s lead time, after all, is your downtime. Meanwhile, you are paying to rent portable units to keep your compressed air system working. All of which makes your blue-light purchase a lot less special.

Since many rental units are diesels, there’s also the additional cost for labor and fuel to keep the rental (and your shop) running. Not to mention the fumes, exhaust and noise.

The Solution: Determine What's in Stock

Ask your OEM what critical items, such as coolers, motors and drives, are in stock and where they are located. Ask for a commitment on lead times.

At Kaishan, we make all our own parts and maintain complete inventories of all major components in our Loxley, AL facility, including motors, drives, coolers and even airends. Most parts orders are filled within two days of ordering.

We are in the process of expanding our plant, allowing us to fill most parts orders within two days. We manufacture all our own parts and maintain complete inventories of all major components in our Loxley, AL facility, including motors, drives, coolers and even airends.

And then there’s the issue of warranties.

Gotcha No. 5: Warranties

Unfortunately, warranties are only as good as the companies that back them. One nasty practice is that some companies have warranty quotas, meaning they won’t pay out more than a certain amount per month (or other time period). If you come in after the quota has been met, you’re once again S-O-L.

The Solution: Read the Fine Print

Make sure the terms of the warranty are clear. Kaishan stands behind its products, offering the best warranties in the industry. If one of our units fails through no fault of the user, we will honor it.

Our standard warranty covers the complete compressor package for 12 months from the date of startup (or 18 months after it’s shipped, whichever comes first), with an airend warranty of 24 months. With our extended warranties (provided at no additional cost), Kaishan’s KRSP and KRSP2 two-stage premium screw compressors are backed by a lifetime warranty on the airend. This point actually is a no-brainer.

An industry-leading, lifetime airend warranty backs Kaishan’s KRSP and KRSP2 screw compressors.

Plus, if you buy a compressor from Kaishan, you are probably working with one of our independent distributors or retail partners, local businesses with a big stake in your success. Which leads to our final gotcha.

Gotcha No. 6: No Local Experts

Company-owned service centers may not be in your area, and it may take days or weeks to get a service tech to your shop. Even if they are nearby, they are not always staffed with compressed air professionals who can analyze your system and make intelligent recommendations for upgrades.

Or with service techs who can help you maintain your equipment, using sophisticated tools, such as data loggers, for analysis of your utilization rates. Or ultrasonic leak detection tools to help you identify and fix air leaks in your system.

The Solution: Local Pros

Find out who will service your unit in accordance with warranty requirements. And determine their costs and availability.

Kaishan USA works with a nationwide network of independent distributors, who can provide on-site help and consultation as needed.

We devote a lot of effort to training distributor personnel, both in the analysis of compressed air systems and in servicing your equipment using the latest technologies. We teach our distributors how to tear down, repair and troubleshoot our equipment. We conduct some classes in-house and also travel to distributor locations.

We partner with independent, local distributors because it's the best way to serve you. We have customer after customer telling us they get next-day—or even same-day service from our distributor partners.

Unlike large corporate suppliers, there's no red tape here; our distributors offer expert guidance, faster response times and personalized support tailored to your needs. They don't just sell compressors—they build relationships, ensuring you get the right system, reliable service and quick access to parts when you need them most.

With factory-trained technicians and a deep understanding of industrial applications, they help maximize efficiency and minimize downtime. So, when you buy through Kaishan, you're getting more than just a product—you're getting a local partner who genuinely cares about your business and wants to see it succeed.

Key Takeaways

- Currently, many air compressor manufacturers are offering their products at extremely low prices.

- Unfortunately, the products with the cheapest price may not deliver the lowest cost of ownership.

- Decide what you need before you shop on price.

- Make sure you understand the full cost of any service contract a manufacturer requires to get an unbelievably low price.

- Ask the manufacturer for a five-year, line-by-line quote on every service item—consumables, hard goods and oil.

- Ask your OEM what critical items, such as coolers, motors and drives, are in stock and where they are located. Ask for a commitment on lead times.

- Make sure the terms of the warranty are clear and ask for a copy of the warranty policy.

- Find out who will service your unit in accordance with warranty requirements. And determine their costs and availability.

The Ultimate Solution: Ask Hard Questions

The best way to avoid the traps and gotchas is to demand hard answers before signing any sales agreement. Specifically, on the “gotchas” mentioned above.

Buying the right air compressor is crucial to the operation of your compressed air system and all the processes that rely on it. If you need help determining the best way to optimize your compressed air acquisitions, get in touch with the experts at Kaishan. Contact us today.

Listen to the Podcast Version

Beyond the Sticker Price

Alright, welcome back to The Big Dog Podcast! Let's cut through the noise and get real about compressed air. I’m Jason Reed, and as always, I’ve got Lisa Saunders with me. Today, we’re talking about something that trips up a lot of folks—those “can’t-miss” deals on air compressors. You know, the ones with the big red tags and the “buy one, get one” banners?Yeah, Jason, and I gotta say, it’s so tempting, right? You see that low sticker price and you think, “Hey, I’m saving the company a ton!” But here’s the kicker—what you pay up front is just a tiny slice of the real cost. According to industry and government research, the initial price is only about 12% of what you’ll spend over the compressor’s life. Electricity? That’s a whopping 76% of the total cost. So, if you’re just chasing the lowest price, you’re probably setting yourself up for a much bigger bill down the road.

Exactly. And those “blue-light specials”—I mean, I remember those old commercials, but in our world, it’s more like, “Here’s a deal on something you don’t even need.” Maybe you need an oil-free compressor, or a two-stage unit for better efficiency, but the special is on a single-stage, basic model. If it doesn’t fit your application, you’re S-O-L. And then you’re stuck with a machine that’s not right for your plant, or you’re missing out on energy savings that could pay for a better unit in just a couple years.

I almost made that mistake once, honestly. I was working with a client who was all in on this “deal” compressor. Looked great on paper—until we dug into the service fees. Suddenly, the math changed. The “cheap” compressor was gonna cost them way more over five years than a higher-quality, energy-efficient model. It’s like, you think you’re getting a bargain, but you’re just moving the costs around—and usually making them bigger.

Yeah, and that’s why you gotta decide what you actually need before you even start shopping. Figure out the right type, the right size, the right features. Then, and only then, start looking at price. Otherwise, you’re just buying trouble. And, honestly, we’ve seen it over and over—folks get lured in by the sticker, but the real pain comes later, when the bills start piling up for power, maintenance, and downtime.

And if you missed our episode on turning air into profit, we talked a lot about how the right system can actually save you money in the long run. So, don’t get blinded by the “deal”—look at the whole picture.

The Gotchas: Service, Contracts, Parts, and Availability

So, let’s talk about the fine print—the “gotchas” that come with those bargain compressors. First up: service contracts. Some manufacturers basically give away the compressor, but then they lock you into these expensive service agreements. You’re paying monthly or yearly, and you have to use their service teams, which can get pricey fast. And don’t even get me started on the parts markup.Yeah, and it’s not just the contract itself. It’s the way they structure it. The initial cost comes out of your capital budget, but all those service fees and parts? That’s operating expenses, and it adds up. I always tell folks—ask for a five-year, line-by-line quote on every service item. Consumables, hard goods, oil, the whole lot. And compare the big-ticket repairs—like airends, motors, drives. That’s where the real money goes.

And don’t forget about parts availability. I mean, it’s wild—some companies don’t even keep critical parts in the country. So, when your compressor goes down, you’re waiting weeks, sometimes months, for a replacement. Meanwhile, you’re renting a portable unit, burning through diesel, paying extra labor, and just bleeding money. Jason, didn’t you have a plant that got stuck in that exact situation?

Oh, yeah. This one plant—big operation—had their airend fail. Turns out, the OEM didn’t have any in stock in the U.S. They had to ship it from overseas, and it took, I wanna say, almost three months. The plant had to rent a backup compressor the whole time, and the rental fees alone were brutal. Not to mention the lost production and all the headaches. That “cheap” compressor ended up being the most expensive decision they made that year.

That’s why you gotta ask the tough questions up front. Where are the parts stocked? What’s the lead time? Can you get a commitment in writing? And, like you said, Jason, get that five-year quote so you know what you’re really signing up for. Otherwise, you’re just hoping for the best—and that’s not a strategy.

And look, every manufacturer wants you to use their OEM parts, but some make it so expensive you’re tempted to cut corners. That’s a bad move. We’ve talked before about how using off-brand parts can wreck your system—fires, explosions, you name it. But the answer isn’t to gouge people on parts. It’s to make it cost-effective to do the right thing. That’s how you keep your system running and your costs down.

Warranties, Local Support, and Avoiding Traps

Alright, let’s get into warranties and support—because this is where a lot of folks get tripped up. Some companies offer these “amazing” warranties, but if you read the fine print, there’s all kinds of loopholes. I’ve even heard of companies with warranty quotas—like, they’ll only pay out so much per month, and if you’re late to the party, you’re outta luck. That’s just… I mean, it’s not right.Yeah, and the length of the warranty doesn’t mean much if the company won’t actually honor it. You want to see the terms, in writing, and make sure you understand what’s covered, what’s not, and who’s actually going to do the work. And honestly, local support makes all the difference. If you’re stuck calling a corporate call center three states away, good luck getting someone out to your plant when you need them.

That’s why I like the way Kaishan does it. They’ve got a lifetime airend warranty on their KRSP and KRSP2 compressors, and they back it up. But more importantly, you’re working with local, independent distributors—folks who know your business, who can get you parts fast, and who actually care if your system is down. No red tape, no waiting weeks for a tech to show up. Just real support, when you need it.

And those local pros—they’re trained, they’ve got the tools, and they’re invested in your success. We’ve heard from customers who get same-day or next-day service, and that’s huge when you’re trying to keep production running. It’s not just about selling you a compressor—it’s about building a relationship and making sure you’re set up for the long haul.

So, bottom line—don’t get blinded by the sticker price or the flashy warranty. Ask the hard questions. Who’s gonna service your unit? What’s actually covered? Where are the parts? And is the company gonna be there when you need them? If you do your homework, you’ll avoid the traps and get a system that actually works for you, not against you.

That’s it for today’s episode. If you’ve got questions, or you’re looking at a “deal” that seems too good to be true, reach out—we’re always happy to help you sort through the details. Jason, always a pleasure.

Same to you, Lisa. Thanks for tuning in, everybody. We’ll be back next time with more real talk on compressed air. Take care!

See you next time on The Big Dog Podcast!

Random stat or

customer quote

textXXtext

text